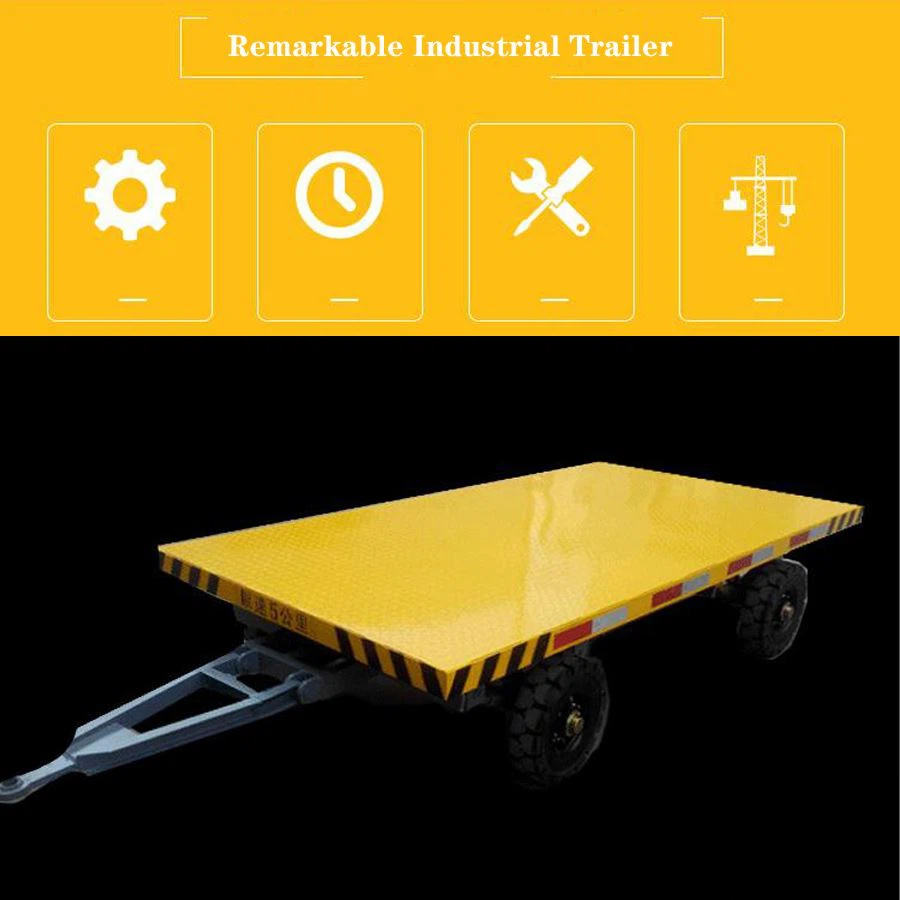

Heavy Duty Industrial trailer is efficient transportation equipment for modern logistics, offering the advantages of high load capacity, high efficiency, and low cost. A single tractor can tow multiple trailers, which are connected to the tractor via pins, making them easy to assemble and disassemble. They are widely used in airports, ports, stations, factories, and warehouses.

- Rated load capacity range: 5 ~ 500 tons

- Platform dimensions (length × width): 2.5 m × 1.6 m to 5.0 m × 2.5 m

- Operating mode: Passive traction

- Maximum travel speed: ≤5 km/h

- Wheel configuration: 4 wheels / 8 wheels / 12 wheels + solid rubber tires

Get your customized Industrial trailers solution now based on your load capacity, dimensions, and application requirements!

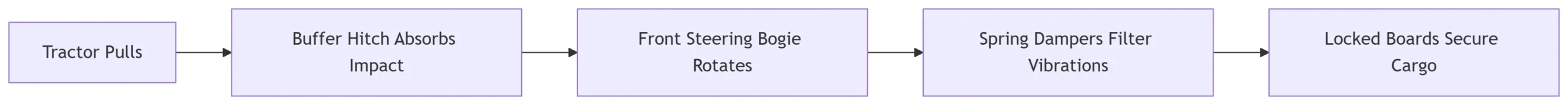

Working Principle

Tire Load Adaption

→ Solid tires (anti-deformation ≤2mm) or pneumatic tires (auto-pressure adjustment) distribute ground pressure for stability.

