The 3-tonne lifting AGV transfer cart manufactured by REMARKABLE is an intelligent transfer cart specifically developed for industrial automated logistics systems. It facilitates unmanned handling of medium-to-heavy loads between production workshops, warehouses, and workstations. This AGV integrates autonomous navigation, stable lifting, and multi-layered safety controls to achieve precise material handover with production lines and tooling equipment. It enhances internal logistics efficiency while reducing manual operation risks, serving as a vital component of modern smart manufacturing and flexible production lines.

了不起 offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- 负载能力 3 Tons

- 尺寸 1800 × 1500 × 500 mm

- Lifting Stroke: Hydraulic lifting, 100 mm

- 电源: Lithium battery

- 速度 0–25 m/min (stepless speed regulation)

- 自定义: 可定制生产,包括附加组件等。

Working Principle of the AGV Transfer Cart

The following explanation of the operating principles of the AGV transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

工作原理:

- Task Triggering and Dispatch Command Issuance

The AGV transfer cart receives transport task instructions from the dispatch system, PLC, or higher-level control system, specifying target workstations, operational routes, and working modes, and enters a standby state for execution. - Automatic Positioning and Path Recognition

Real-time positional data is acquired via magnetic strips, QR codes, laser, or inertial navigation systems. The onboard controller parses and corrects the path, enabling stable operation along the predefined route. - Autonomous Traverse and Speed Regulation

The AGV robot executes autonomous movement according to the planned route, automatically adjusting speed at turns, intersections, or critical junctions to achieve smooth acceleration, operation, and deceleration. - Precise Workstation Positioning

Upon reaching the designated workstation, the equipment achieves accurate positioning via navigation signals or sensors. The system confirms the arrival status, preparing for subsequent lifting and docking operations. - Lifting Execution and Workstation Docking

Under control system directives, the hydraulic lifting mechanism activates, driving the load platform to vertically adjust its height. This aligns the material level with the production line or fixture platform, enabling safe and stable docking. - Status Feedback and Task Completion

Upon completing lifting and docking, the AGV automated guide vehicle updates its operational and task status to the host system. It then awaits further instructions or proceeds to the next transport task. - Safety Monitoring and Anomaly Handling

Throughout the operation, the AGV continuously monitors forward obstacles, operational status, and safety signals. Upon detecting anomalies, the system automatically decelerates, halts, or triggers alarms to safeguard personnel and equipment.

This workflow applies to both single-vehicle operation and multi-vehicle coordination within AGV transfer cart systems. Clients may customise configurations based on process requirements, facility environments, and automation levels.

AGV Transport Cart

The AGV Transfer Cart System

The 3-ton lifting capacity AGV transfer cart employs a modular design philosophy, featuring a stable overall structure and rational layout. It primarily comprises a load-bearing chassis, drive system, lifting system, control system, and safety protection system, enabling reliable operation under prolonged high-load working conditions.

Body Structure: Fabricated from high-strength steel welded components, the structure undergoes finite element analysis and optimised design to deliver exceptional load-bearing capacity and fatigue resistance, making it suitable for continuous heavy-duty operations.

驱动系统: Equipped with industrial-grade drive motors and high-precision gearboxes, it operates smoothly with low noise levels. Supports precise start/stop control and speed regulation, enhancing AGV stability during cornering and docking manoeuvres.

Lifting System: The compact hydraulic lifting mechanism ensures excellent synchronisation, enabling smooth lifting and lowering under 3-tonne loads to accommodate varying workstation heights and process requirements.

控制系统: Utilises PLC and AGV-specific controllers, supporting automatic, semi-automatic, and manual operation modes. Facilitates on-site commissioning, maintenance, and system upgrades.

Safety Protection System: Integrates laser obstacle avoidance, collision sensors, emergency stop buttons, audible/visual alarms, and overload protection devices, comprehensively enhancing operational safety standards.

