Battery Operated Transfer Trolley is a heavy-duty, self-propelled material handling cart powered by a rechargeable battery. It is designed to transport loads safely and efficiently across workshops, warehouses, production lines, or outdoor areas—without the need for fixed rails or cables. With strong load capacity, low maintenance, and flexible turning capability, it is ideal for handling molds, coils, structures, and other large industrial materials.

- Running Type: Battery-powered, trackless self-propelled operation

- Load Capacity: Customizable, 1~100 tons or more

- Control Mode: Remote control + onboard control panel (manual/automatic optional)

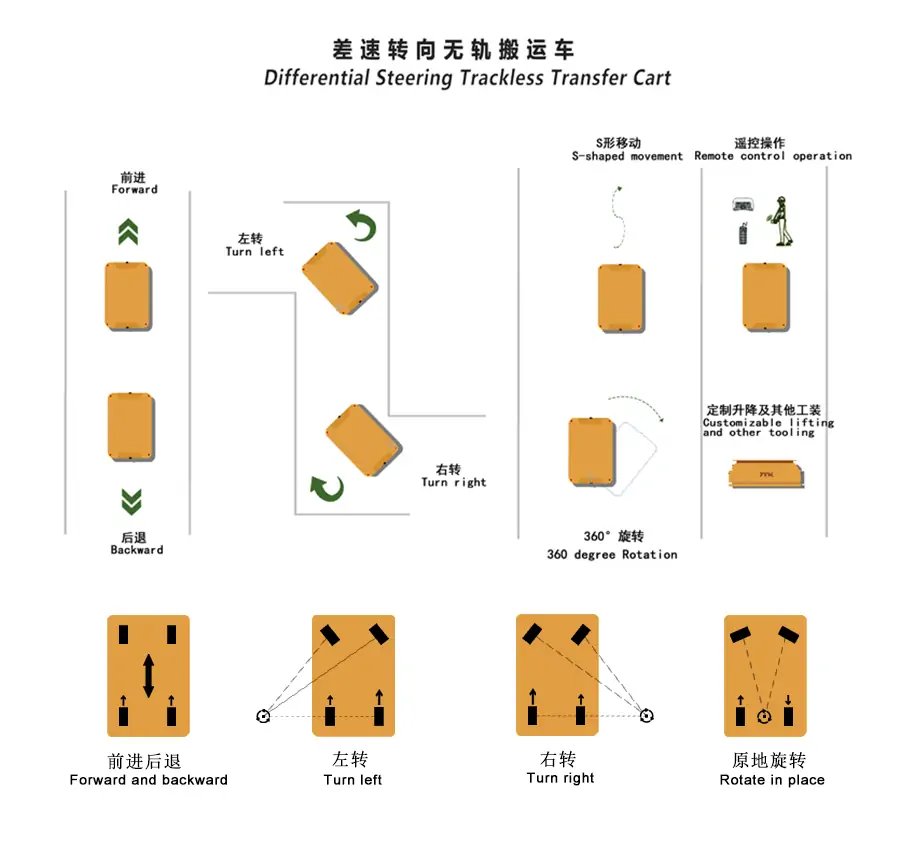

- Steering Mode:360° hydraulic/mechanical turning, fixed-track straight running, or omnidirectional Mecanum wheel (based on model)

Working Principle

The Battery Operated Transfer Trolley is powered by a built-in rechargeable battery that supplies power to the drive motor and control system. When the operator activates the control panel or remote control, the motor drives the wheels forward, backward or around corners as required. The on-board electrical system regulates speed, direction and braking, while optional sensors and limit switches ensure safe operation. The trolley operates independently without the need for guide rails or external power cords, making it ideal for flexible transportation of materials in workshops and outdoor areas.

