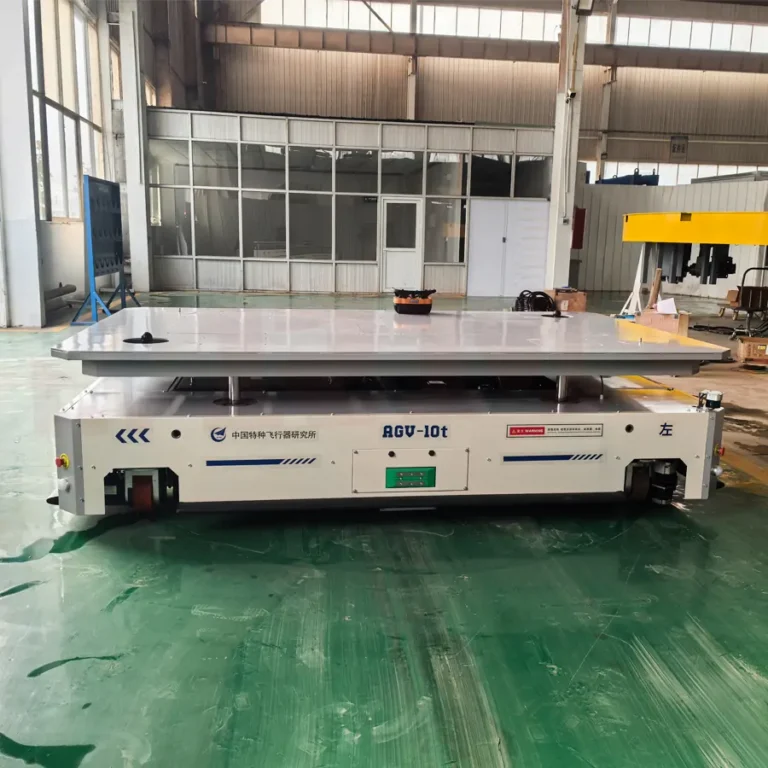

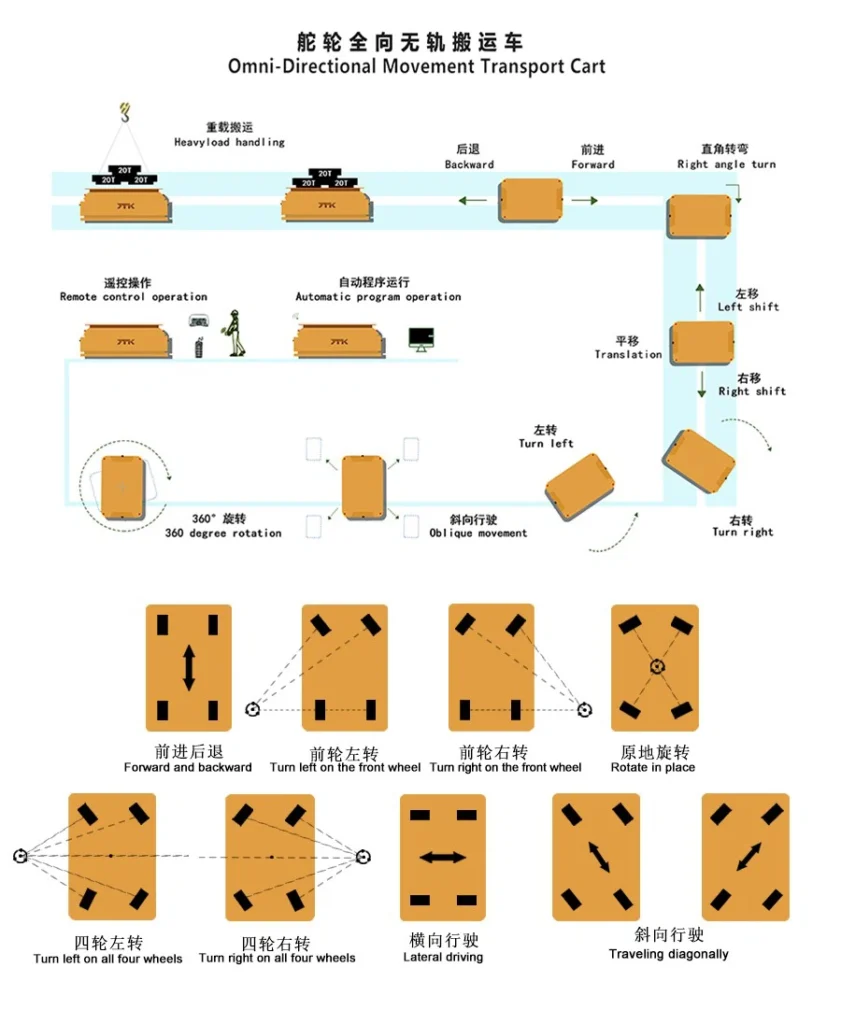

The Omnidirectional Transfer Trolley uses an advanced independent steering control system to provide the most maneuverable performance of any Remarkable transfer carts model. Each wheel can be individually reoriented for omnidirectional movement, including longitudinal, lateral, crab, diagonal travel and zero-radius rotation. Widely used for efficient handling of heavy and bulky cargo such as large industrial equipment, tanks, transformers, large pressure vessels, prefabricated components, wind turbine blades, etc.

- Capacity: 5 tons to 400 tons

- Speed: Up to 30 m/min

- Wheels: Rubber / Polyurethane

- Control: Remote Control / Autonomous

- Power Source: Battery / Diesel

- Steering: Omnidirectional

- Movements: 360° rotation (Carousel) and crab movement (horizontal and diagonal movements)

Working Principle of Omnidirectional Transfer Cart

An Omnidirectional Transfer Cart operates on a multi-wheel independent steering and drive system, maneuverability in confined spaces. Its working principle as the follow:

Independent Steering Control

Each wheel is equipped with its own steering actuator (electrical or hydraulic) and drive motor, allowing individual control of direction (typically 0–360° rotation) and speed, eliminates traditional turning radius limitations.

Coordinated Motion Modes

Longitudinal/Lateral Movement: All wheels align in parallel for straight-line travel (forward/backward or sideways).

Crab Steering: Wheels turn uniformly at an angle for diagonal movement.

Zero-radius Rotation: Wheels rotate tangentially around the cart’s center point for on-the-spot pivoting.

Curved Path Tracking: Wheels adjust dynamically to follow custom trajectories.

Real-Time Control System

A centralized controller processes input (joystick, remote, or programmed path) and calculates each wheel’s optimal speed/angle via kinematic algorithms.

Load Stability Management

Hydraulic or pneumatic suspension compensates for uneven terrain, while load sensors prevent wheel slippage during heavy-load transport (e.g., 50–500+ tons).

