As the development of the smart era progresses, many enterprises are transitioning to intelligent automated factory models. Among automated logistics equipment, AGVs (Vehículos de guiado automático) offer flexibility, safety, and efficiency. They can handle internal factory transportation, warehousing and distribution, and workshop material transfer, making them a crucial tool for businesses to enhance production efficiency. So, why AGV robot popular? This article will explore the reasons behind AGVs’ popularity from two perspectives. Let’s delve into the details.

The Advantages of AGV Robot

Automated guided vehicles offer multiple benefits, including enhanced safety. Below is a detailed analysis of their primary advantages from a business perspective.

Boosting production efficiency

Traditional manual handling is prone to issues like fatigue and inconsistent operation, which can disrupt production line progress. AGVs, however, feature precise positioning and navigation capabilities, enabling stable 24/7 operation unaffected by human factors. This significantly improves internal workshop logistics efficiency, achieving stable and high-efficiency material flow.

Advantages: 1. Repeatable Routes & High Execution Precision 2. Eliminates delays caused by manual handling 3. Ideal for cadence-based production and flexible logistics

Reduce Labour Costs

As labour costs rise and recruitment becomes increasingly challenging, more enterprises are adopting AGV robots to replace repetitive, high-intensity material handling tasks.

Advantages: 1. Minimise manual input, eliminate recruitment and training processes, and save on long-term labour expenses 2. Reduce accidents caused by manual handling and lower personnel injury risks 3. Ideal for multi-shift factories or labour-intensive workshops

Alta seguridad

Heavy AGV robots are equipped with safety devices, including LiDAR, vision systems, infrared sensors, and obstacle avoidance sensors. They can automatically detect obstacles, proactively avoid collisions, decelerate automatically, and stop precisely. Their controllable routes make them safer than traditional transport methods, such as forklifts.

Advantages: 1. Prevents collisions and human errors, reducing accident rates. 2. Automated operation with simple, convenient control enhances overall safety management levels 3. Suitable for precision manufacturing, high-value material handling, and narrow aisles

Highly flexible and extendable

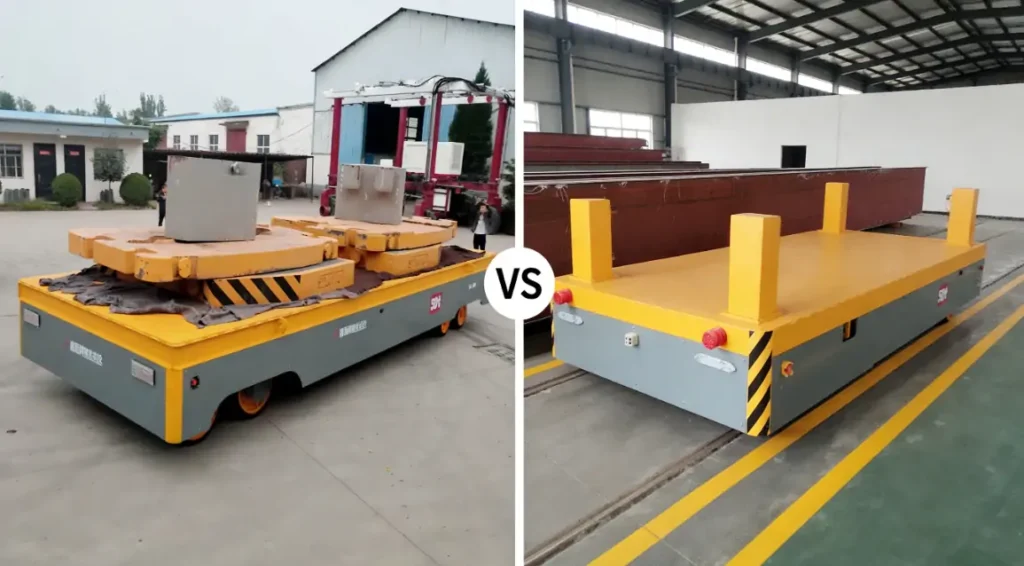

Compared to traditional rail-guided vehicles or fixed conveyors, AGV robots offer superior adaptability. Heavy-duty AGVs feature advanced sensor systems and intelligent management systems, making them ideal for factories with frequent order changes and production line adjustments.

Advantages: 1. The ground requires no major modifications, and routes can be quickly modified. 2. Supports customisation and expansion into Heavy-duty robot fleet management systems. 3. Adaptable to more complex factory environments and logistics scenarios.

We understand that AGVs themselves offer advantages like high efficiency and safety, making them popular among enterprises. Next, let’s examine which aspects of market demand are driving the advancement of heavy-duty robotic transport vehicles.

Market Demand Growth Accelerates for AGV Robot

Increasing market demand is driving the widespread adoption of heavy-duty AGV robots. As the era of smart manufacturing advances rapidly, industries such as automotive manufacturing and logistics warehousing are seeing a growing need for automated guided carts.

