An electric trackless transfer cart is an important equipment for modern industrial transportation, with flexibility and efficiency, widely used in workshops, warehouses, ports, and other scenes. In this article, we will systematically introduce the types of electric trackless transfer carts, common configuration parameters, and selection suggestions to help your business choose a handling solution to meet its needs.

Types of Electric Trackless Transfer Carts

According to different classification standards, trackless transfer vehicles can be divided into a variety of types. The following are common classifications and characteristics:

Classification according to driving mode

Electric Trackless Transfer Cart

With a battery as the power source, it is environmentally friendly and pollution-free, suitable for indoor or places with high environmental requirements.

Hydraulic Drive Transfer Cart

Driven by a hydraulic system, with high carrying capacity, commonly used in large-tonnage cargo handling.

Classified according to function and structure

Flat Transfer Cart

Adopting a no-fence or low-fence design, it can be expanded into a modular combination, used for extra-long or extra-wide cargo, suitable for transporting large equipment, steel, containers, etc.

hydraulic lift transfer cart

Hydraulic lift transfer cart is a kind of trackless handling equipment with a cargo lifting function, which is mainly used for adjusting the height of cargo during short-distance transportation, and is convenient for loading and unloading, stacking, or docking to other equipment (e.g., shelves, production lines, trucks, etc.). It comes with a hydraulic lifting platform, combining handling and lifting functions, and is widely used in logistics, manufacturing, warehousing, construction, and other fields.

Towed Transfer Cart

Without self-propulsion, it needs to be towed by a tractor (e.g., forklift) and is suitable for light or medium-duty transportation.

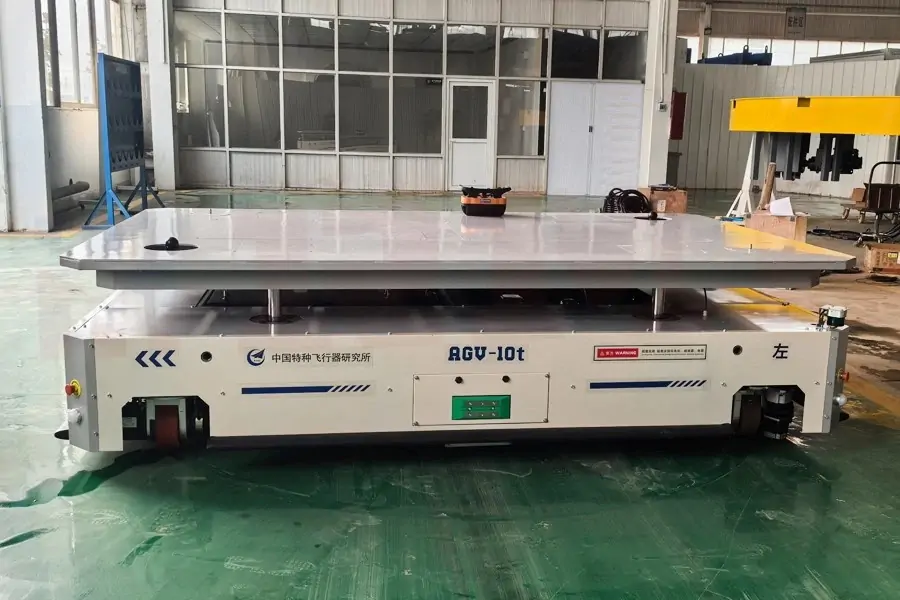

Intelligent AGV Transfer Cart

Equipped with laser navigation, magnetic navigation, or visual navigation to realize fully automatic unmanned transportation, suitable for intelligent factories.

