This customised multi-functional AGV transfer car is an automated electric transport vehicle specifically designed and manufactured for the national Three Gorges Hydraulic Project. It employs laser navigation for autonomous operation and incorporates lifting capabilities, 360-degree rotation, and a V-shaped fixture frame. It interfaces with on-site automated production line equipment signals, lifting to a height of 1.5 metres at designated workstations to precisely dock with third-party machinery. This enables operations including workpiece handling and 360-degree rotation. This multifunctional AGV vehicle integrates vehicle movement, lifting, and platform rotation capabilities, autonomously executing programmed actions to meet automation and safety requirements in precision equipment manufacturing.

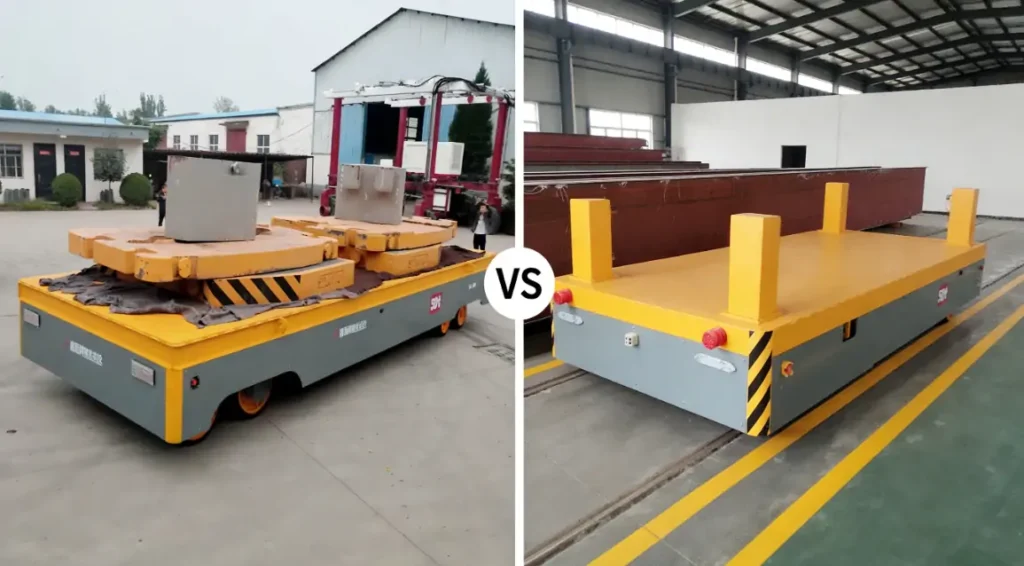

REMARCABLE offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- Model: RWP

- Load Capacity: 3 Tons

- Dimensiones: 1600 × 1000 × 1000 mm

- Lifting Stroke: Hydraulic lifting, 1500 mm

- Fuente de alimentación: Lithium battery

- Speed: 0–30 m/min (stepless speed regulation)

- A medida: Producción personalizada disponible, incluidos componentes adicionales, etc.

Working Principle of the Multi-functional AGV Transfer Car

The following explains the operational principles of the multi-functional automated guided vehicle (AGV), aiding operators and maintenance personnel in swiftly understanding its movement sequences and control logic.

Principio de funcionamiento:

1. Upon powering on, the power battery supplies electricity to the controller, drive system, and hydraulic module. The vehicle automatically performs self-checks on battery charge, brakes, obstacle avoidance, emergency stop, and sensor status. It enters operational mode only when safety conditions are met.

2. Following self-check completion, the operator selects functions such as travel, lifting, or rotation via remote control or control panel. The controller then activates corresponding modules and establishes a safe path.

3. The drive system delivers power through motors. Independent four-wheel steering employs control algorithms to calculate wheel speed and angle in real time, enabling omnidirectional movement, including forward/reverse, lateral, diagonal, and on-the-spot rotation.

4. Encoders and position sensors provide continuous feedback, enabling precise and stable movement within confined spaces and complex routes.

