A rail transfer trolley, also referred to as an electric transfer rail trolley or motorized rail transfer trolley, is a rail-mounted material transfer vehicle powered by electricity. It is widely used for handling heavy materials across production lines, assembly stations, or warehouse areas. It runs along steel tracks and can be powered by battery, cable reel, or low-voltage rail, depending on the application needs.

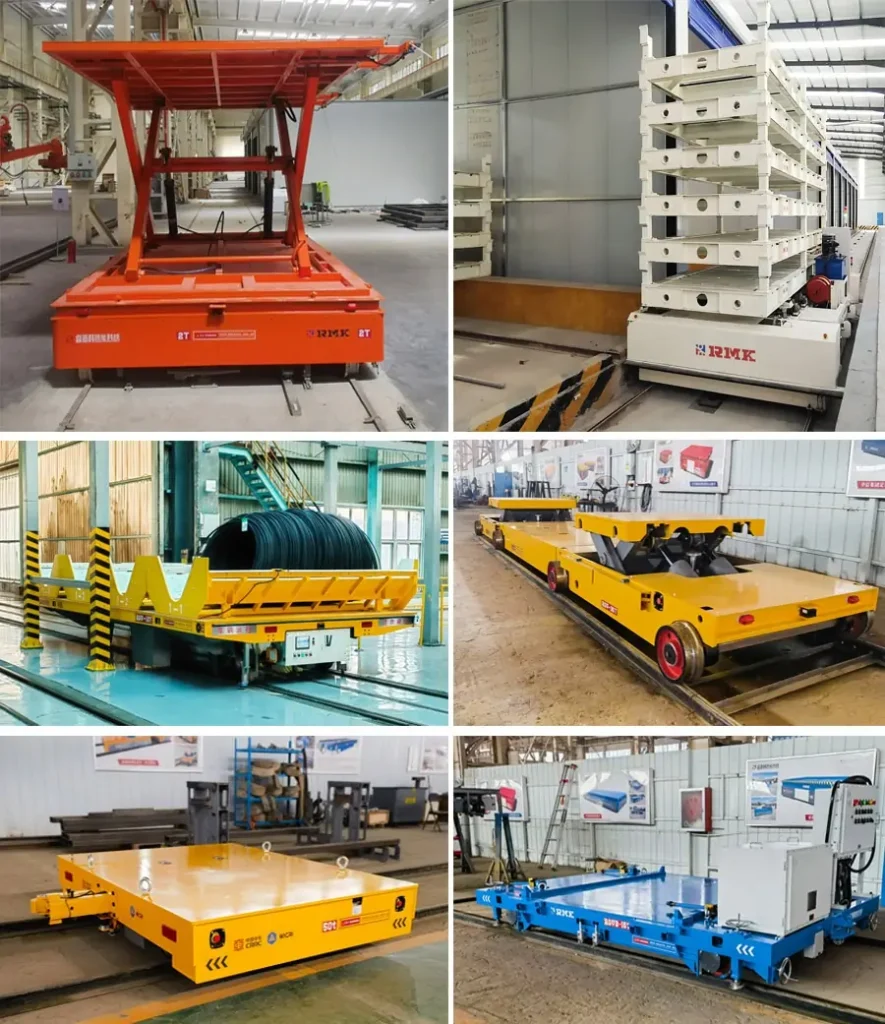

Types of Rail Transfer Trolleys

Industrial Rail Transfer Trolley

General-purpose rail transfer trolley, widely used in industrial fields for material transfer, such as molds, steel plates, equipment parts, etc..

Lifting capacity: 1~300 tons, larger tonnage can be customized.

Features: Simple structure, strong carrying capacity, adapt to a variety of working conditions, stable operation, optional cable, battery or low voltage rail power supply.

Application: Suitable for long-distance handling of heavy loads in steel, automobile manufacturing, heavy industry, machining, warehousing and other industries.

Battery Rail Transfer Trolley

Built-in battery as the power source of the transfer trolley, without external cables, suitable for no electric rail or complex path scenarios.

Lifting capacity: 1 ~ 100 tons common, adaptable to different load requirements.

Features: no cable bondage, flexible turning, can run in any indoor and outdoor area, strong range, suitable for medium and long distance transportation.

Applications: mold workshop, assembly workshop, warehousing and logistics system and other places of operation with high freedom requirements.

