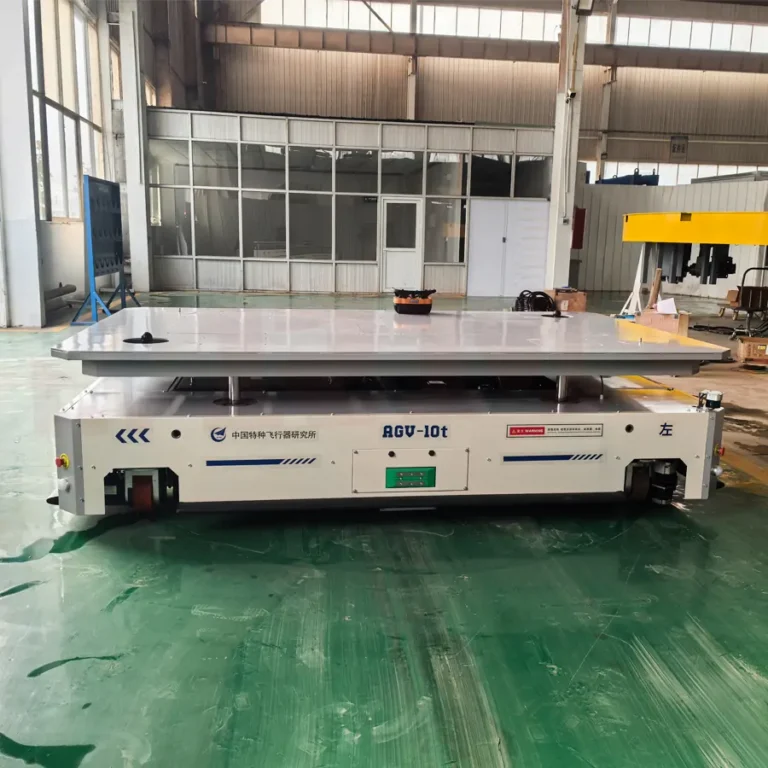

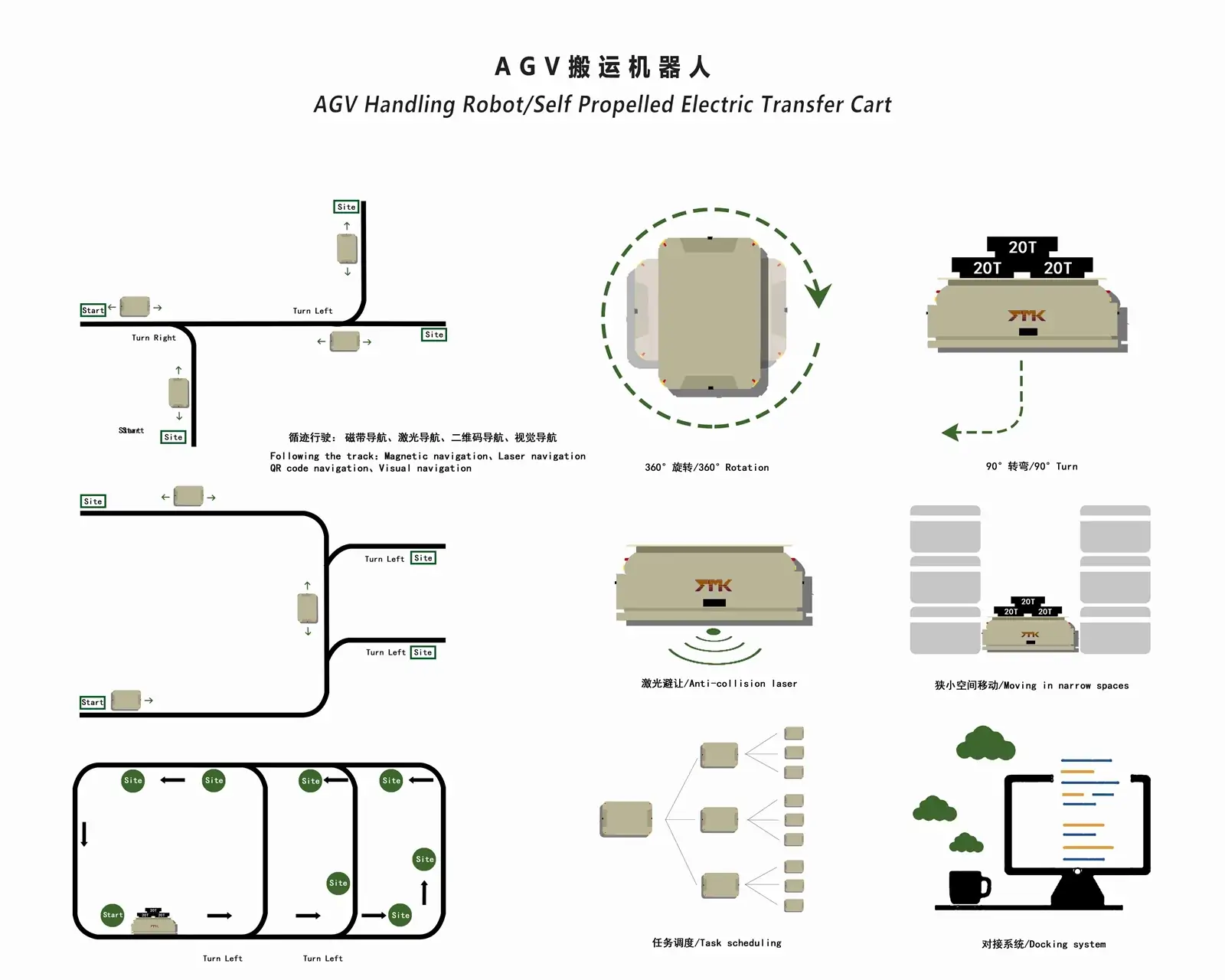

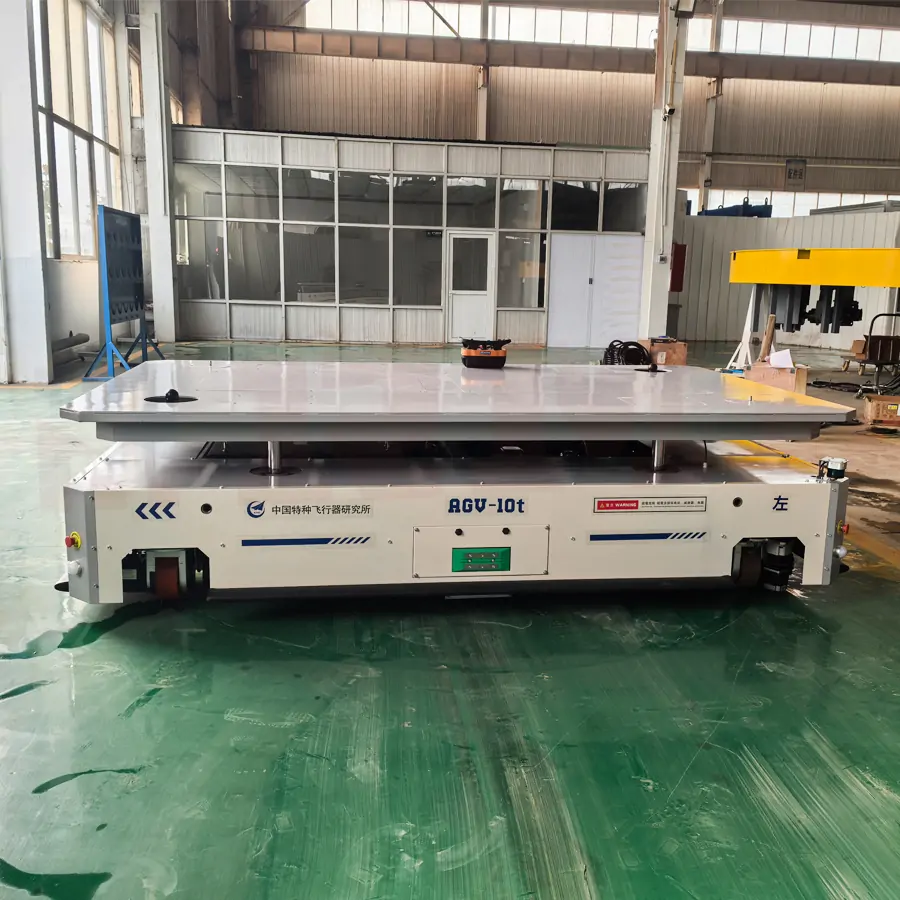

Automatic Transfer Cart, referred to as AGV, is a highly intelligent unmanned transport equipment. AGV automated guided cart system usually uses batteries as a power source, has an advanced navigation control system, and can autonomously drive along a predetermined path to complete tasks such as material handling and cargo transportation. It is widely used in industrial production environments such as logistics, warehouses, and cargo yards.

