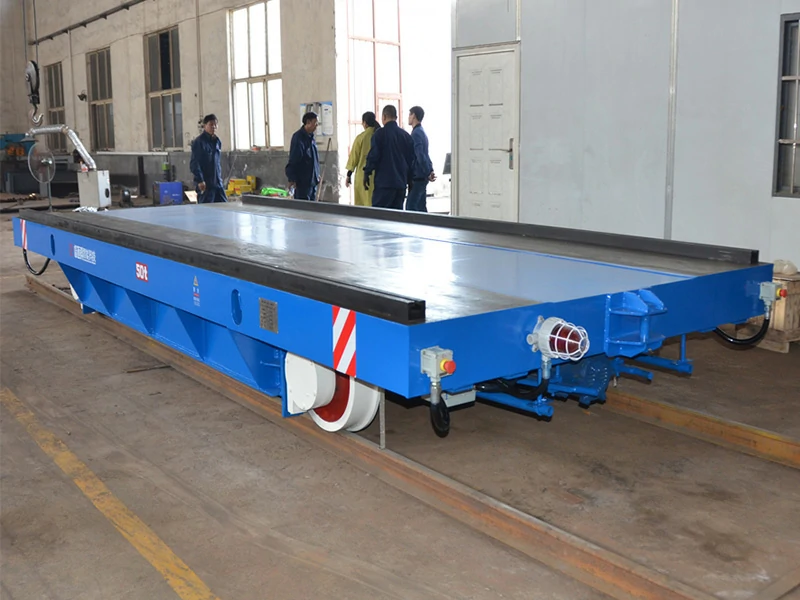

The RGV rail guided transfer cart is an automated heavy-duty material handling system operating along fixed rails, designed for internal factory logistics scenarios demanding high operational stability and positioning accuracy. The 10-tonne dual-lift RGV transfer cart introduced by REMARKABLE employs a PLC-programmed control system, integrating RFID and magnetic guidance for rail-guided travel and high-precision docking.

REMARKABLE offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- Load Capacity: 10 Tons

- Dimensions: 6000 × 2500 × 500 mm

- Lifting Stroke: Hydraulic lifting, 250 mm

- Power Supply: Low-voltage wired power supply

- Speed: 0–20 m/min (stepless speed regulation)

- Custom: Custom production available, including additional components, etc.

