The flat steel ladle transfer cart is a heavy-duty transportation equipment specially designed for the metallurgical industry (e.g. steel mills), mainly used for the safe and efficient transfer of high-temperature ladles (containers of molten steel).

- Capacity: 1~500 ton

- wheel type: Rail/trackless

- power supply: Maintenance free battery, or electric

- drive working speed: 0-35mmin (variable speed)

- Operation mode: Wireless remote control & Hand operate pendant

Working Principle

The ladle transfer cart is suitable for short distances and ensures a seamless flow of molten steel between processes. It is usually used to transfer high-temperature ladles (usually at temperatures of 1500°C or more) within the steelmaking plant, connecting to the steelmaking furnace, continuous casting machine or refining station.

Depending on the process, steel ladle transfer cart can be stationary (e.g. rotary table ladle trucks) or mobile (inter-process transfer), with some models equipped with lifting and rotating functions to match casting.

Application

The Steel Ladle Transfer Cart is widely used in the metallurgical industry for the transfer of high temperature molten steel, especially for the transportation of ladles between electric arc furnaces, converters and refineries. It is commonly used in the following scenarios and processes:

Continuous casting plants: for transferring ladles full of molten steel from the refining station to the intermediate ladle cart or pouring area.

Ingot casting process: the ladle is precisely positioned over the mold to complete the pour.

Foundry and alloy smelting workshop: for the safe handling of molten metal over short distances, it is an indispensable key equipment for the efficient transfer and precise positioning of high temperature liquid metal.

steel plant ladle transfer cart

Specifications

| Modle | KPX-10T | KPX-30T | KPX-50T | KPX-80T | KPX-100T | KPX-150T |

|---|---|---|---|---|---|---|

| Table Size (m) | 3.6*2.0*0.5 | 4.5*2.2*0.6 | 5.5*2.5*0.65 | 6.0*2.6*0.8 | 6.5*2.8*0.9 | 10*3.0*1.2 |

| Power | Maintenance Free Battery | |||||

| Rail inner Gauge | 1435mm | 1435mm | 1435mm | 1800mm | 2000mm | 2000mm |

| Wheel Dia. | 350mm | 400mm | 500mm | 600mm | 600mm | 600mm |

| Running Speed | 0-20m/min | 0-20m/min | 0-20m/min | 0-20m/min | 0-20m/min | 0-20m/min |

| Motor Power | 1.6kw | 3.5kw | 5kw | 8kw | 10kw | 15kw |

| Battery Capacity | 180Ah | 250Ah | 330Ah | 400Ah | 440Ah | 600Ah |

| Battery Volatge | 48v | 48v | 48v | 72v | 72v | 72v |

| Max Wheel Load | 42.6Kn | 110.4Kn | 174Kn | 278.4Kn | 343.8Kn | 265.2Kn |

| Reference weight | 4.2t | 6.8t | 8t | 12.8t | 14.6t | 26.8t |

| Recommend Rail | P24 | P38 | P43 | P50 | QU100 | QU100 |

Products Show

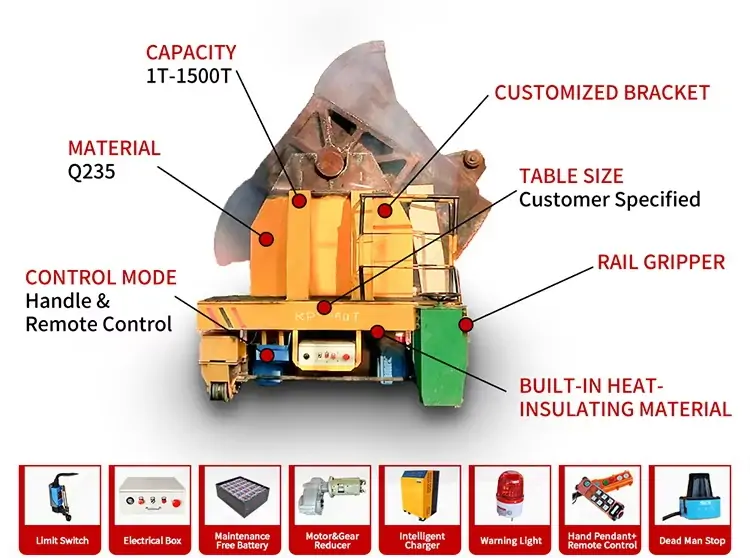

Customized Steel Ladle Transfer Cart Solutions

Steel Ladle Transfer Cart is a heavy-duty transportation equipment specially designed for pyrometallurgical operations, which is mainly used for the stable transfer of ladle between different processes in the steel making process. It can be operated flexibly, custom rail transfer cart or trackless transfer cart according to the layout of the plant, and is often equipped with hydraulic lifting device and high temperature insulation layer to ensure the safety and stability of molten steel without leakage during the transportation process.

- High-temperature insulation customized solutions: We can provide multi-layer protection insulation structure according to different ladle temperatures and running time to prolong the service life of the equipment.

- Exclusive loading platform design: the structural dimensions and clamping devices of ladle holders can be customized to ensure stable placement and transportation of various types of ladles.

- Various power supply configurations: Provide a combination of power supply modes such as storage battery, cable reel, slip line, etc., adapting to complex operation scenarios.

- Intelligent control integration: support PLC control, wireless remote control, automatic navigation and other intelligent functions to enhance operational flexibility and productivity.

- High load-bearing non-standard customization: we can carry out non-standard heavy-duty design of over 200 tons according to user requirements to meet the task of transporting extra-large steel ladles.

- Adaptability to special working conditions: Adapt to harsh metallurgical environments such as high dust, high humidity and high impact to ensure stable operation.

- Full-process service support: provide one-stop service from program design, manufacturing, commissioning to after-sales maintenance.

Features

High-temperature resistant structure design

The body is made of high-strength heat-resistant steel and equipped with heat-insulating layer, which is able to withstand the heat radiation and thermal shock of the steel ladle up to more than 1300℃.

Large load capacity

The load capacity can be customized according to the customer’s demand, from tens of tons to hundreds of tons, to meet the heavy-duty requirements of ladle transportation in large metallurgical enterprises.

Flexible operation mode

Rail type, cable reel power supply, skid line power supply, lithium battery power supply, and even trackless rubber wheel drive, suitable for different workshop working conditions.

Safety control system

Equipped with automatic braking, buffer anti-collision, sound and photoelectric alarm, etc., to ensure the safety of operation under high temperature working environment.

Precise positioning system

Some models can integrate laser or wireless remote positioning system to improve ladle docking precision and pouring efficiency.

Easy Maintenance

Modularized structure design makes maintenance more convenient and reduces downtime.

Steel Ladle Transfer Cart Manufacturer

As a leading of Transfer Cart manufacturer, we specialize in the design and production of heavy-duty transportation solutions tailored for the pyrometallurgical environment. With decades of experience in industrial material handling, our factories are equipped with state-of-the-art manufacturing facilities, specialized engineering teams and strict quality control systems.

We offer customized Steel Ladle Transfer Cart ranging from 10 to over 300 tons that can withstand extreme heat, pounding and continuous operation. Our designs support a wide range of drive systems including rail guides, rubber tires, battery operated, cable reels, hydraulic lifting platforms, automated control systems, and add-on features such as remote operator interfaces that can be adapted to your shop layout and operational needs.

We provide one-stop service and technical support from project consultation and layout planning to manufacturing and on-site commissioning. Our commitment to innovation, durability and customized solutions for our customers has made us a trusted partner for many large steel mills and foundries around the world.

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control