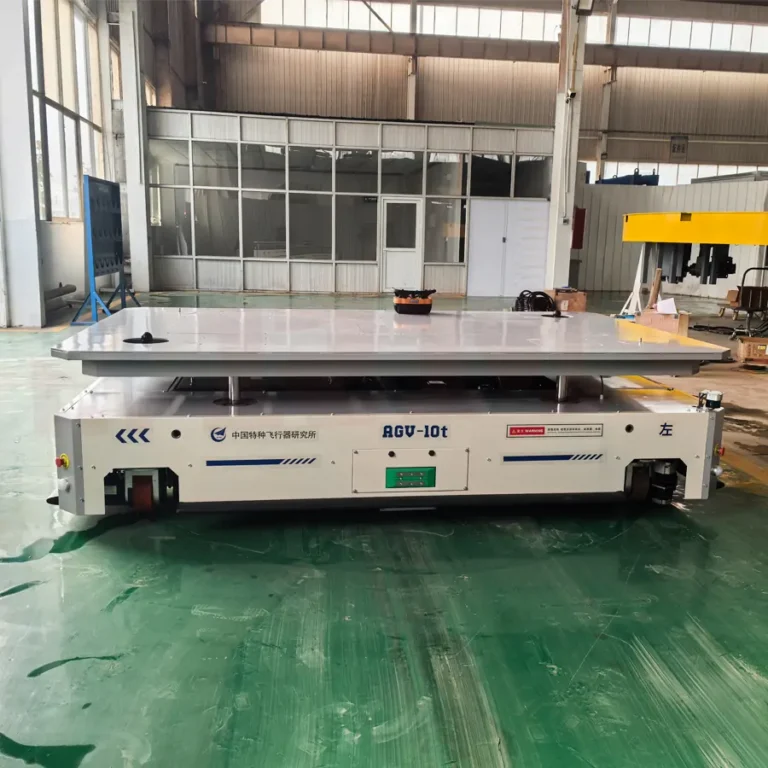

The motorized transfer cart is battery-powered and motor-driven, featuring environmental friendliness and low noise, making them suitable for use in enclosed environments such as indoor workshops.

- Load capacity: 15 tons

- Body dimensions: 4000 × 2000 mm (length × width)

- Drive type: Battery-powered + Electric motor drive

- Steering system: Differential steering (flexible and precise control)

- Wheel material: Polyurethane wheels (wear-resistant + shock-absorbing)

- Environmental protection and low noise: Zero emissions, low noise, suitable for precision workshops/indoor enclosed environments

