AGV Automated Guided Vehicle System is a kind of automated and intelligent handling equipment, which is widely used in factories, warehousing and logistics. Today we will discuss with you what is AGV Automated Guided Vehicle, its features and advantages as well as application scenarios, please continue reading this article.

What is Automated Guided Vehicle?

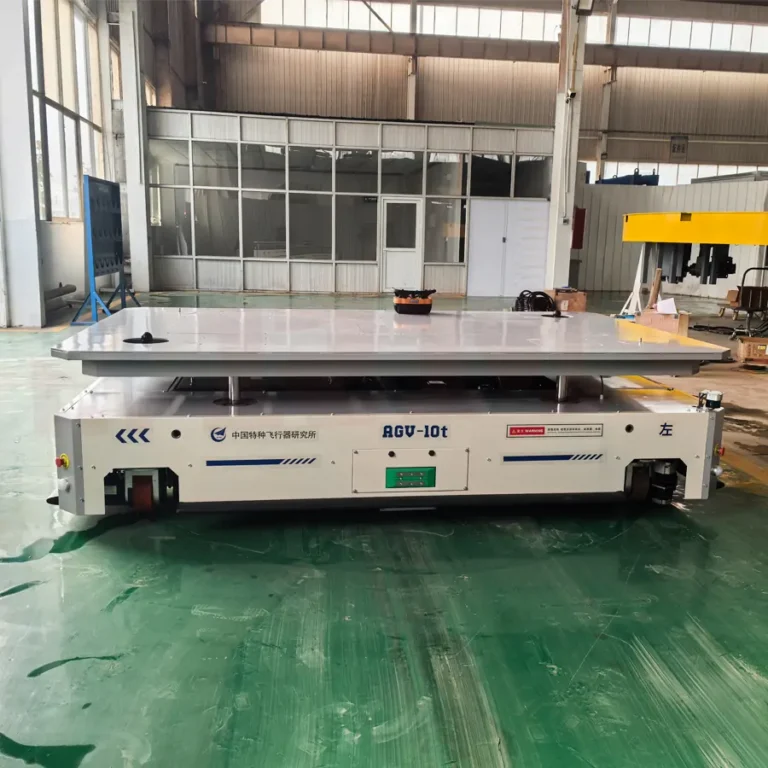

Automated Guided Vehicle, is a kind of test can be controlled by a pre-set system or sensors, without manual driving can be along the predetermined path travelling and complete the material handling tasks of the intelligent transport equipment.

It can be from the simple point-to-point handling, traction, weight and other forms of transfer of materials, and can also be achieved with intelligent equipment such as robotic arms, lifting platforms, special customised, warehousing systems, intelligent robots, and other complex equipment to work together to reduce the manual operation of the transfer equipment.

Common Automated Guided Vehicle System is generally equipped with navigation systems such as magnetic stripe navigation, laser navigation, visual navigation, etc., which can autonomously plan routes to avoid obstacles. If you want to learn more about AGVs and its types, check out this article: Types of AGV Automated Guided Vehicle

Video Show

Automatic guided vehicle has a wide range of application scenarios in modern industry. In the field of heavy manufacturing, it is mainly used for heavy-duty parts transfer, assembly line distribution and cross-workshop transportation; in warehousing and logistics, it is able to efficiently complete the tasks of goods sorting, distribution, loading and unloading. In addition, in special industries such as pharmaceuticals and food, unmanned operation through AGV systems effectively reduces the risk of cross-contamination and ensures the accuracy and safety of material transfer.

This highly flexible automation solution can be adapted to all types of industrial logistics needs. If you would like to evaluate the potential of AGV systems to improve efficiency in your industry, our professional team can provide you with customized handling solution consulting.

Advantages of Automated Guided Vehicle

The main role of automated guided cart system is to replace the traditional manual handling methods or alternative fixed transport equipment, so as to improve the automatic intelligent transfer of materials. It’s advantages as the following:

1. High handling efficiency

Automated Guided Vehicle System can do 24 hours work, and can do stable transport, handling, traction and other work, and not subject to human interference. In the automated production line, it can accurately docking, automatically optimise the handling route, reduce the material waiting time. Thus improve handling efficiency and reduce errors.

2. Reduce labour costs

In traditional handling operations, enterprises mainly rely on forklifts, hand trucks and other equipment, especially in the field of heavy industry, often need to invest a lot of manpower for material handling. With the adoption of automated guided vehicle system, the whole handling process can be run automatically according to the preset program.

The AGV automated guided vehicle system is able to efficiently accomplish all kinds of complex material handling tasks by integrating forklift fittings, lifting platforms and other specialized equipment. For heavy equipment handling needs, AGV can realize fully autonomous operation, significantly reducing labor costs, while improving operational safety and efficiency.

3. Improve safety

Automated Guided Vehicle is equipped with a variety of sensors (such as LIDAR, ultrasonic, collision avoidance strips, etc.), can detect the surrounding environment in real time to avoid collision, and with the heavy load equipment, to achieve automated handling, reducing the contact between personnel and equipment. Compared with the traditional manual driving and manual handling, the safety of personnel and equipment is more protected.

And Automated Guided Vehicle (AGV) also has the advantages of automation, flexibility, precision, energy saving and environmental protection compared with traditional handling equipment, which greatly reduces the cost of enterprises. So it is now also one of the indispensable handling equipment in the enterprise.

The application of Automated Guided Vehicle

The following are several typical applications of Automated Guided Vehicle:

1. Production line material distribution

In automobile manufacturing, electronic assembly and other industries, Automated Guided Vehicle can automatically transport parts from the warehouse to the production line.

2. Warehouse logistics handling

In e-commerce, logistics storage centres, Automated Guided Vehicle can be used with lifting equipment to achieve the loading and unloading of goods, sorting, handling and so on.

3. Workshop transport

In large-scale manufacturing factories, Automated Guided Cart can handle cross-workshop and cross-floor material transport tasks.

4. Special environment handling

In high temperature, low temperature, toxic or clean room and other special environments, the special Automated Guided Vehicle can replace manual handling. 5.

5. Multiple Automated Guided Vehicle Cooperative Operation

Through the Automated Guided Vehicle system, multiple AGV vehicles will work together to optimise the path to avoid congestion and handling heavy materials.

Conclusion:

Through the above introduction, I believe you have understood what is an automatic guided vehicle, characteristics and applications. Its high efficiency, flexibility and safety features make it an important handling tool for enterprises. As a manufacturer of automated guided vehicle systems, we are also actively exploring innovative applications of AGV technology to provide customers with smarter and more efficient handling solutions. If you have a need now, contact us today for smarter handling solutions.