Configuration of Common Electric Trackless Transfer Cart

| Configuration Category | Specific parameters | Parameter description | Suggestions for selection |

|---|---|---|---|

| Powertrain | Motor power | 3.5-15KW | The higher the load, the higher the power. 5T models usually have a power of 7.5KW. |

| Battery type | Lead-acid/lithium battery | Lead-acid is more economical, and lithium battery has long life and fast charging. | |

| Range | 4-12 hours | Continuous operation is recommended to choose more than 8 hours of range | |

| Travel System | Wheel Material | Cast steel + polyurethane cover rubber | Good abrasion resistance and ground protection |

| Number of Wheels | 4-8pcs | Heavy-duty type usually adopts a multi-wheel design, higher stability | |

| Ground Clearance | 50mm or so | Passage is an important indicator; uneven ground needs to increase the clearance. | |

| Control System | Operation Mode | Handle/Remote Control/Automatic | A wireless remote control is preferred for more flexible operation. |

| Safety Protection | Anti-collision radar/sound and light alarm | Recommended for factories/workshops/mixed traffic areas. | |

| Steering System | Differential speed/helm wheel steering | A more flexible steering wheel, suitable for a narrow space. | |

| Structural Parameters | Table Size | Customizable | Customized according to cargo size/space, it is recommended to reserve a certain operating space. |

| Frame Structure | Beam/box | A box-shaped structure has a stronger load-bearing capacity, suitable for heavy-duty operation. | |

| Self-weight load ratio | 1:3 to 1:5 | The smaller the ratio, the higher the structural strength |

How to Select a Suitable Trackless Electric Leveling Vehicle?

Define the load requirement

Determine the maximum transportation weight and add a 20% safety margin on this basis.

Consider the impact load (usually 1.5 times the rated load).

Be careful not to transport overweight, as it will shorten its life of the equipment.

Evaluate the operating environment

Ground conditions: usually concrete or steel plate ground; uneven ground needs to be pre-treated.

Space limitation: Measure the width of the passageway and determine the minimum turning radius.

Environmental characteristics: need to specify the special environment in advance, such as explosion-proof, waterproof, and other requirements.

Determine the operating parameters

Transportation distance: short distance within 50 meters, high-frequency operation is recommended to choose the battery life.

Working frequency: continuous operation is recommended to choose a lithium battery power supply with, longer duration.

Speed requirements: conventional operating speed of 0-20m/min, up to 30m/min.

Selection of control mode

Simple operation: it is recommended to choose handle control, which is more economical and practical.

Complex environment: it is recommended to choose wireless remote control operation, more flexible.

Automation demand: PLC or navigation system can be configured according to the demand of working conditions.

Maintenance cost

Battery life: Lead-acid batteries can usually be used for 2-3 years. The purchase price is lower, more economical, but the load capacity is small. Lithium batteries usually can be used for 5-8 years. The purchase cost is slightly higher, but suitable for heavy-duty load operation, long range, suitable for continuous operation, and is more widely used.

Tire replacement cycle: polyurethane wheels usually need to be replaced in 3-5 years.

Industry Application Recommendations

- Manufacturing industry: BWP 5 ~ 20 tons is recommended, suitable for medium load, with precise positioning and low noise.

- Metallurgical industry: BWP-50 ~ 300 tons is recommended, featuring high temperature resistance, strong load capacity, and stable operation.

- Logistics and warehousing: Recommended AGV intelligent navigation transfer vehicle with high degree of automation and programmable path.

- Harbor terminal: Recommended BWP 30~100 ton, wind and moisture resistant, long range.

How to Maintain an Electric Trackless Transfer Cart?

To ensure the long-term stable operation of the trackless electric flat car, you need to pay attention to daily maintenance and regular maintenance. The following are the precautions:

Battery Maintenance

Regularly check the electrolyte level (lead-acid batteries)

Avoid deep discharging, keep at least 30% of the battery level.

Keep the charging environment ventilated and dry

Mechanical components

Check tire wear monthly

Lubricate the steering mechanism and bearings regularly

Check and tighten all bolt connections

Electrical system

Check cable insulation

Clean the controller cooling components free of dust

Test all safety devices for proper function

Conclusion

Through the above systematic model selection suggestions, I believe you have a preliminary understanding of how to choose the right electric trackless transfer cart for your needs. If you want specific model recommendations and quotes, please contact Remarkable professional manufacturers to get customized solutions. We can help your business achieve efficient and intelligent material handling.