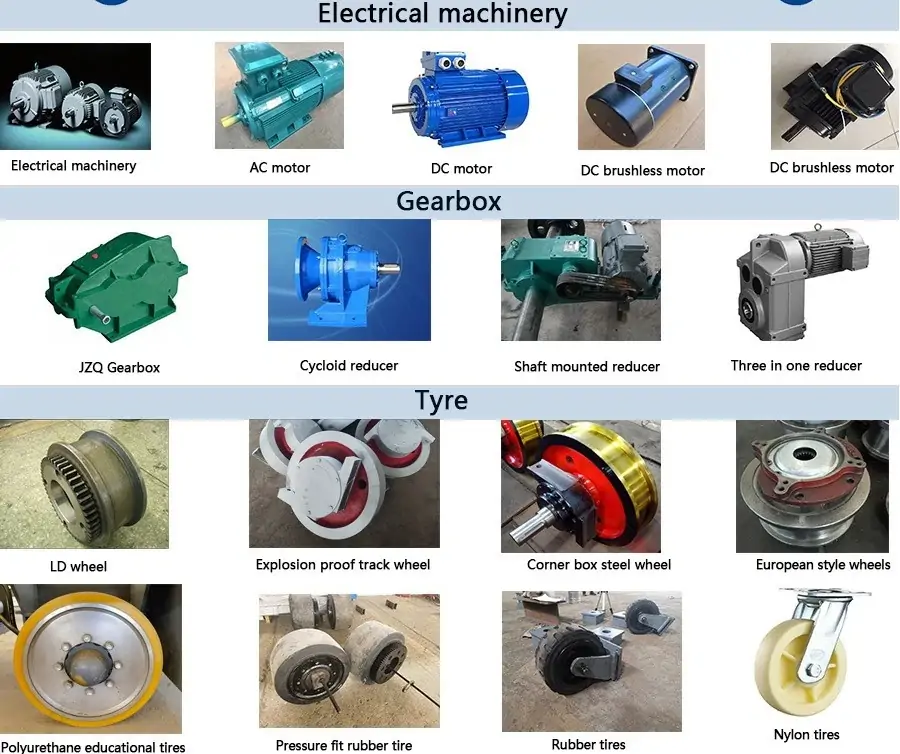

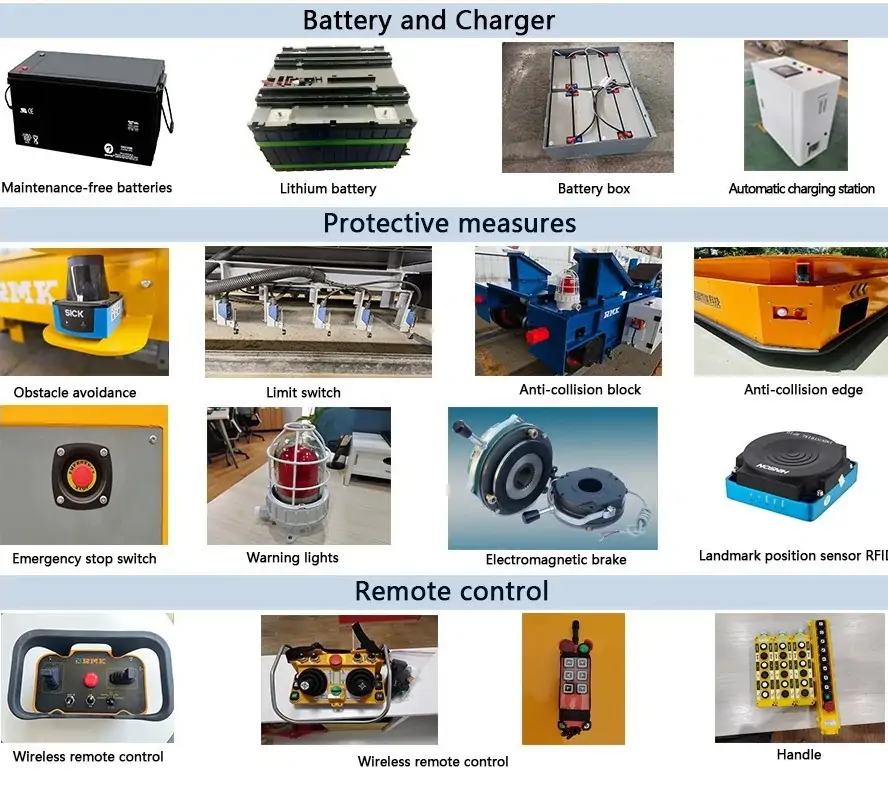

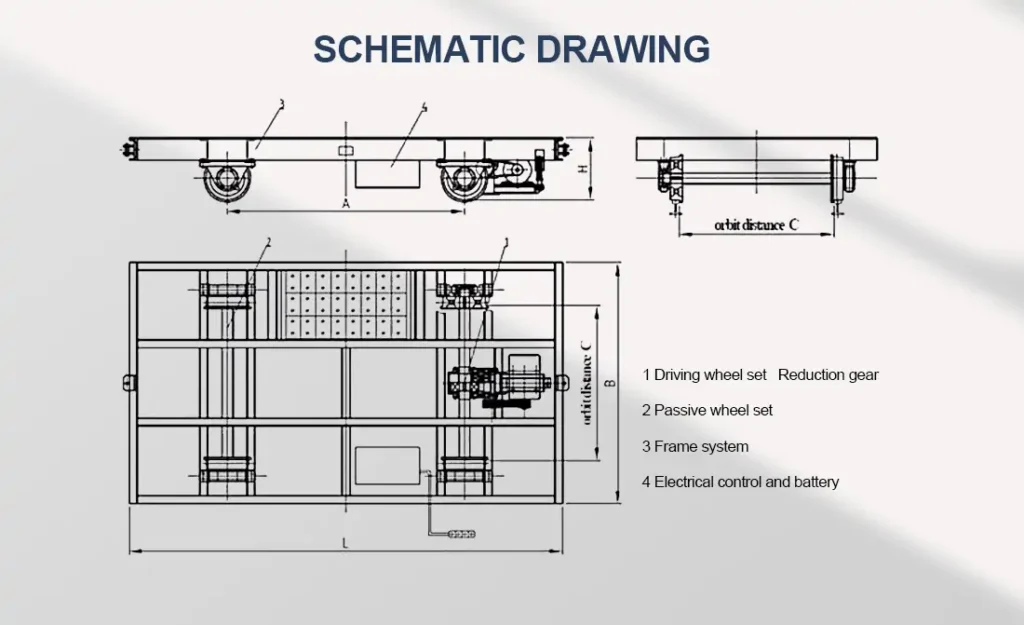

Parts

Omnidirectional Transfer Trolley mainly consists of independent steering drive wheelset (integrated 360° rotating motor/hydraulic motor), high-strength steel frame, intelligent control system (PLC/Motion Controller+Operating Terminal), hydraulic/pneumatic suspension system, safety components (collision avoidance sensors/load monitoring), and power unit (diesel engine/lithium battery pack). Core components. Its modular design supports customized number of wheels (4~16+ wheels) and load capacity (30~1000 tons), optimized for heavy-duty precision handling.

Below is the display of each component:

Videos Show

Specifications

| Rated Load Capacity(t) | 2 ton | 5 ton | 10 ton | 15 ton | 20 ton | 30 ton | 50 ton | 60 ton | 80 ton | 100 ton | 150 ton | 200 ton | ||||

| Table Size(mm) | Length | 2000 | 2400 | 2700 | 3000 | 4000 | 4500 | 4500 | 5000 | 6000 | 6500 | 6500 | 6500 | |||

| Width | 1300 | 1500 | 1800 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2500 | 3000 | 3000 | ||||

| Height | 450 | 500 | 550 | 700 | 700 | 700 | 650 | 700 | 700 | 700 | 750 | 750 | ||||

| Ground Clearance(mm) | ≥50 | ≥100 | ||||||||||||||

| Turning Radius(mm) | 0 | |||||||||||||||

| Steering mode | Steering Wheel/Omni Wheel Steering | Differential Wheel Set Systems | ||||||||||||||

| Operation Method | Remote Control & Hand Operate Pendant | |||||||||||||||

| Move Way | Omnidirectional movement,Forward/backwards, rotation left/right, crab driving left/right,turning while driving with no stop,rotate 360° in place | |||||||||||||||

| Running Speed(m/min) | 25 | 20 | ||||||||||||||

| Motor Type | DC Servo Motor | |||||||||||||||

| Brake Mode | Electromagnetic Brake | |||||||||||||||

| Protective Measures | Audible and visual alarm lamp+ Emergency stop button+Laser obstacle avoidance sensor(Optional)+Anti-collision contact edge(Optional) | |||||||||||||||