- Capacity: 1 ~ 10 tons

- Power Source: Battery / Diesel

- Control: Remote Control / Autonomous

- Wheels: Rubber / Polyurethane

- Movements: 360° rotation (Carousel) and crab movement (horizontal and diagonal movements)

Working Principle

Automatic Transfer Cart refers to an intelligent transportation equipment that relies on one or multiple composite positioning and guiding technologies to autonomously move and perform handling tasks in workshops or warehouses. Through preset or real-time generated path planning, AGV Automatic Transfer Carts can achieve material handling without human operation. They are equipped with multiple protective measures during transportation and can flexibly integrate into modern production and management assembly lines, addressing material handling needs in intelligent or special environmental scenarios across various industries. Automatic Load Transfer Carts offer numerous advantages, such as high transportation efficiency, energy conservation, reliable operation, and the ability to achieve flexible transportation.

AGV Automatic Transfer Carts do not require fixed installations like tracks or support frames in their operational areas, and they are not restricted by venue, roads, or space. They can directly receive instructions from clients’ host computers to realize automated handling processes.

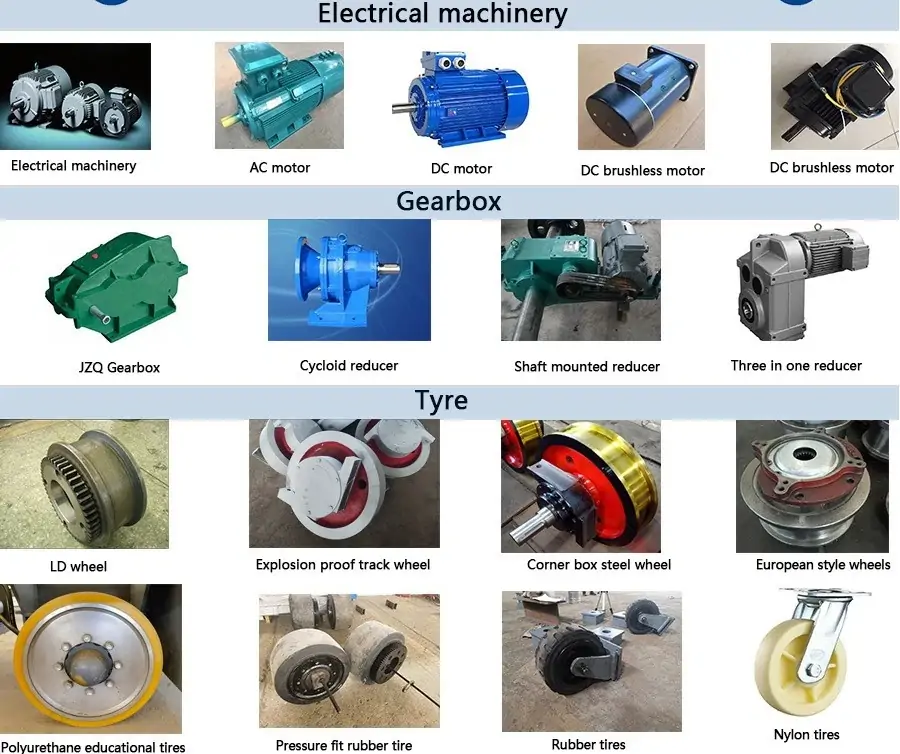

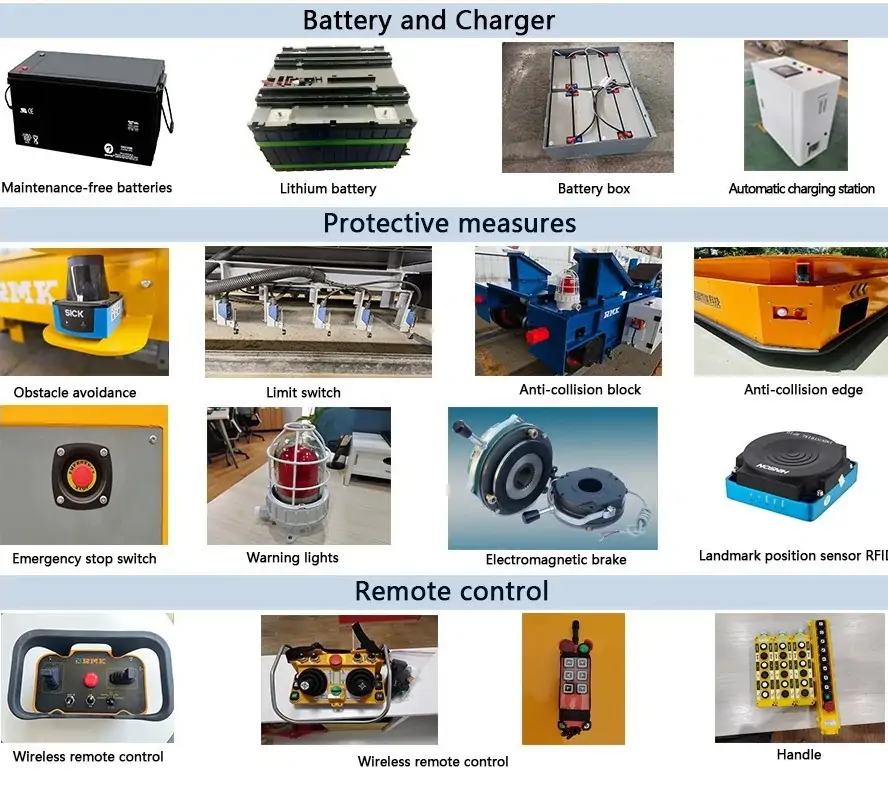

Parts

The AGV components mainly include several major parts such as drive, control, sensing and auxiliary systems.

- The drive system is mainly composed of motor, reducer and tires, which is used to drive the Transfer Cart to move.

- The control system consists of controllers, sensors and actuators, which are used to control the moving direction and speed of Transfer Cart.

- The sensing system consists of various sensors, which are used to sense the surrounding environment in real time and help Transfer Cart carry out path planning and obstacle avoidance.

- The auxiliary system includes charging, drainage, lighting and other functional modules, which are used to meet the needs of Transfer Cart in various environments.