Accelerated Adoption of Smart Manufacturing: When enterprises advance smart factory automation, heavy-load AGV transfer carts are the first choice due to their ease of implementation and favourable cost-benefit ratio. Heavy-duty AGVs offer controllable costs, short implementation cycles, and seamless integration with MES, WMS, and warehouse systems. Their strong applicability across multiple industries—including automotive, packaging, electronics, and metal processing—has led to a steady annual increase in adoption rates.

Growing Enterprise Demand: As market demands become increasingly volatile, factory logistics systems must adapt with flexibility. AGV robots inherently suit rapidly changing production patterns, enabling frequent factory transitions, handling small-batch, high-frequency orders, and accommodating workshops requiring swift capacity scaling. Many enterprises increasingly seek flexible material handling AGVs to upgrade their production models.

Rising Labour Costs: Labour expenses continue to climb in regions like Europe, America, Japan, South Korea, and China. Manufacturers can no longer rely on low-cost labour to maintain competitiveness. Heavy AGVs can replace repetitive workstations, reduce long-term operational costs, and operate effectively in “three highs and three risks” environments (high temperature, high load, high frequency & hazardous, fatigue-prone, error-prone), driving sustained expansion of AGV robot market demand.

Robot AGV

Robot AGV Autonomous-Mobile-Robots-AGV

Autonomous-Mobile-Robots-AGV Automated-Guided-Vehicle-AGV

Automated-Guided-Vehicle-AGV

Driven by market demand, we recognise that many enterprises are increasingly seeking automated guided vehicles, aligning with contemporary industry trends. Below, we briefly introduce our transfer cart supplier.

Reliable AGV Robot Transfer Cart Manufacturer

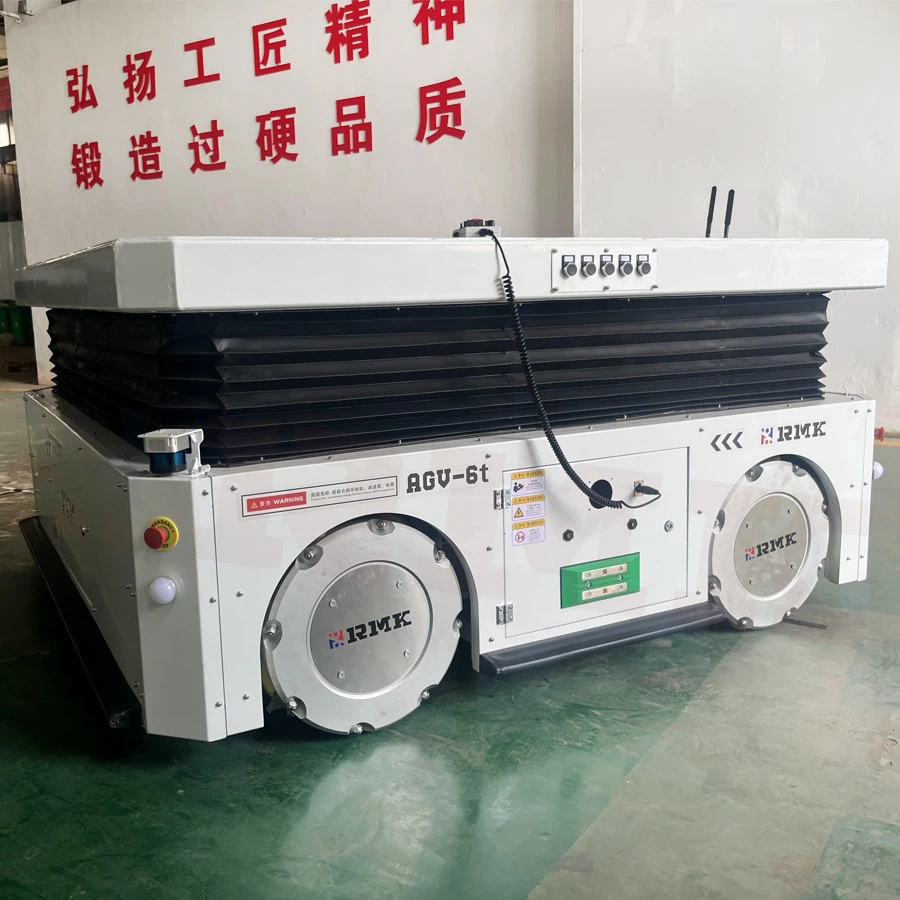

As a specialised manufacturer of transfer cart solutions, REMARKABLE possesses extensive expertise in non-standard customisation, heavy-duty logistics handling, and factory automation upgrades. With robust engineering capabilities, a comprehensive production system, and broad industry experience, it delivers customised AGV material handling solutions tailored to factory layouts, production line rhythms, and material characteristics. This empowers clients to achieve safer, more efficient, and smarter logistics operations.

Conclusión:

Through the above discussion, we understand that AGV robots have become popular equipment in smart manufacturing because they address three major pain points for enterprises: efficiency, cost, and safety. Simultaneously, market trends are further driving the development of AGVs.

If you are interested in our AGV transfer carts, please Contacto. We will assist you in customising an AGV solution or heavy-duty AGV transfer cart. We welcome your inquiries.