| Wheel Quantity | 4 | 8 | 12 | 16 | ||||||||||||

| Suspension Type | Mechanical Automatic Regulation | Hydraulic Suspension | ||||||||||||||

| Drive Wheel Diameter(mm) | Ф200 | Ф250 | Ф300 | Ф410 | Ф300 | Ф410 | Ф400 | Ф500 | Ф400 | Ф500 | Ф550 | Ф550 | ||||

| Wheel Material | Steel Core + Polyurethane /Rubber Tire | |||||||||||||||

| Battery Capacity(kW·h) | 4.8 | 7.2 | 10.5 | 12.5 | 14.4 | 15.1 | 22.5 | 30 | 37.8 | 45.3 | 60.5 | 75.6 | ||||

| Battery Type | Lead-Acid Battery | Lithium Battery | ||||||||||||||

| Battery Endurance | 5h(Customized As Needed) | 4h(Customized As Needed) | ||||||||||||||

| Battery Charging Time | ≤7h | ≤5h | ||||||||||||||

| Battery Charger | AC220V/AC380V | |||||||||||||||

| Ground type | Cement Floor、Steel Plate Ground 、Epoxy Floor,Asphalt Floor | |||||||||||||||

| Full-Load Climbing Capacity | 3% | |||||||||||||||

| Working Environment | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation(Customized for high-temperature and explosion-proof environments) | |||||||||||||||

| Vehicle Body Color | Customized | |||||||||||||||

| Other Functions | Battery Power Display,PLC,Visual Display Screen Designed On The Electric Control Cabinet ,Over Voltage, Under Voltage, Over Current Protection etc | |||||||||||||||

| Versione Automatica – AGV | With navigation modes such as magnetic navigation, laser navigation, QR code navigation, and ribbon navigation, the AGV can achieve automatic handling functions. | |||||||||||||||

1) Other table sizes and load capacities can be customized according to user requirements.

2) For hydraulic steering, a dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints.

3) Battery type and operating time (battery endurance) can be customized to meet customer needs.

4)The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice.

Different Types of Omnidirectional Transfer Trolley For Sale

- Transfer Trolley with Omni Wheel

Mecanum/omni wheels enable diagonal/sideways movement without wheel reorientation. Widely used for factory automation, robotic assembly lines, flexible material transport. - Omnimove Battery Transfer Trolley

Electric-powered omnidirectional movement with lithium battery autonomy. Widely used for Eco-sensitive sites (indoor factories, aerospace component handling). - Self-Propelled Electric Transfer Trolley

Versatile steering modes (pivot/curve/crab) via joystick/remote control. Widely used for automotive production, warehouse heavy item transport. - Omnidirectional Mobile Transfer Trolley

360° steering (longitudinal/lateral/rotation) via independent wheel control. Widely used for heavy load handling in tight spaces (transformers, shipyard modules). - Multiway Transfer Trolley

Hybrid steering (longitudinal + limited lateral/crab mode). Widely used for workshop logistics, steel coil handling, modular construction. - Multi-Drive Battery Transfer Trolley

Dual-mode (manual/AGV) with swappable battery packs. Widely used for high-frequency logistics (e.g., prefab concrete, turbine blade staging).

Transfer Trolley with Omni Wheel

Transfer Trolley with Omni Wheel Omnimove Battery Transfer Trolley

Omnimove Battery Transfer Trolley 160 Ton Self propelled electric transfer trolley

160 Ton Self propelled electric transfer trolley

Customized Omnidirectional Transfer Trolley Solutions

In the field of heavy lifting and precision transportation, it is often difficult for standardized equipment to meet the needs of specific working conditions. Our Omnidirectional Transfer Carts support in-depth customization, providing solutions that are perfectly adapted to your specific application scenarios, load requirements, space constraints and automation needs. The main customized items are as follows:

- Load capacity: 1 ton ~ 500 tons, to meet the needs of different heavy cargo handling.