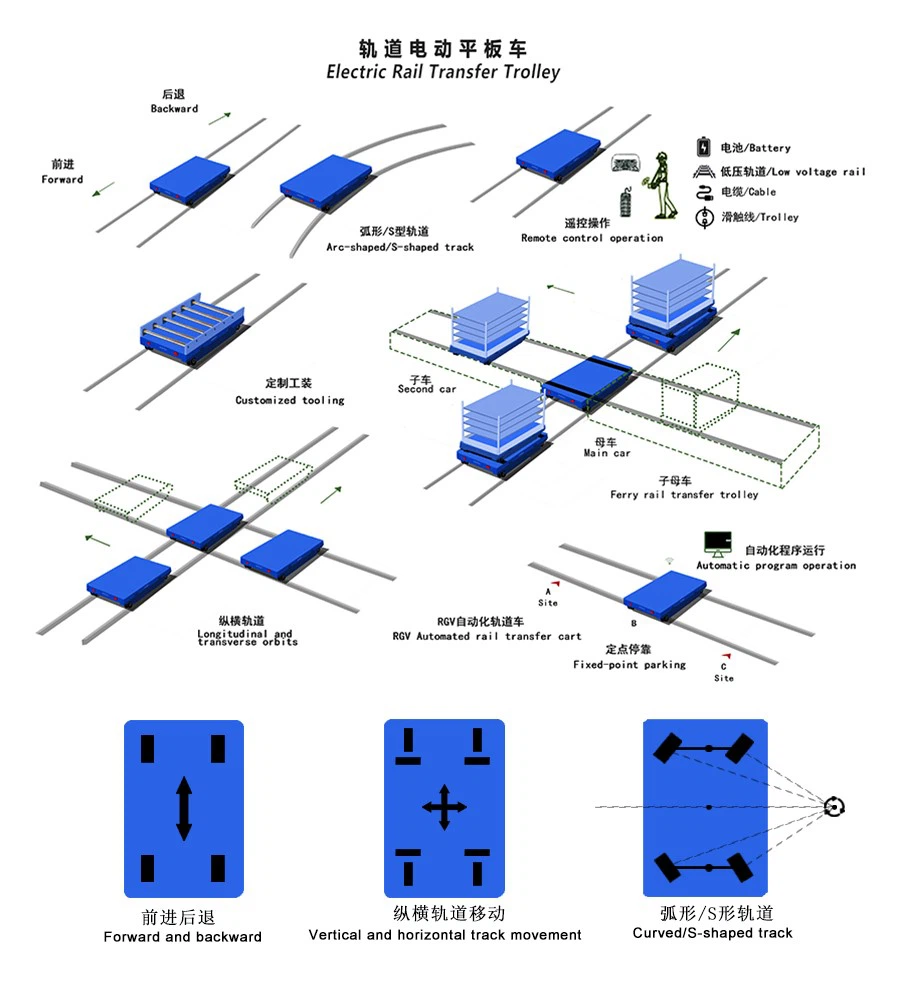

Working Principle of the RGV Rail Guided Transfer Cart

The RGV rail guided transfer cart achieves stable transfer of heavy-duty materials through the coordinated operation of rail guidance, automated control, and a hydraulic lifting system. The specific process is as follows:

- System Task Triggering

The RGV receives operational commands from the automation control system, PLC master station, or LAN dispatch system. - Rail-Guided Travel

The rail-guided vehicle operates along pre-installed P18 steel rails at adjustable speeds of 0–20 m/min, ensuring stable direction and path adherence. - Real-Time Communication and Status Feedback

Via wireless communication modules, the RGV maintains data exchange with the control system, providing real-time feedback on operational status and positional information. - Precision Positioning Control

RFID tags integrated with magnetic positioning devices enable workstation-level precise docking, achieving positioning accuracy of ±3mm. - Hydraulic Lifting and End-to-End Docking

Hydraulic direct-lift mechanisms facilitate 250mm localised elevation, enabling height-matched docking with workstations, platforms, or equipment. - Stable Heavy-Load Material Handling

The lifting platform incorporates locating pins to prevent workpiece displacement during lifting and transport. - Safety Monitoring and Protection

Laser obstacle avoidance, edge contact switches, and emergency stop buttons continuously monitor operations to safeguard personnel and equipment. - Task Completion and Cycle Operation

Upon task completion, the RGV transfer vehicle may return to a standby position or automatically execute the next transfer assignment.

RGV Rail Guided Transfer Cart

RGV Rail Guided Transfer Cart

Technical Specifications Overview

The 10t RGV rail guided transfer cart is a heavy-duty material handling solution designed for fixed-route transportation in industrial environments. The following specifications detail its load capacity, structure, control systems and safety features.

| Item | Specification | Remarks |

|---|---|---|

| Model | RGV-10t | RGV transfer cart |

| Rated Load | 10 t | Safety factor 1.25 |

| Platform Size | 6000 × 2500 × 500 mm | Overall maximum dimensions |

| Lifting Stroke | 250 mm | |

| Lifting Type | Hydraulic direct lifting | Partial lifting |

| Operation Mode | Automatic control + Remote control | |

| Control System | PLC program control | |

| Communication Method | Wireless communication | On-board module transmission |

| Control Function | Receives automation control and LAN wireless dispatch signals | |

| Positioning Method | RFID + Magnetic positioning | |

| Positioning Accuracy | ±3 mm | |

| Wheel Diameter | Φ350 mm | 4 wheels |

| Wheel Material | ZG55 | |

| Motor Power | 2.2 kW | |

| Travel Speed | 0–20 m/min | |

| Frame Structure | I-beam, channel steel, steel plate welding | Standard Q235B |

| Power Supply Mode | Low-voltage cable power supply | |

| Power Input | 380 VAC – 36 V – 380 V | |

| Warning Device | Audible and visual alarm | |

| Protection Devices | Overload, overcurrent, undervoltage, short-circuit protection | |

| Anti-collision Safety | Laser obstacle avoidance + safety edge + emergency stop | |

| Color | Yellow | Customizable |

| Recommended Rail Model | P18 | |

| Platform Positioning | 4 positioning pins installed on lifting platform | 4 positioning pins installed on the lifting platform |

The above details the specifications for our RGV rail guided cart. If you are interested in our rail transfer trolley, please do not hesitate to contact us. We shall provide customised solutions tailored to your requirements.

