Remarkable electric transfer cart is a high-performance industrial material transportation equipment, which provides two configurations of tracked and trackless to meet the material handling needs of different scenarios. The product adopts modular design and supports three power supply modes: cable reel, battery and low-voltage rail, which can be flexibly selected according to the actual working conditions of customers.

- Load capacity: 2 ~150 ton

- Axle distance: 1200 ~ 7000 mm

- Control mode: Button/remote control

- Customized: Rail transfer cart, trackless transfer cart, AGV, trailer, etc.

Types of Electric Transfer Cart

Remarkable provides different types of electric transfer carts, each designed with unique technical features, adaptable configurations, and specific application scenarios. Remarkable specializes in customized material handling solutions for industrial applications including mold transfer, pipeline transport, coil handling, and heavy equipment movement. Our engineering team provides tailored designs, include load capacity, operating speeds, and control modes according to your specific needs.

Battery Powered Rail Transfer Cart

Heavy-Duty Material Transfer Cart

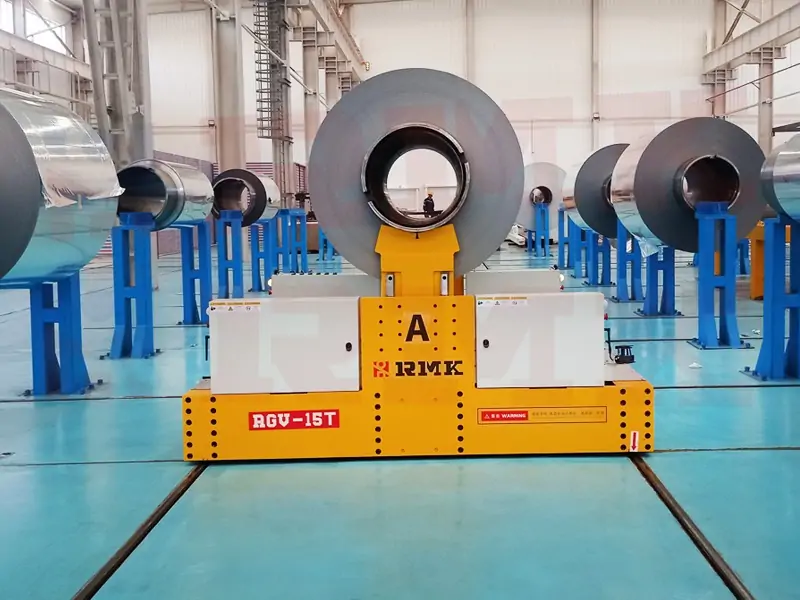

Coil Transfer Cart

Hydraulic Lifting Transfer Cart

Trackless Electric Cart

AGV Electric Transfer Trolley

| Types | Load Capacity | Adjustable Parameters | Features | Applications |

|---|---|---|---|---|

| Battery-Powered Rail Transfer Cart | 5-200 tons | – Rail gauge (standard/custom) – Power voltage (24V/48V/72V) – Speed (0-30m/min adjustable) | – ±5 mm rail guidance precision – 8-12 hour battery life – Optional automatic charging system | Automotive production lines Heavy equipment assembly Large-scale warehousing |

| Heavy-Duty Material Transfer Cart | 10-300 tons | – Deck size (max 6000×3000mm) – IP54 protection – Cabin/remote control | – Box-type welded frame (safety factor ≥3) – Dual brake system (mechanical+electromagnetic) – ATEX explosion-proof option | Steel/metallurgy Large structural transport Heavy machinery manufacturing |

| Coil Transfer Cart | 20-150 tons | – Adjustable V-shaped saddle (60°/90°/120°) – Coil diameter adapters | – Hydraulic locking anti-roll – Soft start/stop control – Overload protection | Cable factories Steel rolling mills Non-ferrous metal processing |

| Hydraulic Lifting Transfer Cart | 2-50 tons | – Lift height 200-800mm – Custom platform size – Lifting speed 4-8m/min | – 4-wheel independent AC drive – Hydraulic synchronous lifting – ±2mm auto-leveling | Multi-level workshop transfer Loading docks Production line connections |

| Trackless Electric Cart | 5-100 tons | – Omni/differential drive – Turning radius 1.5-5m – Laser/magnetic navigation | – 360° omnidirectional movement – Laser guidance (±10mm precision) – Compact design | Confined space operations Flexible manufacturing Multi-process coordination |

| AGV Magnetic Navigation Cart | 0.5-50 tons | – Navigation accuracy (±10mm/±5mm) – Battery capacity (200-1000Ah) – Communication protocol (Modbus/Profinet) | – Magnetic strip/QR code hybrid navigation – Intelligent path planning algorithm – Auto obstacle avoidance (laser+ultrasonic) – WMS/MES system integration | Smart factory logistics Automotive parts distribution Electronics flexible production lines |