The lifting and rotating platform, driven by a hydraulic system, performs vertical lifting, fine positioning adjustments, or full 360° rotation as required. Closed-loop pressure and displacement control ensure stable and controllable lifting operations.

5. During operation, all modules maintain dual interlocking of hardware and software. Should the platform fail to reset or detect an obstacle, the control system immediately restricts movement or posture adjustments.

6. Laser obstacle avoidance, edge detection protection, and audible/visual alarms trigger emergency stops upon detecting hazards. Electromagnetic brakes ensure secure vehicle parking under both normal and abnormal conditions, preventing slippage or drift.

7. Upon task completion, the platform automatically retracts, and the vehicle enters standby mode. The intelligent charging system collaborates with the Battery Management System (BMS) to monitor battery status, preventing overvoltage and overcurrent while optimising energy consumption strategies during low-power conditions.

8. Routine maintenance primarily encompasses hydraulic fluid and tyre inspections, sensor calibration, battery health diagnostics, and brake system servicing to ensure the AGV maintains consistent reliability.

Multi-functional AGV Automated Robot

Primary Functions of the Customized AGV Transfer Car

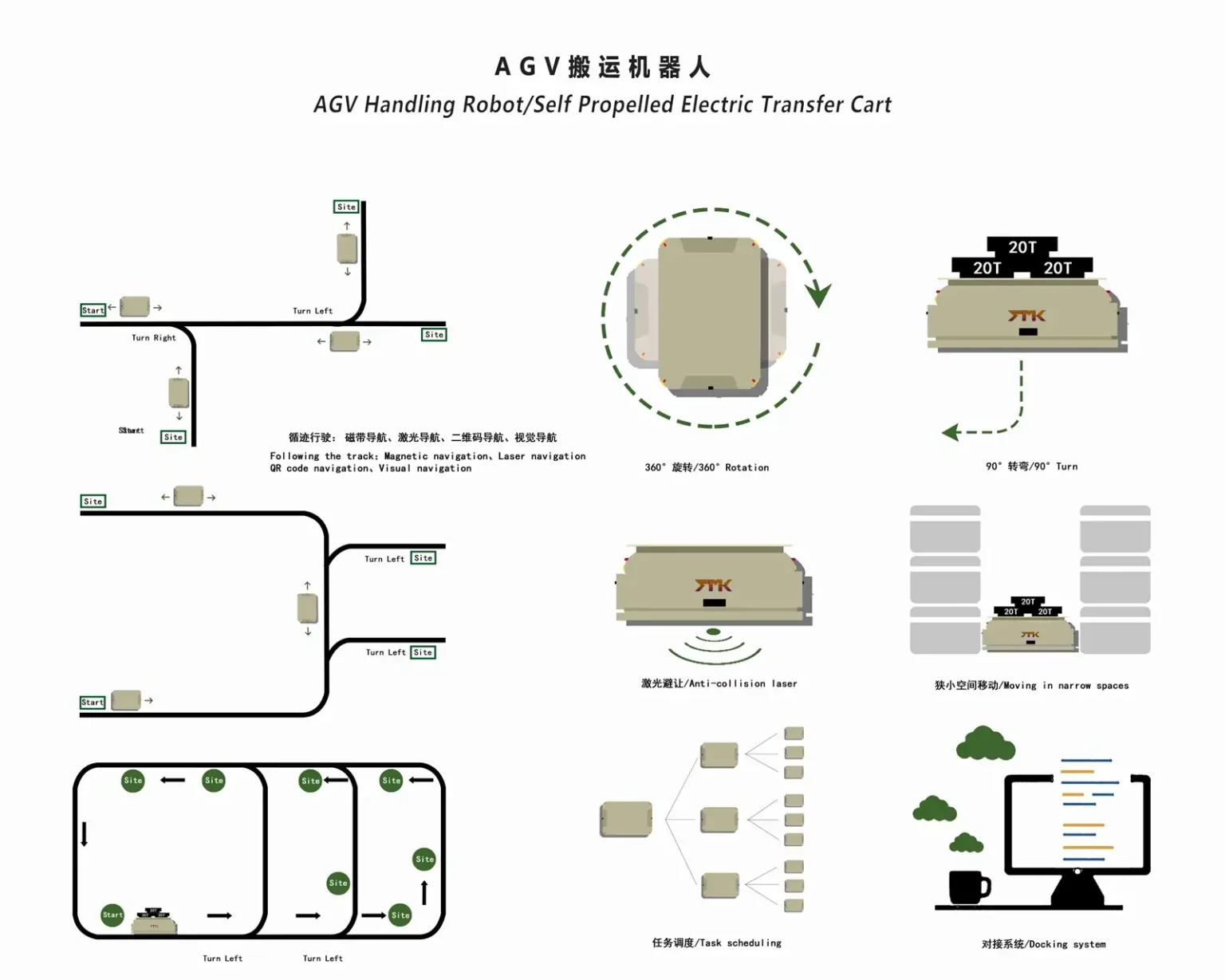

The customised automated multi-functional AGV transfer cart achieves autonomous transport, docking, and process coordination in complex operational conditions through highly integrated navigation, execution, and interconnection systems. Core functional modules include a laser navigation system, lifting mechanism, rotary platform, and clamping table system, collectively forming intelligent operational capabilities.

Autonomous Navigation System (Laser Guidance): Employing laser reflector positioning technology, this system utilises laser scanners to establish real-time positional coordinates, enabling high-precision path tracking and workstation docking. Laser navigation offers high positioning accuracy, rapid route planning, and strong environmental adaptability, making it suitable for industrial environments with complex structures, narrow passages, or stringent path precision requirements.