Videos Show

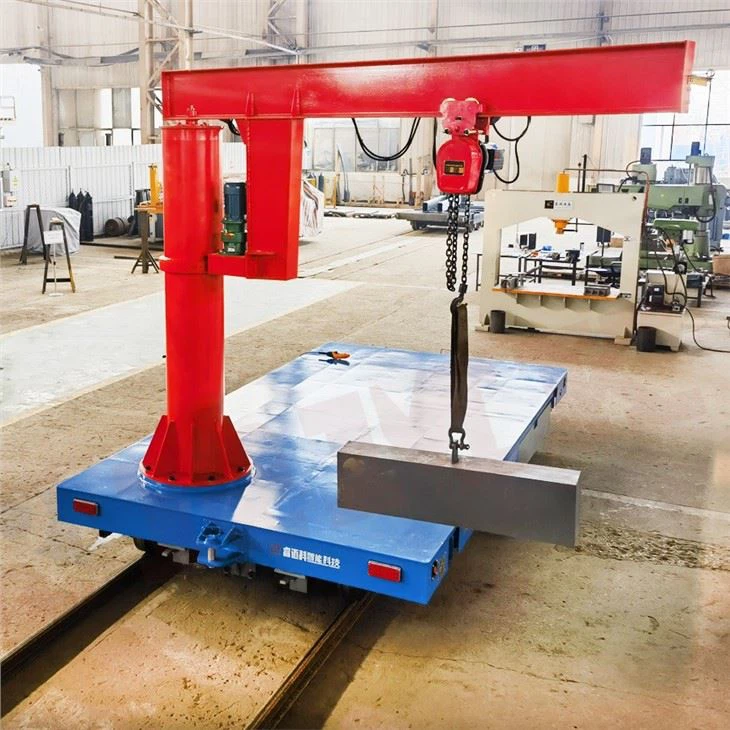

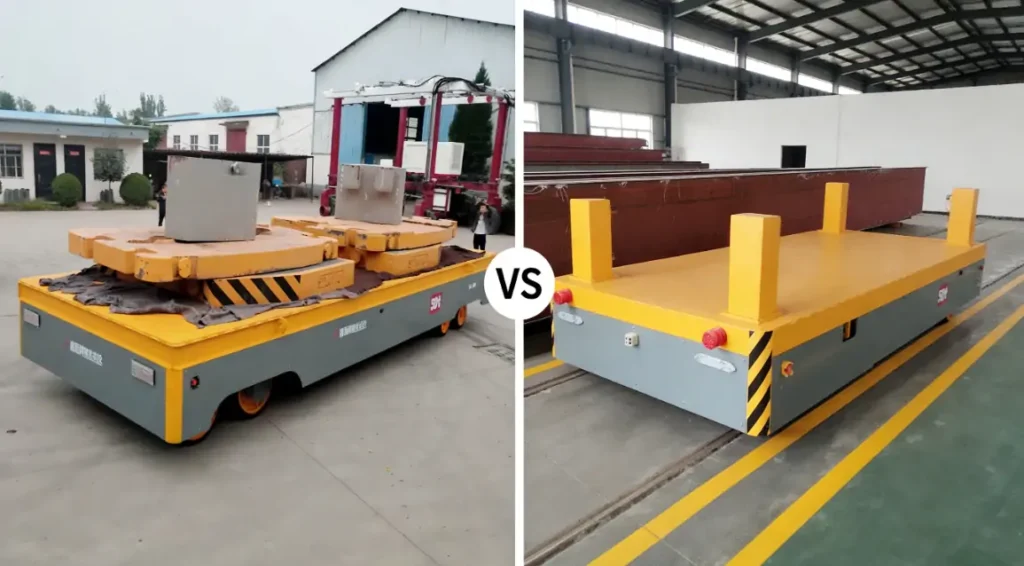

Custom Parts for RGV Rail Guided Transfer Cart

Custom Series Parameters for RGV Rail Guided Transfer Cart

| Parameter Name | Specifications |

|---|---|

| Rated Load Capacity (Ton) | 2.8, 5.9, 8, 14.6, 26.8, etc., are related to the load capacity and structural design. |

| Tabletop Size (mm) | The length can be 2000, 4000, 5500, 6500, 10000, etc., and the width can be 1500, 2200, 2500, 2800, 3000, etc., all customizable as needed. |

| Tabletop Height (mm) | Generally 450, 550, 650, 900, 1200, etc., customizable. |