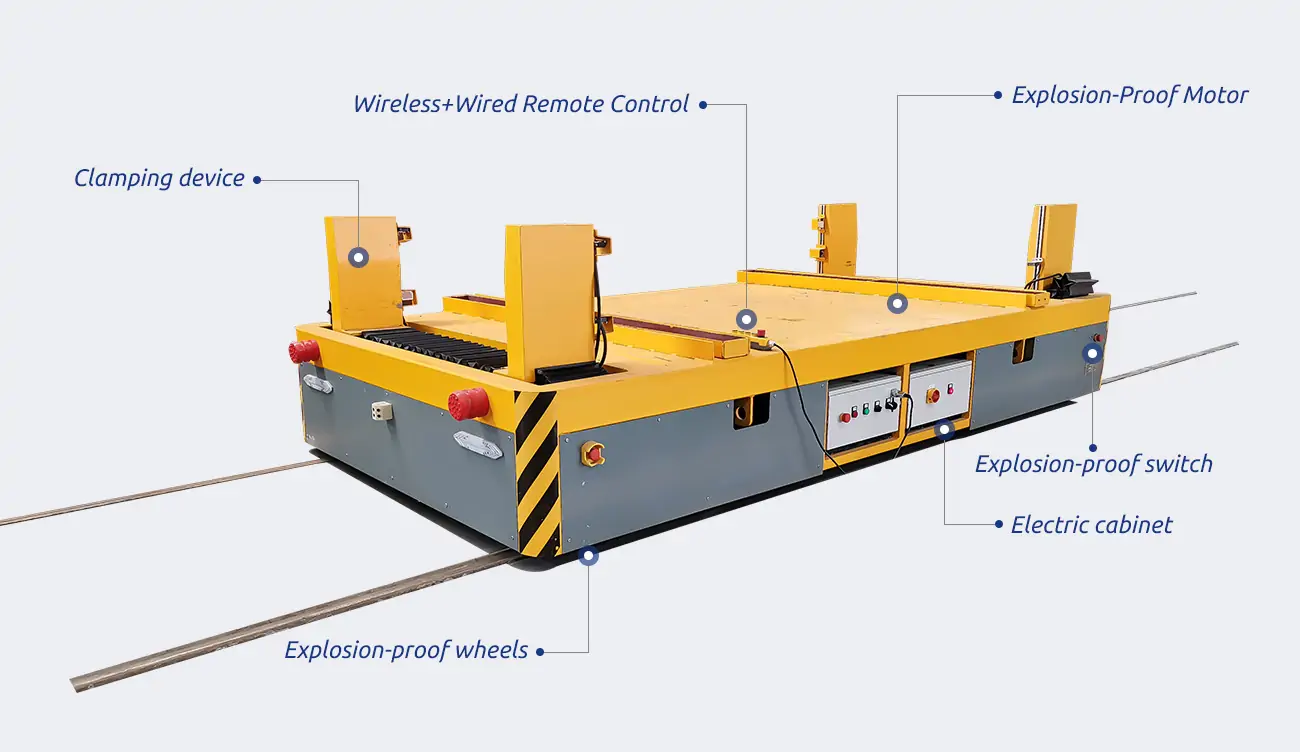

Explosion-proof Rail Transfer Cart

Rail transfer cart specially designed for flammable and explosive environments, the whole cart adopts explosion-proof electrical components and explosion-proof structure.

Lifting capacity: 1~150 tons, can be specially customized according to the site environment.

Characteristics: High explosion-proof grade, high safety factor, suitable for high-risk operation area, support remote operation and automatic control.

Application: Petrochemical, coal mine, dust workshop, natural gas treatment plant and other materials handling in explosive environment.