AGV 转运车

Technical Specifications Overview

Explore the technical specifications of this 3-tonne AGV transfer vehicle. Featuring 360-degree mobility and hydraulic lifting capabilities, it enables safe and precise operation.

| 参数 | Specification | Remarks |

|---|---|---|

| Model Type | AGV Trackless Electric Transfer Cart | 自动导引车 |

| 负载能力 | 3 Tons | Heavy-duty design |

| Overall Dimensions | 1800 × 1500 mm (L × W) | 可定制 |

| Platform Height | 500 mm | Roller conveyor surface |

| 离地间隙 | 50 mm | Suitable for indoor floors |

| Floor Requirement | Cement / Concrete Floor | Smooth and flat |

| 电源 | 锂电池 | Maintenance-free |

| 控制方法 | Laser Navigation + Wired Remote Control | High positioning accuracy |

| 电机功率 | 2 × 2 kW | Drive system |

| Travel Speed | 0–25 m/min (Variable Speed) | Adjustable |

| Braking System | 电磁制动器 | 安全可靠 |

| 车轮材料 | Polyurethane-Coated Wheels | Wear-resistant & low noise |

| Steering Type | Steering Wheel Drive | Flexible maneuvering |

| Travel Modes | Forward / Reverse / Turning While Moving / Diagonal / Lateral Movement | Multi-directional |

| Lifting Stroke | 100 mm | Optional lifting function |

| Charger Installation | Separate Type Charger | Easy maintenance |

| Charging Function | Fully Automatic Intelligent Charging | AGV docking support |

| 安全保护 | Audible & Visual Alarm + Emergency Stop + Laser Obstacle Avoidance | Multiple safety layers |

| Additional Functions | Battery Level Display, Over-voltage, Under-voltage & Over-current Protection | System protection |

These are some of the specifications for our AGV transfer cart. Should you be interested in our intelligent AGV cart, please contact us, and we shall provide customised services tailored to your requirements.