Lifting System (1.5m, customisable): The lifting module employs a hydraulic lifting structure, enabling high-load, low-displacement, long-stroke vertical lifting. Upon reaching workstations, the automated AGV can precisely position itself at designated heights, suitable for equipment docking, maintenance support, and material handling operations. Closed-loop control ensures uniform lifting speed and stable posture, meeting demands for long-term continuous operation.

360° Rotation Platform System: The rotating platform incorporates an integrated drive mechanism enabling continuous forward and backward rotation. The entire vehicle can perform forward/reverse movement, diagonal shifting, and 360° rotation on the spot. Primarily used for angle adjustments in confined workstations, cross-directional docking, or precision assembly. Rotation can be coordinated with travel and lifting functions, reducing repetitive repositioning and enhancing operational efficiency during multi-process transitions.

V-Shaped Workpiece Clamping Platform: Featuring a V-shaped structural design, this platform accommodates cylindrical components, pipes, hydraulic structures, and other irregularly shaped workpieces. Anti-slip and anti-roll mechanisms maintain workpiece stability during transport, lifting, and rotation, effectively minimising displacement and enhancing personnel and equipment safety. It is particularly suited for the precise handling of irregular or easily rolling materials.

Equipment Interconnection System: Automated AGVs enable bidirectional communication with host systems or external devices, facilitating automatic workstation requests, autonomous docking, task-triggered signal exchange, and status monitoring. They execute automated action sequences based on workflow protocols, implementing intelligent transport and maintenance logic where workstations locate equipment and workpieces find processes.

Multifunctional AGV Transfer Car

Technical Specifications Overview

This transfer vehicle features 360° omnidirectional movement, hydraulic lifting, and anti-slip platform functionality, enabling safe and precise operation. Additionally, it incorporates customisable features to facilitate efficient inspection and maintenance of hydraulic equipment. Below, we present the detailed specifications of this multi-functional automated AGV transfer vehicle.

