Transfer carts are the core transportation tool for automated material handling and are widely used in industries such as steel, automotive, molds, new energy, and warehousing and logistics. Trackless transfer carts and rail-mounted transfer trolleys are the two most widely used types.

However, many companies are confused when choosing between the two types of transfer carts: What are the differences? How should they choose? Let’s take a look at the differences and how to choose between them.

trackless transfer cart

trackless transfer cart Rail-Transfer-Trolley

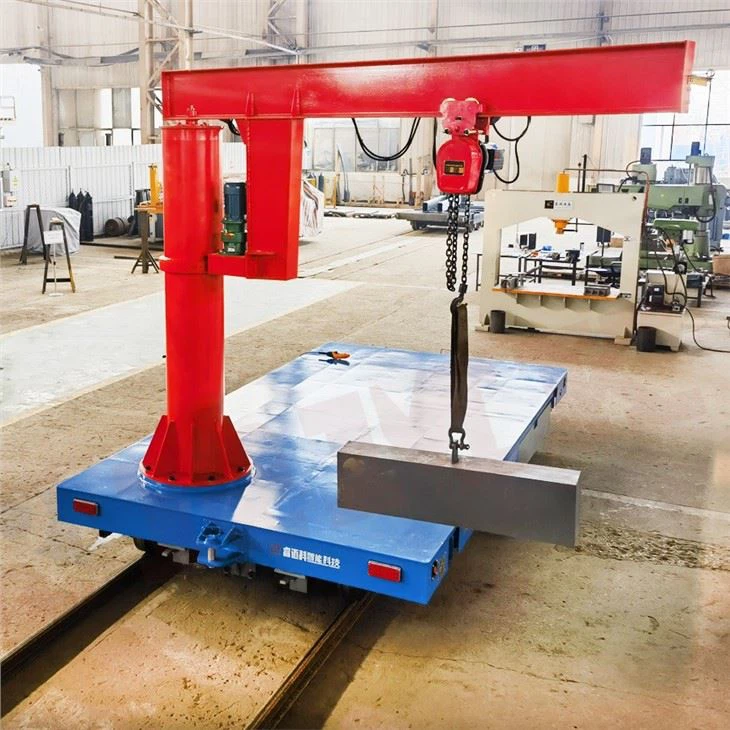

Rail-Transfer-Trolley

What is a Trackless Transfer Cart?

The trackless transfer is a battery-powered intelligent transport device. Requiring no fixed tracks, its motor-driven wheels enable a variety of movement modes, including forward, backward, lateral, diagonal, and in-situ rotation. Equipped with intelligent control systems such as laser, magnetic stripe, and inertial navigation, the trackless transfer vehicle can operate flexibly in complex environments. Its features include easy installation, flexible steering, and a high degree of automation, making it suitable for flexible production lines and multi-station material scheduling. For more detailed information about trackless transfer carts, please refer to this article: What is Trackless Transfer Cart?

What is a rail-mounted transfer trolley?

A rail transfer trolley (also known as a rail-powered flat car) is a type of transport equipment that runs along fixed tracks, relying on track guidance for precise movement. It offers smooth operation and high safety, making it suitable for repetitive transport of heavy loads over long distances along fixed routes. It is a heavy-duty transport equipment commonly used in traditional industrial handling. For more detailed information about rail-mounted transfer trolleys, please refer to this article: What is Rail Transfer Trolley?

Rail-mounted-Transfer-Trolley

Rail-mounted-Transfer-Trolley

The Difference Between a Trackless Transfer Cart and a Rail Transfer Trolley

To better understand these two types of transport equipment, we compare and summarize the main differences between them:

| Comparative aspects | Trackless transfer cart | Rail transfer trolley |

|---|---|---|

| Operation Mode | Trackless, free-travel, multi-directional steering | Runs straight along the track, fixed route. |

| Power Supply | Battery Power (Wireless Rechargeable) | Powered by Track, Cable Drum, or Busbar |

| Control System | Remote Control / Wireless Control / Automatic Navigation Control | Button Control / Remote Control / Fixed-Point Control |