| Wheel Track (mm) | Such as 1200, 2800, 4200, 4900, 7000, etc. Different load capacities correspond to different wheel tracks. |

| Inner Distance between Rails (mm) | Commonly 1200, 1435, 2000, etc., depending on the type and design of the rails. |

| Number of Wheels(Piece) | Generally is 4, and it may be 8 when the load capacity is large. |

| Ground Clearance (mm) | 50, 75, etc., which affects the passing ability. |

| Running Speed (M/min) | The speed range is generally between 0 – 18 and 0 – 25, and the speed is adjustable. |

| Motor Power (Kw) | 1, 2.2, 5, 10, 15, etc., determined according to the load capacity and running speed. |

| Battery Capacity (Ah) | 180, 330, 440, 600, etc., which affects the endurance |

| Battery Voltage (V) | 24, 48, 72, etc., related to the battery pack configuration. |

| Full-load Running Time (Hour) | Such as 4.32, 4, 3.3, 3.2, 2.9, etc., depending on the battery capacity and running conditions. |

| Running Distance per Charge (Km) | 2.8, 5.9, 8, 14.6, 26.8, etc., are related to the load capacity and structural design. |

| Maximum Wheel Pressure (kN) | 14.4, 77.7, 174, 343.8, 265.2, etc., reflecting the load-bearing capacity of the wheels. |

| Reference Dead Weight (Ton) | 2.8, 5.9, 8, 14.6, 26.8, etc., related to the load capacity and structural design. |

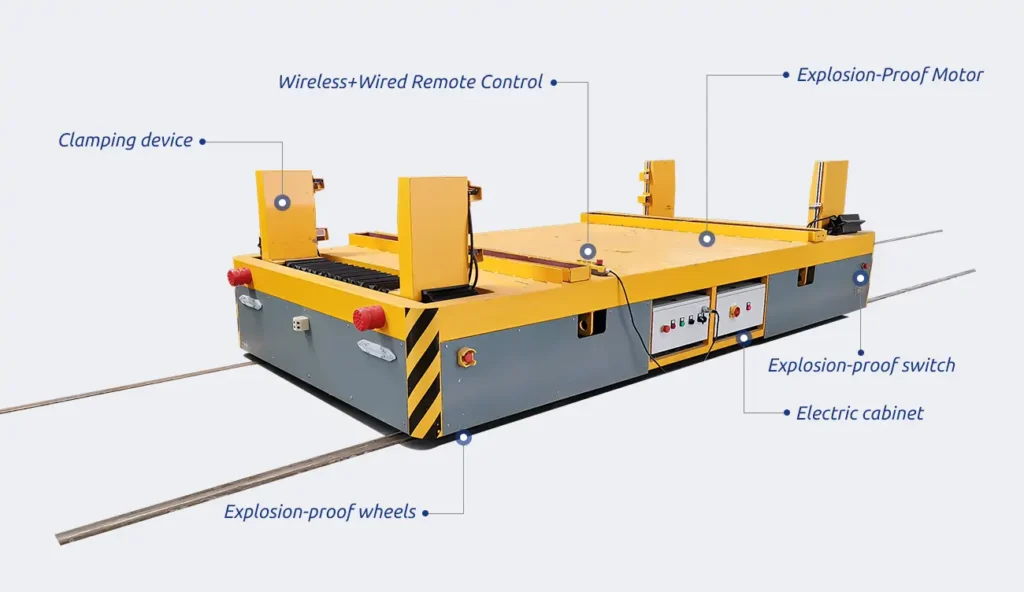

Features of RGV Rail Guided Transfer Cart

Heavy-duty Construction

High-strength steel frame capable of bearing 10 tonnes, suitable for prolonged heavy-load operation.

Hydraulic Lifting at Both Ends

Equipped with hydraulic direct-lift mechanisms enabling synchronised lifting at both ends for precise height alignment.

Rail-guided Operation

Operates along fixed steel rails for controlled, stable movement, ideal for high-frequency, repetitive routes.

High-Precision Positioning

RFID and magnetic positioning systems enable workstation-level accurate docking, meeting automated production line requirements.

Automated Control Architecture

PLC-programmed control supports multiple operating modes, facilitating flexible integration with automated systems.

Safety Protection

Equipped with laser obstacle avoidance, edge collision prevention, emergency stop buttons, and multiple electrical safety devices.

