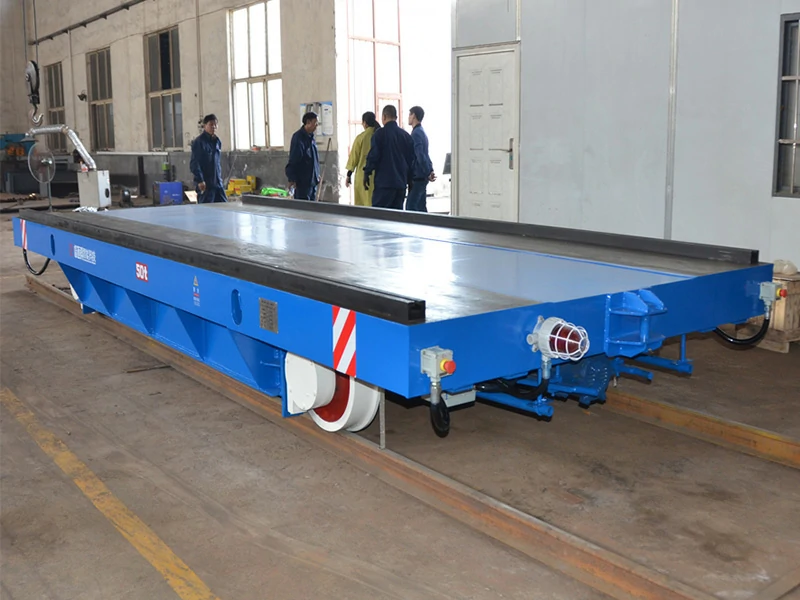

An AGV system, also known as an Automated Guided Vehicle system, comprises an AGV transfer cart and control systems to achieve autonomous material handling within factories or warehouses. Utilising laser or magnetic strip navigation, it can automatically avoid obstacles, plan routes, and precisely interface with production lines. This reduces manual intervention while improving transport safety and operational accuracy.

A 3-ton lift transfer AGV supplied by REMARKABLE incorporates an AGV system comprising navigation, control, material handling execution, and safety modules. Beyond standard transport, it performs lifting, rotation, and workstation docking operations, substantially enhancing logistics efficiency. This article explores the AGV system, detailing its component modules below.

AGV Navigation System

The navigation system forms the core of AGV autonomous mobility, enhancing positioning accuracy and path planning capabilities within factories or warehouses. Common navigation methods include:

- Magnetic Tape Navigation: Guides vehicles via ground-mounted magnetic tape or studs, offering low cost and simple installation, suitable for fixed-path transport.

- Laser Guided Navigation: Utilises laser scanning of environmental reflection points for positioning, offering high precision and adaptability to dynamic conditions.

- Vision Guided Navigation: Employs cameras to recognise floor markings or environmental features, providing high flexibility and suitability for complex operational scenarios.

A 3-tonne lifting AGV transfer vehicle from REMARKABLE employs laser navigation, enhancing transport accuracy and safety. Following navigation system selection, task allocation and scheduling for AGVs rely on the control system.

AGV Control System

The control system primarily manages task assignment, path planning, and coordinated operation of multiple AGVs. Key components include:

- Vehicle Controller: Executes path tracking, speed regulation, and lifting operations to ensure stable AGV guidance vehicle performance.

- Fleet Management System (FMS): Manages simultaneous operations of multiple AGVs, enhancing transport efficiency and preventing vehicle collisions.

- Data Interface: Integrates with ERP, MES, or WMS systems to coordinate production planning with logistics operations, boosting efficiency.

Through strategic AGV system deployment, enterprises can establish efficient logistics networks, reducing empty runs and congestion. While the navigation and control system facilitates material handling tasks, the execution relies on the design of the handling module and lifting mechanism.

AGV Handling Module

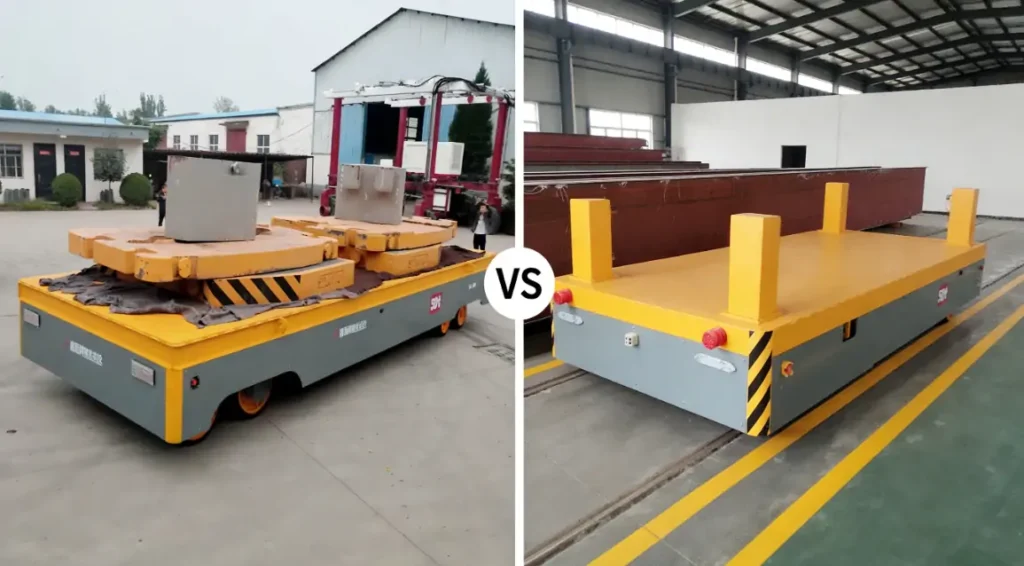

Handling modules impact an AGV’s load capacity and operational flexibility, particularly for lift-type AGVs:

- Lift Platform: Utilising hydraulic or electric drive, it enables height adjustment for loads ranging from 0.5 to 20 tonnes.

- Load Bed / Pallet Table: Designed as flat surfaces, V-shaped or roller tables to accommodate diverse cargo specifications.

- Rotation / Positioning Mechanism: Features such as 360° rotation or automatic alignment facilitate precise docking with production stations or handling equipment.

All AGV handling systems can be customised to meet specific requirements. Should you have relevant needs, please contact us for the optimal solution. Safety systems are paramount during handling operations, ensuring protection for both cargo and personnel.

AGV Safety System

The safety system constitutes a vital component of AGV systems, ensuring stable equipment operation while safeguarding personnel and minimising accidents. Common safety features include:

- Laser Obstacle Detection: Scans the immediate vicinity via laser beams to detect obstacles in real-time, triggering automatic deceleration or halting.

- Infrared Sensors: Detect nearby objects and personnel to prevent collisions, particularly effective in confined passages or dynamic work zones.

- Emergency Stop Button: Operators can immediately activate emergency braking to halt the vehicle swiftly in abnormal situations, mitigating safety risks.

- Audible and Visual Alarm Systems: Emit alerts when the AGV starts, stops, or encounters anomalies, warning nearby personnel and enhancing site safety.

- Safety Management System: Some high-end AGVs feature centralised monitoring and fault warning capabilities, continuously tracking vehicle status to prevent potential hazards.

Through these multi-layered safety designs, AGV systems enhance operational efficiency while reducing accident risks during heavy-load transport, enabling efficient and secure automated logistics operations.

Conclusion:

This article has provided a detailed overview of AGV system modules. AGV transfer vehicles equipped with comprehensive systems deliver greater flexibility, efficiency, and safety. If you require an AGV automated guided vehicle, please contact us. We offer bespoke services and optimal solutions tailored to your requirements.