A transfer cart is an industrial material transportation equipment used for the transportation of heavy materials, machinery, and heavy equipment within a factory, allowing them to move horizontally within the factory. They are also called Transfer carts, material handling vehicles, or Transfer carts. Transfer carts not only simplify the industrial transportation process but also make it safer and more efficient.

This article introduces you to the workings, types, uses, and advantages of transfer carts, as well as how to choose and customize the right one.

Working principle of the transfer cart:

From simple trolleys to thousand-ton heavy-duty transport platforms, the working principle of Transfer carts always revolves around the core needs of efficiency, stability, and safety. First of all, we need to choose the driving power of the Transfer cart according to the different materials being transferred, such as manpower, electricity, fuel, or intelligent control to drive it to work. By choosing the appropriate equipment to adapt to the load, the goods can be transferred from A to B.

However, during this period, we need to choose its power source and control its moving direction so that the goods can reach the preset location accurately. The core goal of the Transfer cart is to complete the short-distance transportation and relocation tasks safely, accurately, and efficiently. Because of the different goods being transferred, the types of Transfer carts that can be selected are also different. We need to choose the appropriate load-bearing vehicle to work with according to the goods.

Types of Transfer cart

The main types of transfer carts, depending on the need and application, are as follows

Rail Transfer Carts

Rail Transfer Carts Trackless Transfer Cart

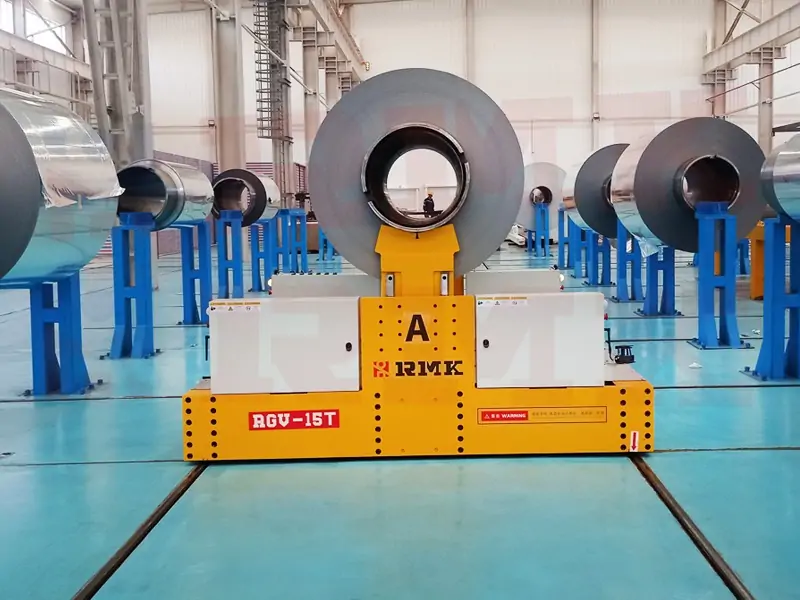

Trackless Transfer Cart Coil Battery Transfer Cart

Coil Battery Transfer Cart AGV Electric Transfer Trolley

AGV Electric Transfer Trolley Mold Transfer Cart

Mold Transfer Cart Hydraulic Lifting Transfer Cart

Hydraulic Lifting Transfer Cart

| Types | Basic Functional Characteristics | Application Scenarios |

|---|---|---|

| Rail Transfer Carts | High load carrying capacity, sturdy structure, usually equipped with a hydraulic or mechanical support system. | Factory floor, production line material transfer, heavy machinery manufacturing. |

| Trackless Transfer Cart | Trackless design, high flexibility, can move freely on flat ground. | Warehousing and logistics, temporary handling, multi-site flexible transportation. |

| Battery-Powered Transfer Carts | Battery-powered, environmental protection and energy saving, flexible operation, suitable for short and medium distance transportation. | Indoor work, electronic assembly, light and medium-sized material transfer. |

| Heavy Load Transfer Carts | Steel, shipbuilding, large equipment, and heavy parts transportation. | Specially designed for coils, with an anti-roll device for stable clamping and transportation of coils. |

| Coil Transfer Carts | Plastic injection molding, press shop, mold replacement, and maintenance. | Iron and steel mills, aluminum industry, coil storage and processing workshop. |