Application

Electric Transfer Carts are characterized by its simple structure, economy and practicality, which makes it the first choice of equipment for material handling in modern industry. This product is widely used in machinery manufacturing workshops, chemical production plants, warehousing and logistics centers and metallurgical processing and other industrial areas, and can efficiently complete the material transfer tasks within the factory, across the workshop and between the building facilities. It is widely used in the following industries and scenarios:

Aerospace Equipment

Aerospace Equipment Automotive Manufacturing

Automotive Manufacturing Steel & Foundry

Steel & Foundry Nuclear Power

Nuclear Power Shipyard

Shipyard

- Machinery manufacturing industry: inter-workshop transfer of large molds, convergence of precision parts and components, and distribution of heavy equipment assembly lines.

- Chemical industry: in-plant transportation of reaction vessels, material turnover in explosion-proof areas, distribution of piping system components.

- warehouse logistics: bulk cargo loading and unloading operations, cross-regional goods allocation, heavy materials in and out of the warehouse transfer.

- Metallurgical industry: hot transfer of metal slabs, inter-regional transportation of wire rod coils, and warehousing of rolled products.

- Equipment manufacturing industry: assembly and distribution of large structural parts, turnover of heavy machinery parts, factory shipment of complete machine products.

Working Principle of Electric Transfer Cart

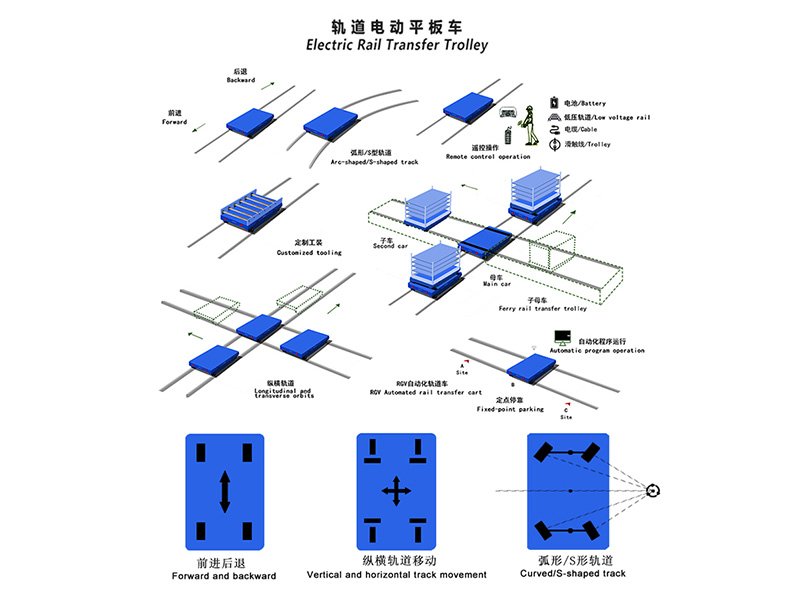

Electric Transfer Cart can be divided into two major types, railed and trackless, according to different ways of guiding, and their working principles are as follows:

Rail Electric Transfer Cart

Rail electric transfer cart realizes physical guidance through preset rails (steel rails or I/U rails), and is driven by motor-driven gears or friction wheels that mesh with the rails for transmission, ensuring high precision positioning of ±2-5mm.

Its power supply includes low-voltage rail power supply (36V/48V DC), cable reel or battery, which is suitable for heavy loads (up to 300 tons) and long-distance transportation. The control system adopts PLC or frequency conversion technology, supports automated scheduling (e.g. RFID positioning), and is suitable for fixed-point, highly repetitive operations, commonly used in iron and steel metallurgy, heavy machinery and three-dimensional warehouse scenarios.

