Background

Saudi Arabia Metal Products Ltd. is a company specializing in hot-dip galvanizing, metal fabrication, small hardware manufacturing, as well as the production of painted, corrosion-resistant, and plastic products. During the production process, the company needs to efficiently and safely transfer heavy metal components, galvanized parts, hardware, and other raw materials in order to increase productivity and reduce the risk of manual handling. For this purpose, the Saudi customer chose 10 sets of trackless material transfer carts designed and manufactured by Remarkable to meet the needs of material transportation of different loads and sizes.

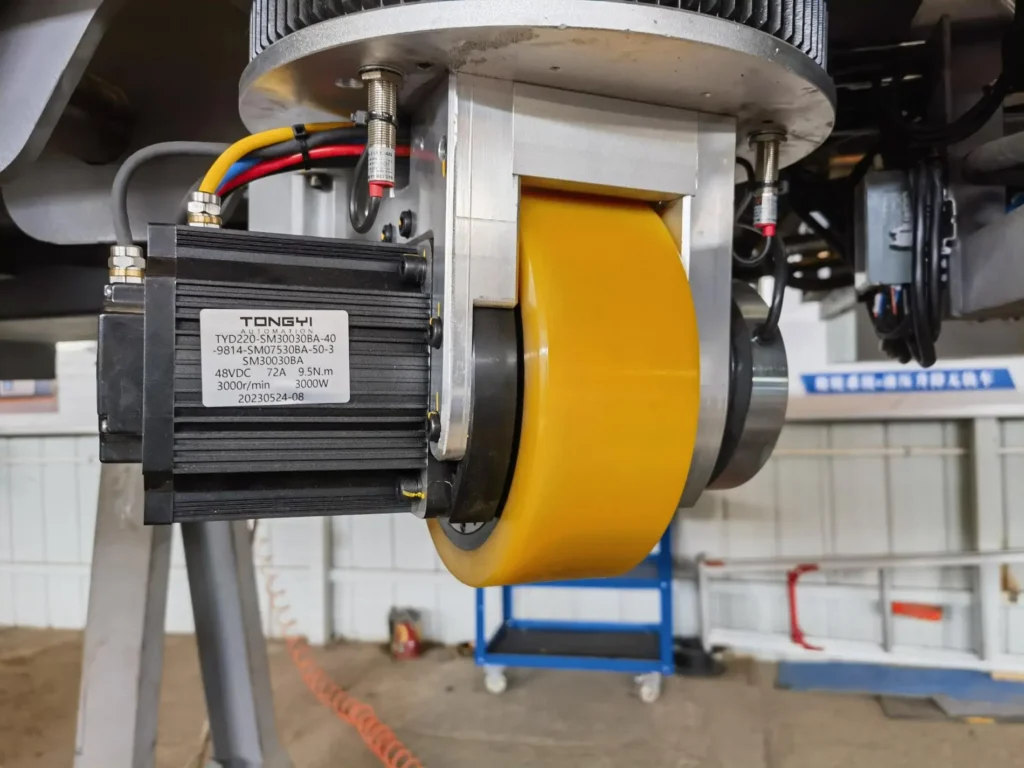

The material transfer carts are powered by maintenance-free lead-acid batteries and offer flexible trackless operation for heavy-duty material transfer between workshops, warehouses, and production lines. Depending on the customer’s specific needs, Remarkable offers 5, 10, 15, and 25 ton capacities and can be customized with size, motor power, battery capacity, and additional features (such as lifting devices) to ensure a perfect match between the equipment and the production process.

Solutions

- Load capacity: 25 tons (to meet the needs of heavy material transportation).

- Table size: 4000×2000mm (large-size platform, suitable for all kinds of metal products).

- Intelligent control: wireless remote control + manual operation, support forward, backward, and turn on the move without stopping.

- Stepless speed regulation: 0~20 m/min, precise control of transportation speed.

- Efficient power supply: maintenance-free battery with a split automatic charger, reducing downtime.

- Safe braking: electromagnetic braking system, smooth stopping, improved operation safety.

Photos Show

Factory Test Videos

Outcome

Since their delivery 4 months ago, the 10 sets of customized material transfer carts provided by Remarkable have been frequently used to transport galvanized parts, metal components, and hardware products, replacing their traditional manual handling and fixed rail transport methods, helping the company to improve the efficiency of heavy material transfer. The customer highly appreciated the stability, flexible handling, and maintenance-free design of the equipment, and indicated that they would continue to deepen the cooperation to further optimize the production logistics system of the enterprise.t