Application of RGV Rail Guided Transfer Cart

The 10-tonne RGV rail guided transfer cart is primarily deployed in automated material handling scenarios involving heavy loads and fixed routes, serving extensively across heavy industry manufacturing, automated production lines, and equipment manufacturing sectors. Its stable operation and precise positioning fulfil the demands for high-frequency, heavy-load, safe, and reliable transfer operations.

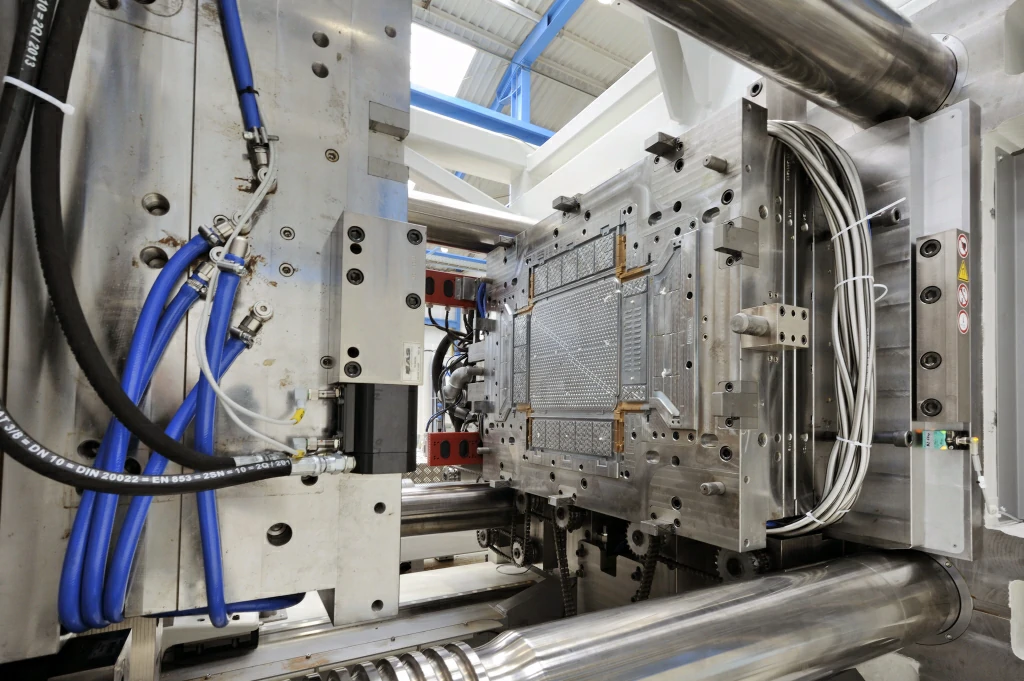

Automotive Manufacturing: Facilitates rail-based transfer of engines, moulds, and body components between workstations, enabling precise integration with assembly lines to enhance production cadence and automation levels.

Heavy Industry & Equipment Manufacturing: Suited for workshop transfer of large structural components, heavy machinery, and steel framework parts, enabling secure and efficient heavy-load handling along fixed routes.

New Energy & Power Equipment: Employed for production and assembly transfer of battery modules, transformers, and complete power equipment sets, ensuring stable and reliable heavy-load material transport.

Automated Production Line Integration: Serves as the logistical interface between production lines, enabling continuous material flow between processes and boosting overall production efficiency.

Machining and Tooling Workshops: Meets the directional transfer requirements for large workpieces and moulds between machining and assembly zones, reducing manual handling intensity and safety risks.

RGV Transfer Cart Videos Showcase

RGV Rail Guided Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and RGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised electric transfer carts, rail-guided trolleys, omnidirectional mobile transfer carts, trackless transfer carts, AGV robots, and industrial trailers.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

Why Choose Us?

- Industry-Specific Expertise – We serve power generation, shipbuilding, construction, and aerospace sectors with tailored solutions for transformers, wind turbine components, prefabricated modules, and more.

- Fully Customised – From load capacity (1–500+ tons) to drive systems (electric, hybrid, or diesel), meet your exact requirements.

- Advanced Control Systems – Options include manual remote control, semi-automatic path planning, or fully automated navigation (AGV integration).

- Quality & Durability – Robust steel frames, high-torque steering modules, and CE, ISO-certified.

- Full Project Support – From initial consultation to after-sales service, our engineers provide lifetime technical assistance.

Related Articles

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control