Passive Towing Drive

→ Powered externally by tractors (e.g., forklifts/AGVs) via a buffer hitch, with no self-propelled system.

Steering Coordination

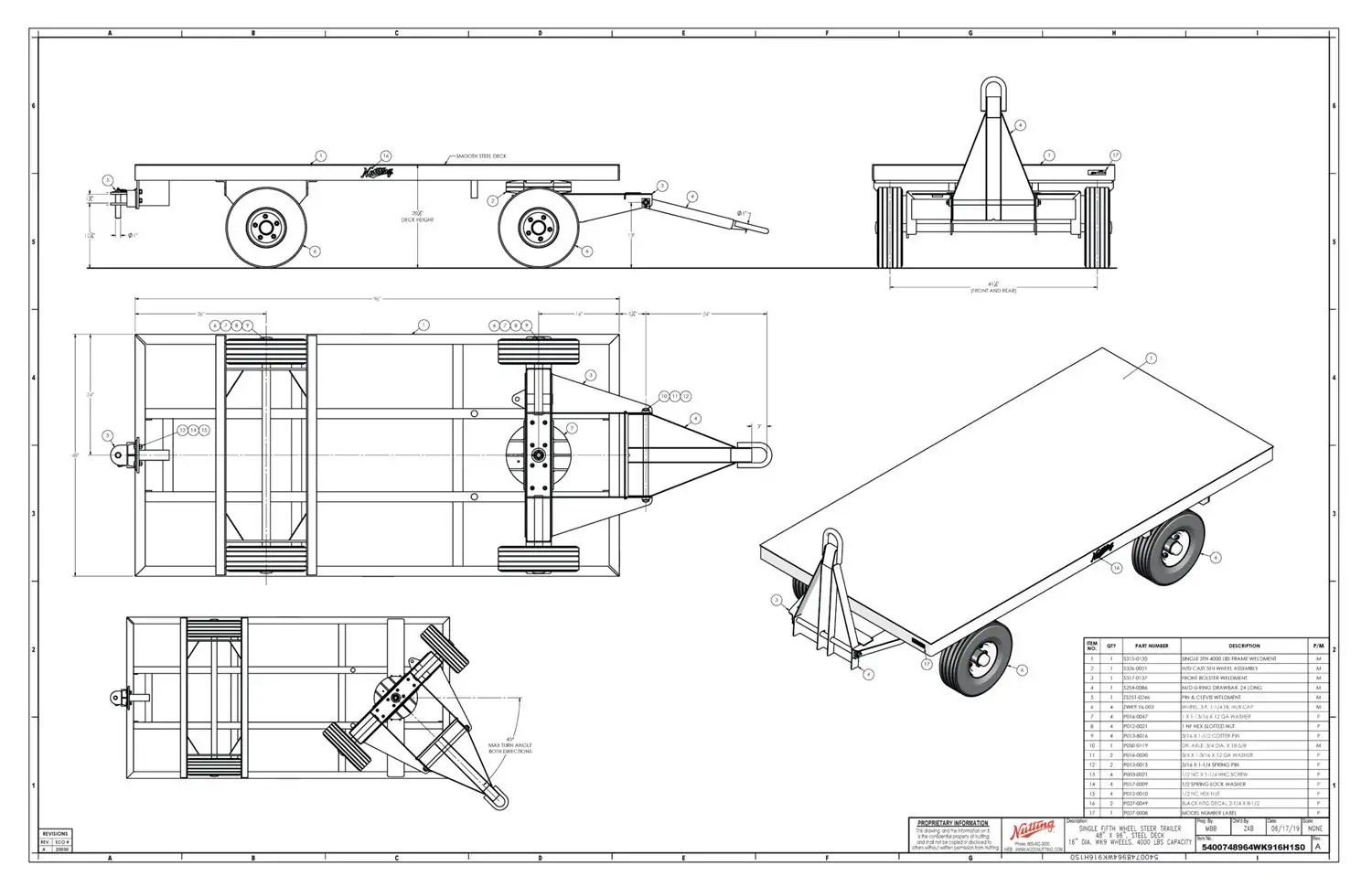

→ Front steering bogie auto-rotates with pulling direction; rear fixed wheels maintain linear tracking (min. turning radius ≤3m).

