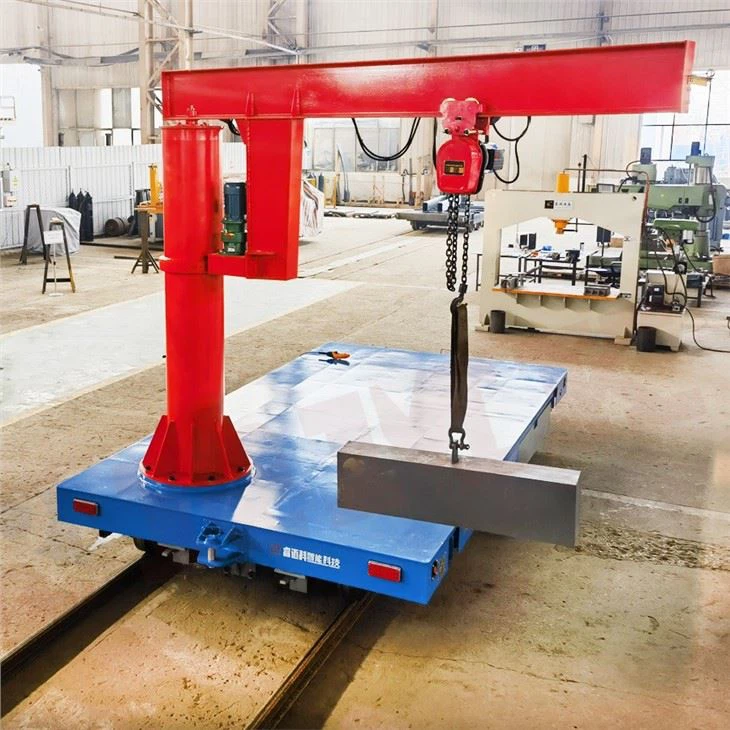

The electric mold transfer cart is a kind of industrial handling equipment designed for factory floors, mainly used to transfer heavy moulds such as injection moulds and stamping moulds safely and efficiently. It is suitable for mould installation, mould change and maintenance.

- 负载能力 1~50 tonnes, heavy-duty models can reach more than 100 tonnes

- 驾驶模式: manual/hydraulic/electric, electric model speed 0.1~0.5m/s

- Lifting adjustment: hydraulic or mechanical lifting and lowering, stroke 50~300mm, accuracy ±1mm

