The Battery Transfer Cart is a flatbed electric handling equipment powered by a storage battery installed in the body of the vehicle and is mainly used for short-distance cargo transportation, material turnover, loading and unloading operations. It is suitable for the transfer of raw materials and finished products in factory workshops, the transportation of pallets and bulky goods in warehousing and logistics, and the short-distance movement of heavy equipment in construction sites, airports and wharves.

- Lifting capacity: 2 ton~150 ton

- Table size: Customizable

- Battery voltage: 24~72V

- Operation speed: 0~30m/min

- Control method: Button/remote control

Cases of Battery Transfer Cart

30 tons battery Powered transfer cart for Motor factory handling

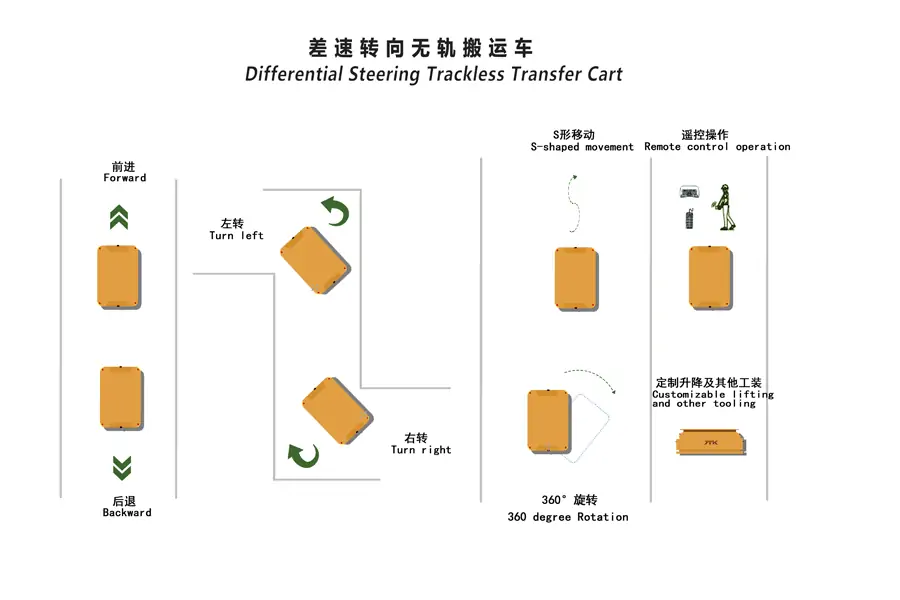

This is another order of 70 tons and 160 tons steering wheel type omni-directional battery transfer cart for our Nangaochi company’s new factory project after our previous order of several 30 tons battery transfer cart from our company. Here are the detailed parameters of the equipment:

- Load capacity: 30 tons

- Size: 3000 * 3000 * 600 (L * W * H)

- Power supply: lithium battery

- Operation mode: wireless remote control + vehicle handle control

- Running speed (m/min): 0-30 stepless speed regulation

- Walking mode: forward and backward, turn while walking, 360°rotation.

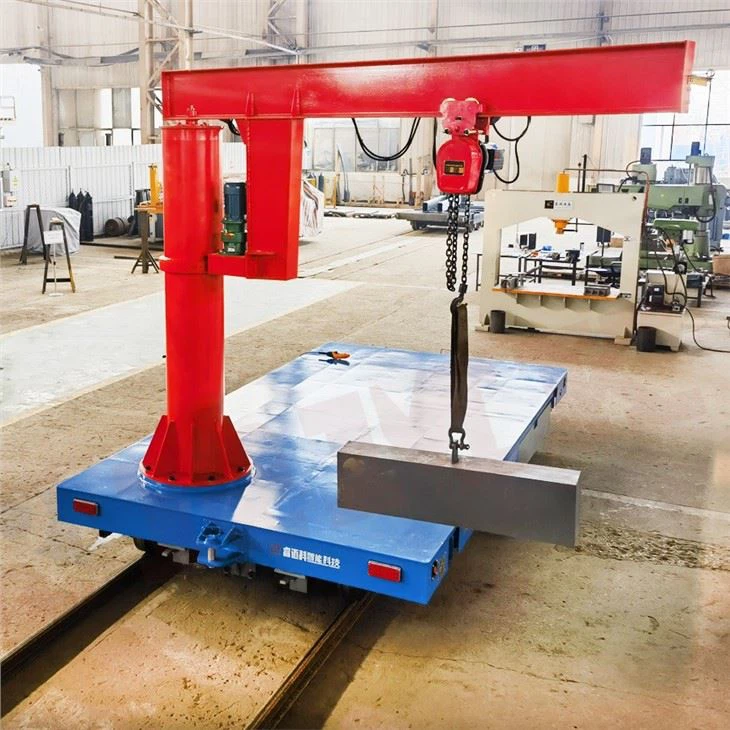

40 Tons Steel Billet Battery Rail Transfer Cart

This battery rail battery transfer cart is a heavy-duty rail transportation system driven by a high-efficiency battery pack and a low-voltage AC motor, specially designed for transferring 40 tons of steel billets, and is suitable for high-frequency heavy material transfer scenarios, such as metallurgy and steel rolling. The jib crane is integrated according to customer requirements in order to realize the synergistic operation of billet transportation and lifting. The following are the specific parameters:

- Load capacity: 40 tons

- Table size: 4000 * 2000 * 600 mm

- Power supply mode: battery Battery

- Movement mode: forward, backward

- Safety device alarm light + emergency stop button

Working Principle

Battery powered transfer cart adopts lithium battery to supply power, and its power system is driven by low-voltage AC motor or permanent magnet synchronous motor, which is transferred to steel wheel/tire walking mechanism through the deceleration mechanism, and with PLC control unit and frequency conversion speed control system to realize 0-20m/min stepless speed change. The equipment is equipped with mechanical/hydraulic dual braking system, integrated positioning (±5mm accuracy) and CAN bus communication, supporting cab control, wireless remote control and automation operation mode.

Specifications

| Rated load (T) | 2 | 10 | 20 | 30 | 50 | 63 | 150 | |

| Table Size | Length (l) | 2000 | 3600 | 4000 | 4500 | 5500 | 5600 | 10000 |

| Width (W) | 1500 | 2000 | 2200 | 2200 | 2500 | 2500 | 3000 | |

| Height (H) | 450 | 500 | 550 | 600 | 650 | 700 | 1200 | |

| Wheelbase (mm) | 1200 | 2600 | 2800 | 3200 | 4200 | 4300 | 7000 | |

| Inside track gauge (mm) | 1200 | 1435 | 1435 | 1435 | 1435 | 1435 | 2000 | |

| Wheel diameter (mm) | 270 | 300 | 350 | 400 | 500 | 600 | 600 | |

| Operating speed (min) | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor power (kW) | 1 | 1.6 | 2.2 | 3.5 | 5 | 6.3 | 15 | |

| Battery capacity (Ah) | 180 | 160 | 180 | 250 | 330 | 400 | 600 | |

| Battery voltage (V) | 24 | 48 | 48 | 48 | 48 | 48 | 72 | |

| Maximum wheel load (KN) | 14.4 | 42.6 | 77.7 | 110.4 | 174 | 221.4 | 265.2 | |

| Reference weight (t) | 2.8 | 4.2 | 5.9 | 6.8 | 8 | 10.8 | 26.8 | |

Products Show

Features

Highly maneuverable

The battery transfer cart with heavy duty wheel/tire construction, it can move freely on tracks and flat surfaces.

Super Load

The load range is 1-500 tons, which meets the heavy-duty requirements of different industrial scenarios.

Intelligent Steering

Equipped with hydraulic steering or omni-directional wheel system, the steering can be precisely maneuvered in narrow space.

Autonomous drive

Integrated high-efficiency battery power system supports independent operation without traction.

Multi-machine cooperation

Modularized structure design allows multiple vehicles to work together to transport oversized cargo.

Multiple Safety Protection

Equipped with multiple braking system, anti-skid platform and emergency stop device as standard, and passed ISO safety certification.

Cases Show

Types of Battery Transfer Cart

Battery transport vehicles are divided into two types: railed and trackless. The following are their differences and characteristics.

Trackless Transfer Cart

A trackless transfer cart is a heavy-duty industrial transfer vehicle that utilizes a wheel or omni-directional roller system to move freely on flat surfaces without the need for a fixed track. They typically have a load capacity of 1-300 tons and can be fitted with a forklift, lift mechanism or custom platform. They are more flexible than railcars and can operate in workshops, warehouses, confined spaces and outdoor environments.

Railed Transfer Cart

Railed transfer cart, operate on fixed tracks or rails, similar to a small railway system. Typically handles 1–500 tons, commonly used in workshops, assembly lines, and heavy-load transportation where a predefined path is required.

Battery Transfer Cart Application

- Automobile and machinery manufacturing: assembly line and ring line production, parts transportation, workshop workpiece, large mechanical parts, mold transfer, lathe and machining center equipment shifting and transfer, etc.

- Metallurgical industry: short-distance transfer of steel ladle, transportation of billet, steel plate, steel coil, steel pipe and section steel structure.

- Logistics and warehousing: warehouse heavy goods such as pallets, container handling, automated three-dimensional warehouse material turnover.

- Shipbuilding and marine engineering: ship repair and assembly segment transportation, port container transshipment

- Construction and bridge engineering: transportation of prefabricated concrete components (beams and columns), on-site transportation of bridge steel structures, modular construction of simple buildings, etc.

- Energy and chemical industry: oil industry (oil pumps, pumping rods and pipe transportation), chemical equipment (electrolysis tanks, reactors) displacement, new energy (polysilicon ingots, wind turbine blades, generator stator) transshipment, etc.

- Railway and rail transportation: track maintenance (rail, sleeper transportation), rolling stock assembly and overhaul, etc.

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control