As factory logistics automation continues to advance, enterprises are seeking more efficient and safer internal transport solutions to replace traditional forklifts and manual handling. Automatic transfer carts and AGV robots (automated guided vehicles) are two widely used types of automated handling equipment in modern manufacturing, warehousing, and heavy industry. However, distinct differences exist between them. Below, let us explore both.

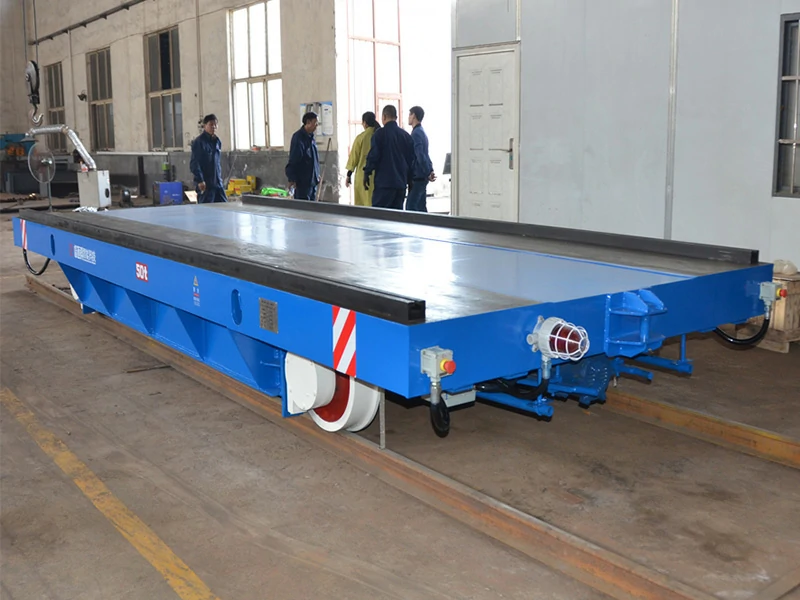

What is an Automatic Transfer Cart

An automatic transfer car is an industrial transport vehicle that operates autonomously along fixed routes, tracks, or magnetic strips. It is powered by batteries, cable reels, or track-based systems. Characterised by robust construction, high load capacity, and smooth operation, it is typically employed for transporting heavy-duty materials such as steel coils, moulds, and large metal components. It can integrate with turntables, lifting platforms, or roller conveyor systems to fulfil more complex automated transfer requirements.

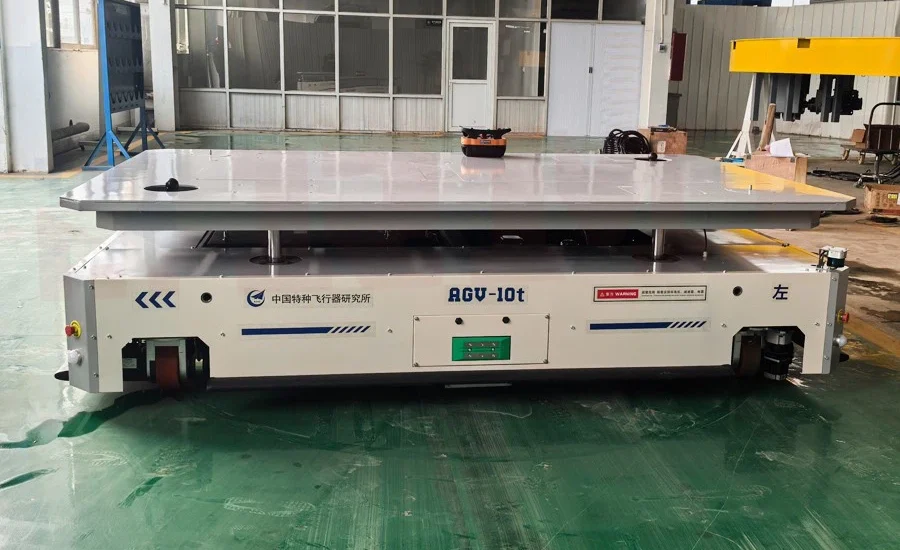

What is an AGV Robot

Heavy-duty AGVs are intelligent transport robots that autonomously navigate factory environments using laser guidance, magnetic strips, QR codes, or SLAM technology. It operates without fixed routes, adapting paths flexibly to process changes while achieving autonomous obstacle avoidance, intelligent scheduling, and multi-vehicle coordination. With high flexibility and intelligence, AGVs are commonly employed for flexible handling of medium-to-light loads and can interface with MES/WMS systems to enable unmanned logistics management.