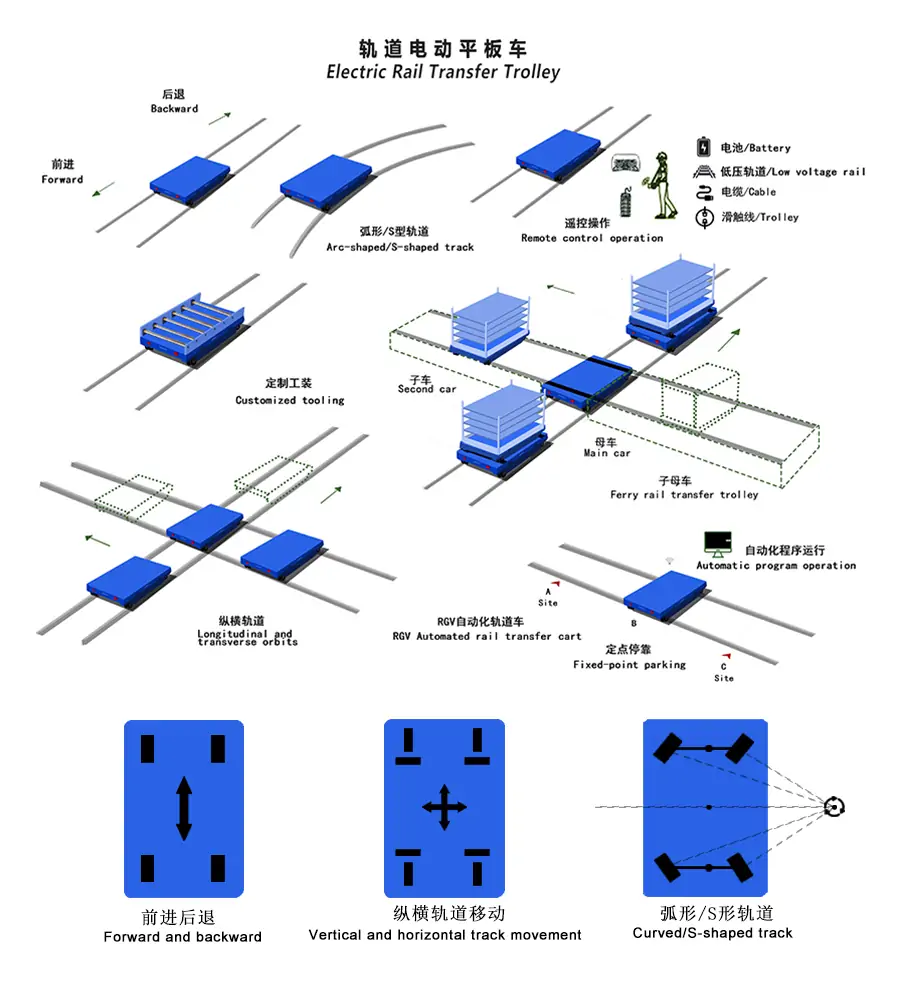

Steering Mode

Videos Show

50 tons Press fit solid rubber tire Trackless Transfer carts for heavy duty

Lifting battery transfer cart with omni-wheels

Battery Operated Transfer Trolley types:

RWP Battery Trackless Transfer Trolley

- No need to lay tracks, flexible to adapt to different sites, saving installation costs. No need to modify the ground, the path can be adjusted at any time, suitable for temporary or dynamic production lines.

- Widely used in new energy battery production lines, automobile manufacturing workshops and warehousing and logistics centers to efficiently complete the flexible handling of heavy batteries and accurate docking operations.

Battery Rail Transfer Trolley

- Running along the fixed rail, accurate positioning, suitable for high-precision transportation needs. Anti derailment design, emergency stop device and obstacle detection ensure safety.

- Specialized in new energy battery production line, automobile manufacturing and energy storage system assembly, it realizes efficient, accurate and automated transfer operation of heavy batteries through fixed rail.

Omnidirectional Battery Transfer Cart

- Omni-directional battery transporter adopts multi-wheel synergistic drive technology, realizing 360°flexible movement and accurate positioning; large loading capacity and compact body design, suitable for narrow space operation.

- It is widely used in new energy battery production lines, laboratories and warehousing centers to efficiently complete battery handling, docking and storage management under complex paths, effectively improving space utilization and logistics efficiency.