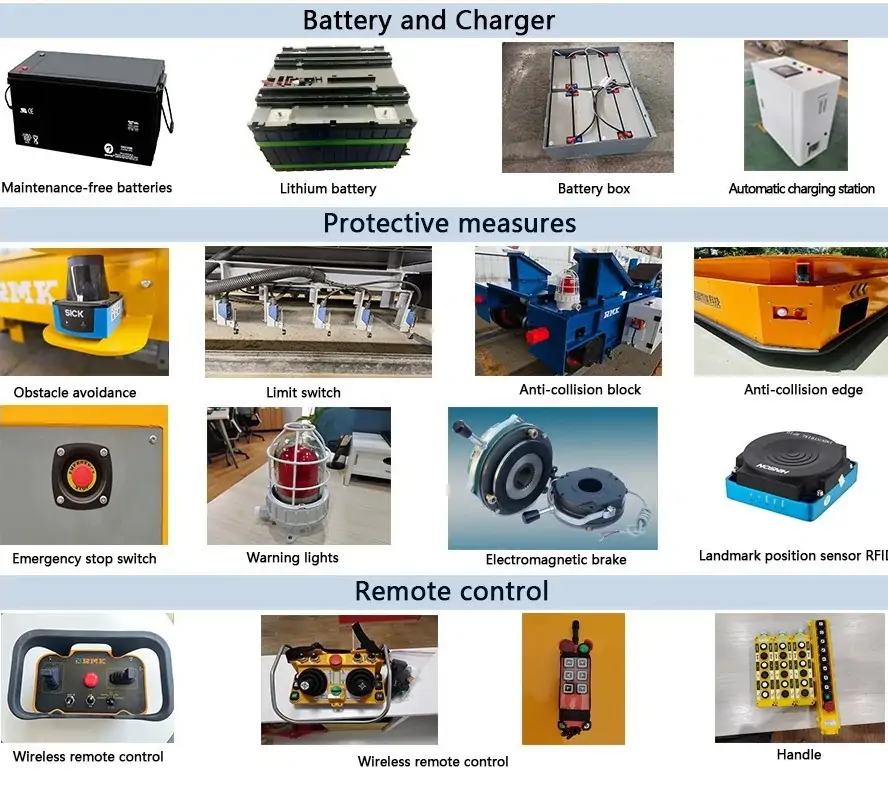

- Safety protection: Laser obstacle avoidance + emergency stop button (automatic shutdown upon encountering obstacles)

- Trackless flexibility: No tracks required, free path planning, space-saving

Working Principle

The motorized electric transfer cart is powered by a lithium battery motor and uses a differential control system to independently adjust the speed of the left and right wheels, enabling flexible steering without tracks. It uses polyurethane wheels to reduce road vibration and ensure smooth transport of goods. At the same time, it uses laser radar to scan the environment in front of it in real time. If there are obstacles within 5 meters, it will immediately trigger emergency braking to keep people, goods, and equipment in a safe environment and ultimately complete the precise transport of heavy loads.

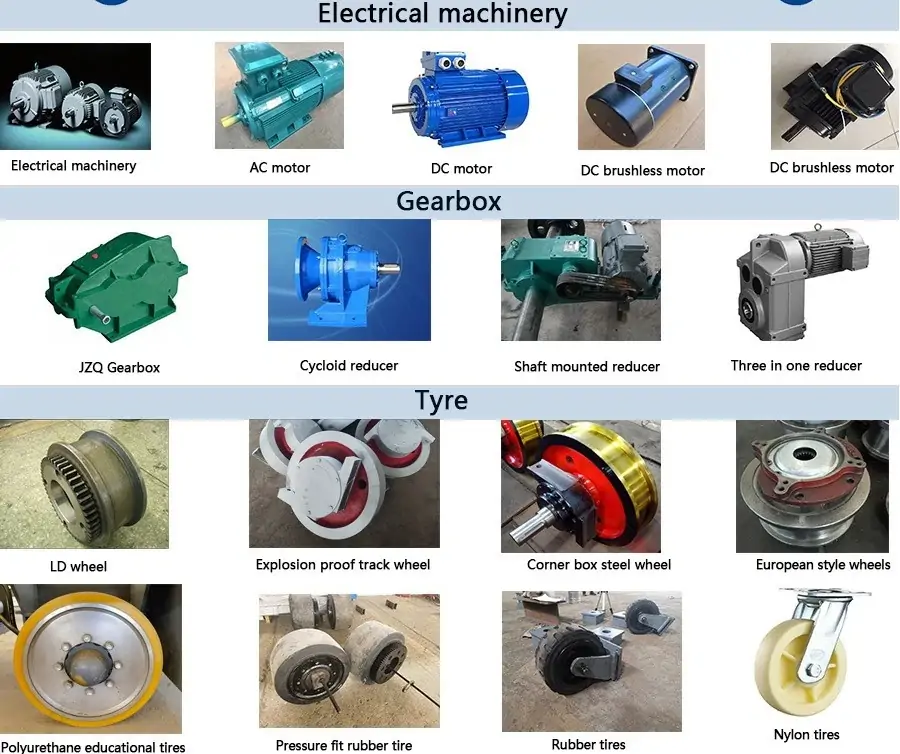

Parts

Drive System

The Motorized Transfer Cart is equipped with a motor, reducer, and drive wheels. When the motor receives power, it starts up and transmits power to the drive wheels through the reducer, driving the vehicle body to run smoothly along the track.