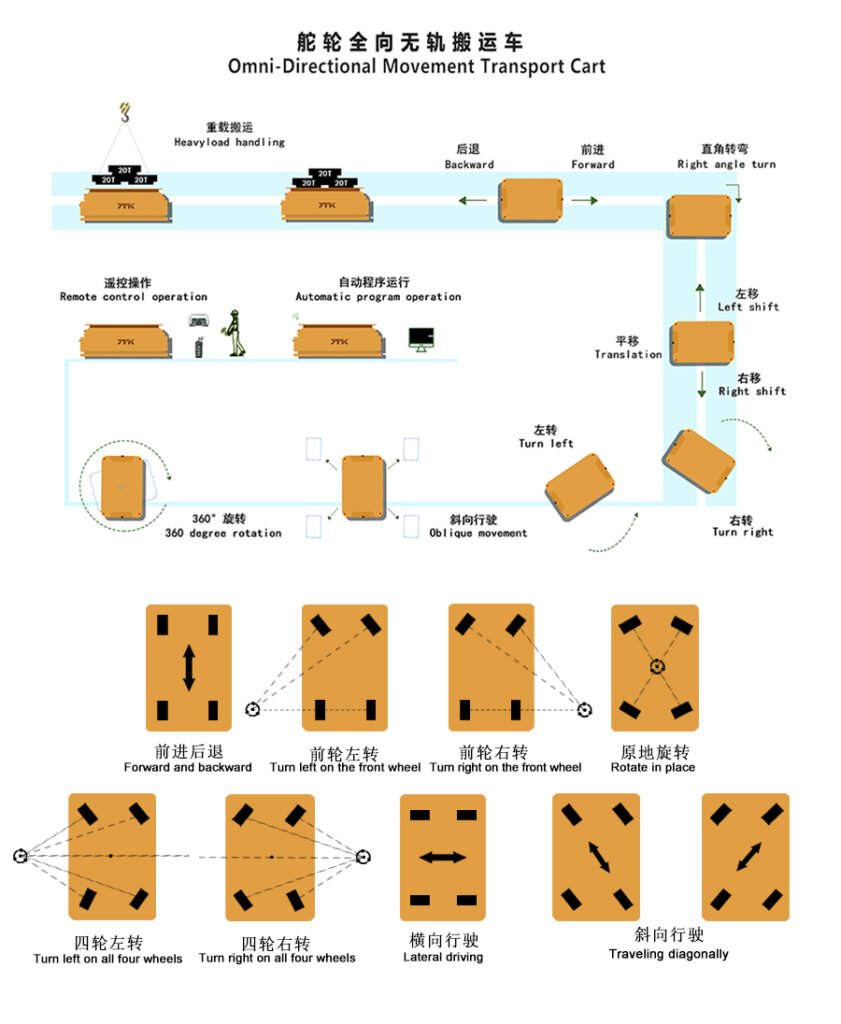

- Mobility: universal wheels (with brakes) or rail, 360° steering

- 桌子大小 customised, with non-slip design

- 安全: anti-tipping structure to ensure stable handling Structure, cushioning device, emergency braking, barricade detection system

工作原理

The working principle of the Mold Flat Transfer Cart is based on the synergy of mechanical drives and hydraulic systems to achieve safe handling and precise positioning of moulds. Its working process can be divided into the following key links:

- Carrying and moving: the moulds are placed on a reinforced steel platform with heavy-duty universal or track wheels at the bottom, which can be flexibly moved by electric drive or hydraulic power.

- Lifting and adjusting: Hydraulic cylinder, screw or shear mechanism is used to control the lifting and lowering by hand pump, electric hydraulic system or pneumatic device, and the height is precisely adjusted to match the working table of the injection moulding machine or press.

- Positioning and docking: Some models are equipped with micro-adjustment devices (e.g. slides, positioning pins) to ensure quick alignment of the mould with the machine and improve the efficiency of mould change.

- Safety locking: After lifting, the position is fixed by mechanical locking or hydraulic holding pressure to prevent accidental falling and ensure stable handling.

The whole working process of Mold Transfer Cart is coordinated by all systems to achieve smooth transport, precise lifting and safe positioning of moulds from the storage location to the production equipment.

Mold Transfer Cart Accessories

Load-bearing system: high-strength alloy steel table, extendable platform extension plate, mould positioning block/stop block, V-groove positioning guide rail

Lifting system: hydraulic cylinders (single-stage/multi-stage), hand-operated hydraulic pumps, electro-hydraulic power units, scissor lifting mechanism (mechanical), lifting and lowering safety locking pins

