Heavy load handling rail transfer cart can perfectly cope with high-precision positioning, narrow space steering and extreme load handling through modular design, intelligent control and customized load-bearing structure, especially in the handling of super-heavy objects across workshops; high-frequency repeated handling and long-term work in high-risk environments have played a significant role in convenience, safety, efficiency and economy, and are also the core equipment for heavy-duty handling in modern smart factories. Let us take a look at how heavy load transfer carts work and what type of Heavy load transfer cart should be used in what industry? Let’s see how heavy load handling rail transfer carts safely move 50-500 tons of materials?

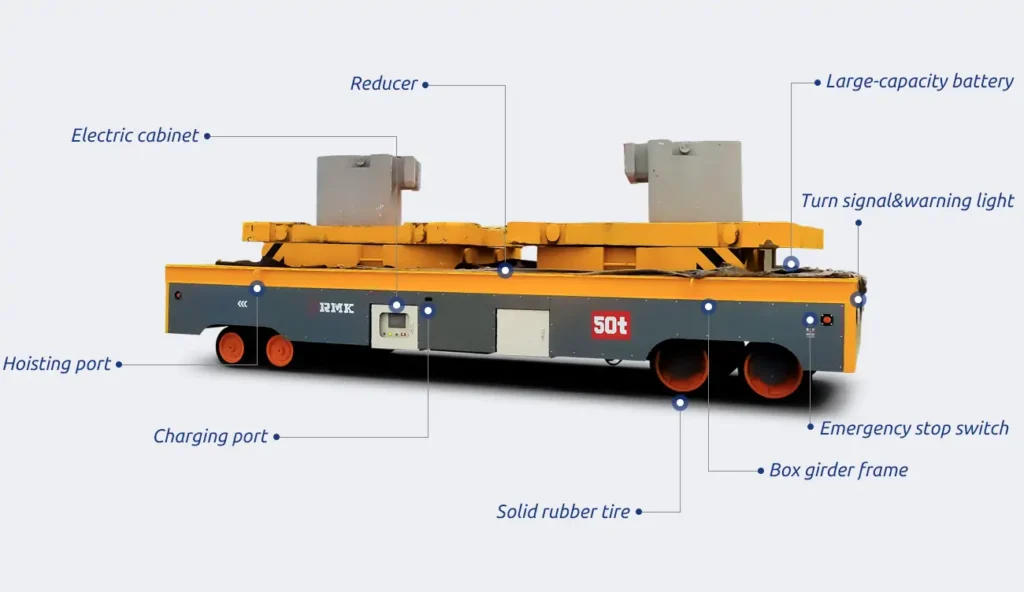

Heavy Load Transfer Cart Parts

The structure of the heavy-load handling rail transfer cart is mainly composed of a frame, a power system, a suspension and braking system, a heavy-duty cargo box or a load-bearing device, tires/wheels, and an intelligent safety control system.

- Electric drive: three electric drive modes of low-voltage rail power supply, battery pack, or cable drum, according to the weight of the goods, the distance of transportation is reasonably selected.

- Power transmission: The motor transmits power to the wheel group through the reducer, and the variable frequency speed regulation technology is used to control the 0-20m/min stepless speed change. Pay attention to safety when starting.

- Hydraulic drive: hydraulic motor drive, with a multi-wheel independent steering system, suitable for complex road conditions.

- Frame design: uses a box beam welded structure, high-strength alloy steel material, does not deform under extreme loads, and can be customized according to usage requirements.

- Wheel set: Track type equipped with QU80/QU120 heavy-duty rails, wheels with flanges to prevent derailment; Trackless type equipped with polyurethane solid tires or hydraulic suspension wheels to adapt to uneven ground.

- Balance system: multi-wheel set load-balancing design (such as 8-wheel/12-wheel layout) to avoid local overload.

- Operation mode: Remote control: wireless remote control (up to 500 meters) accurately controls forward movement, steering, and speed regulation;

- Automated operation: docking with the factory MES system, and realizing unmanned transportation through preset paths or laser navigation;

- Safety protection: real-time monitoring of current, temperature, and load distribution, automatic power off when exceeding the limit; dual braking system (electromagnetic braking + mechanical brake), anti-slip during slope transportation; anti-collision laser radar + sound and light alarm.

Working Principle

Take the transportation of stamping dies in automobile factories as an example:

- Loading positioning: the heavy load handling rail transport cart accurately stops by laser guidance (±5mm error);

- Starting transportation: the operator starts remotely, and the inverter accelerates slowly to avoid shaking of the goods.

- Path execution: the track type runs along the preset track, and the trackless type avoids obstacles through SLAM navigation.

- Unloading docking: the hydraulic lifting platform adjusts the height and seamlessly connects with the production line.

The heavy-duty electric transfer cart is simple to operate, easy to use, and highly economical, making it the core equipment for large-scale material transportation in modern factories.

So we know how to use heavy load handling rail transport carts, so what kind of transporters should we use in that scenario? Let’s read together below:

Heavy Load Handling Rail Transfer Cart Applications

| Industry | Model | Capacity | Drive/Navigation | Key Features | Primary Applications |

| Steel & Metallurgy | RGC-300T Rail-Type | 100-500T | Low-voltage rail + VFD | Heat-resistant frame (≤800°C), anti-oxidation coating | Slab/continuous caster transfer |

| Wind Power | WPD-200T Trackless | 50-300T | Hydraulic steering + GPS | Tower saddle, anti-tip stabilization | Wind tower/blade assembly |

| Shipbuilding | SHP-500T Modular | 200-500T+ | Diesel-electric hybrid | Hull-curve adapters, IP67 waterproofing | Ship sections/propeller transport |

| Chemical | EXD-150T Explosion-Proof | 50-200T | Battery + magnetic guide | ATEX certification, stainless steel body | Reactor vessel handling in hazardous zones |

| Automotive | AGC-100T Automated | 20-100T | Li-ion + SLAM navigation | AGV integration, ±2mm positioning | Stamping die/body shop logistics |

| Aerospace | ATC-80T Precision | 10-80T | Servo motor + air bearing | Micro-vibration control (≤0.1mm) | Rocket engine cleanroom transport |

| Port Logistics | PTS-400T Multi-Mode | 100-400T | Dual-power (diesel/electric) | Twist locks, storm anchors | Container/heavy machinery handling |

| Cement & Construction | CBM-250T Dust-Proof | 100-250T | Conductor rail power | Sealed wheels, auto dust-cleaning | Kiln/precast component transfer |

Through the above article, I believe you have got a certain understanding and choice about the working principle of heavy load handling rail transfer cart and moving 50-500 tonnes of goods, if you are now confused about moving your heavy goods, contact us now, we have a professional team to solve your confusion, we have rich experience in moving and a lot of successful cases, contact us now, looking forward to working with you!