The agv roller conveyor transfer car is an automated logistics device within the automated guided vehicle category, capable of autonomously transporting materials with flexibility and efficiency. This article will provide an in-depth analysis of its definition, characteristics, application domains, and factors to consider when selecting a manufacturer.

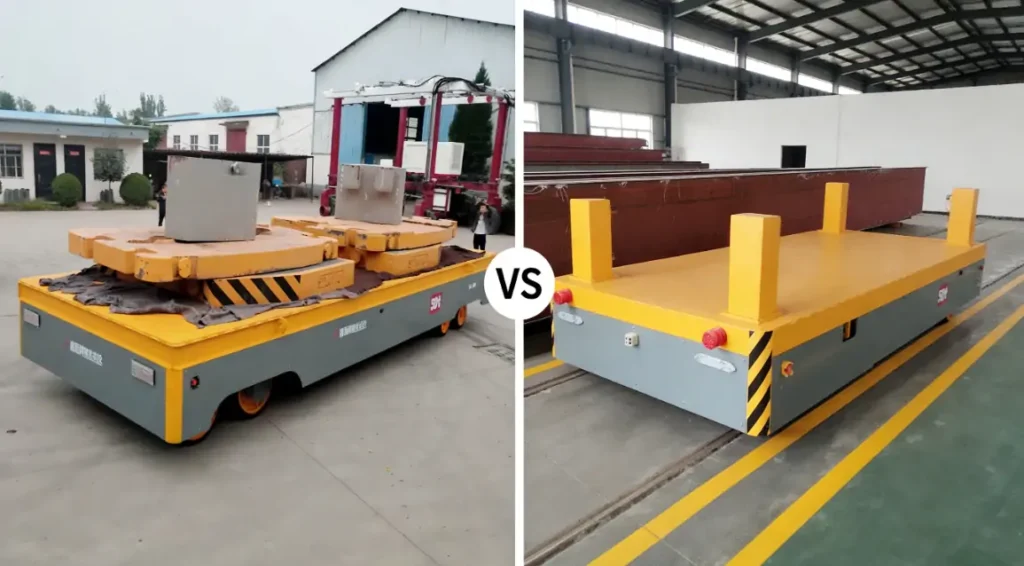

What is a Roller Conveyor Transfer Car?

The roller conveyor transfer car is an industrial transfer device featuring an integrated roller conveyor structure on its upper platform, also termed an AGV roller transfer cart. Unlike conventional flatbed transfer cars, it enables automatic rolling transfer of materials between workstations via rollers, eliminating manual handling or secondary lifting. When interfacing with conveyor lines or production equipment, pallets, fixtures, or workpieces can be loaded/unloaded through the rollers, significantly enhancing logistics efficiency.

Having briefly introduced the roller conveyor transfer vehicle, let us now examine its advantages.

Advantages of Roller Conveyor Transfer Cars

Roller Conveyor Platform

The top platform of the AGV roller conveyor transfer car features multiple rows of stainless steel rollers, enabling the automatic rolling in and out of materials. This effectively reduces manual pushing and pulling operations, making it suitable for automated production lines requiring frequent loading and unloading.

Integrated AGV Navigation System

As a roller AGV cart, it utilizes navigation methods such as magnetic strips, QR codes, laser guidance, or SLAM technology to achieve autonomous movement and precise positioning, thereby fulfilling the requirements of unmanned logistics.

