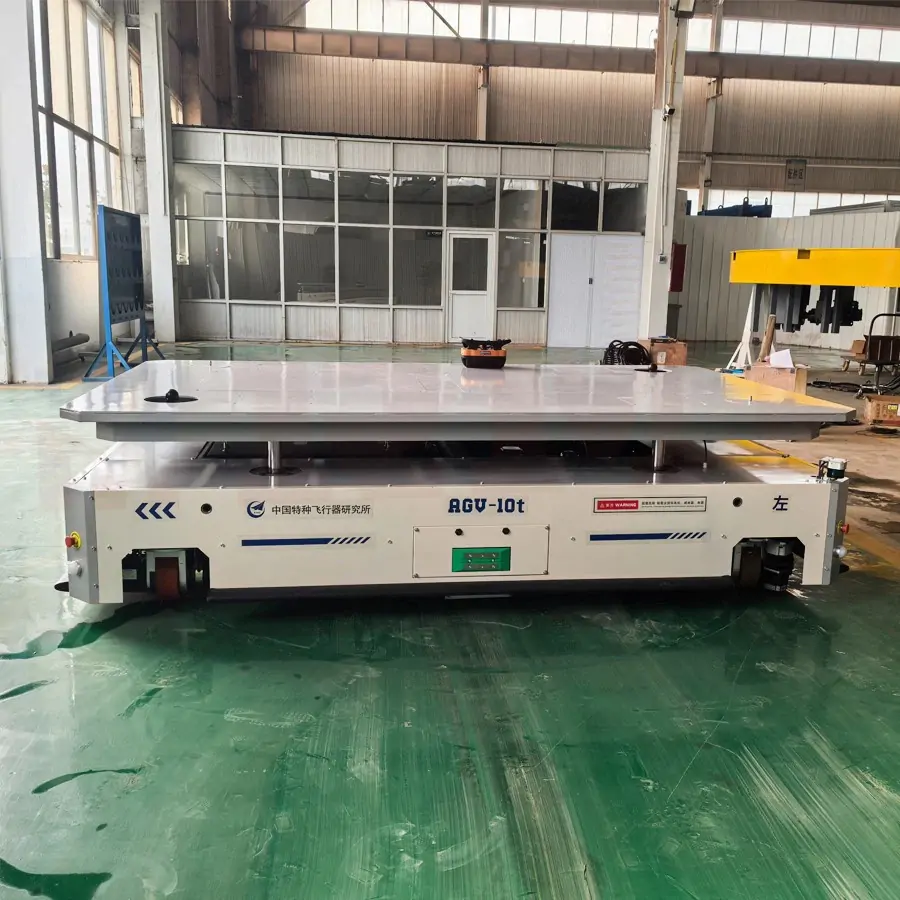

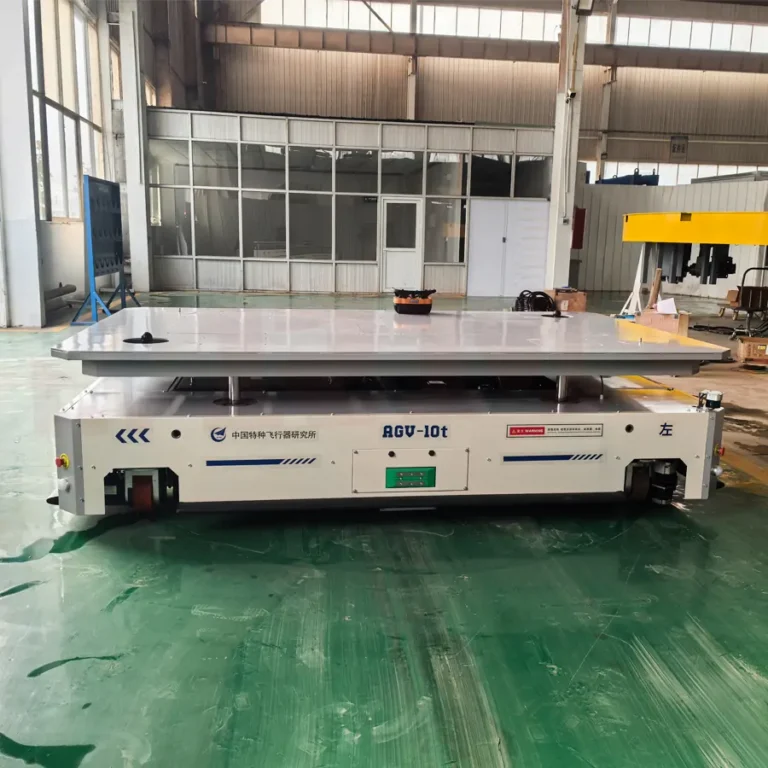

AGV Automated Guided Cart, also called AGV Transfer Cart, is a kind of intelligent handling equipment with automatic navigation technology, which can autonomously complete the transportation, loading and unloading, sorting and other operations of heavy materials in accordance with the preset path or dynamic planning route. It is widely used in intelligent manufacturing, warehousing and logistics, medical care, food processing and other industries, and is the core equipment of automated logistics system.

- Load capacity: 2 tons~500 tons

- Table size: customizable

- Operating speed: 0~25m/min

- Control mode: push button/remote control

- Functions: Laser SLAM/magnetic navigation/visual navigation, high-precision positioning, intelligent scheduling and control, and multi-machine cooperative operation.

Description

AGV Automated Guided Cart has a load capacity of 0 to 500 tons, can be equipped with various navigation methods (such as laser SLAM, magnetic navigation, visual navigation, etc.), and has the functions of high-precision