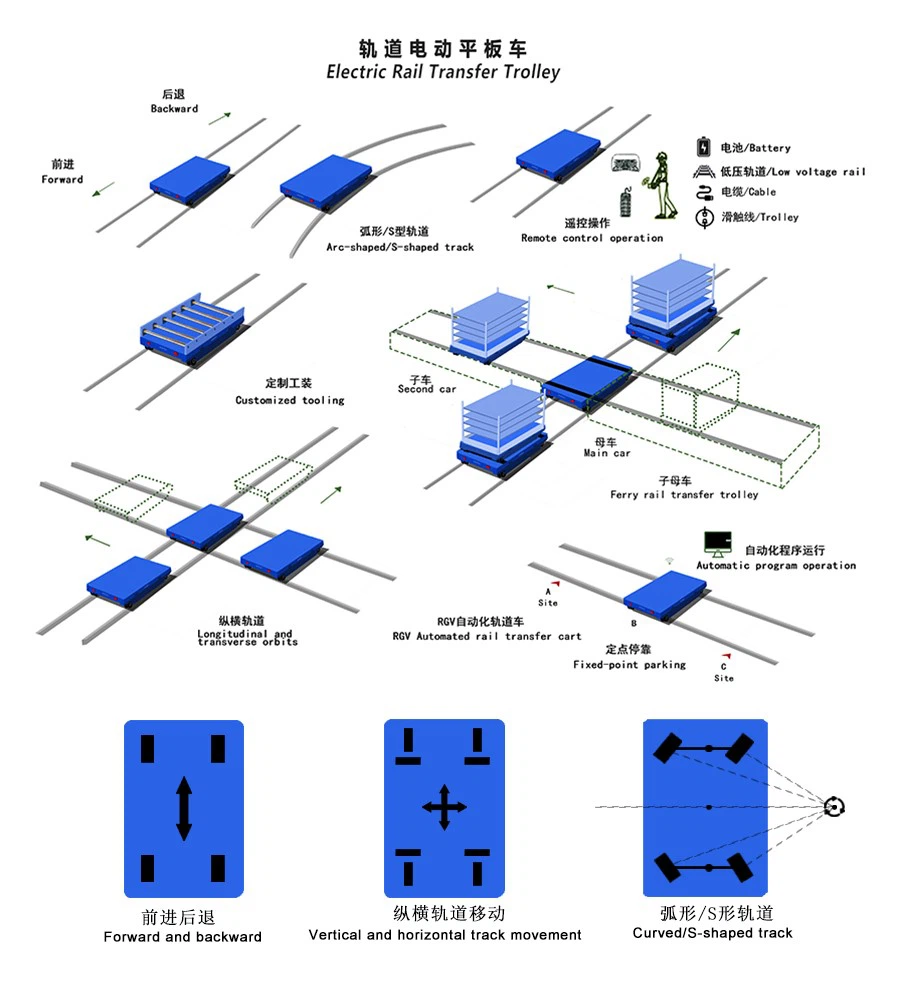

Rail Transfer Cart with Longitudinal and Lateral Movement

Rail transfer cart with longitudinal and lateral movement, the cart can switch the direction between several cross tracks.

Lifting capacity: 1 to 80 tons, generally used for transportation within the multi-station system.

Features: flexible operation, high space utilization, suitable for narrow workshop or multi-track interlocking layout scene.

Application: Used for complex process line layout, such as mold storage, multi-workshop linkage of automatic conveyor system.

Cross-track Rail Transfer Cart

It can realize cross-track operation of electric flat car, used for free switching between multiple tracks, commonly used in track crossing or grid layout system.

Lifting capacity: 10 to 100 tons, customizable.

Characteristics: Equipped with multi-directional guiding wheelsets, supporting 90° traverse between rails, changing rails without manual intervention.

Application: Suitable for large-scale factory floor cross-tracking systems to realize cross-station heavy-duty transfer.

Turning Rail Transfer Cart

Specialized transfer cart for curved rail system, which can run smoothly along a certain bending radius.

Lifting capacity: 10 to 200 tons, according to the radius of the curve and car body size customized.

Characteristics: Adjustable turning radius, special design of wheelset structure, support curved track operation.

Application: Used in the workshop with limited space and curved rail design, corner process section and other scenarios.

High-Temperature Rail Transfer Cart

High-temperature rail transfer cart specially designed for high-temperature working conditions such as casting and heat treatment workshop.

Lifting capacity: 20 to 300 tons, usually carrying high-temperature ladles, castings or furnace charge.

Characteristics: special protective structure of the car body, equipped with heat-resistant insulation board, motor and electrical system with high-temperature protection.

Application: Widely used in foundries, steel mills, heat treatment workshops, smelting workshops and other high-temperature work areas.

Foundry Heavy Duty Rail Transfer Cart

Special transfer cart for heavy equipment or molten material transportation in foundry industry, emphasizing heavy load and heat resistance.