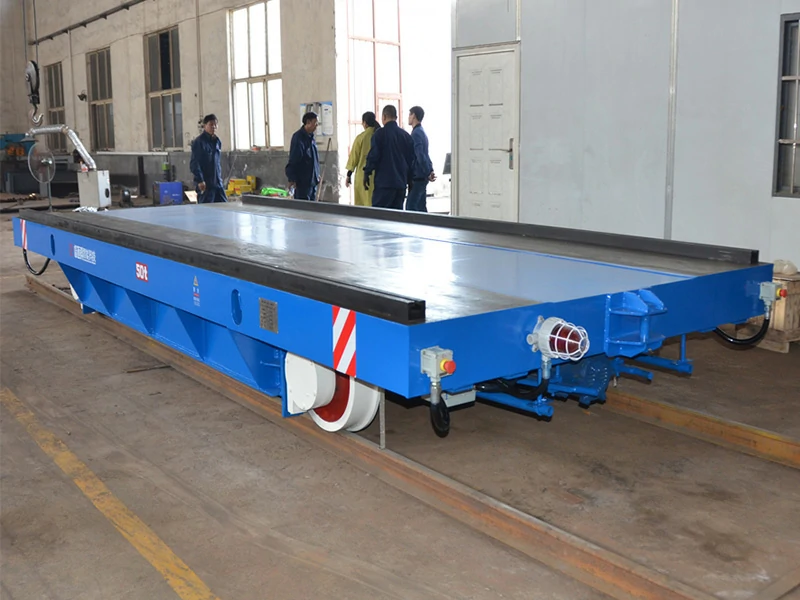

High Load Capacity

Constructed with high-strength steel structures and industrial-grade drive systems, it maintains stable operation under medium-to-heavy loads and high-frequency usage, making it suitable for long-term deployment as industrial-grade transfer equipment.

Highly -Customized

Wheel dimensions, spacing, platform size, load capacity, and control methods can be tailored to on-site conditions, adapting to diverse production lines and complex manufacturing processes.

High Safety

Automated rolling transfer reduces safety risks associated with manual intervention while maintaining a stable logistics cadence, enhancing overall production efficiency.

The roller conveyor transfer car offers flexibility, efficiency, and safety. It finds extensive application across multiple industries. Below, we explore its primary application domains.

Application Areas for Roller Conveyor Transfer Cars

AGV roller conveyor transfer cars feature efficient docking capabilities and stable operational performance, finding extensive application in the following sectors.

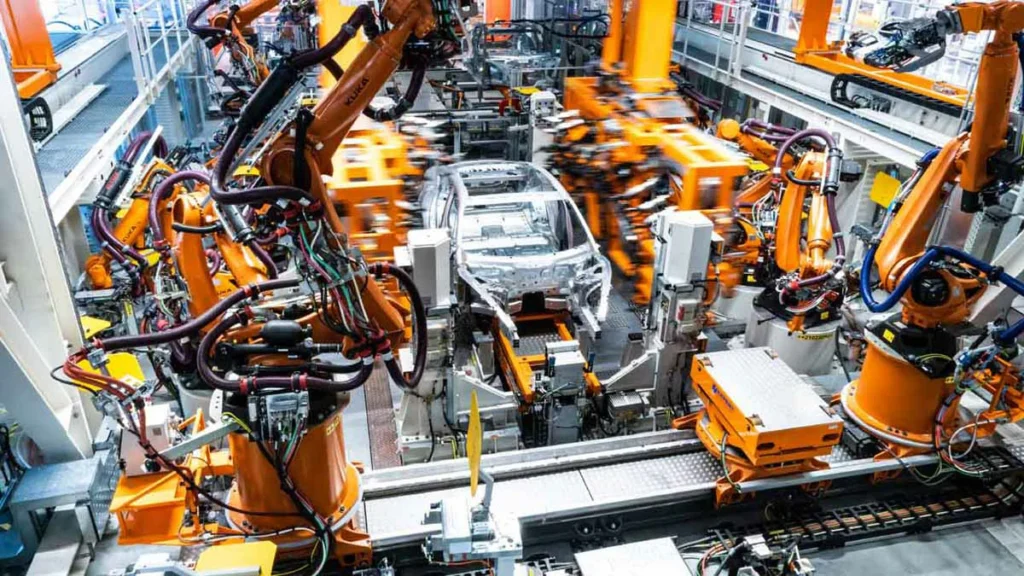

Automated Assembly Lines: Commonly employed in automotive and home appliance assembly sectors, they interface precisely with conveyor lines and production workstations. This enables continuous material transfer between assembly stations, enhancing overall efficiency.

Manufacturing Workshops: Frequently utilized between machining, welding, and inspection processes, they ensure stable and efficient movement of workpieces and components. This reduces material accumulation and waiting times, thereby improving workshop operational efficiency.

Warehousing and logistics: Serving as automated transfer equipment between storage systems and production lines, roller conveyor AGV enables intelligent material diversion, automated transport, and scheduling, elevating automation levels.