positioning (±5mm~±10mm), intelligent scheduling and control, seamless connection with MES/WMS system, and cooperative workstation operation, etc. It can also be equipped with special tooling racks and workstations. It can also be equipped with special functions such as special tooling racks, jacking mechanism, roller conveyor, etc. to meet the material handling needs of different industries.

We provide full-process customized AGV transportation solutions, from solution design to system integration according to customers’ specific application scenarios, welcome to contact our professional team at any time.

Working Principle

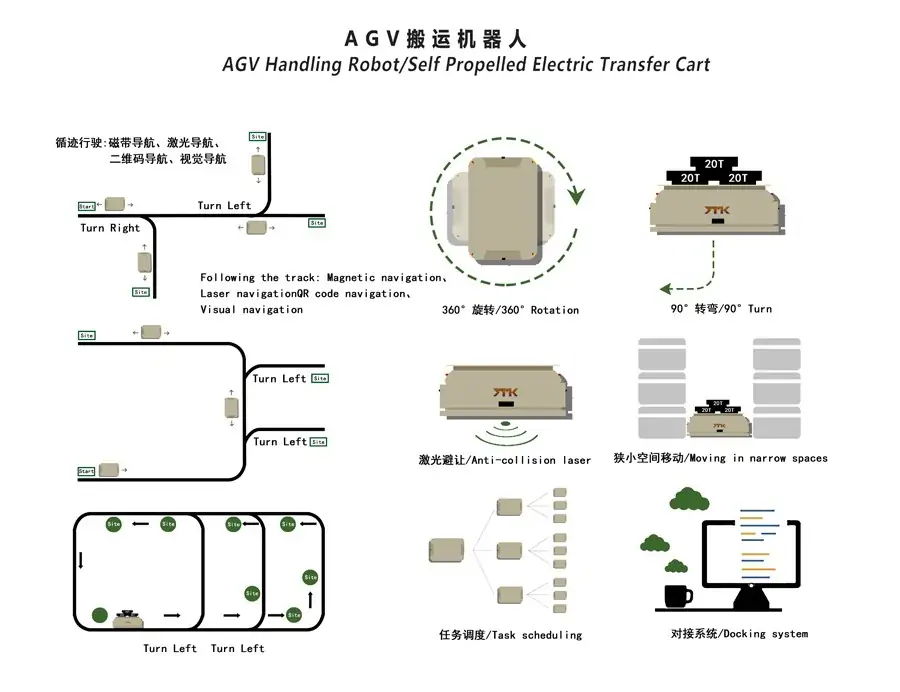

AGV Automated Guided Cart collects environmental data in real time through LIDAR/vision/magnetic navigation sensors and realizes high-precision autonomous positioning by combining SLAM algorithm. Then the central control system generates the optimal route based on the path planning algorithm and integrates multi-sensor data for dynamic obstacle avoidance. The servo drive system accurately controls the wheel movement to arrive at the target position smoothly.