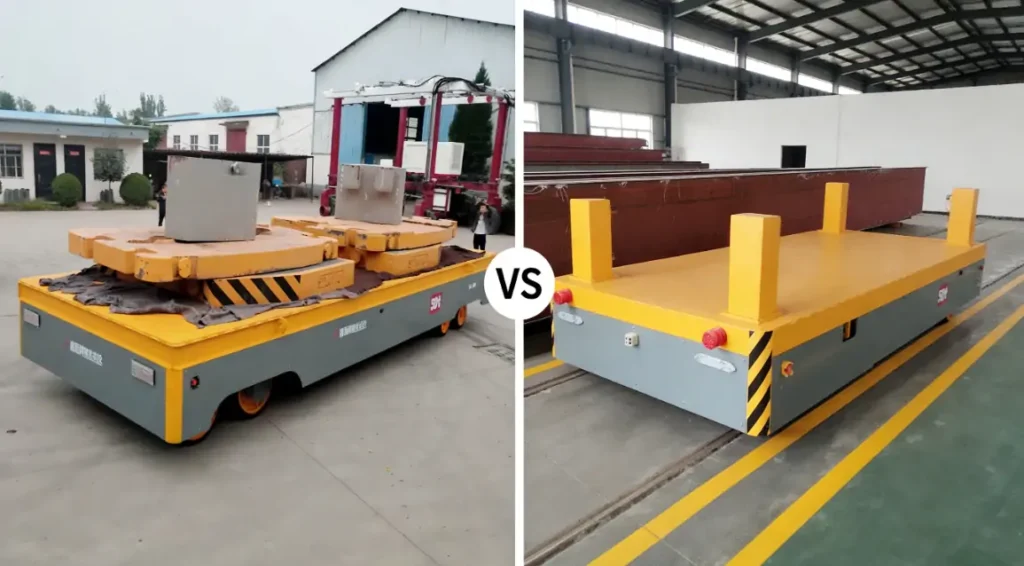

Having outlined automated transfer vehicles and heavy-duty AGV robots, let us now examine the distinctions between the two.

自动搬运车与 AGV 机器人

Both automatic transfer cars and AGVs are commonly used automated material handling equipment, yet they differ in operational methods, load capacity, and other aspects. Below is a brief comparative analysis of the two.

| 比较项目 | 自动传送车 | AGV Robot |

|---|---|---|

| Operating Mode | Fixed route (rails/magnetic strips/ground guidance), stable operation | Free path (laser/SLAM/magnetic strips), route changeable at any time |

| 负载能力 | High load (5–300 tonnes) | Light to medium load (0.3–5 tonnes) |

| 灵活性 | Fixed routes, low flexibility | High flexibility, routes can be altered at any time |

| Navigation Capability | Relies on tracks/magnetic strips/limit switches | Laser-based systems, intelligent obstacle avoidance, multi-vehicle coordination |

| 地面要求 | Laser-based systems, intelligent obstacle avoidance, and multi-vehicle coordination | Requires relatively flat surfaces, significantly affected by environmental changes |

| Investment Cost | Lower cost, simple maintenance | High investment cost, complex system maintenance |

| Site Modification | Requires track laying or fixed route installation | Minimal modification, better suited for retrofitting older factories |

| Applicable Materials | Heavy loads: moulds, steel coils, large structural components | Light/medium loads: pallets, components, material bins |

| 适用行业 | Heavy industries, steel, foundry, moulding, wind power | Automotive, 3C, smart factories in warehousing and logistics |

自动传送车

自动传送车 Lifting Automated Guided Vehicles

Lifting Automated Guided Vehicles

The above outlines a simplified comparison. Should you have any queries or interest, please contact us. We shall provide you with a bespoke transfer cart solution. Now, let us examine their respective operational scenarios.

Transfer Cart Industry Application Selection

Different industries and operational conditions require distinct transfer cart types. Below, we outline the suitability of automatic transfer carts versus AGV robots for specific industries.

Steel and Metal Processing Industry: Opt for automatic transfer carts. Materials such as steel coils, aluminium coils, and plates are exceptionally heavy and require stable support, which AGVs struggle to handle or find prohibitively costly. Fixed-route, high-frequency shuttle operations are better suited to automatic transfer cars, enhancing load capacity and durability.