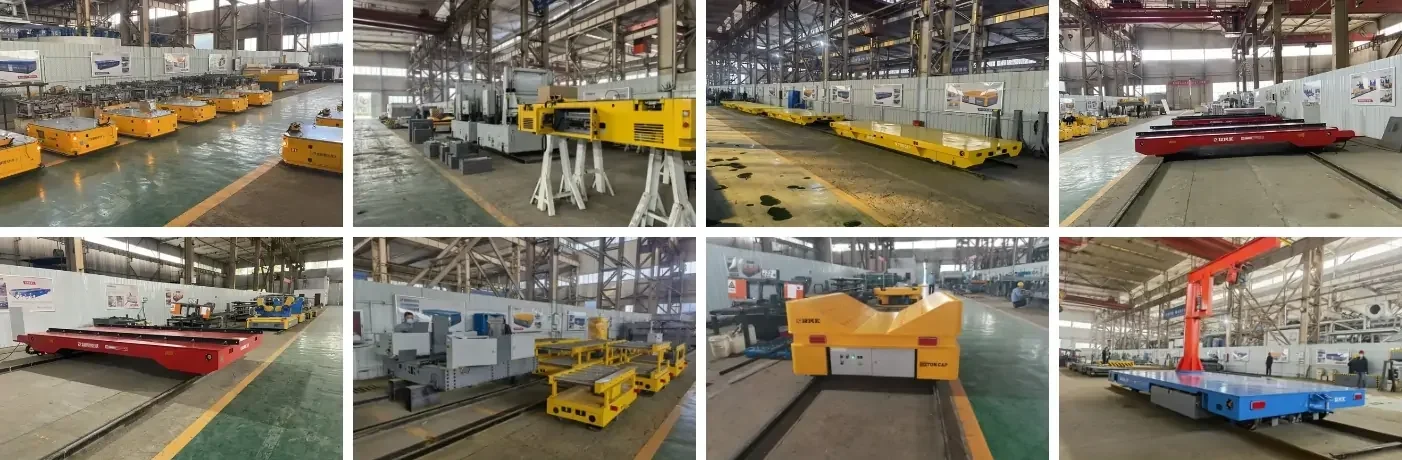

Different Types of Automatic Transfer Carts

Remarkable offers various types of Automatic Transfer Carts to meet different handling needs. These include Heavy load robot, Heavy load AGV /ARM, RGV Automatic rail transfer cart, AGV Automated Guided Cart. Below, we will explore the unique features, applications, and benefits of these automated transfer carts to help you choose the ideal one for your operation. solutions for your operation.

Heavy Load Robot

A high-load, high-precision industrial robot designed for heavy-duty material handling, usually equipped with a robotic arm or fixture to perform precise gripping, handling and placement tasks.

- High load capacity: typically 0.2 tons to 10 tons

- Operational flexibility: can be adapted to different workpieces and paths

- Customization options: optional grippers, suction cups, or customized end-effector

- Collaboration capability: some models support human-machine collaboration mode

Heavy Load Robot is widely used in the following scenarios:

- Heavy Manufacturing: e.g. automotive chassis, aerospace component handling, large equipment assembly lines

- Foundry and Forging: high temperature/high risk environments such as steel mills, metallurgy, etc.

- Ports and Warehouses: heavy load stacking of containers, large cargoes

Heavy Load AGV Automatic Trackless Transfer Cart

Heavy load automated handling system combining AGV (Automated Guided Vehicle) and robotic arm (ARM) to complete transportation and loading/unloading tasks in an unmanned environment.

- AGV+Robotic Arm Collaboration, Integrated Mobility+Gripping

- Load from 1~50 tons, adaptable to large workpieces

- Intelligent navigation, e.g., laser/vision SLAM, dynamic obstacle avoidance

- Automatically docked to production lines, racks or machine tools

- Supports MES/WMS system integration

Heavy Load AGV/Automatic Trackless Transfer Cart is widely used in the following scenarios:

- Heavy machinery manufacturing: e.g. construction vehicles, ship component transportation

- Automated warehousing: handling of large containers, steel coils

- Flexible production lines: automated transfer between multiple processes

RGV Rail Guided Vehicle

An automated transportation equipment running along a fixed track, suitable for high-precision, high-repeat linear or circular path handling.

- Track navigation, stable operation

- High speed and efficiency, speed up to 2m/s, suitable for scenes with strict beats

- Simple structure, easy maintenance, low failure rate

- Load capacity up to 50 tons, suitable for heavy materials

- Multi-vehicle coordination, track can be designed to fork, support multi-vehicle scheduling

RGV Rail Guided Vehicle is widely used in the following scenarios:

- Automated three-dimensional warehouses, inter-shelf shuttles

- Automotive welding/painting lines, bodywork spotting

- Mechanical loading and unloading, fixed-rail cyclic operation

AGV Automated Guided Cart

Unmanned carts with flexible navigation technology, suitable for small and medium-sized material transportation with dynamic path adjustment.

- Flexible navigation, e.g. laser/QR code/magnetic stripe, path programmable

- Lightweight design, loads typically 50kg~2 tons

- Highly adaptable, dynamically adjustable routes for complex environments

- Multi-machine collaboration, supports hundreds of AGVs for co-scheduling

- No infrastructure modifications required, low-cost deployment

AGV Automated Guided Cart is widely used in the following scenarios:

- Electronics and pharmaceutical industries, lightweight material distribution

- E-commerce warehousing, goods-to-person picking

- Flexible production lines, multi-species and small batch logistics

Videos Show

Specifications

| Model | 2t | 20t | 50t | 100t | 150t | |

| Rated Load (t) | 2 | 20 | 50 | 100 | 150 | |

| Table Size (mm) | Length (L) | 2000 | 4000 | 5500 | 6500 | 10000 |

| Width (W) | 1500 | 2200 | 2500 | 2800 | 3000 | |

| Height (H) | 450 | 550 | 650 | 900 | 1200 | |

| Wheel Base (mm) | 1200 | 2800 | 4200 | 4900 | 7000 | |

| Rail Inner Gauge (mm) | 1200 | 1435 | 1435 | 2000 | 2000 | |

| Wheel Diameter (mm) | 270 | 350 | 500 | 600 | 600 | |

| Wheel Quantity | 4 | 4 | 4 | 4 | 8 | |

| Ground Clearance (mm) | 50 | 50 | 50 | 75 | 75 | |

| Running Speed (min) | 0-25 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor Power (kw) | 1 | 2.2 | 5 | 10 | 15 | |

| Running time When Full Load | 4.32 | 4 | 3.3 | 3.2 | 2.9 | |

| Running Distance for Once Charge (KM) | 6.5 | 4.8 | 4 | 3.8 | 3.2 | |

| Reference Weight (t) | 2.8 | 5.9 | 8 | 14.6 | 26.8 | |

| Recommended Rail Model | P15 | P24 | P43 | QU100 | QU100 | |

Customized Automatic Transfer Cart Solutions

We provide fully customized automatic transfer cart solutions, according to your actual working conditions, flexible design of different sizes, specifications, structural forms and carrying capacity of the model.

| Type | Navigation mode | Load capacity | Flexibility | Applicable scenarios |

|---|---|---|---|---|

| Heavy Load Robot | Robotic arm trajectory programming | 1~50 tons | High | High-precision heavy-duty handling/assembly |

| Heavy AGV/ARM | Laser/SLAM | 1~50 tons | Medium-high | Mobile heavy-duty loading and unloading |

| RGV | Fixed track | 1~100 tons | Low | High-speed, fixed-path transportation |

| AGV | Laser/vision/magnetic stripe | 50kg~2 tons | High | Dynamic path, flexible logistics |

Features

High load capacity

The load capacity is 1-1000 tons, which is suitable for heavy industry and manufacturing and other large load scenarios.

Automatic operation

With automatic navigation and path control function, it can realize unmanned operation and improve transportation efficiency.

Diversified navigation methods

Supports magnetic stripe, laser, inertial or rail navigation to meet the needs of different sites and operating environments.

Perfect safety system

Equipped with laser obstacle avoidance, emergency stop, buzzer and light alarm and other safety devices to ensure the safety of human and machine operation.

Sturdy and durable structure

Adopting high-strength steel and industrial-grade drive system, adapting to complex working conditions and long-term operation.

Customizable design

It can be flexibly customized according to the parameters of load, size, running path and control system to meet the individual needs of different customers.