视频展示

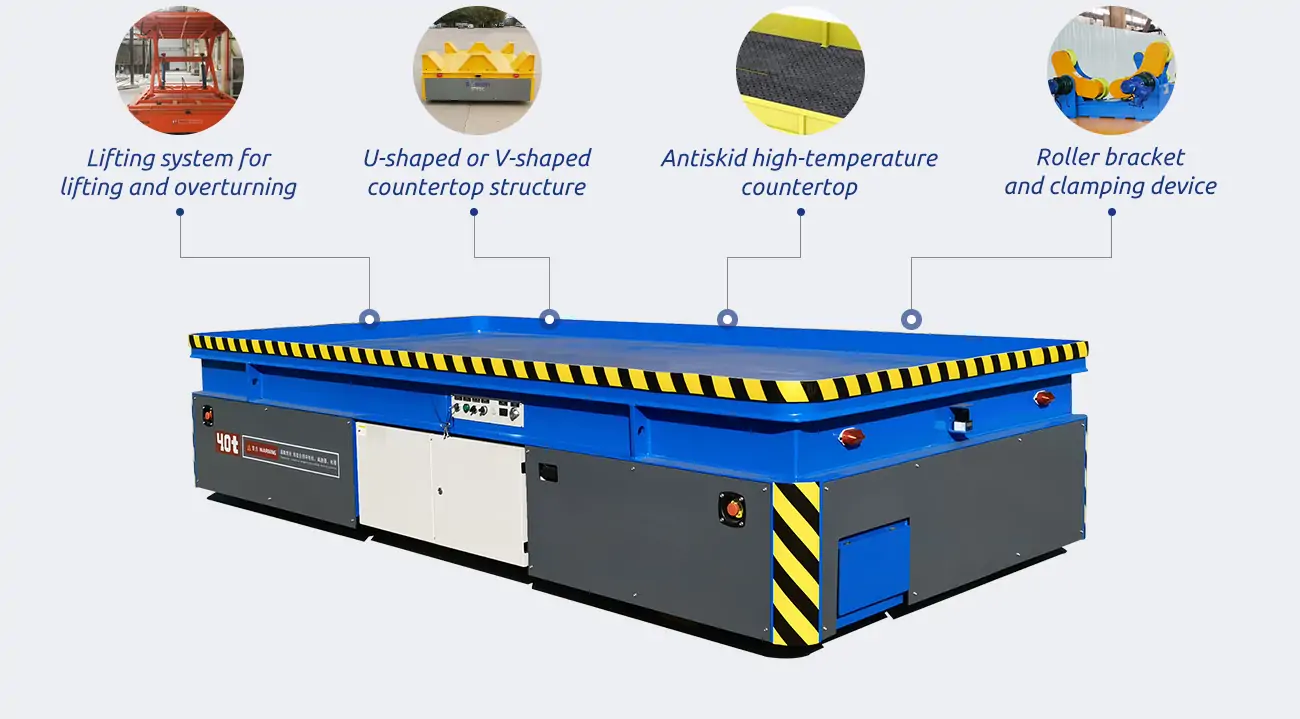

Custom Parts for AGV Transfer Cart

Custom Series Parameters for AGV Trackless Electric Transfer Cart

| Technical Parameters Table Of RWP Trackless Electric Transfer Cart | |||||||||||

| 额定负载能力(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| 工作台尺寸(毫米) | 长度 | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| 宽度 | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| 高度 | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| 离地间隙(毫米) | ≥50 | ≥100 | |||||||||

| 转弯半径(毫米) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| 转向模式 | 差速转向 | 液压转向 | |||||||||

| 操作方法 | Remote Control & Hand-Operated Pendant | ||||||||||

| 移动方式 | Forward, backwards, turning while driving with no stop | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customised for high-temperature and explosion-proof environments) | |||||||||

| 运行速度(米/分) | 25 | 20 | |||||||||

| 电机类型 | Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| 制动模式 | 电磁制动器 | ||||||||||

| 保护措施 | 声光报警灯+ 紧急停止按钮+ 激光避障传感器(选配)+ 防碰撞接触边缘(选配) | ||||||||||

| 车轮数量 | 4 | 6 | 8 | ||||||||

| 驱动轮直径(毫米) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| 车轮材料 | Steel Core + Polyurethane | ||||||||||

| 电池容量(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| 电池类型 | 铅酸电池 | 锂电池 | |||||||||

| 电池续航时间 | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| 电池充电时间 | ≤7h | ≤5h | |||||||||

| 电池充电器 | AC220V/AC380V | ||||||||||

| 地面类型 | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| 满负荷攀爬能力 | 5% | 3% | |||||||||

| 工作环境 | 电池电量显示、过压、欠压、过流保护等功能 | ||||||||||

| 车身颜色 | 定制 | ||||||||||

| 其他职能 | 备注 1) Other table sizes and load capacities can be customised according to user requirements. 2) 在液压转向方面,可根据场地空间限制选择双液压转向系统,以减小转弯半径。 3) 电池类型和工作时间(电池续航时间)可根据客户需求定制。 4)产品会不断改进和升级,表中规格如有变更,恕不另行通知。 | ||||||||||

| 备注 1) Other table sizes and load capacities can be customised according to user requirements. 2) 在液压转向方面,可根据场地空间限制选择双液压转向系统,以减小转弯半径。 3) Battery type and operating time (battery endurance) can be customised to meet customer needs. 4)产品会不断改进和升级,表中规格如有变更,恕不另行通知。 | |||||||||||

特点

高负载能力

Rated load capacity of 3 tonnes, suitable for handling various heavy-duty materials.

Stable Lifting

Hydraulic platform ensures smooth and steady elevation for safe and reliable operation.

安全保护

Laser obstacle avoidance, emergency stop and overload protection ensure operational safety.

Precise Positioning

Supports magnetic strip, laser and QR code navigation for accurate positioning.

Low-noise operation

Smooth and quiet drive system minimises operational noise and vibration.

Flexible Customisation

Load capacity, dimensions, lifting height, and functional configurations can be tailored.

应用

This 3-tonne lifting AGV transfer cart finds application not only in automated logistics warehousing but also across automotive manufacturing, aerospace, and other sectors. It significantly enhances safety and efficiency, meeting diverse requirements for flexible and reliable material handling.

