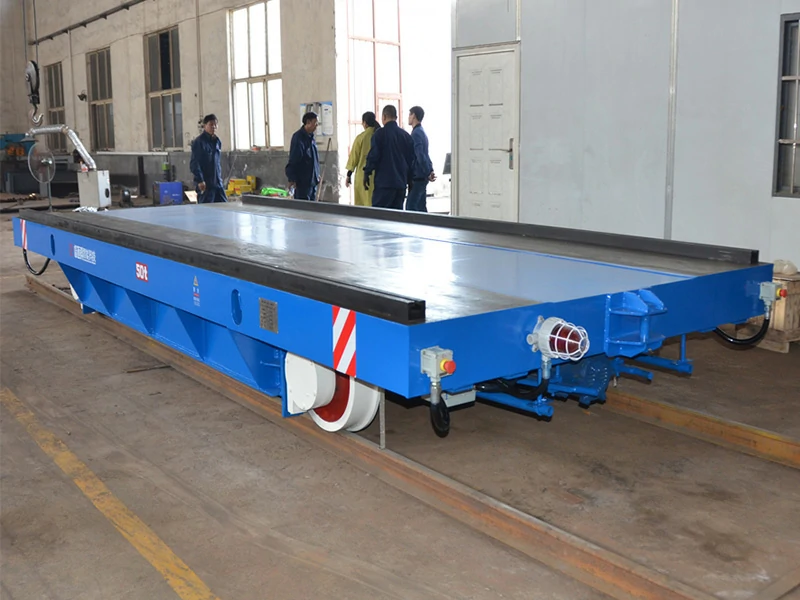

The roller conveyor rail transfer trolley is a rail-based material handling device that integrates powered or unpowered roller conveyor systems onto a traditional rail transfer cart. It operates stably along fixed tracks, automatically conveying and docking materials upon arrival, serving as a crucial component within rail conveyor systems that combines transport and transfer functions. Its applications are extensive. Today, we shall primarily explore the industries where it finds use.

Automated Production Lines

Applicable Industries: Automotive manufacturing, home appliance production, electronics assembly, construction machinery, etc.

Within automated production lines, multiple workstations require consistent cycle-time operation. If transfer equipment merely docks upon arrival, relying on manual labour or forklifts for loading/unloading, cycle interruptions become likely.

By employing roller conveyor transfer trolleys for production lines, materials are automatically conveyed via rollers to the next workstation upon the transfer cart’s arrival, enabling seamless integration with roller conveyors, chain conveyors, and similar equipment. This represents an excellent choice for automated rail transfer solutions.