Flexible Depth | High flexibility, can cross workshops, navigate obstacles, and turn freely. | Low flexibility, operates only within fixed tracks. |

| Installation and Construction | No track construction required, fast deployment | Requires track laying, a long construction period |

| Load Range | 5-150 tons (customizable up to 300 tons) | 10-500 tons and above |

| Operational Stability | Highly affected by floor surface flatness | Strong stability, not prone to drift |

Safety | Equipped with obstacle avoidance, speed limiting, and emergency stop protection. | Relies on manual monitoring and mechanical protection |

| Maintenance Cost | Low, primarily battery and tire maintenance | High, primarily track and cable maintenance |

| Construction Cost | Low, no ground modification required | High requires track construction and maintenance |

| Applicable Environments | Variable, complex, and space-constrained locations | Stable, enclosed, fixed-route factory areas |

| Typical Industries | Mold manufacturing, equipment assembly, warehousing, and logistics | Iron and steel metallurgy, heavy machinery, and shipbuilding |

Based on the table above, we can see that trackless transfer vehicles are more flexible and intelligent, while rail transfer vehicles are more stable and have a larger load capacity. So, what are the application scenarios for each? Let’s take a look together.

Application Scenarios of Trackless Transfer Cart

Trackless transfer carts, with their flexible and intelligent features, are widely used in the following applications:

- Mold Shop: Mold transfer, online and offline operations

- Automotive Manufacturing: Cross-workstation handling of car bodies and parts

- Steel Metallurgy: Transport of steel coils, castings, and steel plates

- New Energy Equipment Manufacturing: Transport of battery modules and energy storage systems

- Warehouse Logistics: Multi-area automated handling, coordinated with AGV systems.

This system is particularly suitable for scenarios with complex workstation layouts, frequently changing routes, and the need for flexible transportation.

Application Scenarios of Rail Transfer Trolley

Rail transfer vehicles offer stability and heavy-duty capabilities, making them suitable for the following applications:

- Transport of ladles and coils in steelmaking plants

- Material transfer between large-scale machining production lines

- Route-based logistics in the automotive and shipbuilding industries

- Frequent transfer of heavily-loaded workpieces

- Stable operation in high-temperature environments

They are suitable for fixed-point material transfer production lines with stable routes, frequent transport, and long-term continuous operation.

How to Choose a Suitable Transfer Cart

When selecting a transfer vehicle, companies should consider the following factors:

Production Environment and Ground Conditions: Trackless transfer carts are more advantageous for applications requiring high surface flatness and route flexibility. If a fixed track infrastructure is already in place, rail-mounted transfer trolleys are more economical.

Material Weight and Frequency: For extremely heavy and repetitive transport tasks, rail-based carts offer greater stability. For applications with material weights under 300 tons and requiring frequent adjustments to production schedules or routes, trackless transfer vehicles are more efficient.

Degree of Automation Required: If a company plans to integrate an AGV system or intelligent warehousing system, trackless transfer cars offer better automated scheduling. Rail-mounted vehicles are more suitable for controlling production cycles within a fixed schedule.

Budget and Lifecycle Cost: Trackless ccarts have a higher initial investment but save on track construction and subsequent adjustments. Rail-mounted trolleys are initially cheaper, but have higher long-term maintenance and modification costs.

Safety and Ease of Use: Trackless transfer carts feature multiple obstacle avoidance sensing systems and are more suitable for collaborative production environments. Rail-mounted carts operate in a closed environment, offering greater safety but limited flexibility.

To choose a suitable transfer cart, companies need to consider all aspects comprehensively based on the characteristics of different transfer vehicles and their own working conditions, and choose a trackless or rail transfer vehicle that suits them.

Conclusion:

Through the above content, we know that the production environment requires flexible scheduling and multi-directional operation. Trackless transfer vehicles are the right choice. For high-load, long-distance, fixed-route transportation, rail transfer vehicles have more advantages.

If you have any questions about the transfer carts, please contact us immediately. We are a Chinese manufacturer specializing in custom material handling vehicles and will provide you with the best solutions.