What Information Is Needed to Customize an Electric Flat Cart?

Before custom electric transfer cart (转运车), preparing the key parameters in advance can greatly reduce repeated communication and the risk of rework later.

Based on our years of experience, the design of a custom electric transfer cart mainly revolves around three core data dimensions: load parameters, dimension parameters, and operation parameters. These directly affect whether the equipment is safe, easy to use, and durable.

Load Parameters

Load is the top priority in designing a custom electric transfer cart, directly determining the overall structure, motor configuration, and safety factor.

额定负载

- Please provide the maximum weight of the daily transported goods (e.g., 5 tons, 20 tons, etc.).

- In practice, we usually leave a certain safety margin on top of the rated load to cope with short-term peak conditions.

Cargo Characteristics

In addition to weight, please indicate:

- Weight of a single item

- Whether goods are laid flat or stacked

- Center of gravity height

In previous customer feedback, the center of gravity height is often the easiest to overlook but also the most likely to cause issues.

If goods are stacked and the center of gravity exceeds 1 meter, targeted reinforcement is usually required in the structure and protection of the custom electric transfer cart.

Special Load Requirements

For example, when transporting:

- Flammable or explosive materials

- Precision equipment or valuable components

Please indicate in advance requirements for protection, explosion-proofing, waterproofing, etc., such as whether IP65 or explosion-proof standards need to be met.

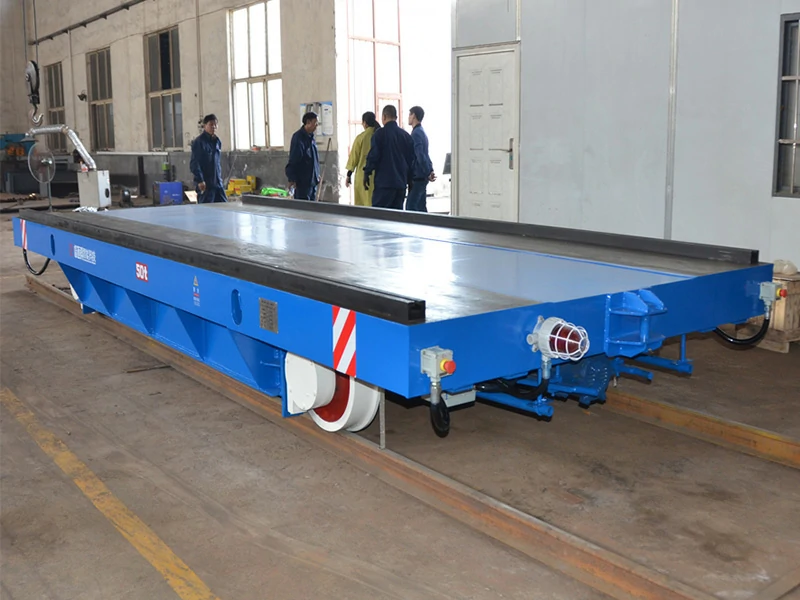

Dimension Parameters

Dimension parameters determine whether a custom electric transfer cart can smoothly enter the site and operate within existing passageways.

Platform Size

The platform size should be based on the cargo dimensions, leaving some clearance around the edges to facilitate loading and unloading.

For example:

- Cargo size: 3m × 1.5m

- Recommended platform size: at least 3.2m × 1.7m

Track Parameters

- Track gauge: Please provide the actual gauge of existing tracks; newly laid tracks are usually 600mm or 900mm

- Track length

- Slope of operation (generally recommended not to exceed 5°)

- Turning radius (has a significant impact on structural design)

On-site Passage Restrictions

Please provide:

- Workshop door width

- Elevator size

- Minimum width of turning areas

This information can effectively prevent situations where the custom electric transfer cart cannot enter the site after manufacturing.

Operation Parameters

Operating Speed

- Short-distance transport within the workshop: generally 0.5–3 km/h is safer and more controllable

- Long-distance transport (e.g., over 100 meters one way): speed can be increased accordingly, but the braking system must match

Transport Distance

- The one-way or round-trip distance directly affects the choice of power supply:

- Short distance: battery-powered is more flexible

- Long distance or continuous operation: busbar or cable reel is more stable

Start-Stop Frequency

If used frequently (e.g., more than 10 starts and stops per hour), the custom electric transfer cart’s:

- Motor

- Braking system

- 控制系统

- should be reinforced to ensure long-term stable operation.

Operating Environment

Please indicate:

- Temperature range (e.g., whether it drops below -20°C in cold environments)

- Humidity conditions

- Presence of corrosive gases or dust

These will affect the material selection, battery solution, and protection level of the custom electric transfer cart.

Usage Scenarios

For example:

- Factory workshop

- Warehouse

- Outdoor site

- Different scenarios have different requirements for wheels, protection, and control methods.

Additional Requirements

Depending on actual usage, you may choose the following features:

- Function expansion: lifting (e.g., 0.5–1.2 meters), rotation, lateral movement, etc.

- Automation needs: whether it needs to interface with MES/WMS systems or add RFID/vision navigation

- 安全配置: emergency stop button, anti-collision device, overspeed alarm, etc.

- Power and energy:

- Battery, cable reel, or busbar power supply

- Special requirements for endurance or charging cycles

- Other personalized requirements:

- Specified color

- Company logo

- Specific additional equipment

- Custom control interface or software logic

- All can be indicated during the planning stage.

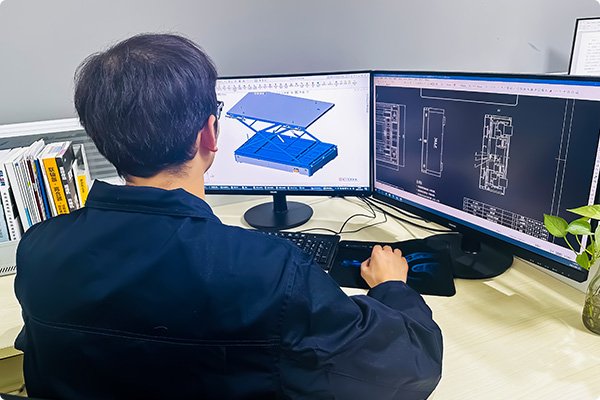

Practical Advice

If some parameters cannot be provided accurately for the time being, it’s completely fine.

In actual projects, you can provide cargo samples, site photos, or short videos. Our experienced team can still complete a professional assessment based on experience.

We once customized a 100-ton custom electric transfer cart for an international new energy industry client. Through early parameter optimization, the cart met strength requirements while reducing its own weight by approximately 12%.

About Us

Remarkable specializes in custom electric transfer carts, electric flat carts, transfer carts, and material handling carts.

We can provide safer and more efficient handling solutions according to different operating conditions, industries, and usage scenarios.

If you have any questions regarding parameter confirmation or solution selection, please contact our professional team. We are happy to help clarify everything in one go.

电子邮件: transfercart@rmkzn.com

Phone: +86-18637369355