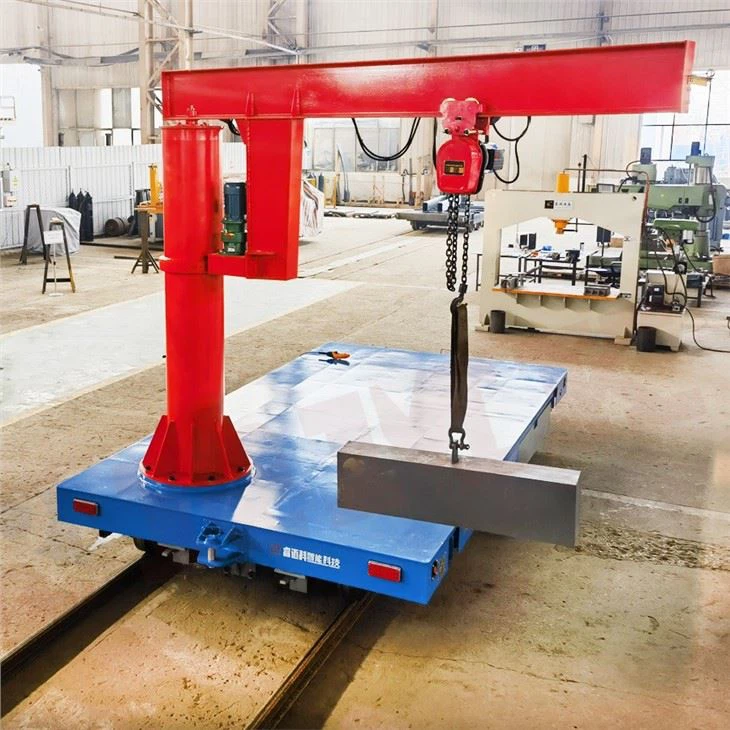

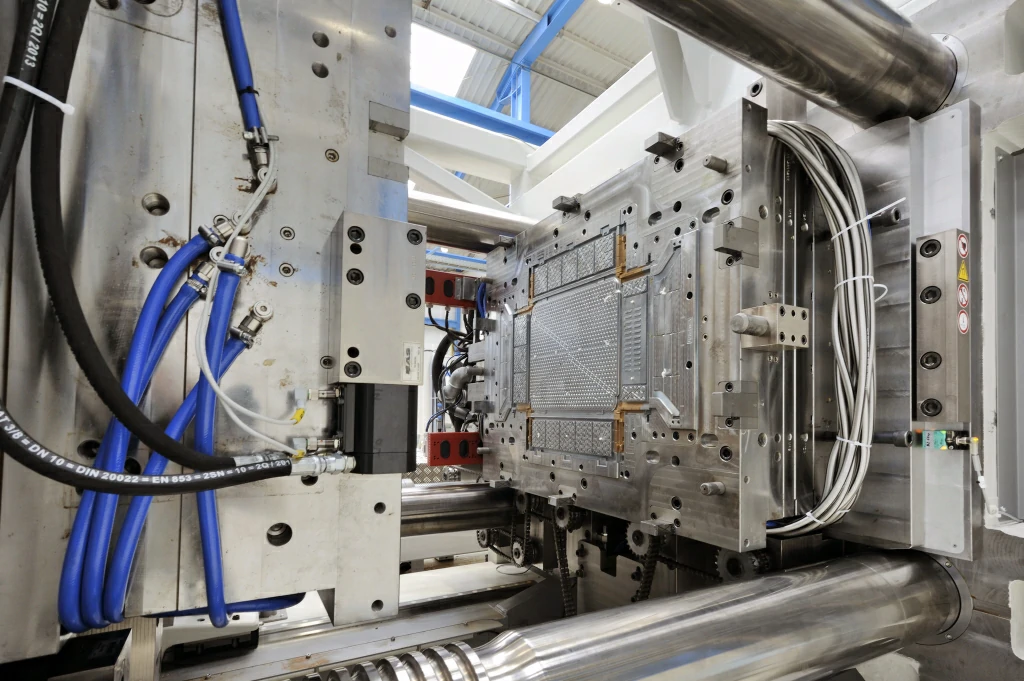

Heavy-duty and oversized workpieces

Applicable Industries: mould manufacturing, steel structures, equipment manufacturing, foundries, rail transit equipment, etc.

During production, moulds, large structural components, or heavy parts require frequent cross-station or cross-area transfer. Relying solely on overhead cranes or forklifts proves inefficient and poses significant safety risks.

The heavy-duty roller conveyor rail transfer trolley operates along fixed tracks, offering high load capacity and excellent running stability. Its roller conveyor structure enables non-hoisting loading/unloading of heavy components, making it suitable for heavy-duty, continuous operation scenarios.

Warehousing and Logistics

Applicable Industries: New energy, power equipment, heavy industrial warehousing, steel metallurgy, and chemical equipment.

In many factories, significant distances between warehouses and production lines, coupled with non-standardised material specifications, present challenges for traditional manual transfer. This approach is labour-intensive, physically demanding, and poses safety risks, making it difficult to meet continuous production requirements.

Employing a rail transfer cart with roller conveyor as an intermediate platform between storage and production lines facilitates automated material conveyance, temporary storage, and cycle buffering. This contributes to establishing a stable, efficient internal logistics system.

Multi-station Production Line Logistics Systems

Applicable Industries: Discrete manufacturing, customised production facilities, automated integration projects.

In factories handling diverse product ranges, small batches, or multiple concurrent production lines, dedicating separate conveying equipment to each line proves costly and inflexible.

Through rational track layout planning, roller conveyor rail transfer carts can repeatedly shuttle between multiple workstations or production lines, facilitating material transfer between different processes under system coordination. This approach is highly prevalent in roller conveyor rail transfer trolley applications and suits factories requiring flexible scalability.

Automotive Manufacturing

Automotive Manufacturing Equipment Manufacturing

Equipment Manufacturing Warehousing and Logistics

Warehousing and Logistics Moulding Industry

Moulding Industry Steel and Metal Processing Industry

Steel and Metal Processing Industry Energy and Power

Energy and Power

Above, we have briefly explored the primary application domains of roller conveyor transfer cars, which serve an extensive range of industries. So, how does one select the appropriate transfer cart based on specific application scenarios? Let us examine this together.

How to Select the Roller Conveyor Rail Transfer Trolley

In practical applications, no single configuration of roller conveyor rail transfer trolley suits all scenarios. The selection should be based on operational conditions to ensure the trolley is suitable for the specific factory environment. Below are key factors enterprises should prioritise during selection:

Load Capacity and Material Dimensions: Different operational conditions demand varying load-bearing capacities. For heavy-duty applications such as moulds or large components, a heavy-duty rail transfer cart with roller conveyor and fixed track structure is recommended to ensure long-term operational stability.

Conveying Method and Equipment Integration: Select appropriate roller types, spacing, and drive mechanisms based on the existing conveyor line configuration. This ensures seamless integration with roller conveyors, chain conveyors, or workstation equipment, enabling automated loading and unloading.

Number of Workstations and Operational Path: Point-to-point transfers versus multi-station repetitive operations necessitate differing track layouts and control methodologies. Comprehensive planning based on actual logistics routes is essential to avoid future constraints.

Automation System Integration Requirements: Consideration must be given to communication needs with PLC, MES, WMS, and other systems. Select appropriate control solutions and system architectures to deliver an automated rail transfer solution.

Roller Conveyor Rail Transfer Trolley

Roller Conveyor Rail Transfer Trolley Roller Conveyor Rail Transfer Trolley

Roller Conveyor Rail Transfer Trolley

Supplier Capabilities:

- Understanding Site Conditions: Assessing key aspects such as load capacity, conveying methods, workstation quantity, and cycle times based on actual factory requirements.

- Robust Customisation: Deeply tailoring vehicle structure, roller design, drive solutions, and control systems according to client material specifications, conveyor line types, site layouts, and automation system demands.

- System Integration Capabilities: Possess technical expertise for seamless integration with automation systems, including PLC, MES, and WMS, enabling roller conveyor trolleys to function within automated ecosystems.

- Mature Project Experience and Service Assurance: Deliver end-to-end services from solution design, manufacturing, and commissioning to on-site installation support, ensuring smooth equipment commissioning and operation.

Selecting the appropriate rail transfer trolley requires consideration of multiple factors. A comprehensive selection of transfer equipment suited to operational conditions enhances efficiency and reduces overall costs.

Conclusion:

Through the preceding discussion, we have explored the primary applications of roller conveyor transfer trolleys and the factors influencing their selection. If you are seeking a transfer trolley tailored to your factory or operational needs, please contact us immediately. We shall provide the most appropriate customised transfer trolley solution.