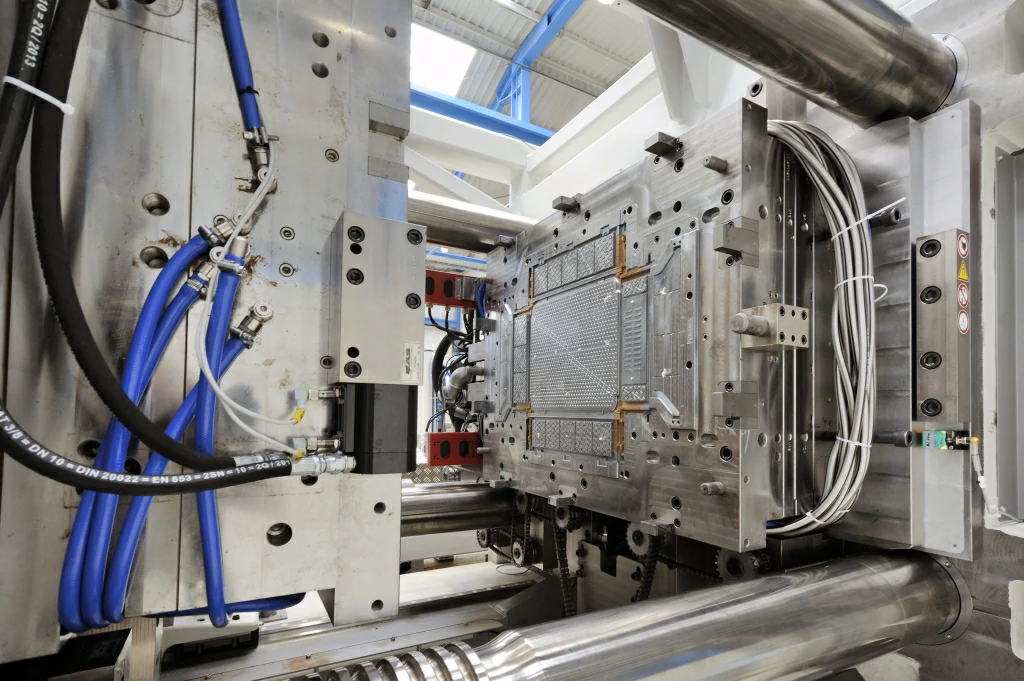

Mould Manufacturing and Injection Moulding Industry: Prioritise automatic transfer trolleys (with lifting capability). Moulds are high-value, heavy components requiring precise docking, where automatic transfer carts’ robust structures offer reliability. For unmanned mould changes, heavy-duty AGVs can be deployed, though this significantly increases investment.

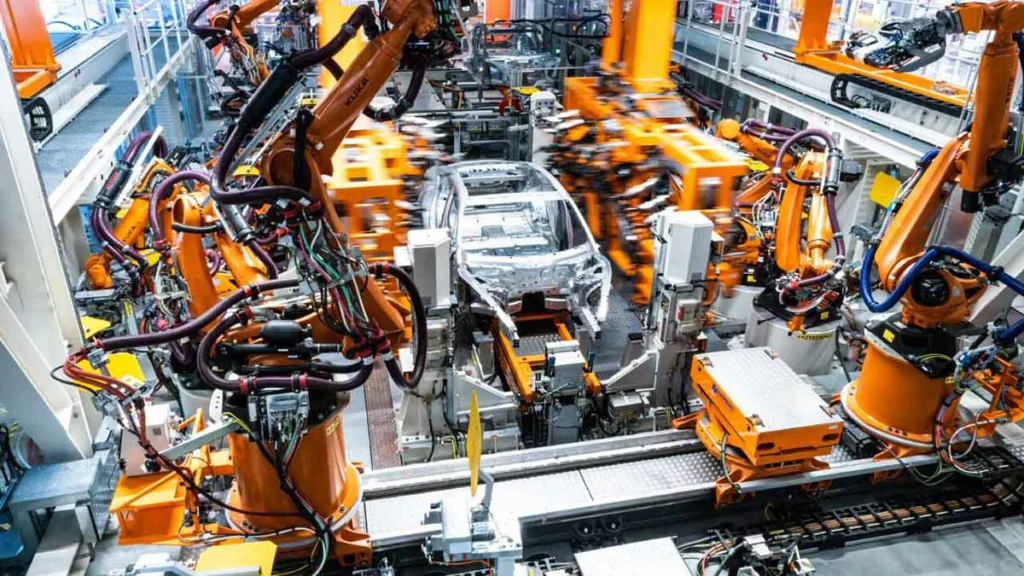

Automotive Manufacturing and Smart Factories: Opt for AGV robots. Complex workshop layouts and frequent path changes highlight AGVs’ advantages in flexible routing and automatic obstacle avoidance. Suitable for final assembly line delivery, material replenishment, and warehouse-to-production line connectivity, enhancing intelligent operations.

Warehousing and Logistics Sector: Opt for AGVs where extensive repetitive material transport and multi-vehicle coordination are required. Automated guided vehicles enable automated replenishment and distribution, particularly suited for high-frequency, continuous transport of pallets, containers, and light-load materials.

Steel and Metal Processing Industry

Steel and Metal Processing Industry Mould Manufacturing and Injection Moulding Industry

Mould Manufacturing and Injection Moulding Industry Automotive Manufacturing and Smart Factories

Automotive Manufacturing and Smart Factories Warehousing and Logistics Sector

Warehousing and Logistics Sector

In summary, both automated handling systems possess distinct advantages. The specific choice must be determined by the actual operational requirements of the industry.

结论

Through the above article, we have gained an understanding of automated transfer carts and AGV transfer vehicles, recognising the distinctions between the two. Should you have any queries regarding which transfer vehicle to select, or if you are interested in our transfer vehicles, please do not hesitate to 联系我们. As a specialist transfer vehicle manufacturer, we shall provide you with the most suitable transfer vehicle solution. We welcome your enquiries.