| Die Transfer Carts | Precision positioning with anti-vibration design for smooth handling and installation of molds. | Intelligent factories, automated production lines, warehousing, and logistics. |

| AGV Transfer Carts | Hydraulic lifting system, adjustable platform height, stable load bearing, and support electric/manual control. | Automatic navigation (AGV), intelligent obstacle avoidance, programmable path, and reducing manual intervention. |

| Omnidirectional Transfer Carts | Four-wheel independent steering, small turning radius, suitable for complex path transportation. | Confined space operation, precision assembly, aerospace. |

| Four-Wheel Steered Transfer Carts | Omni-directional wheel design, can move laterally, diagonally, or rotate in place, with high flexibility. | Large equipment assembly, multi-obstacle environment, narrow aisle handling. |

| Hydraulic Lifting Transfer Cart | Heavy equipment installation, production line height adjustment, maintenance workshop, and storage stacking. | Heavy equipment installation, production line height adjustment, maintenance workshop, storage stacking. |

Today, we mainly talk about heavy-duty handling equipment:

Heavy-duty handling equipment is professional equipment used for transporting, loading and unloading, and positioning oversized and overweight materials, and is used in heavy industrial fields such as energy, infrastructure, manufacturing, and aerospace. Hydraulic axis vehicles/modular transport vehicles can transport thousands of tons of equipment.

Regarding heavy-duty transport equipment, the following are its core reference parameters:

| Parameter | Typical Range | Example Equipment |

| Rated Load Capacity | 50-5,000 tons | SPMT (up to 5,000 tons) |

| Axle Load | 12-36 tons/axle | Hydraulic modular transporter |

| Lifting Height | 0.5-3 meters | Self-lifting platform trailer |

| Steering Mode | All-wheel steering/Crab steering | Multi-mode SPMT |

| Drive System | Hydrostatic/Electric | Hybrid power module transporter |

Advantages of Transfer Carts

1. Improved Safety: Transfer cars reduces manual handling of heavy items and avoids workplace injuries caused by handling heavy items. They also have safety features such as emergency stops and alarms to prevent accidents.

2. Save Time and Energy: Transfer cars can save time and energy by reducing the need for labor and speeding up the transportation of goods. They can also save energy by reducing the number of trips required to transport heavy items.

3. Reliable and Efficient: Transfer carts are designed for reliability and efficiency, ensuring that goods are transported on time without any damage or delays. They can also be customized to meet specific transportation needs.

How to Select A Suitable Transfer Cart for Your Business?

Choosing the right transfer cart requires a thorough evaluation based on actual usage scenarios and needs. Firstly, the weight and size of the goods should be considered to determine the required carrying capacity and model type; secondly, the suitable driving method (e.g., electric, diesel, or AGV automatic guided vehicle) should be selected in conjunction with the transportation environment, such as the ground condition and whether dust and explosion-proof are required. In addition, it is also necessary to decide whether to use a manual, remote control, or fully automated transfer program according to the operating frequency and automation requirements. Finally, while meeting the budget, priority is given to a modular design with stable performance and high scalability in order to adapt to future business changes.

Below, I will introduce you to the core selection parameters.

1. Load Characteristics

| Parameter | Key Considerations |

| Rated Load | Must exceed maximum single-piece weight (including packaging/fixtures), recommend 20% safety margin |

| Load Distribution | Concentrated or distributed load? Need load balancing plates or special supports? |

| Center of Gravity | High COG equipment (e.g., towers) requires low-profile vehicles to prevent tipping |

2. Site Conditions

| Parameter | Key Considerations |

| Ground Conditions | Concrete or dirt surface? Minimum 10MPa bearing capacity, soft ground requires multi-axle pressure distribution |

| Space Constraints | Consider turning radius, passage width, clearance height (e.g., workshop doorways) |

| Environment | Explosion-proof (chemical areas), dust-proof (clean rooms), low-temperature operation (-30°C) |

This is my little advice to you, more options and suitable solutions can contact us, we will provide you with free consulting services and quotes!

Conclusion

In summary, when choosing a transfer cart, a number of factors such as load capacity, usage environment, degree of automation, cost budget, and future expandability should be considered comprehensively according to actual needs.

If you have more questions or want more quotes and technical support about the transfer cart, please contact us as soon as possible. We will work with you to solve your problems as soon as possible and give you a more complete transportation and transshipment solution.