Control System

The control system can be divided into the following types according to the operation method:

- Manual Operation: The vehicle body can be started, stopped, moved, shifted, and emergency stopped through a handle or remote control. The operation is simple and suitable for scenarios requiring manual intervention.

- Automatic control: Equipped with a PLC control program, it can be integrated with upper-level computers, sensors, limit switches, and other devices to achieve automated operation, precise positioning, obstacle avoidance control, and other functions, suitable for intelligent manufacturing systems.

Safety System

To ensure operational safety, the track transfer vehicle is equipped with multiple safety devices, such as audio-visual alarms, emergency stop buttons, limit switches, collision buffers, and speed controllers, effectively safeguarding personnel and equipment safety.

Motorized Transfer Cart Specifications

| Rated load (T) | 2 | 10 | 20 | 30 | 50 | 63 | 150 | |

| Table Size | Length (l) | 2000 | 3600 | 4000 | 4500 | 5500 | 5600 | 10000 |

| Width (W) | 1500 | 2000 | 2200 | 2200 | 2500 | 2500 | 3000 | |

| Height (H) | 450 | 500 | 550 | 600 | 650 | 700 | 1200 | |

| Wheelbase (mm) | 1200 | 2600 | 2800 | 3200 | 4200 | 4300 | 7000 | |

| Inside track gauge (mm) | 1200 | 1435 | 1435 | 1435 | 1435 | 1435 | 2000 | |

| Wheel diameter (mm) | 270 | 300 | 350 | 400 | 500 | 600 | 600 | |

| Operating speed (min) | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor power (kW) | 1 | 1.6 | 2.2 | 3.5 | 5 | 6.3 | 15 | |

| Battery capacity (Ah) | 180 | 160 | 180 | 250 | 330 | 400 | 600 | |

| Battery voltage (V) | 24 | 48 | 48 | 48 | 48 | 48 | 72 | |

| Maximum wheel load (KN) | 14.4 | 42.6 | 77.7 | 110.4 | 174 | 221.4 | 265.2 | |

| Reference weight (t) | 2.8 | 4.2 | 5.9 | 6.8 | 8 | 10.8 | 26.8 | |

Video

10 tons motorized rail transfer cart

10 tons motorized trackless transfer cart

Customized Motorized Transfer Cart

Please provide the following information, or simply describe your application scenario (e.g., workshop mold transportation or port container handling), and we will tailor the most cost-effective material handling solution for you, providing detailed quotes and technical specifications within 24 hours!

- Load capacity and dimensions: Maximum load capacity (tons) and platform dimensions (length × width).

- Track conditions: Track type (rail/I-beam track), track gauge (mm), and operating distance.

- Power supply method: Battery/low-voltage track/cable reel/slide contact line (select applicable options).

- Control requirements: Remote control/automatic/variable frequency speed control, whether PLC or intelligent interlocking is required.

- Environmental requirements: Indoor/outdoor, explosion-proof, high-temperature resistance, or other special conditions.

- Safety configuration: Basic protection (limit switches, emergency stop) or advanced collision prevention, load monitoring.

Features

Precise handling

Equipped with a dual motor differential control system, it can maneuver flexibly in narrow steel processing workshop aisles and accurately connect to equipment such as presses and cutting tables, with a positioning error of ≤5mm.

Extended battery life and fast charging

Equipped with a 48V/200Ah high-density lithium iron phosphate battery, it can run for up to 8 hours on a full charge and supports 1.5-hour fast charging. The battery has a built-in liquid cooling temperature control system, allowing it to operate continuously for 24 hours

Upgraded core components

Customized high-elasticity polyurethane wheels effectively resist wear and tear on sandy Middle Eastern surfaces. The unique honeycomb structure design absorbs 80% of vibration energy, distributes wheel pressure evenly, leaves no marks, and does not damage epoxy flooring.

Active Safety Protection

Dual laser radars scan 270° to construct a dynamic map of the workshop in real time, automatically braking within 0.3 seconds when encountering obstacles such as people or shelves. The physical emergency stop button features a dual redundancy design to eliminate the risk of collisions in enclosed environments.

