An industrial transfer cart is intelligent handling equipment designed for transporting materials, steel coils, molten metals, and heavy components within factory premises. Offering high load capacity, smooth operation, and strong customization capabilities, they are widely used in mold manufacturing, metallurgy, and equipment manufacturing industries. Industrial transfer carts come in various types. How can they be classified, and how does one choose the appropriate cart? Let’s explore.

Main Types and Characteristics of Industrial Transfer Carts

Based on transported material type, usage scenarios, and operating methods, industrial transfer carts can be categorized as follows:

| Type Primary | Features | Load Capacity | Operation Method | Application | Suitable Industries |

|---|---|---|---|---|---|

| Mold Transfer Cart | High load capacity, safe, and stable | 10–200 tons | Electric/Hydraulic | Mold transportation and installation | Mold manufacturing, injection molding, stamping |

| Coil Transfer Cart | V-shaped anti-slip/anti-roll brackets | 10–100 tons | Rail/trackless | (steel/copper) handling | Metallurgy, metal processing |

| Ladle Transport Cart | High-temperature resistance, leak-proof | 20–150 tons | Rail-based | Molten steel/liquid metal transport | Steelmaking, foundry |

| Heavy-Duty Material Transfer Carts | Ultra-high load capacity, customizable | 50–500 tons | Cable/Battery | Large machinery and structural component handling | Equipment manufacturing, heavy industry |

| Rail-Guided Transport Cart | Stable operation, suitable for continuous work | 5–300 tons | Rail-guided | Fixed-route material transfer | Automated production lines |

| Die Transfer Cart | Off-track operation, agile and lightweight | 5–100 tons | Electric/Wireless remote control | Flexible mold transportation | Injection molding, mold manufacturing |

Different transfer cart types feature distinct characteristics and industry applications. If you’d like to learn more about industrial transfer carts, you may also refer to the following article: Five Common Types of Industrial Transfer Cart and Uses. What factors should be considered when selecting the appropriate industrial transfer cart? Let’s explore how to choose the right transfer cart for your specific operational requirements.

How to Select Industrial Transfer Carts?

An industrial transfer cart is key to enhancing production efficiency and transportation safety. Since different factories vary in transported materials, spatial layouts, and operational methods, multiple factors must be comprehensively considered during selection. Below is a detailed selection guide:

Load Capacity and Platform Dimensions Matching:

- Load Selection Principle: The rated load capacity should be 1.2 to 1.3 times the maximum transported material weight, allowing for a safety margin.

- Platform Dimension Matching: Platform length and width must correspond to the base dimensions of the transported object to prevent center of gravity shift or localized stress.

- Structural Strength: For high-load or large equipment handling, a high-strength steel chassis is recommended.

Recommendations: Mold handling typically ranges from 10 to 60 tons; coil and heavy structural components generally fall between 50 and 300 tons. Special applications (e.g., ladles, castings) require high-temperature protection and center-of-gravity stabilization designs.

Power Supply Selection:

Industrial transfer carts feature diverse power supply methods, with each method determining the equipment’s application scope and flexibility:

| Power Supply | Method Features | Suitable Scenarios |

|---|---|---|

| Cable Reel Power Supply | Low-cost, stable power supply, simple maintenance | Fixed workstations, shuttle-type transport |

| Sliding Contact Rail Power Supply | Continuous power supply, suitable for long-distance operation | Rail-based continuous production lines |

| Battery Power | Cable-free operation, agile turning | Trackless systems, complex layouts, or cross-area operations |

| Rail Conductor Power | High stability, extended lifespan | High-frequency operations, long-cycle production environments |

Recommendation: For fixed factory layouts with short transport paths, cable-powered models are suitable. For complex spaces with frequent cross-area operations, battery-powered trackless transport vehicles are recommended.

Operating Environment and Spatial Layout:

- Floor Conditions: Floor flatness affects operational stability. For uneven surfaces, select models equipped with suspension damping systems or rubber anti-slip wheels.

- Aisle Width: For workshops with narrow aisles or multiple turns, prioritize trackless designs capable of 360° on-the-spot turning.

- Operating Temperature: High-temperature zones (e.g., metallurgical workshops) require models with thermal insulation and high-temperature-resistant drive motors. Cleanrooms demand low-noise, maintenance-free battery types.