Lifting capacity: 50 ~ 300 tons, especially suitable for heavy mold or ladle handling.

Characteristics: Structural reinforcement design, thickened chassis, high temperature resistance, impact resistance, smooth running.

Application: Used in heavy load, high temperature or vibration frequent scenes such as steel ladle transfer, large casting handling, mold workshop.

Rail Shuttle Vehicle

Intelligent rail vehicle that can be operated back and forth between two points, often used for cyclic conveying tasks between production lines.

Lifting capacity: 1 to 50 tons, suitable for small and medium-sized pieces of continuous operation needs.

Characteristics: fast running speed, high positioning accuracy, suitable for automatic loading and unloading system, supports automatic charging.

Applications: automated production lines, three-dimensional warehouses, assembly lines and other multi-site, frequent conveying occasions.

Automatic Electric Transfer Cart

Intelligent transfer cart with autonomous operation capability, supporting path planning, obstacle avoidance, intelligent scheduling and other functions.

Lifting capacity: 1 ~ 100 tons, suitable for automation system integration.

Features: Integrated PLC/industrial control system, support RFID positioning, laser navigation and other technologies to realize unmanned operation.

Applications: automatic transfer scenarios in the fields of intelligent manufacturing, digital workshop, intelligent warehousing, AGV system supplementation, etc.

Working Principle

On rail transfer cart, is a kind of electric transportation equipment running along the preset track, through the motor drive wheels moving on the track, to realize the short distance transfer of materials or equipment. The core working principle is that the motor transmits power to the driving wheels through the speed reducer, drives the car body to move smoothly on the track, and realizes forward, backward, speed regulation and precise stopping through the electric control system (such as remote control, slide wire or battery power supply). Some high-end models are equipped with automatic positioning or anti-collision devices, which are suitable for heavy-duty and frequent transportation needs in factories, warehouses, docks and other scenes.

30 ton Customizable heavy duty Rail industrial transfer cart

rail guided heavy duty die transfer trolley

Power Supply Mode of Rail Transfer Trolley

According to the different use environment and running distance, Rail Transfer Trolley can adopt various power supply modes, and its core working principle is as follows:

- Battery power supply: the car body is equipped with high performance rechargeable battery to provide DC power for the transfer car, which has the features of no cable bondage, flexible turning, wide adaptability to the site, etc., and is suitable for complex paths or non-powered track scenes.

- Cable reel power supply: the external power is introduced into the car body through the cable reel installed on the car body, and the cable is automatically retracted and put away with the running of the car, which is suitable for short-distance straight-line running.

- Low-voltage rail power supply: insulated conductive rails are laid on both sides or in the middle of the rail, and the transfer vehicle takes power directly from the rail through the collector, which is suitable for long-distance and high-frequency operation scenarios, with good continuity and low maintenance cost.

