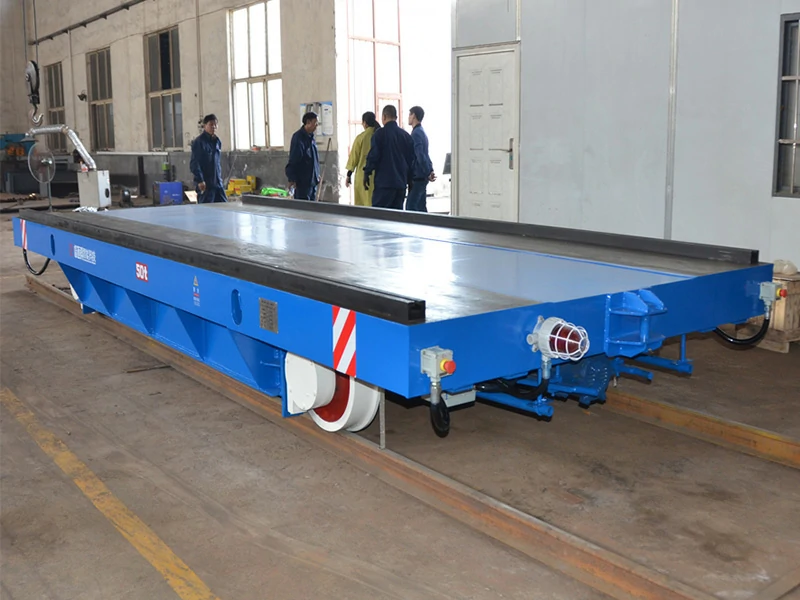

Electric rail carts are factory-based material handling equipment that run along fixed tracks and are powered by electricity. They transport heavy loads through the interaction of steel wheels and rails, and are widely used in steel mills, mould workshops, machining centres, and warehousing logistics.

With electric rail carts becoming increasingly prevalent, certain use issues have drawn significant attention. For instance, cart derailments can stem from multiple factors. Below is a detailed analysis of derailment causes and corresponding solutions.

Main reasons for the Electric Rail Cart derailment

Numerous factors contribute to electric rail cart derailments. Below are the three most common and direct causes requiring particular attention.

Rail Issues

Uneven Rail Installation: When rails are installed unevenly, with gauge deviations or minor deformations, it causes slight deviations in wheel running direction. This forces vehicles to operate under prolonged uneven loading, increasing the risk of rail climbing and derailment.

Loose Rail Joints: Loose connections or minute gaps at rail joints generate impact vibrations when the electric rail cart passes over them. This reduces stability, accelerates wheel-rail wear, and increases the likelihood of derailment incidents.

Rail Wear or Damage: Damage to rails caused by corrosion, foundation settlement, or prolonged heavy loads compromises the rail’s guiding precision. This can cause wheels to bounce or slip during operation, leading to deviations from the normal running path.

Electric Rail Cart

Electric Rail Cart Electric Rail Cart

Electric Rail Cart

Wheel & Axle Issues

Wheel Wear and Flange Thinning: Long-term operation causes wheel surface wear and reduced flange height, preventing wheels from securely engaging the rail edge. This leads to lateral deviation during acceleration/deceleration or minor load shifts.

Loose Axle or Misalignment: Failure to maintain the horizontal and vertical alignment of axles causes uneven force distribution between left and right wheels. This induces persistent lateral drift in transfer cars, potentially leading to derailment over time.

Frame Deformation: Overloading, impact, or prolonged fatigue can cause slight frame distortion, shifting wheel positions, and altering the vehicle’s centre of gravity. This shifts the running direction toward the outer rail.

Improper Loading

Overloading Condition: Exceeding the rated load capacity causes wheel pressure to surge sharply, accelerating tread wear and weakening the vehicle’s adhesion to the track. This results in track deviation during starts or turns.

Uneven Load Distribution: Concentrating material on one side causes uneven wheel loading, tilting the entire vehicle sideways, and eventually causing it to slide along the rail edge or climb the rail.

Sudden Impact Under Load: Frequent heavy-load starts or abrupt stops generate intense shocks, causing fluctuating forces on the vehicle and momentarily deflecting wheels from the guide centerline.

Electric Rail Cart

Electric Rail Cart Electric Rail Transfer Cart

Electric Rail Transfer Cart

Other Reasons

Foreign Objects on Rail: Tools, scrap, packaging, or other debris on the track can obstruct the rail, causing slippage or derailment.

Power Supply Interruption: Aging power lines, short circuits, or poor connections can cause sudden power loss to the rail cart. If the vehicle stops in an unfavorable position, the risk of derailment increases.

Dual-drive Synchronization Issues: When the left and right drive speeds of the rail transfer cart are inconsistent, it may cause the vehicle to veer off course and subsequently derail.

Having thoroughly examined the causes of electric rail cart derailments, how can we prevent or reduce such occurrences? Below, we briefly outline the solutions.

Electric Rail Transfer Cart Solutions:

To reduce derailment risks and enhance operational stability, electric rail cart purchasers can implement improvements in the following aspects:

- Regularly inspect and calibrate tracks: Check track gauge, surface levelness, and weld integrity, and promptly repair subsidence areas.

- Maintain and replace wheels: Periodically inspect flange wear, diameter variations, and bearing conditions; replace aged wheels according to schedules to improve equipment stability.

- Load Control and Loading Methods: Operate within rated load capacity, maintain centered placement of materials to prevent uneven forces causing operational drift.

- Regular Track Cleaning: Inspect for foreign objects, clear debris, and maintain oil-free, residue-free track surfaces to reduce operational resistance and sudden deviations.

- Optimize operating procedures: Verify synchronization of dual drive motors and train operators to ensure smooth starts and steady speeds, minimizing human-induced risks.

Conclusion:

Through the above analysis, we know the reason for the electric rail cart derailments and the solution. If you have more questions about the transfer cart, you can contact us at any time. We are a professional electric transfer cart manufacturer have rich experience in solving your material handling problems.