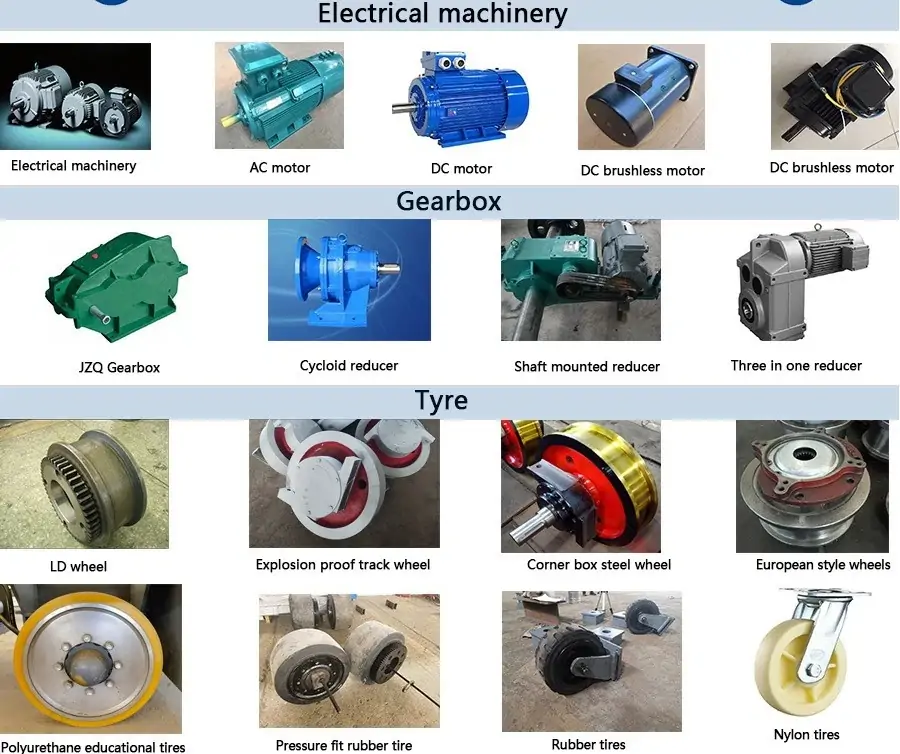

Mobile system: heavy-duty universal wheels (with double brakes), rail-specific steel wheels, polyurethane wrapped wheels (anti-vibration type), axle lubrication system

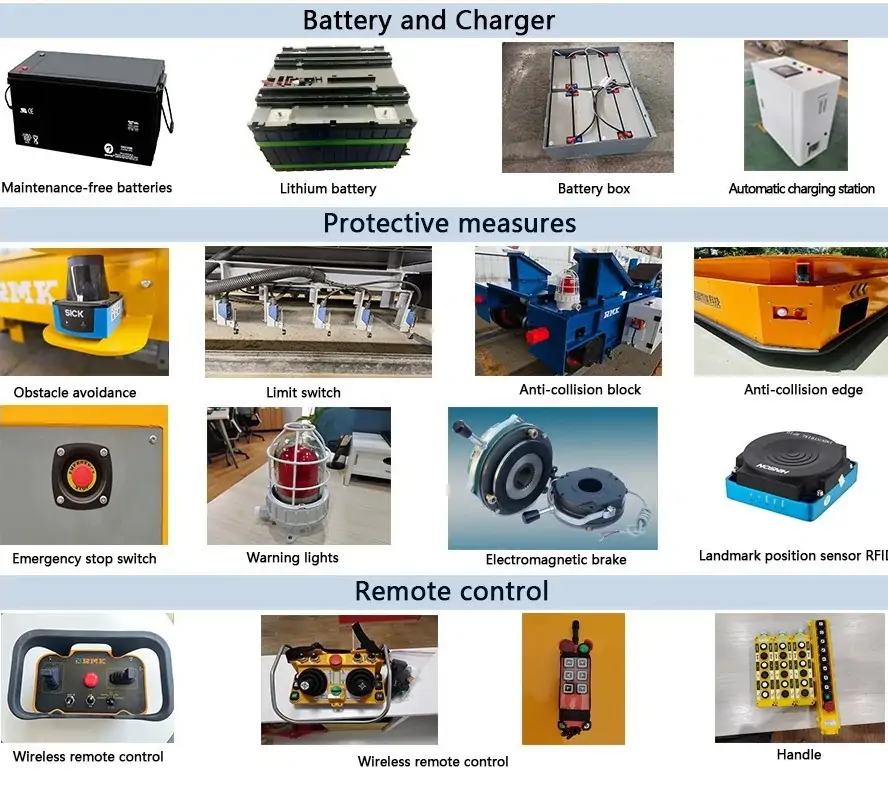

控制系统: hydraulic control handle, wireless remote control (electric type), foot-operated hydraulic switch, emergency stop button.

Safety system: overload protection sensor, tilt alarm, anti-collision buffer bar, hydraulic explosion-proof valve.

Positioning system: laser alignment indicator, digital height display, mould docking guide bar, adjustable support foot cups

Maintenance system: special hydraulic oil, wheelset dismantling tool, lubricating grease filler, spare battery (electric type)

Optional systems: mould preheating device, automatic weighing system, RFID mould identification module, anti-static coating components, explosion-proof configuration

Fastening system: High-strength connecting bolts, quick-disassembly pins, anti-loosening nuts, safety chain rings

视频

Electric Mould transfer cart for automobile manufacturing industry

12 ton injection mold transfer carts

特点

High load

Load capacity 1-100 tonnes, reinforced steel structure, anti-deformation design.

Precision Positioning

Laser/V-groove guide, ±0.5mm accuracy, fast alignment.

Multi-mode drive

Manual/electric/pneumatic optional, frequency conversion speed regulation 0.1-0.5m/s.

Intelligent safety

overload emergency stop + tilt alarm + hydraulic locking, CE certification.

Module Extension

Platform can be extended to 5m, RFID/weighing optional, MES docking.