Steering Mode

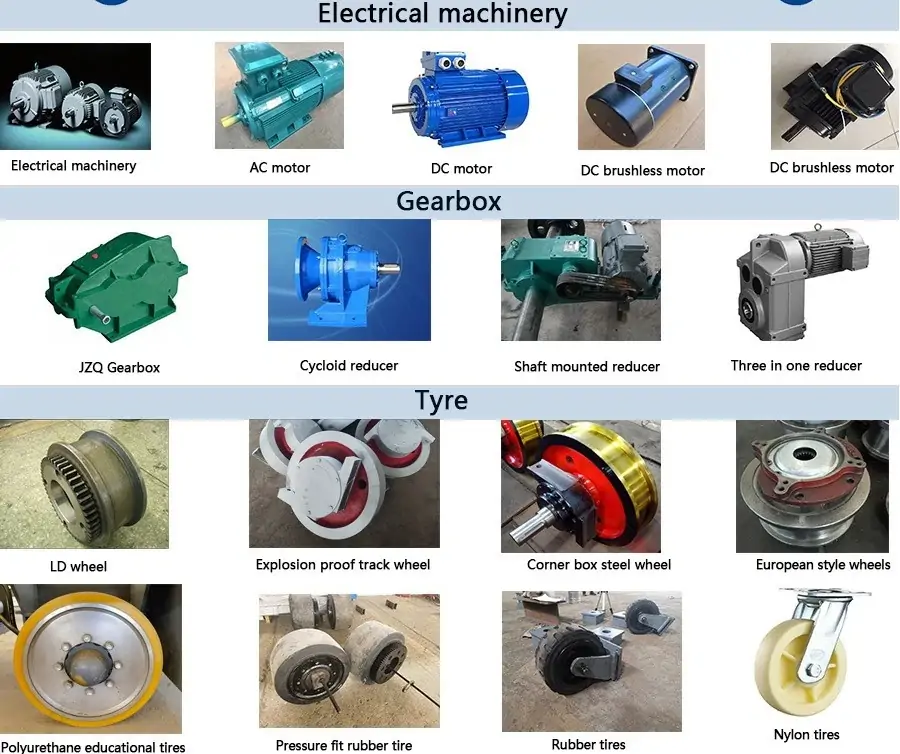

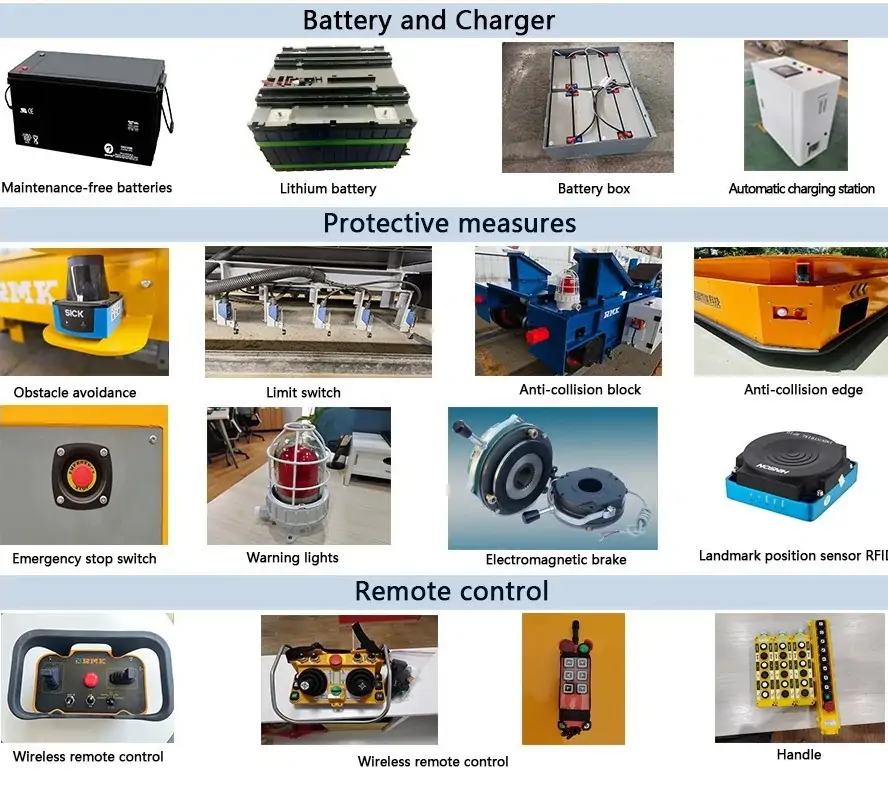

Parts

Specifications

| Parameter Name | Specifications |

|---|---|

| Rated Load Capacity (Ton) | Common specifications include 2t, 20t, 50t, 100t, 150t, etc., and can be customized according to requirements. |

| Tabletop Size (mm) | The length can be 2000, 4000, 5500, 6500, 10000, etc., and the width can be 1500, 2200, 2500, 2800, 3000, etc., all customizable as needed. |

| Tabletop Height (mm) | Generally 450, 550, 650, 900, 1200, etc., customizable. |

| Wheel Track (mm) | Such as 1200, 2800, 4200, 4900, 7000, etc. Different load capacities correspond to different wheel tracks. |

| Inner Distance between Rails (mm) | Commonly 1200, 1435, 2000, etc., depending on the type and design of the rails. |

| Number of Wheels(Piece) | Generally 4, and it may be 8 when the load capacity is large. |

| Ground Clearance (mm) | 50, 75, etc., which affects the passing ability. |

| Running Speed (M/min) | The speed range is generally between 0 – 18 and 0 – 25, and the speed is adjustable. |

| Motor Power (Kw) | 1, 2.2, 5, 10, 15, etc., determined according to the load capacity and running speed. |

| Battery Capacity (Ah) | 180, 330, 440, 600, etc., which affects the endurance |