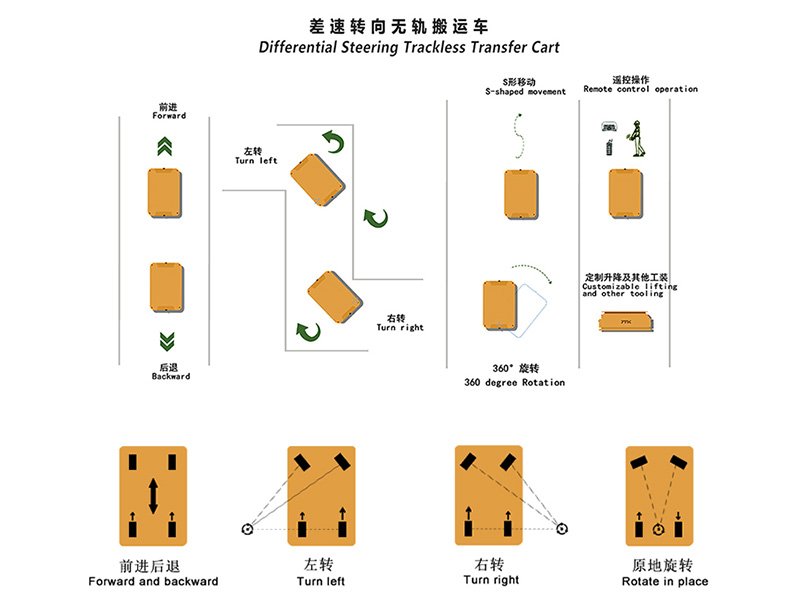

Trackless Electric Transfer Cart

Trackless Electric Transfer Cart relies on magnetic navigation (±10mm), laser navigation (±5mm) or inertial navigation to realize autonomous trajectory, without the need for fixed tracks. Driven by omni-directional wheels (e.g. McNamee wheels) and independent servo motors, they support 360° steering and dynamic path planning.

Powered by Li-ion battery (4-8 hours range), combined with intelligent control system (e.g. ROS algorithm), it can be docked to WMS/ERP and realize multi-vehicle cooperation (AGV cluster). With high flexibility (turning radius <1m) and a load capacity of 0.5-50 tons, they are suitable for flexible production lines, automotive assembly and narrow space operations.

Videos

AGV-Automated transport vehicle

Specifications

| Capacity(t) | 6 | 10 | 16 | 25 | 40 | 63 | 100 | |

| Platform | Length | 3600 | 3600 | 4000 | 4500 | 5000 | 5600 | 6300 |

| Size (mm) | Width | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2800 |

| Height | 550 | 550 | 580 | 650 | 700 | 850 | 900 | |

| Working speed (m/min) | 30 | 30 | 30 | 30 | 25 | 25 | 20 | |

| Bottom of Board Size (mm) | 50 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Wheel base A(mm) | 2000 | 2000 | 2200 | 2500 | 2800 | 3200 | 3600 | |

| Wheel back distance C(mm) | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | |

| Power | 380V, 3PH or battery | |||||||

Features

Intelligent navigation system

The electric transfer cart equipped with laser navigation and path planning function, realizing high-precision positioning and automatic tracking operation.

Multiple operation modes

Such as straight, diagonal, horizontal, and in-situ rotation, with a minimum turning radius of only 1.2m, which is adaptable to complex working conditions.

Safety protection system

Integrated three-dimensional obstacle avoidance system (laser + ultrasonic + mechanical collision avoidance bar), automatic emergency stop in case of obstacles, CE safety certification.

Strong power

Adopts AC servo motor, with a maximum climbing capacity of 20°, load range of 2-200 tons, and adjustable speed of 0-20m/min.

Intelligent control

Optional WMS/WCS system docking, supporting remote monitoring, fault diagnosis, and statistical analysis of data.

Modular expansion design

Provides standardized interfaces, which can be quickly retrofitted with lifting, rotating, clamping and other functional modules to meet individual needs.

Related Articles

Customize Electric Transfer Cart

Fill out the form below for a customized electric transfer cart solution and quote!

Remarkable as a professional electric transfer cart manufacturer and supplier in China, we provide a full range of electric transfer cart customized services, please provide the following key parameters: rated load, platform size, running distance and frequency, running speed and control mode. Our professional engineering team will provide you with model recommendation, 3D layout plan, configuration list and detailed quotation within 24 hours.