Recommendation: For complex layouts with variable routes, trackless models offer greater flexibility. For single-path, repetitive tasks, track-based models provide superior stability.

Operation and Control Methods:

The control system of industrial transfer vehicles impacts operational convenience and safety. Common configurations are as follows:

| Control Method | Features | Suitable Scenarios |

|---|---|---|

| Manual Control | Low cost, intuitive operation | Single-operator, low-frequency tasks |

| Wireless Remote Control | Flexible, convenient, extended safety range | Medium-to-high frequency transport, open spaces |

| PLC Automatic Control | Precise control, programmable paths | Automated production lines, MES integration |

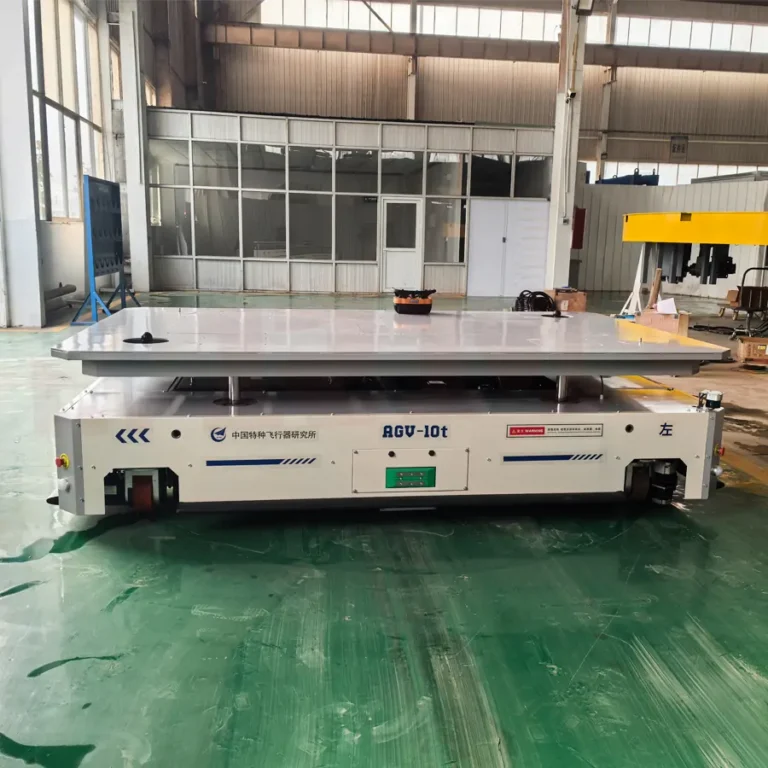

| AGV Navigation System | Unmanned operation, intelligent scheduling | Smart factories, high-end manufacturing |

Safety and Protection Configuration:

Safety is an often-overlooked yet critical factor in selecting industrial transfer vehicles. Qualified transfer equipment should incorporate the following fundamental protective measures.

- Collision Prevention System: Infrared or ultrasonic sensors trigger automatic braking

- Speed Limiter: Adjusts travel speed based on load weight

- Emergency Stop Buttons: Multiple points for quick shutdown

- Anti-Slip Platform & Limiters: Prevents cargo slippage

- Audible/Visual Alarm System: Indicates operational status and prevents entry into hazardous zones

Cost and Maintenance:

When selecting industrial transfer cart equipment, consider not only the purchase cost but also long-term operational expenses, including energy consumption, replacement of wear parts, and maintenance cycles. Battery-powered models require minimal maintenance but have a limited range. Conductor rail and track power systems suit continuous production with extended maintenance intervals. Opt for transporters with modular structural designs to facilitate future repairs and part replacements.

Manufacturer Capabilities:

A reputable industrial transfer cart manufacturer should possess the following capabilities:

- Provide 3D layout solutions and load capacity analysis

- Design power supply configurations and steering mechanisms tailored to operational conditions

- Support functional expansions like smart control, automatic mold change, and production line integration

- Maintain comprehensive after-sales response mechanisms and technical training support

RMK manufacturers with design customization capabilities and robust after-sales systems can significantly reduce long-term maintenance and retrofitting costs for enterprises.

Conclusion:

Through this article, you should now have a foundational understanding of selecting industrial transfer carts suited to your needs. For specific model recommendations and quotations, contact us, a professional manufacturer. We will provide customized solutions to empower your enterprise with efficient, intelligent material handling.