The rail transfer cart is an electrically powered, flat-surface material handling device that operates along fixed tracks. Its operation relies on the seamless integration of an electric drive system, track guidance system, and electrical control system to achieve automated material transfer between different workstations or zones.

The entire operation of the rail transfer trolley process can be divided into four core stages: Power Supply → Drive → Control → Operation and Braking. Let’s explore it.

Power Supply of the Rail Transfer Car

The energy system constitutes the core component of the rail transfer cart. Different power supply methods determine the vehicle’s operational characteristics and applicable scenarios. Common power supply methods include the following:

Battery Power Supply (KPX Type)

Equipped with a high-capacity lead-acid or lithium battery as an independent power source, it requires no external cables or power rails. It is typically used in confined spaces, complex track layouts, or environments requiring inter-vehicle transport.

Battery-powered vehicles offer advantages such as high flexibility, freedom from cable constraints, and improved safety. However, they have limitations such as a limited range and the need for regular charging and maintenance.

KPX rail transfer trolley

KPX rail transfer trolley

Sliding Contact Rail Power Supply (KPC Type)

rail transfer trolley

rail transfer trolley

A sliding contact rail is installed along one side of the track. Vehicles are equipped with a collector device and a sliding contact. As the vehicle moves, the sliding contact maintains continuous contact with the rail to draw electrical power.

Sliding contact rail power supply is suitable for high-current, high-power applications. However, it requires a more demanding installation environment and is commonly used in steel, shipbuilding, and metallurgical industries.

Low-Voltage Track Power Supply (KPD Type)

Conductive rails are installed on the track to transmit low-voltage current (typically 36V or 48V) to the vehicle. Power is obtained through contact between the wheels and the track, enabling continuous operation.

Low-voltage track power supply allows for extended, uninterrupted operation with stable power delivery. However, it demands high track insulation standards and involves slightly higher installation costs.

rail transfer trolle

rail transfer trolle

Cable Reel Power Supply (KPJ Type)

rail transfer trolley

rail transfer trolley

One end of the cable connects to the power source, while the other end supplies power to the vehicle via a reel mechanism. As the vehicle moves, the reel automatically retracts and extends the cable, maintaining an uninterrupted power supply.

Cable reel power supply features a simple structure, easy maintenance, and low cost. However, it has a limited operating distance and experiences relatively rapid cable wear.

There are various types of rail-mounted transfer carts. If you wish to select one suitable for your specific operating conditions, please refer to the following article: How to Select a Rail Transfer Car? Now that we’ve learned about several common power supply modes for rail transfer vehicles, let’s explore their drive systems and power control.