Lifting Battery Transfer Trolley

- Equipped with an adjustable lifting platform, the lift truck supports the precise handling of batteries of different sizes; the integrated safety fall prevention and stable guiding design ensures safe and efficient heavy-duty transportation.

- It is widely used in new energy battery production lines, power exchange stations and storage and logistics centers to realize vertical lifting, horizontal transfer and automated docking of batteries and optimize the production process.

Application

Battery Operated Transfer Trolley is widely used in many industrial fields for efficient and safe handling of heavy loads and enhancing production automation. The following are the main application industries and typical use scenarios:

| Industry | Application Scenarios |

|---|---|

| Metallurgy | Transporting steel coils, aluminum ingots, molds; inter-process transfer in casting lines |

| Automotive Manufacturing | Moving car bodies and components between assembly stages |

| Machinery & Mould | Handling large parts and injection molds; transport during mold maintenance |

| Shipbuilding & Heavy Equipment | Transferring large structural parts or machinery between workstations |

| Electric Power & Energy | Moving transformers, cable reels, and power plant components |

| Aerospace | Transferring aircraft parts and molds in dust-free or special environments |

| Warehousing & Logistics | Automated transportation of bulk materials and pallets within smart warehouses |

| Paper & Printing | Moving large paper rolls and printing plates to maintain continuous production flow |

Features

Rail-Free Operation

No fixed tracks required; flexible movement across workshops, warehouses, and outdoor areas.

High Load Capacity

Customizable for loads ranging from 1 ton to over 100 tons, suitable for heavy-duty transport.

Flexible Steering Options

Supports straight-line, turning, and omnidirectional movement to suit different layout conditions.

Remote & Manual Control

Dual control modes for easy operation, safety, and adaptability.

Low Noise & Zero Emission

Battery-powered system ensures environmentally friendly, quiet operation.

Customizable Design

Platform size, speed, steering type, and safety features can be tailored to specific application needs.

Trackless Transfer Trolley Specifications

| Rated Loading capacity(T) | 40 ton |

| Table size(mm) | 4000*2000 (L*W) |

| Cart height(mm) | 800 |

| Ground type | Cement floor, Epoxy floor,Asphalt floor |

| Operation method | Rocker remote control & Hand operate pendant |

| Running speed(m/min) | 0-20 (Stepless speed regulation) |

| Wheel material | Polyurethane coated rubber wheel |

| Wheel quantity | 6 |

| Power supply | Maintenance free lead-acid battery |

| Protective device | Audible and visual alarm lamp and emergency stop button, Laser obstacle avoidance |

| Steering Gear | Hydraulic steering |

| Electronic Control Mode of Turning | Electric button control |

| Adjustment of floor flatness | Mechanical automatic regulation |

| Battery charger function | Automatic charging |

| Other functions | Equip display screen,PLC, lifting holes, etc. |

| Move Way | Forward,backward and turn 360 degrees,turning while driving with no stop |

| Flat car’s protection | Overvoltage, undervoltage, overcurrent protection etc |

Rail Transfer Trolley Specifications

| Parameter Name | Unit | Typical Value or Description |

| Rated Load Capacity | T | Common specifications include 2t, 20t, 50t, 100t, 150t, etc., and can be customized according to requirements. |

| Tabletop Size | Mm | The length can be 2000, 4000, 5500, 6500, 10000, etc., and the width can be 1500, 2200, 2500, 2800, 3000, etc., all customizable as needed. |

| Tabletop Height | Mm | Generally 450, 550, 650, 900, 1200, etc., customizable. |

| Wheel Track | Mm | Such as 1200, 2800, 4200, 4900, 7000, etc. Different load capacities correspond to different wheel tracks. |

| Inner Distance between Rails | Mm | Commonly 1200, 1435, 2000, etc., depending on the type and design of the rails. |

| Number of Wheels | Piece | Generally 4, and it may be 8 when the load capacity is large. |

| Ground Clearance | Mm | 50, 75, etc., which affects the passing ability. |

| Running Speed | M/min | The speed range is generally between 0 – 18 and 0 – 25, and the speed is adjustable. |

