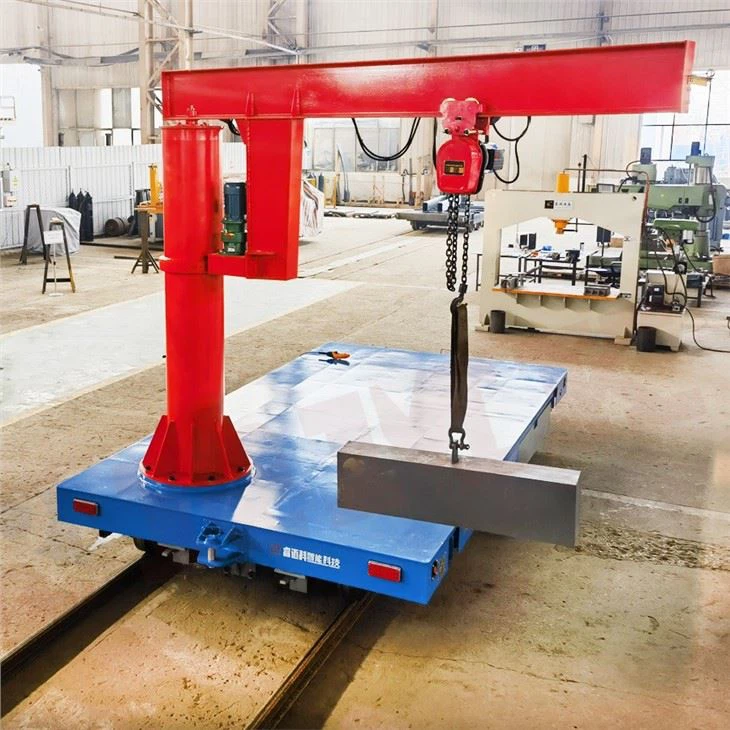

Vertical and horizontal moving rail transport cart-15 tons RGV Video Introduction

The rail transport vehicle is a special transport equipment that transports along a preset track. It is driven by an electric motor and moves using tires, tracks, or other moving accessories. It is often used in current industrial production and logistics management.

For the vertical and horizontal rail transport vehicles in the video, we have added designs and improvements in vertical and horizontal movement. It makes the transport more flexible and convenient, reduces the difficulty of transportation, and improves the safety of manual transport.

Workflow: The goods are placed on the loading platform → the transport vehicle moves along the horizontal track to the target position → the vertical lifting mechanism adjusts the height → the goods are unloaded to the designated workstation or shelf.

Functions

- Increase space utilization: Through the combination of vertical lifting + horizontal movement, make full use of the vertical space of the warehouse or workshop and reduce the ground occupation.

- Automation and precise positioning: PLC, sensors, and upper system can be integrated for fully automatic handling; positioning accuracy can reach ±5mm.

- Strong customization: It can be customized from light load to heavy load; the track length, lifting height or cargo platform form can be expanded according to needs.

- Increase work efficiency: 7×24 hours operation; the horizontal speed is usually 1-2m/s, and the vertical lifting speed is 0.3-0.8m/s.

- Safe production: equipped with an anti-fall device, an emergency stop button, obstacle detection (photoelectric/ultrasonic sensor) to ensure human and machine safety; the track structure is less affected by the ground environment than mobile robots such as AGV, and maintenance is simple.

- Energy saving and environmental protection: motor drive + track friction resistance is small, long-term use cost is lower; pure electric design, suitable for clean workshops or places with strict environmental protection requirements.

- Integration: It can be connected to conveyor lines, AGVs, robotic arms, or ERP systems to form an intelligent logistics closed loop.

- Multiple scenarios: It can adapt to various scenarios such as production lines, cross-floor, cold chain, etc., by customizing track layout (straight, circular, multi-branch) and lifting height.