Application

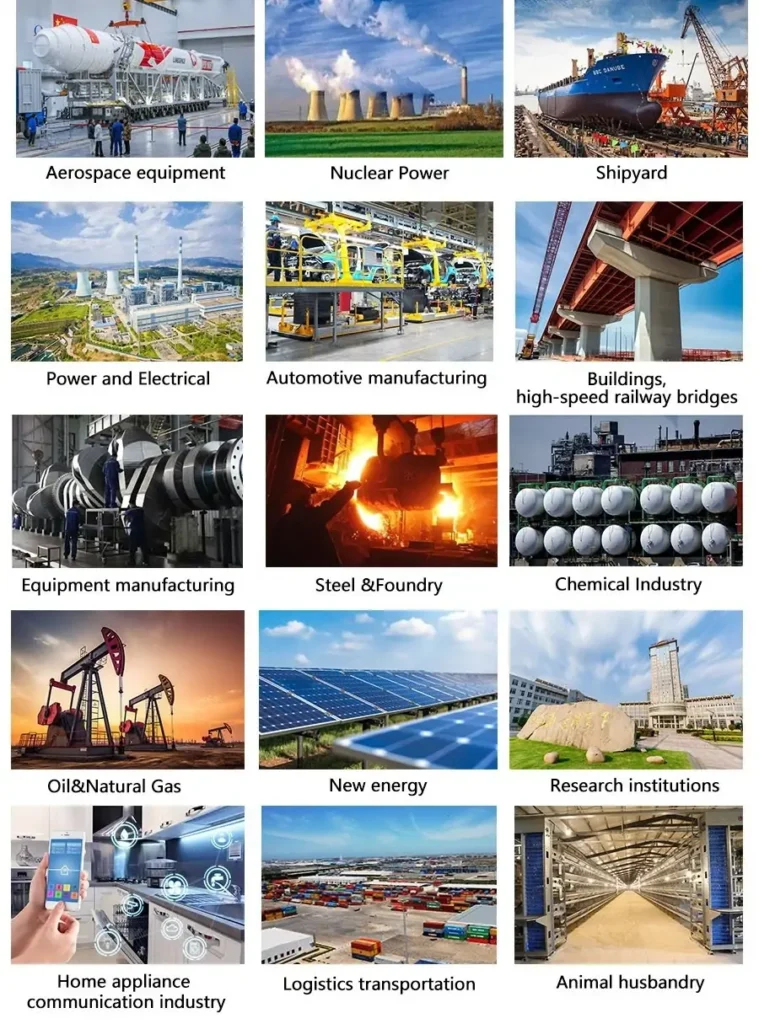

Automatic Transfer Cart is widely used in industries such as automotive, power, chemical, steel, military aerospace, nuclear power, mechanical manufacturing, port cargo yards, and warehousing logistics. REMARKABLE can design and customize comprehensive handling solutions tailored to customer needs.

- Automotive Manufacturing: Enables flexible, precise material delivery for improved assembly efficiency and multi-model production line compatibility.

- Power/Chemical/Steel Industries: High-temperature & explosion-proof design ensures safe bulk material handling in hazardous environments.

- Military & Aerospace: Supports heavy-duty (100+ ton capacity) and high-precision component transfer with reliable positioning.

- Nuclear Power: Radiation-resistant electric drive enables unmanned operation in high-risk zones while maintaining cleanroom standards.

- Machinery Manufacturing: Modular design seamlessly integrates with CNC/machining lines to optimize material flow.

- Ports & Freight Yards: Autonomous container/bulk cargo transfer with intelligent routing for 24/7 operations.

- Warehousing & Logistics: Integrates with WMS/AGV systems to reduce picking errors and cut labor costs by 70%.

Automatic Transfer Cart Manufacturer

As a leading Automatic Transfer Cart Manufacturer.Remarkable provides customized industrial handling solutions and various application material transport solutions to the world. To solve material handling problems for important customers in industries such as Aerospace industry, nuclear power, steel,shipyard,heavy industry, manufacturing, power and electrical, hydropower and wind power, petroleum, Chemical Industry, Automotive manufacturing, new energy, construction, high-speed railway bridges, metallurgy, coal, security and communication, scientific research institutions (universities), and animal husbandry. Remarkable transportation solutions are applicable to various industries around the world. Its products have been exported to the United States, Mexico, the Netherlands, Poland, Saudi Arabia, the Czech Republic, Italy, Switzerland, Türkiye, Singapore, Thailand, and other countries.

Why Choose Us?

- Industry-Specific Expertise – We serve power generation, shipbuilding, construction, and aerospace sectors with tailored solutions for transformers, wind turbine components, prefabricated modules, and more.

- Fully Customization – From load capacity (1–500 tons) to drive systems (electric, hybrid, or diesel), meet your exact requirements.

- Advanced Control Systems – Options include manual remote control, semi-automatic path planning, or fully automated navigation (AGV integration).

- Quality & Durability – Robust steel frames, high-torque steering modules, and CE, ISO-certified.

- Full Project Support – From initial consultation to after-sales service, our engineers provide lifetime technical assistance.

Certification

Related Articles

Related Products

Customized Intelligent Material Handling Solutions

To ensure that a customized transfer cart fits your needs perfectly, please provide the following details:

- Load Capacity: _____ tons (1~500 ton)

- Table Size: _____ × _____ mm/m (e.g., 1500×3000)

- Power Options:

- ☐ Lead-acid ☐ Lithium-ion ☐ Other: _____

- ☐ Cable: _____V/_____A

- ☐ Standard 380V/50Hz/3-phase

- Cargo Details:

- Type: _____ (e.g., steel coils, machinery)

- Special Needs: _____ (e.g., anti-slip, corrosion-proof)

- Optional Features:

- ☐ Emergency stop ☐ Anti-collision sensors

- ☐ Rail guides ☐ Lifting mechanism ☐ Remote control