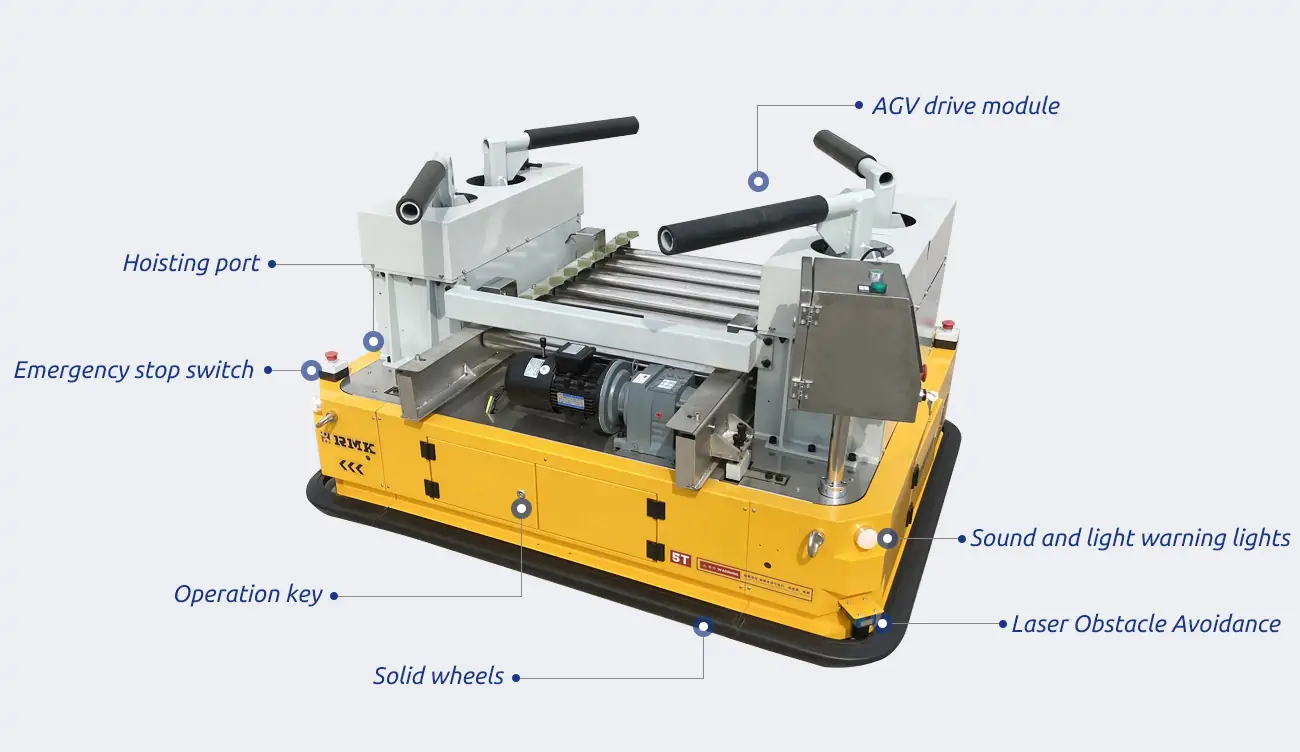

Parts

AGV Automated Guided Cart consists of navigation system, drive system, traverse/rotation, control system, power system, safety system, actuator and other components, the following are the functional characteristics of each component:

- Navigation system: including LIDAR/2D code/magnetic stripe/inertial navigation, which can realize precise positioning and path tracking, and adapt to different environments (SLAM technology supports trackless navigation).

- Drive system: consists of servo motor + reducer + drive wheel, provides smooth operation, supports forward/backward/traverse/rotation (omnidirectional AGV adopts McNamee wheel).

- Control system: composed of PLC/ICC + scheduling software, used to process sensor data and manage multi-vehicle cooperative operation (e.g. traffic control, task assignment).

- Power system: composed of Li-ion battery/supercapacitor, the endurance time is usually 4-12 hours, supporting fast charging or automatic charging.

- Safety system: Equipped with laser obstacle avoidance sensor/emergency stop button/anti-collision bar, conforms to ISO 3691-4 safety standard, automatically decelerates or stops when encountering obstacles.

- Actuator: composed of jacking platform/mechanical arm/roller conveyor, which can be adapted to different carriers (pallets, bins, containers) according to the demand to realize automatic loading and unloading.

