What Is the Difference Between AGV and RGV?

AGV (Automated Guided Vehicle) and RGV (Rail Transfer Trolley) are two core types of automated material handling equipment in industrial logistics.

In the comparison of AGV vs RGV, the main differences between the two are reflected in navigation methods, flexibility, automation level, and applicable scenarios.

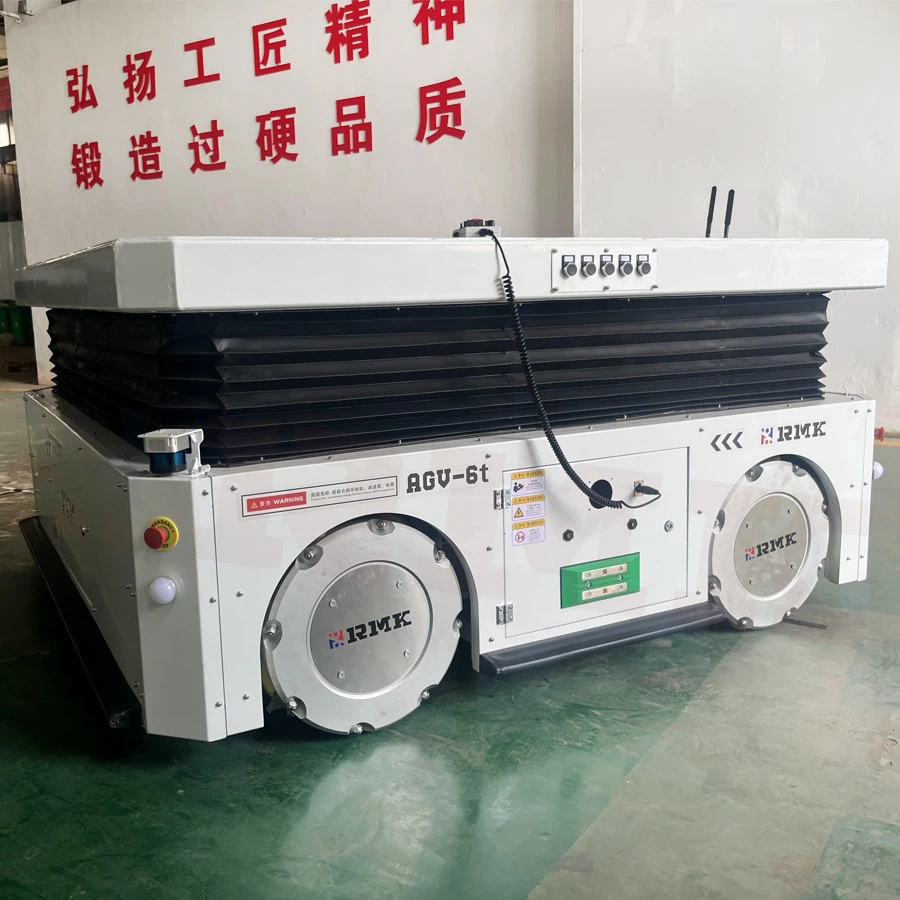

AGV

AGV RGV

RGV

The following content systematically analyzes the differences between them to help users make reasonable selections in actual projects.

Core Difference Comparison

The table below provides a direct comparison of AGV vs RGV from key dimensions of industrial material handling:

| Comparison Dimension | AGV (Automated Guided Vehicle) | RGV (Rail Guided Vehicle) |

| Navigation Method | Flexible navigation (laser, vision, magnetic tape, etc.), no fixed track required, capable of autonomous path planning | Rail navigation (steel rail / guide rail), paths completely depend on track installation |

| Flexibility | Very high, routes can be freely adjusted and obstacles can be avoided | Very low, only operates along tracks with fixed paths |

| Automation Level | Equipped with environmental perception and autonomous decision-making capabilities, supports multi-vehicle coordinated scheduling | Relies on upper-level system scheduling, weak autonomous decision-making capability |

| Load Capacity | Generally several tons to tens of tons, some models can exceed 100 tons | Simple structure with strong load capacity, up to hundreds of tons |

| Cost | Lower initial investment, but complex technology and relatively higher maintenance costs | High initial track investment, simple later maintenance, controllable costs |

| Application Scenarios | Flexible production, complex warehousing, dynamic logistics scenarios | Fixed production lines, heavy-duty transportation, high-density warehousing |

| Typical Advantages | Strong flexibility and high level of intelligence | Precise positioning, high speed, strong heavy-load capability |