- Driving mode: electric (lithium battery/rail-powered), diesel-driven or hybrid, adapting to indoor and outdoor working conditions.

- Steering mode: 4-wheel, 8-wheel, multi-wheel set independent steering.

- Control system: manual remote control, semi-automatic path planning or fully automatic navigation (laser/magnetic stripe/GPS).

- Special requirements: explosion-proof design (for petrochemical and nuclear power), high/low temperature resistance, high precision positioning (±1mm), etc.

Please provide your specific needs (such as load, size, working environment, etc.), our engineers will provide you with professional advice and quotation within 24 hours.

Features

Omni-directional flexible movement

Supports 360° traveling in any direction (forward, backward, lateral, diagonal, in-situ rotation), breaking through the traditional vehicle turning radius limitations.

Multi-mode control

Manual remote control, automatic path planning or programmed control can be switched to adapt to the needs of complex working conditions.

High-precision Positioning

Precise positioning is realized through encoder/laser navigation, suitable for precision equipment inst

Intelligent Safety Protection

Multiple intelligent safety protection devices, integrated anti-collision radar, tilt alarm, overload protection and emergency braking system.

Reduced overall costs

Reduced dependence on infrastructure such as tracks/ramps, low maintenance costs, and multiple conventional equipment working together.

Meet different customization needs

Modular design can be customized in terms of the number of wheelsets, power (electric/diesel) and load capacity to meet the needs of energy, military, infrastructure and other industries for overloaded cargo transportation.

Application

Omnidirectional Transfer Trolley is widely used in industries that require flexible handling of large and heavy materials in narrow spaces. It is especially suitable for working conditions with limited space, high requirements for handling accuracy or over-limit loads, helping enterprises to improve logistics efficiency and reduce labor and equipment costs. Main application industries and typical scenes:

- Energy industry

Power equipment: installation and transfer of transformers, generators, high-voltage switchgear.

Nuclear power: precision positioning of reactor pressure vessels, steam generators, and nuclear waste containers.

Oil & Gas: In-plant transportation of large storage tanks, compressor modules and refining equipment. - Heavy Machinery and Manufacturing

Wind power: assembly and storage and transportation of wind turbine blades, towers, nacelles.

Shipbuilding: precise docking of hull segments, propellers, large deck modules.

Construction machinery: production line transfer of excavators, shield machines and other over-limit equipment. - Construction and Infrastructure

Precast concrete: transportation and installation of large wall panels, bridge segments, tunnel tube sheets.

Steel structure: transportation and positioning of plant trusses and large steel beams. - Aerospace and Military

Aircraft components: assembly line transfer of wings, fuselage segments, engines.

Spacecraft: vibration-free precision handling of satellites and rocket modules.

Cases Show

Omnidirectional Transfer Trolley Manufacturer

As a leading manufacturer of Omnidirectional Transfer Trolleys, we specialize in designing and building high-performance, custom-engineered solutions for heavy and oversized load handling across industries. With 10+ years of expertise in omnidirectional steering technology, we deliver reliable, precision-driven transfer carts that optimize space utilization and operational efficiency in constrained environments.

Why Choose Us?

- Industry-Specific Expertise – We serve power generation, shipbuilding, construction, and aerospace sectors with tailored solutions for transformers, wind turbine components, prefabricated modules, and more.

- Fully Customization – From load capacity (1–500+ tons) to drive systems (electric, hybrid, or diesel), meet your exact requirements.

- Advanced Control Systems – Options include manual remote control, semi-automatic path planning, or fully automated navigation (AGV integration).

- Quality & Durability – Robust steel frames, high-torque steering modules, and CE, ISO-certified.

- Full Project Support – From initial consultation to after-sales service, our engineers provide lifetime technical assistance.

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control