| Parameter | Specification |

|---|---|

| Capacidad de carga | 3T |

| Dimensions (L × W, mm) | 1600 × 1000 |

| Table Height (mm) | 1000 |

| Distancia al suelo (mm) | 60 |

| Floor Requirement | Concrete |

| Power Supply | Batería de litio |

| Operation Mode | Wireless Remote Control + Automatic Control |

| Drive Motor Power | 4×1.5KW |

| Velocidad de desplazamiento (m/min) | 0–30 |

| Braking Type | Freno electromagnético |

| Material de la rueda | Polyurethane Coated |

| Turning Mode | Rudder Wheel Steering |

| Movement Mode | Forward/Reverse, Turn-while-moving, Diagonal Movement, Sideways Movement, Spot Turning |

| Charger Installation | Vehicle-mounted |

| Charger Function | Fully Automatic Intelligent Charging |

| Lift Stroke (mm) | 750 |

| Safety Measures | Audible & Visual Alarm, Emergency Stop, Laser Obstacle Avoidance |

| Otras funciones | Battery Level Display, Overvoltage, Undervoltage, Overcurrent Protection |

These are some of the specifications for our intelligent AGV vehicles. Should you be interested in our intelligent AGV transfer cars, please contact us and we shall provide customised services tailored to your requirements.

Vídeos

Custom Parts for AGV Transfer Car

The REMARKABLE intelligent AGV car supports 100% customisation for specific operational scenarios, enabling in-depth design tailored to industry requirements, manufacturing processes, and workpiece characteristics. Customisation options include:

- Load Capacity Customisation: Capacity ranges from 1 tonne to over 200 tonnes, with chassis structure and powertrain engineered according to workpiece weight.

- Platform Structure Customisation: V-shaped fixture surfaces, platform tilting, bidirectional or multidirectional rotation, and high-precision positioning platforms to fulfil diverse workpiece support, rotation, and machining requirements.

- Lifting Height and Method Customisation: Adjustable range from 500mm to 2000mm, with options for electric screw jacks or hydraulic lifting systems to accommodate varying production line heights and docking configurations.

- Navigation Method Customisation: Laser navigation, inertial navigation, magnetic strip navigation, hybrid navigation, etc., adaptable to open, semi-enclosed, or complex site environments.

- Communication and control logic customisation: Tailored to specific production line requirements, including PLC integration methods, process trigger logic, remote monitoring interfaces, production cycle timing, and path planning. This enhances the integration of intelligent AGV robots into existing automation systems.

- Safety and protection customisation: Includes obstacle avoidance radar, anti-collision strips, audible and visual alarms, and emergency stop systems. These can be configured according to on-site safety requirements.

The following is a reference table for customisation options related to the RWP series transfer carts:

| Technical Parameters Table Of RWP Trackless Electric Transfer Cart | |||||||||||

| Capacidad de carga nominal(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Tamaño de la mesa (mm) | Longitud | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Anchura | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Altura | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Altura libre al suelo(mm) | ≥50 | ≥100 | |||||||||

| Radio de giro(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Modo de dirección | Dirección diferencial | Dirección hidráulica | |||||||||

| Método de funcionamiento | Remote Control & Hand-Operated Pendant | ||||||||||

| Muévete | Forward, backward, turning while driving with no stop, and a 360° rotation | Forward, backward, turning while driving with no stop | |||||||||

| Velocidad de carrera(m/min) | 25 | 20 | |||||||||

| Tipo de motor | Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| Modo Freno | Freno electromagnético | ||||||||||

| Medidas de protección | Luz de alarma acústica y visual+ Botón de parada de emergencia+Sensor láser de prevención de obstáculos(Opcional)+Borde de contacto anticolisión(Opcional) | ||||||||||

| Cantidad de ruedas | 4 | 6 | 8 | ||||||||

| Diámetro de la rueda motriz(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Material de la rueda | Steel Core + Polyurethane | ||||||||||

| Capacidad de la batería(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Tipo de batería | Batería de plomo-ácido | Batería de litio | |||||||||

| Resistencia de la batería | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| Tiempo de carga de la batería | ≤7h | ≤5h | |||||||||

| Cargador de batería | AC220V/AC380V | ||||||||||

| Tipo de suelo | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| Capacidad de ascenso a plena carga | 5% | 3% | |||||||||

| Entorno de trabajo | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customized for high-temperature and explosion-proof environments) | ||||||||||

| Color de la carrocería del vehículo | Personalizado | ||||||||||

| Otras funciones | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection etc | ||||||||||

| Notas: 1) Se pueden personalizar otros tamaños de mesa y capacidades de carga según los requisitos del usuario. 2) For hydraulic steering, a dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints. 3) Battery type and operating time (battery endurance) can be customized to meet customer needs. 4)The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||||||

REMARKABLE offers a range of customisable capabilities. If you have any questions or are interested in our intelligent AGV transfer car, please contact us. We shall provide the optimal solution.