Videos Show

Features

High-precision automated operation

AGV adopts advanced navigation technology (laser/vision/SLAM) to realize precise positioning and autonomous path planning, and can complete transportation tasks without human intervention.

Flexible Production Adaptation

Supporting rapid path reprogramming and modular modification (such as switching rollers / jacking mechanism), it can be flexibly adapted to the needs of production line changes, multi-species material handling, etc.

7×24 hours continuous operation

Equipped with intelligent charging system (automatic docking/fast charging), it realizes uninterrupted operation and greatly improves the handling efficiency, especially suitable for high-intensity and repetitive logistics scenarios.

Multi-machine Cooperative Intelligent Scheduling

Through the central control system, it realizes traffic control and task optimization allocation of AGV clusters, and supports the cooperative operation of multiple machines.

All-round safety protection

Compliant with ISO 3691-4 safety standards, integrated laser obstacle avoidance, emergency stop button and anti-collision strip triple protection to ensure operational safety.

Traceability of whole process data

Real-time recording of transportation data (time, path, load, etc.) provides digital basis for production optimization and helps enterprises realize transparent logistics management.

AGV Automated Guided Cart for Sale

Submerged AGV: Submerged in the bottom of the shelf to lift and carry (for standard pallets).

Forklift AGV: Replaces manual forklift and supports high shelves (e.g. Toyota automatic forklift).

Towed AGV: towing multiple material trucks (applicable to automotive assembly lines).

Composite robot: AGV + robotic arm to realize mobile gripping (e.g. UR collaborative robot + MiR trolley).

Specifications

| Capacity (t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 |

| Maximum Impact Load (t) | 7.5 | 15 | 22.5 | 30 | 45 | 60 | 75 |

| Chassis Structure | Steel plate welded beam structure | ||||||

| Steel Plate Thickness | 8 | 10 | 12 | 14 | 14 | 16 | 16 |

| Gross Vehicle Weight (t) | 4.3 | 5.3 | 6.6 | 7.9 | 8.8 | 10 | 10.5 |

| Maximum Wheel Pressure(t) | 2.8 | 4.6 | 4.3 | 5.6 | 7.7 | 10 | 12 |

| Ground Requirements | Concrete floor Steel plate floor | ||||||

| Overall Dimensions (mm) | 3000X2000 | 3600X2000 | 4000X2200 | 4500X2200 | 5000X2200 | 5500X2300 | 6000X2300 |

| Vehicle Height (mm) | 450 | 530 | 600 | 600 | 650 | 700 | 700 |

| Ground Clearance (mm) | 50 | ||||||

| Wheelbase (mm) | 1500 | 1700 | 1800 | ||||

| Wheelbase (mm) | 2500 | 3100 | 3400 | 3900 | 4300 | 4800 | 5200 |

| Turning Radius (mm) | 2501 | 3101 | 3401 | 3901 | 4301 | 1801 | 5201 |

| Turning Method | Seamless edge walking and turning | ||||||

| Turning Electronic Control Method | Electrical button control | ||||||

| Steering Mechanism | Mechanical operation | ||||||

| Motor Power (Kw) | 3.5 | 5 | 6 | 7 | 10 | 12 | 15 |

| Wheel Diameter (mm) | 300(4) | 350(4) | 400(4) | 400(6) | 500(6) | ||

| Wheel Material | ZG55+ | ||||||

| Travel Speed (m/min) | 0-15 | 0-12 | |||||

| Braking Method | Electromagnetic brake | ||||||

| Ground Leveling Adjustment | Mechanical automatic adjustment | ||||||

| Remote Control Operation Method | Wired + wireless connectivity | ||||||

Application

Manufacturing: for automotive assembly line material distribution, electronic workshop SMT shelf transfer, and heavy machinery parts handling.

Warehousing and logistics: for “goods to people” picking in e-commerce sorting centers, automated three-dimensional warehouse access.

Medical: for automatic distribution of drugs/devices in hospitals, and sample transfer in laboratories.

Food & Beverage: Cold chain storage and handling, empty and full pallet circulation on packaging lines.

Aerospace: for large-sized aircraft parts transfer (high load-bearing AGVs, e.g., 50-ton class).

Cases Show

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control