Dynamic Shock Absorption

→ High-strength spring dampers absorb road vibrations; a hydraulic buffer in the hitch reduces start/stop impacts (↓30% cargo shift risk).

Lockable Cargo Protection

→ Four-sided mechanically locked boards form an enclosed space; adjustable height (0.4-1.2m) prevents cargo from falling.

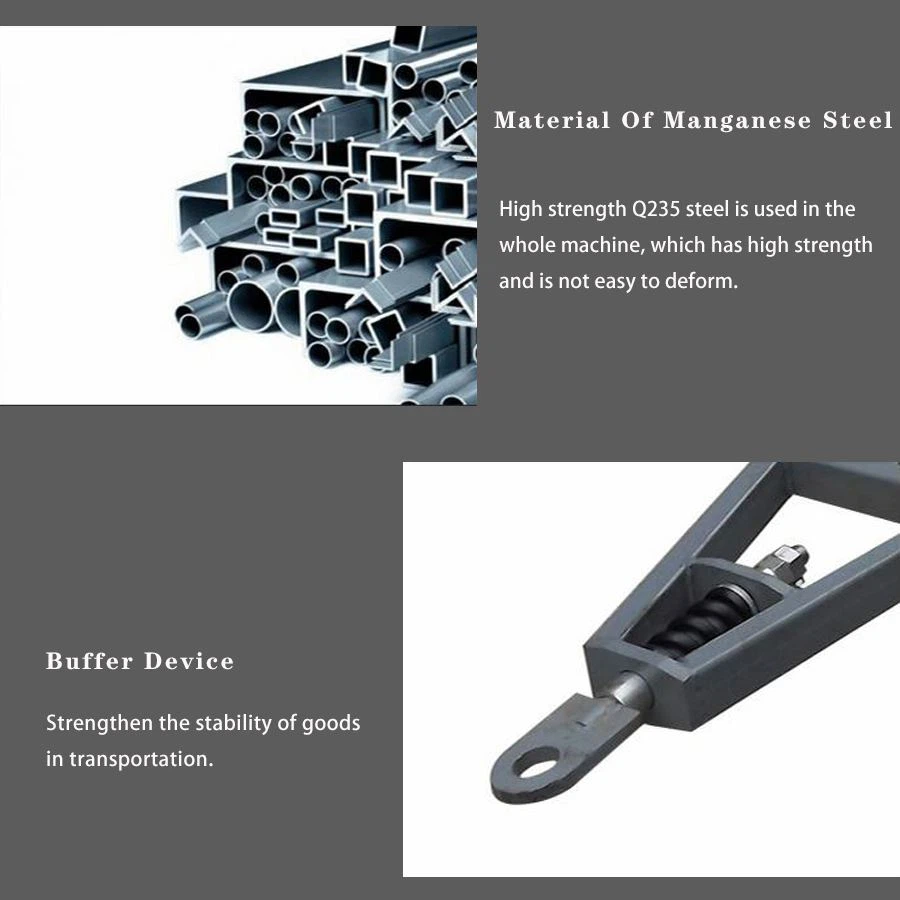

Parts

Closed panel: Movable panel design for stable cargo transport and anti-falling, with adjustable height/removable.

Tires: Optional iron core solid tires (puncture resistant) or white non-marking pneumatic tires (clean environment), suitable for different working conditions.

Steering and suspension: Front suspension steering frame + rear suspension directional wheel assembly, paired with high-strength spring suspension. When carrying ≥5 tons, dual springs are reinforced.

Towing: Rectangular tube towing frame with standard spring anti-fall lock and hydraulic cushioning device, absorbing 30% of impact force.

