Project Overview

Remarkable has customized three efficient and cost-effective rail transfer carts, including a 10-ton steel pipe transfer cart, a 20-ton steel coil transfer cart, and a cable-powered turntable, to optimize the transportation of steel coils and pipes for its Thai customer. The 20-ton lithium battery-powered steel coil transfer cart is the core equipment, which has the advantages of flexible design, stable performance, energy saving, and environmental protection, and effectively improves the efficiency of steel coil transfer and reduces the operation cost.

Customer Requirements

The main requirement of the customer is to transfer heavy steel coils safely and efficiently, while being cost-effective and adaptable. Specific requirements included:

- Load capacity: 20 tons of steel coils needed to be transported, and could be used to transfer other materials.

- Track adaptability: the customer plans to use lightweight square steel track, hoping that the equipment can reduce the wheel pressure on the track and reduce the cost of laying.

- Power supply solution: Long-range and fast charging were required to minimize downtime.

- Versatility: The steel coil fixing device needs to be adjustable to accommodate different sizes of steel coils.

Solutions

Based on customer needs, Henan Remarkable provides the following customized solutions:

20 tons lithium battery rail steel coil transfer cart

Power system: powered by lithium iron phosphate batteries, with long endurance and support for rapid charging to meet the needs of high-intensity operations.

Drive design: Equipped with a low-voltage AC motor, European-style trolley wheels, and a reducer, it runs smoothly and saves energy.

Wheel set optimization: In order to reduce wheel pressure and adapt to the light rail, it adopts 8 European-style LD trolley wheels, which spread the load and reduce the wear of the rail. The optimized structure reduces the cost of track laying for customers and ensures the long-term stable operation of the equipment.

Steel coil fixing device:

Provide a fixed V-frame and an extra design removable V-frame to meet the transportation of different materials.

72 round holes are accurately machined on the V-frame, which is convenient for customers to adjust the fixing position of the steel pipe according to the size of the steel coil to enhance flexibility.

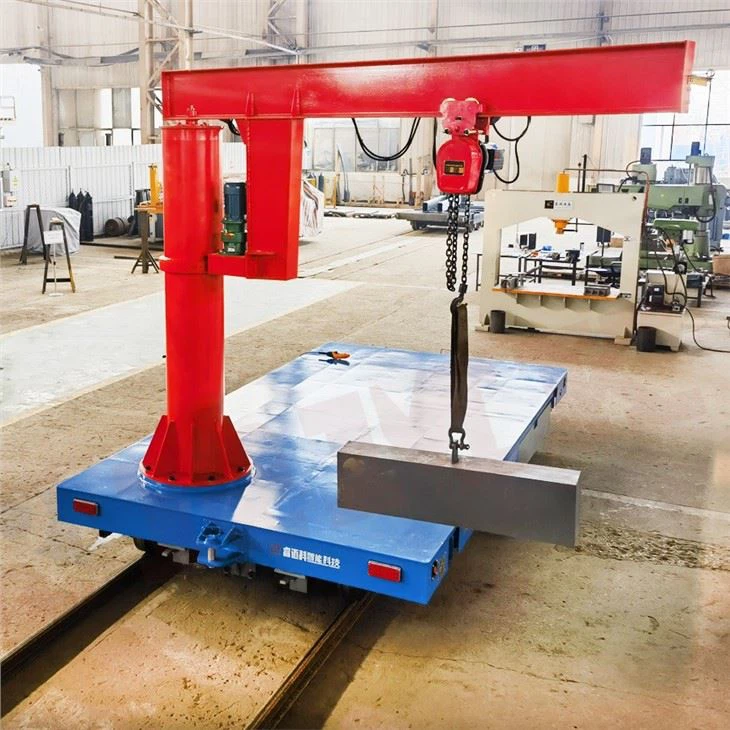

Matching Turntable System

The addition of a 25-ton cable-powered turntable allows the 20-ton steel coil transfer cart to rotate 90° on the track, realizing seamless multi-track connection and optimizing the logistics path.

Conclusion

This steel coil transfer cart project fully embodies Remarkable’s philosophy of “customer needs as the core”, and provides customers with cost-effective solutions through innovative design and lean manufacturing. We look forward to continuing to help our global customers realize more efficient and smarter material handling with our high-quality products and services.

If you would like to learn more about steel coil transfer carts, please read the articles:

- What is Steel Coil Transfer Cart?

- How to Choose A Coil Transfer Trolley?

- Coil Rail Transfer Cart Automated Longitudinal and Transverse Tail Video Introduction