Detailed Difference Comparison

Navigation and Path

AGV:

AGV systems usually adopt flexible navigation methods such as laser, vision, or magnetic tape. Paths can be quickly adjusted through software without large-scale physical modification.

For example, laser navigation AGVs can scan the environment through LiDAR and build maps to independently plan optimal driving routes; vision navigation AGVs complete positioning by recognizing environmental features through cameras. This approach makes AGVs very suitable for production and warehousing environments with multiple product types, small batches, and frequently changing processes.

RGV:

RGVs rely on fixed tracks for operation, including ground steel rails or overhead guide rails. Once the path is determined, later changes require re-laying tracks, resulting in longer construction cycles and higher costs.

However, their advantage lies in extremely high positioning accuracy, and they are commonly used in automated warehouses or production line material handling systems with strict docking accuracy requirements.

Automation and Intelligence Level

AGV:

In the comparison of automation capability in AGV vs RGV, AGVs have stronger autonomous decision-making capabilities. Through sensors such as LiDAR and cameras, AGVs can perceive the environment in real time, achieve autonomous obstacle avoidance, path re-planning, and multi-vehicle coordinated operation, adapting to complex and variable production rhythms.

RGV:

RGVs have relatively fixed operating logic and mainly execute tasks along preset tracks. They do not have complex environmental perception or obstacle avoidance capabilities and usually rely on upper-level systems (such as WMS or MES) for unified scheduling. They are more suitable for application scenarios with stable processes and fixed rhythms.

Cost and Maintenance

AGV:

AGVs do not require track installation, so the initial infrastructure investment is relatively low. However, due to high system integration, maintenance costs for core components such as LiDAR, control systems, and batteries are relatively high. Continuous investment is required for software upgrades and battery maintenance in later stages.

RGV:

RGVs require track construction investment in the early stage, especially for circular or multi-track systems. However, their equipment structure is simple, and later maintenance mainly focuses on mechanical components such as tracks and motors. Maintenance costs are relatively controllable, and service life is long.

Application Scenario Selection

When comparing AGV vs RGV, application scenarios are the most critical decision factor.

Scenarios where AGV is preferred:

- Flexible production environments, such as electronic manufacturing with frequently adjusted assembly lines

- Dynamic warehousing systems, such as order picking in e-commerce warehouses

- Industries with high environmental adaptability requirements, such as pharmaceuticals and semiconductors

Scenarios where RGV is preferred:

- Fixed production lines, such as material transportation on automotive assembly lines

- Heavy-duty transportation, such as handling of steel coils and heavy machinery components

- High-density automated warehouses that pursue high efficiency and high stability

Conclusion

AGV and RGV each have their own irreplaceable advantages.

AGVs are more suitable for production and warehousing systems with high flexibility and intelligence requirements, while RGVs perform more stably and reliably in fixed-path, heavy-load, and high-efficiency transportation fields. In actual selection, comprehensive evaluation should be carried out based on load requirements, production rhythm, site conditions, and long-term operation and maintenance costs.

Remarkable focuses on the customized design and manufacturing of various electric transfer carts, transport carts, and material handling vehicles. According to different working conditions and industry requirements, we provide safer and more efficient automated material handling solutions.

If you have any questions during the AGV vs RGV selection process, please feel free to contact our professional team for targeted solutions.

Email: transfercart@rmkzn.com

Phone: +86-18637369355