Customizable services: Dimensions (2-8m platform/0.4-1.2m guardrails), load capacity (≤15 tons), material (stainless steel/explosion-proof design), and towing interface (AGV/forklift) can all be customized.

industrial tugger trailers parts

industrial tugger trailers parts industrial tugger trailers parts

industrial tugger trailers parts industrial tugger trailers parts

industrial tugger trailers parts industrial tugger trailers parts

industrial tugger trailers parts

Videos Show

50 Ton Heavy Duty Industrial Trailers

Customizable Heavy Duty Industrial Trailers-30 ton Directional Rotational Steering trolley

Heavy Duty Industrial trailer types:

Below is a detailed breakdown of the three main types of Heavy-Duty Industrial Trailers, including mode of operation, load capacity, features and typical applications:

1. Trackless Transfer Industrial Trailer

The trackless transfer industrial trailer relying on tires or tracks to travel on level ground, without fixed tracks, load capacity of 5~200 tons, modular design can be combined to higher loads. It can be towed by electric (battery), diesel engine or manpower (small model). Three types of maneuvering, including manual push, remote control operation or automatic driving (AGV system).

- High flexibility: adapts to complex paths and narrow spaces.

- Steering versatility: can be equipped with multi-wheel steering (crab-walking / diagonal-walking / rotating in place).

- Environmental adaptation: explosion-proof, waterproof or corrosion-resistant models are available.

Applications: short barging of containers and heavy equipment, transfer of stamped parts and bodies, transportation of prefabricated parts and steel structures, etc.

2. Rail Trailers

The rail trailers moves along pre-set tracks (ground or elevated), usually cable-powered or battery-operated. Load capacity 10~500 tons. The control methods are manual operation, remote control or full automation (linked with production line).

- High precision positioning: suitable for repetitive handling tasks.

- Low energy consumption: low rail friction resistance, suitable for long-distance heavy-duty transportation.

- Strong stability: rail fixed, no risk of overturning.

Applications: workshop transfer of steel coils and continuous casting billets, installation and transportation of turbines and transformers, transportation of large machine tools and presses, etc.

3. Industrial Tugger Trailers

The industrial tugger trailers are trains consisting of multiple trailers towed by an electric or diesel tractor (Tugger), which can be connected in tandem (e.g. 1 trailer towing 4~6 sections). Control: Manual driving or automatic path tracking (magnetic stripe/laser navigation). Load: Individual trailers: 2~20 tons | Train: 10~100 tons (depending on the number of trailers).

- Efficient Circular Transportation: Suitable for circular distribution of materials on fixed routes.

- Modular design: trailers can be disassembled/combined quickly.

- Low maintenance cost: Simple structure, no complex power system.

Applications: Just-in-time (JIT) distribution of parts from warehouse to assembly line, transfer of precision parts such as chips, displays, etc., batch material handling in large warehouses, etc.and transformers, transportation of large machine tools and presses, etc.

Features

100-ton load capacity

Steel wheel low-friction design, breaking through the 100-ton load limit

Multi-scenario use

Rail/non-rail dual mode, precise transportation with anti-drift functionality

Heavy-duty safety

Overturn-proof design + steel wheel pressure-resistant and explosion-proof structure

Ultra-simple traction

Plug-and-play without power, saving equipment and energy costs

Military-grade connection

Quick-release pin design, bidirectional traction at the front and rear for efficient scheduling

Full-process customization service

Color/parameter configuration tailored to your needs, creating a customized logistics solution

Application

In steel mills: Transporting large steel coils, heavy steel billets, and finished steel products in high-temperature environments.

In automobile assembly plants: efficiently handling vehicle frames, chassis assemblies, and large component modules.

At shipyards: Precise transportation and positioning of large ship hull sections, cabin modules, and other heavy components.

At heavy machinery plants: Safe transportation of hundred-ton-class large injection molds and core components of heavy equipment.

At aircraft manufacturing/maintenance plants: Smooth transportation of precision aircraft engines, wings, landing gear, and other critical components.

At ports/logistics hubs: Flexibly transporting standard containers, large construction machinery, and oversized cargo.

At power generation equipment factories/power plants: Moving and positioning core components of heavy-duty power generation units (such as turbines and generators).

At large factories/warehouse centers: Internally transporting heavy raw materials, semi-finished products, and large finished goods.