| Battery Voltage (V) | 24, 48, 72, etc., related to the battery pack configuration. |

| Full-load Running Time (Hour) | Such as 4.32, 4, 3.3, 3.2, 2.9, etc., depending on the battery capacity and running conditions. |

| Running Distance per Charge (Km) | 6.5, 4.8, 4, 3.8, 3.2, etc., related to the battery performance and running speed. |

| Maximum Wheel Pressure (kN) | 14.4, 77.7, 174, 343.8, 265.2, etc., reflecting the load-bearing capacity of the wheels. |

| Reference Dead Weight (Ton) | 2.8, 5.9, 8, 14.6, 26.8, etc., related to the load capacity and structural design. |

Features

- Track-guided operation: traveling along the preset track, accurate positioning, no need for manual steering, suitable for straight line or circular fixed path transportation.

- High loading capacity: Heavy duty steel structure design, can be adapted to loads from 1 to 500 tons, meeting the needs of heavy materials or equipment handling.

- Flexible driving mode: support battery, low-voltage rail power supply, cable reel or skid line power supply, adapt to different working conditions and environments (e.g. explosion-proof, outdoor).

- Stable and low-noise operation: motor + reducer drive, smooth starting and stopping, low vibration, low noise, suitable for precision workshops or sensitive environments.

- Perfect safety protection: standard equipped with limit switch, anti-collision buffer, emergency stop button, some models are equipped with sound and light alarm or automated obstacle avoidance system.

- Strong expandability: can be customized with flat plate, hydraulic lifting or rotating table, and integrated with automation control system (e.g. PLC or RFID identification) to realize intelligent logistics.

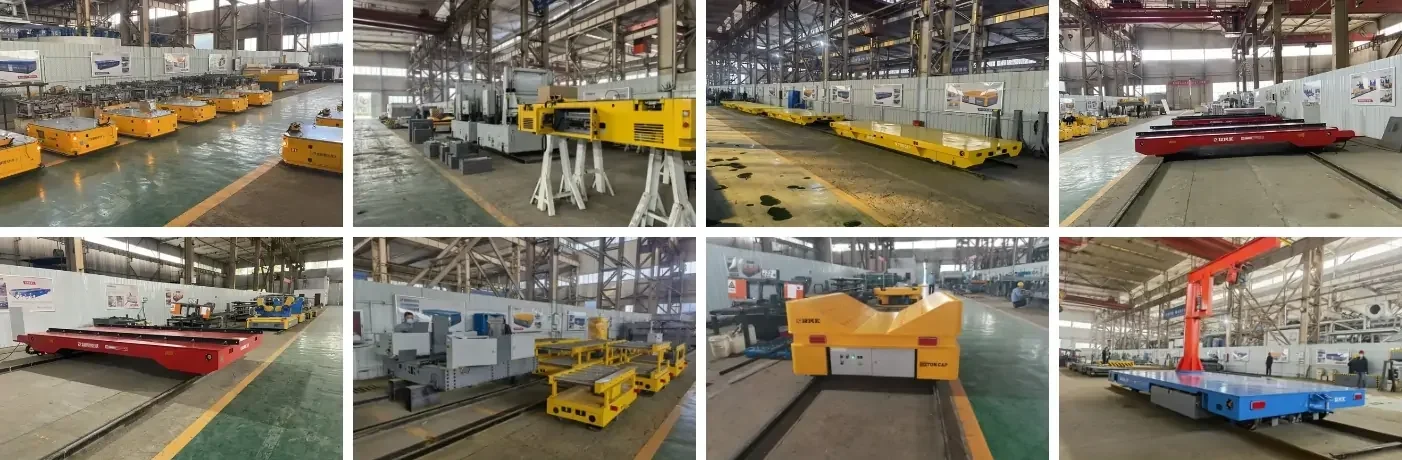

Trusted Rail Transfer Trolley Manufacturer & Supplier

As a leading rail transfer trolley manufacturer in China, Remarkable specializes in providing heavy-duty, customized rail transport solutions for global industries. We have advanced manufacturing, in-house engineering, and responsive after-sales support, Remarkable delivers reliability, safety, and long-term value. Contact Remarkable today for expert consultation and a customized solution.We’ll help you optimize your production flow with the right transfer trolley on rail system.

Certification

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control