Características

Multifunctional

Features transport, lifting, rotation, and anti-slip capabilities to facilitate multi-process operations.

Gran capacidad de carga

Employing high-strength design for stable handling and lifting of workpieces weighing 3 tonnes or more.

Fully Automated

Supports autonomous navigation, automatic docking, lifting, and rotation, executing end-to-end operations via command systems.

Precision Handling

Supports PLC/MES system integration for automated multi-device docking, interaction, and precise positioning

Alta seguridad

Equipped with multiple safety mechanisms including laser obstacle avoidance, emergency stop, interlock logic, and posture monitoring.

Highly Custom

Supports bespoke configurations for platform dimensions, tooling fixtures, navigation methods, and lifting strokes.

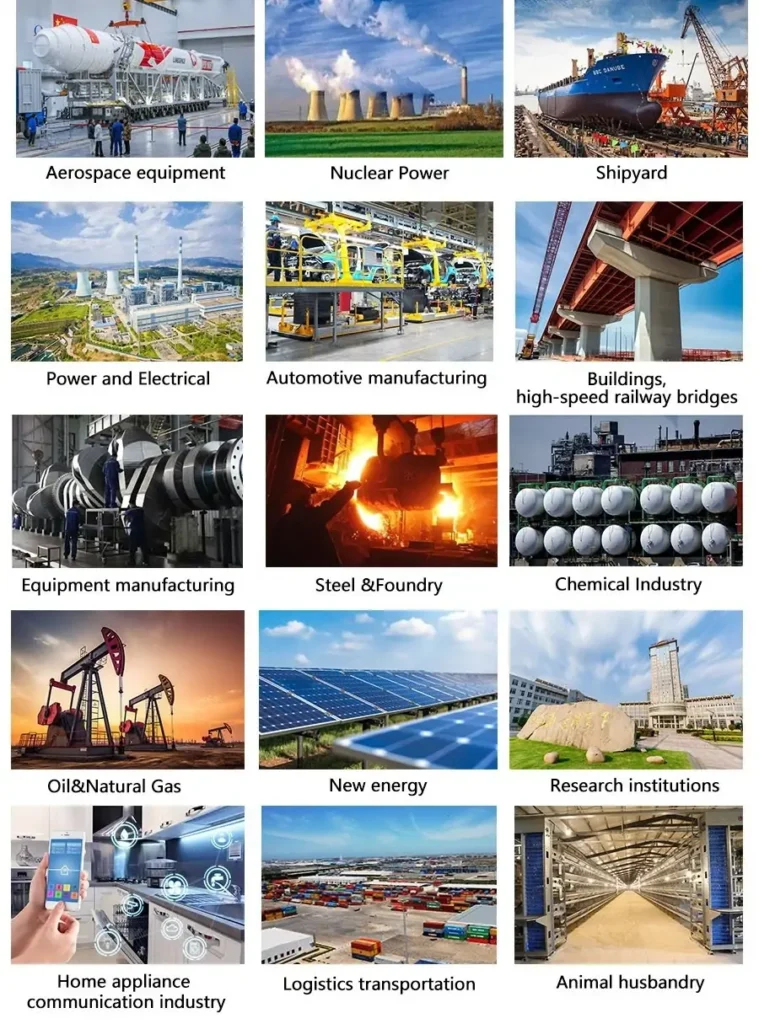

Application for AGV Transfer Car

The multi-functional automated guided vehicle transport system, featuring omnidirectional mobility, precise positioning and robust load-bearing capacity, serves not only as a primary transport solution for the water resources sector but also across numerous other industries.