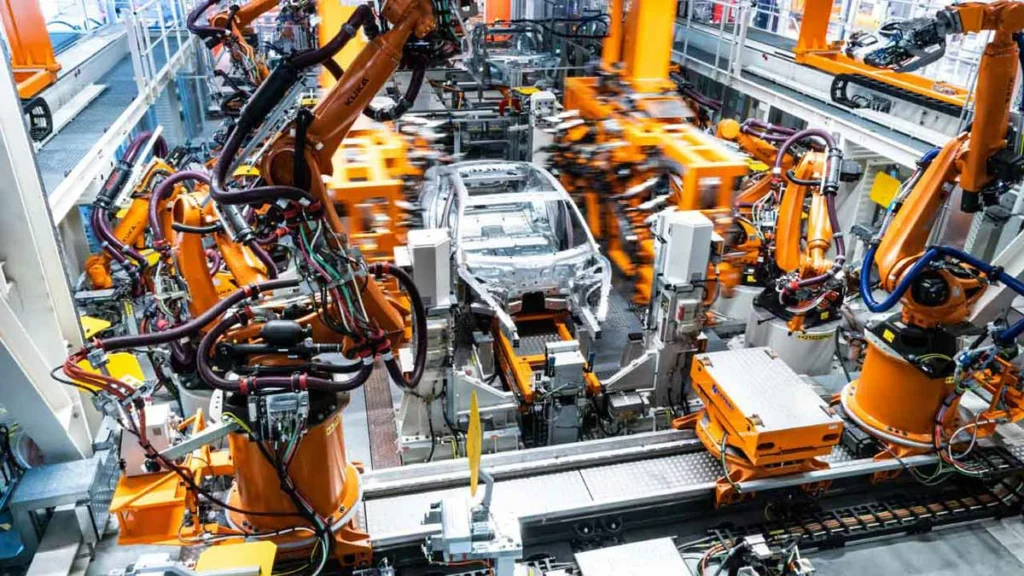

汽车制造: Used for the automated transfer of engines, moulds, and body components between workstations, achieving precise integration with production lines to boost assembly efficiency.

Metallurgy and Steel: Designed for high-load and high-dust environments, the AGV transfer cart safely handles steel structures, tooling, and heavy components, ensuring stable transportation.

Equipment Manufacturing: Enables continuous transfer of heavy components between welding, assembly, and inspection processes, optimising production cadence and enhancing overall workshop logistics efficiency.

Energy and Power: Suitable for internal workshop transport of heavy materials such as power generation equipment and electrical components. Ensures safe transportation of high-value equipment through stable lifting and precise navigation.

航空航天: The 3-tonne lifting capacity AGV transfer cart enables smooth and precise handling of critical components, meeting intelligent logistics demands in high-standard production environments

Transfer Cart Case Showcase

AGV Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and AGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised electric transfer carts, rail-guided trolleys, omnidirectional mobile transfer carts, 无轨运输车, AGV robots和 工业拖车.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

为什么选择我们?

- 特定行业的专业知识 - 我们为发电、造船、建筑和航空航天领域提供变压器、风力涡轮机组件、预制模块等定制解决方案。

- Fully Customised - 从负载能力(1-500 多吨)到驱动系统(电动、混合动力或柴油),都能满足您的确切要求。

- 先进控制系统 - 选项包括手动遥控、半自动路径规划或全自动导航(AGV 集成)。

- 质量与耐用性 - 坚固的钢架、大扭矩转向模块,并通过了 CE 和 ISO 认证。

- 全面项目支持 - 从初步咨询到售后服务,我们的工程师将提供终身技术援助。

相关文章

定制的智能物料装卸解决方案

为确保定制的转运车完全满足您的需求,请提供以下详细信息:

- 负载能力:_____ 吨(1~500 吨)

- 工作台尺寸:_____ × _____ mm/m(如 1500×3000)

- 电源选项:

- 铅酸电池 ☐ 锂离子电池 ☐ 其他:_____

- ☐ 电缆:_____V/_____A

- ☐ 标准 380 伏/50 赫兹/3 相

- 货物详情:

- 类型:_____ (如钢卷、机械)

- 特殊需求:_____ (例如防滑、防腐蚀)

- 可选功能

- ☐ 紧急制动 ☐ 防碰撞传感器

- ☐ 导轨 ☐ 提升装置 ☐ 遥控装置