Heavy Duty Industrial Trailer Specifications

| Technical Parameters Table Of RWT Heavy Duty Industrial Trailers | |||||||

| Rated Load Capacity(t) | 5 | 10 | 15 | 20 | 30 | 40 | |

| Table Size(mm) | Length | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 |

| Width | 1600 | 2000 | 2000 | 2200 | 2200 | 2500 | |

| Height | 600 | 650 | 700 | 700 | 850 | 850 | |

| Operation Method | Passive Traction | ||||||

| Running Spee(km/h) | ≤5 | ||||||

| Wheel Quantity | 4 | 4 | 8 | 8 | 8 | 12 | |

| Wheel Diamete(mm) | Ф435×150 | Ф400×200 | Ф457×203 | Ф457×229 | Ф559×254 | Ф559×254 | |

| Wheel Material | Solid Rubber | ||||||

| Vehicle Body Color | Yellow/Blue/Customized upon request | ||||||

| Notes: 1) Other table sizes and load capacities can be customized according to user requirements. 2) The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||

Customized Heavy Duty Industrial Trailers

Tell us your needs! To design the perfect trailer for your application, please provide basic details such as load capacity, operating environment, and special requirements. The following are key parameters we need to customize your solution:

Load Capacity (e.g., 10 tons, 50 tons, 100+ tons)

Operating Environment (e.g., indoor/outdoor, high temperature, corrosive)

Power Type (e.g., electric, diesel, manual, hybrid)

Mobility Requirements (e.g., trackless, rail-bound, steerable wheels)

Special Features (e.g., explosion-proof, hydraulic lifting, automation-ready)

Let us tailor a trailer that fits your exact needs!

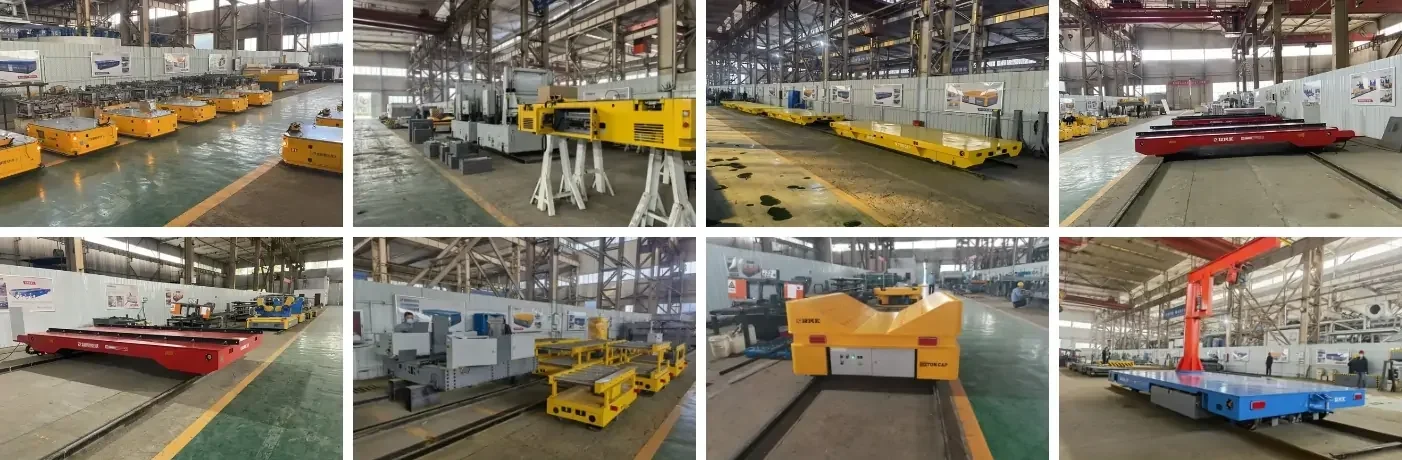

Heavy Duty Industrial Trailers Manufacturer

RIMAIK is a leading manufacturer of heavy-duty industrial trailers, specializing in high-capacity, reliable, and customized material handling solutions. We have advanced engineering capabilities, professional technical teams, rigorous quality control, committed to providing customers with quality trailers designed for every industrial environment. Contact us today for a consultation! Let’s discuss your requirements and build the perfect solution for your business.

Certification

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control