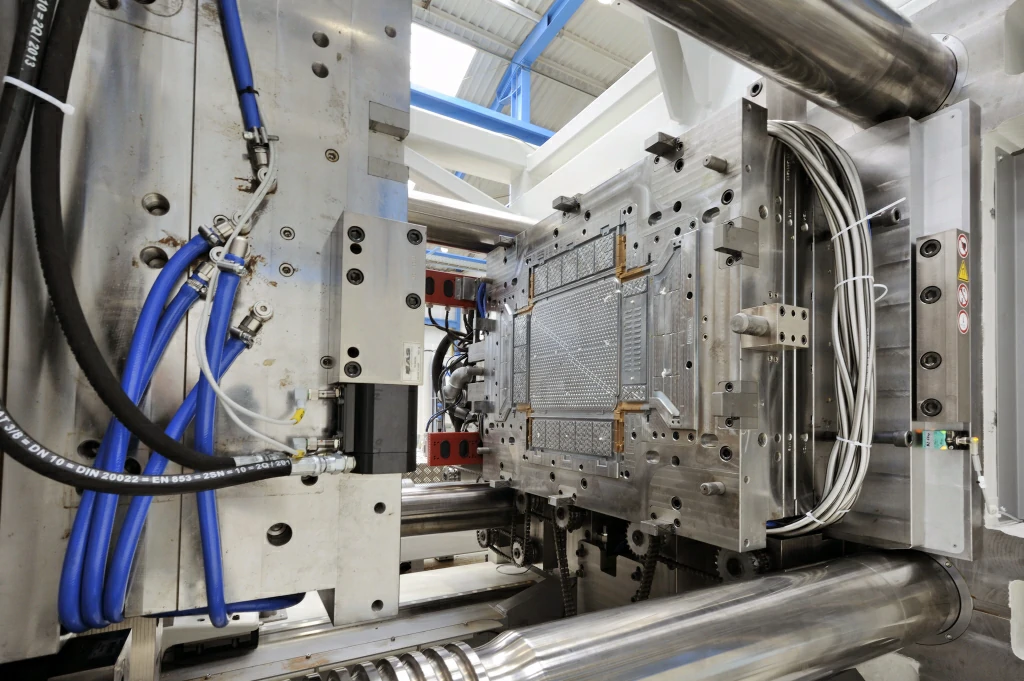

Tooling and moulding industry: Designed for large-volume, heavyweight, or high-value tooling, moulds, and heavy components, they facilitate smooth, secure rolling transfer, minimizing handling risks and safeguarding equipment and personnel.

Automated Assembly Lines

Automated Assembly Lines Manufacturing Workshops

Manufacturing Workshops Warehousing and Logistics

Warehousing and Logistics Moulding Industry

Moulding Industry

AGV roller conveyance transfer carts are suitable for diverse applications, including light-load assembly and heavy tooling, accommodating various complex operational conditions.

If you need an AGV automated guided vehicle, you may select a manufacturer with professional design and customization capabilities. Below, we shall analyze how to choose a suitable transfer cart manufacturer.

How to Choose the Right Manufacturer for Roller Conveyor Transfer Cars

Selecting a reliable AGV roller conveyor transfer car manufacturer is crucial for the smooth implementation and long-term operation of your project.

- Customization Capabilities: The manufacturer should offer bespoke designs tailored to actual working conditions and client requirements, rather than being limited to standardized products.

- AGV Technology and Project Experience: The transfer cart supplier must possess mature technical expertise to enhance navigation precision and system stability.

- Quality Control and Safety Standards: The AGV cart manufacturer should maintain comprehensive manufacturing and inspection systems to ensure long-term, stable equipment operation.

- After-Sales and Technical Support Capabilities: Industrial transfer vehicle manufacturers require professional service teams to address equipment commissioning, subsequent upgrades, and maintenance issues.

REMARKABLE is a specialist supplier dedicated to the R&D and manufacturing of industrial transfer vehicles and AGVs, with extensive experience in customized design and production across diverse transfer vehicle types. Our expertise in structural design, system integration, and industry applications enables us to deliver reliable, flexible automated logistics solutions.

Conclusion:

AGV roller conveyor transfer cars integrate automated guidance technology with roller conveyor structures, offering an efficient, safe, and customizable material handling solution. Should you require a dependable transfer car manufacturer, please contact REMARKABLE for professional support and customized services.