| Motor Power | KW | 1, 2.2, 5, 10, 15, etc., determined according to the load capacity and running speed. |

| Battery Capacity | Ah | 180, 330, 440, 600, etc., which affects the endurance |

| Battery Voltage | V | 24, 48, 72, etc., related to the battery pack configuration. |

| Full-load Running Time | H | Such as 4.32, 4, 3.3, 3.2, 2.9, etc., depending on the battery capacity and running conditions. |

| Running Distance per Charge | Km | 6.5, 4.8, 4, 3.8, 3.2, etc., related to the battery performance and running speed. |

| Maximum Wheel Pressure | kN | 14.4, 77.7, 174, 343.8, 265.2, etc., reflecting the load-bearing capacity of the wheels. |

| Reference Dead Weight | t | 2.8, 5.9, 8, 14.6, 26.8, etc., related to the load capacity and structural design. |

Customized Battery Operated Transfer Trolley

Our Battery transfer trolleys are fully customizable in size, capacity, and design to perfectly match your operational needs.

- Load Capacity: 1-100 Ton

- Table Size: Customized

- Control Modes: Pendant / Remote / PLC

- Mobility: 360° rotation, continuous turning, multi-directional movement

- Safety: Anti-collision sensors, emergency stop, visual/audio alarms

- Steering/Braking: Differential steering & electromagnetic brake

- Track-Free Design: Flexible movement without rails

- Power Options: Battery / Cable / Rail powered

- Color: Customizable

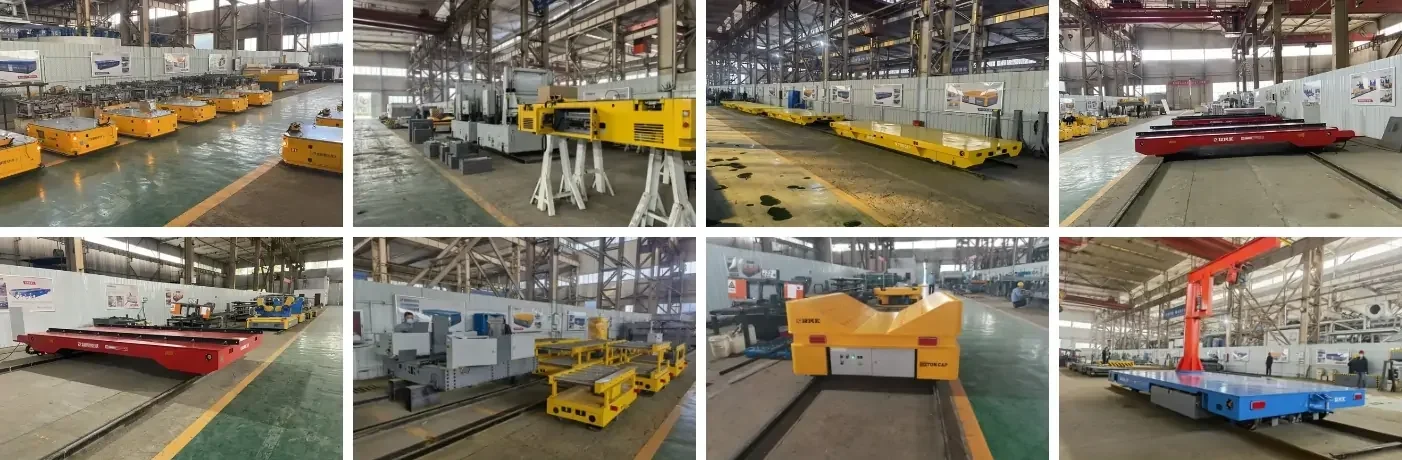

Battery Operated Transfer Trolley Manufacturer

We are a professional Battery Operated Transfer Trolley manufacturer and supplier, offering customized solutions to meet your specific material handling needs. From design and production to on-site guidance and after-sales support, we provide a full range of services to ensure efficient and safe transportation in your facility. Contact us today to get a tailored solution and competitive quote for your project.

Certification

FAQS

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control