Customised production

Adjustment of dimensions/functions on request, support for non-standard designs.

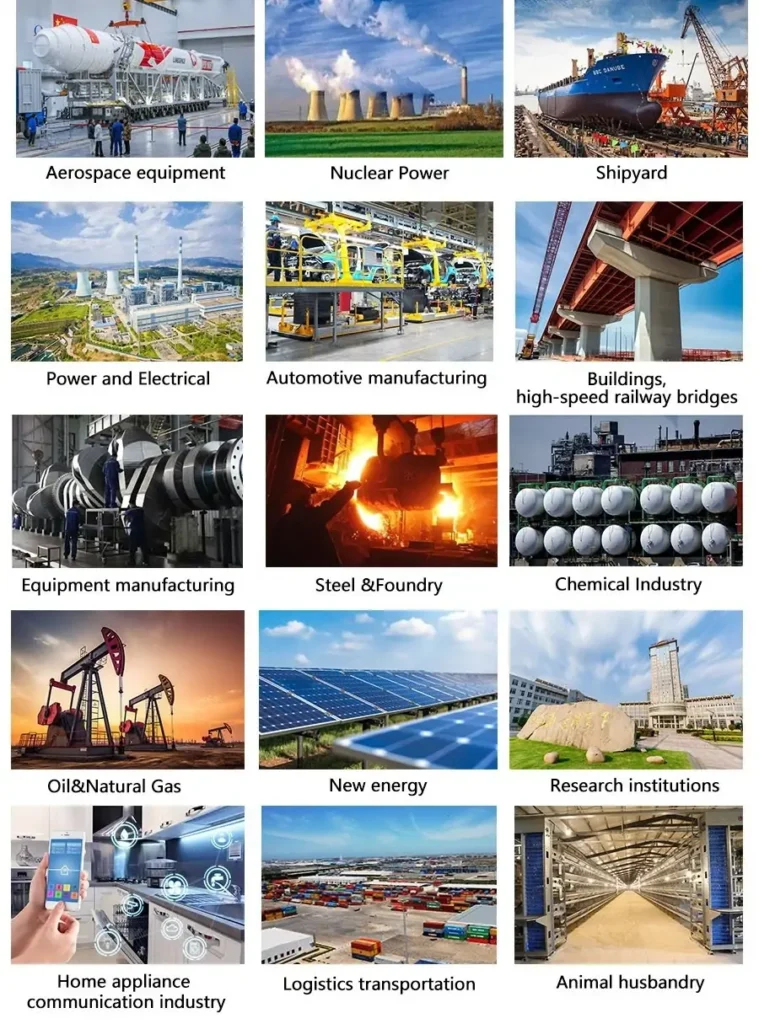

应用

Automobile manufacturing industry: for stamping moulds, plastic injection moulds (such as interior/exterior parts) handling and quick mould change.

Home appliance manufacturing industry: production line transfer and equipment docking for large injection moulds such as refrigerators/air conditioners/washing machines, etc.

Consumer electronics industry: anti-static transfer and positioning of precision injection moulds (mobile phone cases/electronic components)

Medical device industry: clean handling and height adjustment of medical plastic moulds in aseptic environment.

Aerospace industry: Heavy-duty transport and precise positioning of composite moulds (wings/pods).

Daily necessities packaging industry: batch handling and warehouse management of fast turnover moulds such as caps/containers.

Building materials industry: inter-regional transfer and installation positioning of prefabricated component moulds (e.g. cement formwork, decorative panel moulds)

Mold Transfer Cart Specifications

| 项目 | 规格 |

|---|---|

| 模型 | RWP-35T |

| 额定载重量(T) | 35 |

| Safety load factor | 1.2 |

| 工作台尺寸(毫米) | 5600*3200 (L*W) |

| 推车高度(毫米) | 900 |

| 地面类型 | 水泥地面、环氧树脂地面、沥青地面 |

| Climbing slope | No more than 2 degrees |

| 操作方法 | Wireless remote control & Hand operate pendant |

| Traveling speed(m/min) | 0-20(无级调速) |

| 车轮材料 | Press fit solid rubber wheels |

| 车轮数量 | 8 |

| Brake mode | 电磁制动器 |

| 电源 | 免维护铅酸电池 |

| 保护装置 | Audible and visual alarm lamp and emergency stop button,Laser obstacle avoidance |