Precision Manufacturing

The multi-functional AGV transfer car enables high-precision movement, lifting and angular adjustment, enhancing docking accuracy while resolving issues of positioning inaccuracy and spatial constraints.

Machining and Metal Fabrication

Heavy-duty chassis and V-clamp work surfaces safely transport bulky, irregularly shaped or rolling materials, enhancing load capacity while boosting transport efficiency and safety.

Water Resources and Energy Equipment Manufacturing

Facilitates handling large components in confined spaces, with lifting and rotating platforms aiding installation and maintenance. Supports inspection, modification and secure heavy-load manoeuvring.

Automated Production Lines / Smart Factories

Intelligent AGVs autonomously request workstations, dock with precision, and execute automated loading/unloading, boosting production line automation efficiency while reducing labour costs.

Railway Engineering Sector

Multi-functional transport vehicles enable precise positioning of tools and components, accelerating inspection tasks and minimising downtime around rolling stock.

Industria aeroespacial

Delivers high-payload, high-precision, multi-degree-of-freedom workpiece handling, enhancing safety during transport of specialised materials and large components.

This versatile AGV transfer car improves safety, efficiency, and workflow, meeting diverse material handling requirements with flexible and reliable solutions.

Transfer Cart Case Showcase

Multifunctional AGV Transfer Car Manufacturer

Henan Remarkable Intelligent Technology Co., Ltd is located at No. 22, Xinchang North Line, Xiaodian Town, Hongqi District, Xinxiang City, Henan Province. It is a professional handling equipment company integrating R&D, design, manufacturing, sales, and after-sales service. It specializes in the production of various types and tonnages of handling equipment and their accessories, and provides professional R&D, design, and manufacturing of various non-standard and Carros de transferencia eléctricos, Carros de transferencia sobre raíles, Carros de transporte móviles omnidireccionales, Battery transfer carts, Carros de transporte de cargas pesadas, Robots de manipulación AGVy remolques industriales.

Products from REMARKABLE strictly adhere to the JB/T6127-2010 mechanical industry standard and hold ISO certifications for quality, environmental management, and occupational health and safety systems, alongside CE certification. The company possesses multiple national patent technologies, delivering reliable, safe, and efficient industrial material handling solutions to its users.

¿Por qué elegirnos?

- Conocimientos específicos del sector - Servimos a los sectores de generación de energía, construcción naval, construcción y aeroespacial con soluciones a medida para transformadores, componentes de aerogeneradores, módulos prefabricados y mucho más.

- Fully Customized - Desde la capacidad de carga (1-500+ toneladas) hasta los sistemas de propulsión (eléctrico, híbrido o diésel), satisfaga sus requisitos exactos.

- Sistemas de control avanzados - Las opciones incluyen control remoto manual, planificación semiautomática de rutas o navegación totalmente automatizada (integración de AGV).

- Calidad y durabilidad - Robustos bastidores de acero, módulos de dirección de alto par y certificación CE, ISO.

- Apoyo total al proyecto - Desde la consulta inicial hasta el servicio posventa, nuestros ingenieros ofrecen asistencia técnica de por vida.

Artículos relacionados

Soluciones inteligentes de manipulación de materiales personalizadas

Para garantizar que un carro de traslado personalizado se adapte perfectamente a sus necesidades, facilítenos los siguientes datos:

- Capacidad de carga: _____ toneladas (1~500 toneladas)

- Tamaño de la mesa: _____ × _____ mm/m (por ejemplo, 1500×3000)

- Opciones de alimentación:

- ☐ Plomo-ácido ☐ Ión-litio ☐ Otros: _____

- ☐ Cable: _____V/_____A

- Estándar 380 V/50 Hz/3 fases

- Detalles de la carga:

- Tipo: _____ (por ejemplo, bobinas de acero, maquinaria)

- Necesidades especiales: _____ (por ejemplo, antideslizante, resistente a la corrosión)

- Características opcionales:

- ☐ Parada de emergencia ☐ Sensores anticolisión

- ☐ Guías de carril ☐ Mecanismo de elevación ☐ Mando a distancia