Trackless Intelligent Navigation

Comes standard with a handheld remote control and a reserved laser SLAM navigation interface, allowing for seamless upgrades to the AGV system. Achieves unmanned transportation through path planning, with an accuracy of ±10 mm.

Customizable

Structure: Vehicle dimensions, load capacity

Protection: IP65 dustproof/corrosion-resistant coating

Range: Extended range battery pack

Safety: Dual-language audio-visual alarm switching

etc.

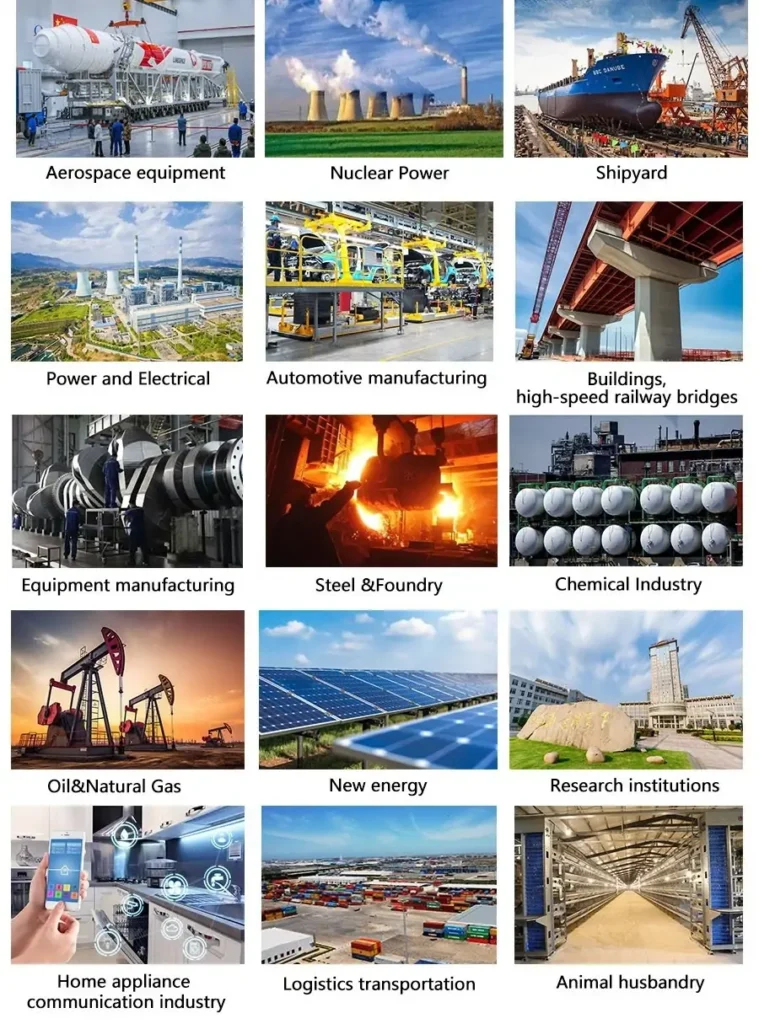

Application

Core Application Scenarios for Motorized Transfer Carts

Heavy Manufacturing Workshop: Short-distance transportation of 15-ton steel coils and large metal components

Precision Machining Area: Dust-free delivery of precision instruments/parts between CNC machine tools

Automobile Assembly Line: Flexible transportation of heavy assemblies such as engines and transmissions on narrow production lines

High-bay Warehouse Center: High-frequency consolidation of palletized goods (20+ trips per day)

Special Operating Conditions: Heavy-duty material handling in petrochemical explosion-proof warehouses/50°C foundry workshops

Multilingual Factory: Cross-regional logistics coordination in Arabic/English mixed factory zones

Automation Upgrade Project: Traditional workshops transformed into the foundation for AGV intelligent logistics systems

Motorized Transfer Cart Manufacturer

Certification

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control