| Color | 定制 |

| 转向齿轮 | 液压转向 |

| Electronic Control Mode of turning | 电动按钮控制 |

| 调整地面平整度 | 机械自动调节 |

| Battery working time | Can continually work about 3 hours after full charge |

| 电池充电器功能 | 自动充电 |

| 移动方式 | Forward,backward and rotate 360 degrees,turning while driving with no stop |

| 平车的保护 | 过压、欠压和过流保护等 |

Customized Mold Transfer Cart

请提供以下信息,或简单描述您的应用场景(如车间模具运输或港口集装箱装卸),我们将为您量身定制最具成本效益的物料装卸解决方案,并在 24 小时内提供详细报价和技术规格!

负载能力和尺寸 最大载重量(吨)和平台尺寸(长×宽)。

赛道情况 轨道类型(钢轨/工字钢轨道)、轨距(毫米)和运行距离。

供电方式: 电池/低压轨道/电缆卷筒/滑触线(选择适用选项)。

控制要求: 远程控制/自动/变频调速,无论是否需要 PLC 或智能联锁。

环境要求: 室内/室外、防爆、耐高温或其他特殊条件。

安全配置: 基本保护(限位开关、紧急停车)或高级防碰撞、负载监控。

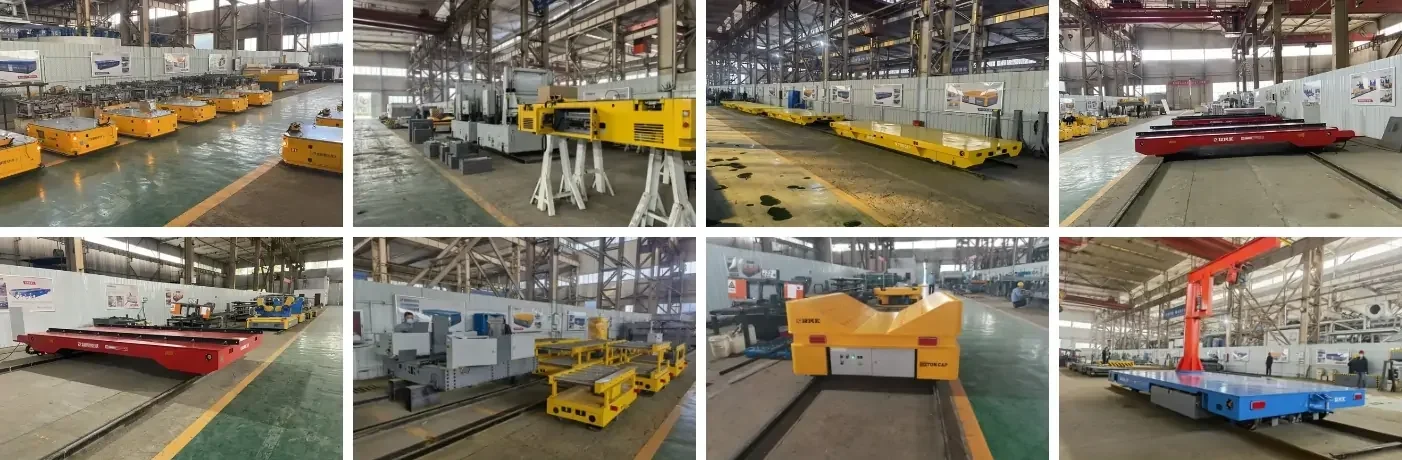

Mold Transfer Cart Manufacturer

认证

相关文章

相关产品

定制的智能物料装卸解决方案

为确保定制的转运车完全满足您的需求,请提供以下详细信息:

- 负载能力:_____ 吨(1~500 吨)

- 工作台尺寸:_____ × _____ mm/m(如 1500×3000)

- 电源选项:

- 铅酸电池 ☐ 锂离子电池 ☐ 其他:_____

- ☐ 电缆:_____V/_____A

- ☐ 标准 380 伏/50 赫兹/3 相

- 货物详情:

- 类型:_____ (如钢卷、机械)

- 特殊需求:_____ (例如防滑、防腐蚀)

- 可选功能

- ☐ 紧急制动 ☐ 防碰撞传感器

- ☐ 导轨 ☐ 提升装置 ☐ 遥控装置