Steel Coil Transfer Cart is a kind of heavy-duty transfer equipment specialized in handling steel coils, steel strips and other coil materials, which is widely used in steel mills, warehousing bases, rolling mills and other places. With sturdy structure and smooth operation, this equipment can effectively improve the transfer efficiency of steel coils between production and warehousing, and at the same time, reduce the risk of manual handling and improve the overall safety and automation level of the operation.

- Model: KPX

- Capacity: 1-300T

- Material: Q345

- Type: Rail type or trackless

- Power Mode: Battery or motorised

- Operation Type: Pendant/Remote Control

- Advantage: 360 Degree Turning Around

Working Principle

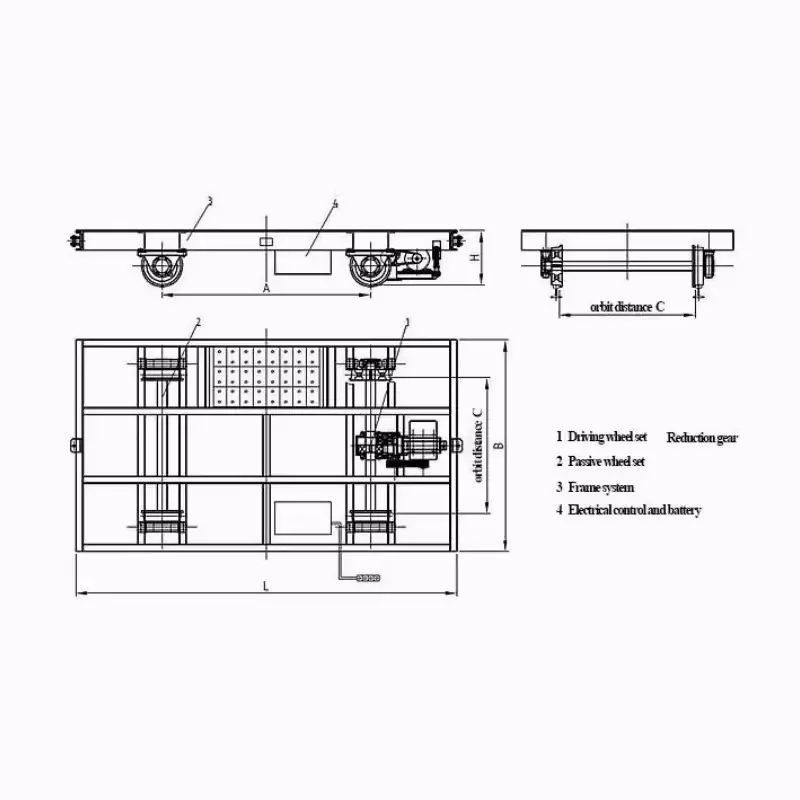

The Steel Coil Transfer Cart operates on the principle of an electrically powered system that drives the wheels to achieve smooth forward motion or steering. The power source can come from a battery, a slip wire, or a cable reel. The motor transmits power to the wheels through a gearbox to drive the cart along a predetermined route. The control mode usually adopts a handheld controller or wireless remote control, and the operator can precisely control the vehicle start and stop, acceleration and deceleration, steering, and other actions. In order to ensure transportation safety, the vehicle body is equipped with a steel coil limit frame or V-shaped bracket to prevent the material from rolling or displacement in the process of moving.

Videos Show

Application

The Steel Coil Transfer Cart is not only suitable for the transfer of steel coils in the steel industry, but can also flexibly cope with a wide range of heavy-duty material handling needs, serving a wide range of industrial sectors. Typical applications include:

Steel and metallurgical industry: transferring heavy materials such as coils, tubes, profiles, billets, intermediate ladles, ingots, etc., for efficient operation between rolling lines, heat treatment lines, raw material storage, and finished product storage;

Paper mills: for the transportation of paper coils from the production line to the warehouse, or from the storage area to the converting shop.

Paint shops: for the safe transportation of workpieces to paint booths or curing ovens;

Shipbuilding: transfer of large hull structural parts, steel plates, and welding modules, suitable for cross-shop logistics of large parts in shipyards;

Quarrying and mining: handling ores, billets, and large components, adapting to harsh operating environments;

Warehousing and multi-workshop linkage: connecting different production processes or storage areas.

Customized Steel Coil Transfer Cart

- Load Capacity: Usually 5~50 tons, larger load can be customized according to the demand.

- Table Size: customized length, width and height according to the specification of steel coil.

- Power Supply: Battery, cable reel, slide wire, low voltage rail, etc.

- Running Speed: Usually 0-30m/min, variable frequency speed control.

- Rail Type or Trackless: choose the running mode according to the site operating environment.

- Turning Radius: Suitable for multi-direction operation in narrow field.

- Coil Support Structure: such as V-frame, U-channel or adjustable support frame.

- Control Mode: Handheld button, wired/wireless remote control, automatic navigation, etc.

- Safety Protection Devices: such as emergency stop devices, warning lights, limit switches, anti-collision systems, etc.

If you need to get a customized quote or technical solution, please contact our engineer team, we will provide you with professional and efficient handling solutions.

Specifications

The Steel Coil Transfer Cart is highly adaptable and can be customized according to different load types, such as adding V-frames to fix coils or installing rotating tables to achieve multi-angle transfer, to meet the diversified handling needs in complex operating environments.

| Modle | KPX-10 Ton | KPX-30 Ton | KPX-50 Ton | KPX-80 Ton | KPX-100 Ton |

|---|---|---|---|---|---|

| Table Size (m) | 3.6*2.0*0.5 | 4.5*2.2*0.6 | 5.5*2.5*0.65 | 6.0*2.6*0.8 | 6.5*2.8*0.9 |

| Power | Maintenance Free Battery | ||||

| Rail inner Gauge | 1435mm | 1435mm | 1435mm | 1800mm | 2000mm |

| Wheel Dia. | 350mm | 400mm | 500mm | 600mm | 600mm |

| Running Speed | 0-20m/min | 0-20m/min | 0-20m/min | 0-20m/min | 0-20m/min |

| Motor Power | 1.6kw | 3.5kw | 5kw | 8kw | 10kw |

| Capacity | 180Ah | 250Ah | 330Ah | 400Ah | 440Ah |

| Volatge | 48v | 48v | 48v | 72v | 72v |

| Max Wheel Load | 42.6Kn | 110.4Kn | 174Kn | 278.4Kn | 343.8Kn |

| Reference weight | 4.2t | 6.8t | 8t | 12.8t | 14.6t |

| Recommend Rail | P24 | P38 | P43 | P50 | P100 |

If you would like to learn more or choose the right steel coil transfer trolley, please read this article: How to Choose A Coil Transfer Trolley?

Features

Efficient transport

Designed for heavy steel coils with a load capacity of more than 50 tonnes, it is equipped with a high-performance drive system to optimise the production process.

Precise positioning

Adopting advanced frequency conversion speed control and automated guidance technology, millimetre stopping, perfect docking to production line and storage place.

Ultra-strong structure

All-steel body, the key parts are heat-treated and anti-corrosion spraying, adaptable to high temperature, dusty and other harsh environments, with a service life of more than 10 years.

Flexible customisation

Can be customised with rail/trackless, electric/hydraulic drive, etc., and can be added with tilt-proof, weighing system or remote control module.

Energy saving and environmental protection

Equipped with energy recovery system and low-power motors, the noise level is less than 75dB, which is in line with the green manufacturing standard.

Intelligent safety protection

Laser obstacle avoidance, emergency braking, overload alarm and automatic power-off, etc., real-time monitoring of equipment status and effective prevention of accidents.

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control