Drive System of The Rail Transfer Cart

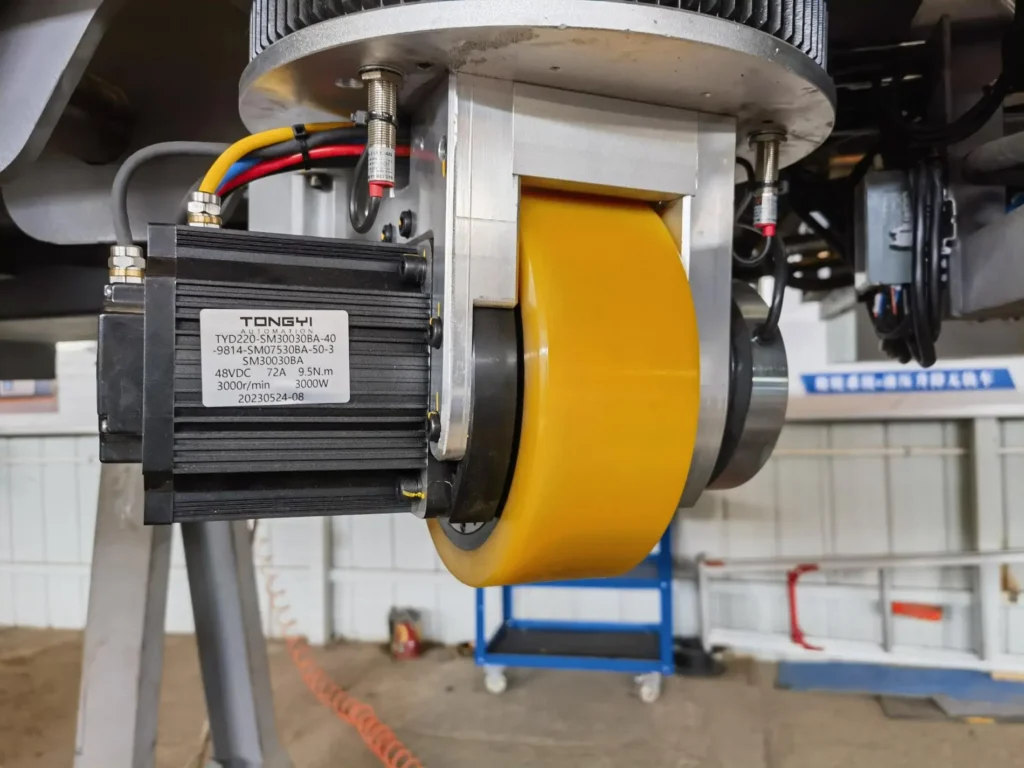

After the power supply is established, electrical energy is transmitted through the electronic control system to the drive system, where it undergoes energy conversion via the motor-gearbox-wheel assembly.

The motor converts electrical energy into mechanical energy. The gearbox reduces rotational speed while increasing torque, and this decelerated power is transmitted to the drive wheels, propelling the vehicle along the track.

The design of the drive system determines the vehicle’s operational smoothness and noise levels. Certain models feature a dual-drive system (dual-motor configuration) to enhance balance and power stability during heavy-load operation. High-end models typically employ AC variable frequency drive (VFD) technology, enabling soft starts and stepless speed regulation to effectively reduce mechanical impact and energy loss.

Electrical Control System of The Rail Transfer Carts

The electrical control system serves as the brain of the rail transfer cart, responsible for command transmission and safety protection. Its functions include:

- Start/stop control

- Speed regulation and directional control

- Overload protection, short-circuit protection, motor overheat protection

- Audible and visual alarms with the emergency braking system

- Remote control or PLC automated control.

Select intelligent models support:

- Wireless remote operation (enabling long-distance start/stop and speed adjustment),

- PLC programming control (for automated integration with production lines),

- Laser positioning or magnetic navigation systems (enabling automatic path-following and precise parking).

These technologies endow the rail transfer trolley with advanced intelligence and safety capabilities.

Operating and Braking Systems of the Rail Transfer Cart

The motion control of rail transfer carts requires precise track guidance systems. Tracks typically consist of P-shaped rails or square rails, fixed to the ground to enable straight or curved vehicle movement. Braking systems ensure safety and generally employ the following types:

- Electromagnetic Braking: Achieves rapid braking through electromagnetic force.

- Mechanical Braking: Utilizes brake discs or brake wheels, suitable for heavy-duty applications.

- Energy-Recuperative Braking (Premium Configuration): Converts kinetic energy into electrical energy during braking for enhanced efficiency.

Large-scale equipment incorporates additional safety modules such as collision buffers, infrared detection systems, and limit switches. These features automatically decelerate or halt the vehicle during operation, preventing unintended collisions and significantly enhancing overall safety.

Conclusion

The operational process of rail transfer carts can be summarized as follows: through the coordinated action of electric drive, mechanical transmission, and intelligent control systems, they achieve stable transport of heavy materials along rails. With their efficient, safe, and customizable characteristics, they have become core transport equipment for enhancing logistics automation and production efficiency on industrial production lines.

If you have any questions or requirements regarding transfer carts, please feel free to contact us. As a Chinese manufacturer specializing in customized transfer vehicles, REMARKABLE will provide you with the latest solutions.