With the rapid advancement of smart manufacturing, internal logistics requirements within enterprises extend beyond mere material handling. There is a growing demand for multi-task coordination and flexible operational capabilities. To meet these heightened industry demands, REMARKABLE has engineered a Multi-Functional automated AGV guided vehicle. This innovative intelligent AGV integrates multiple functions—transportation, lifting, rotation, alignment, and pick-and-place operations—into a single unit. It achieves deep integration with production lines, enabling end-to-end automation. Let us explore its capabilities.

What is a Multi-Functional Automated AGV Guided Vehicle?

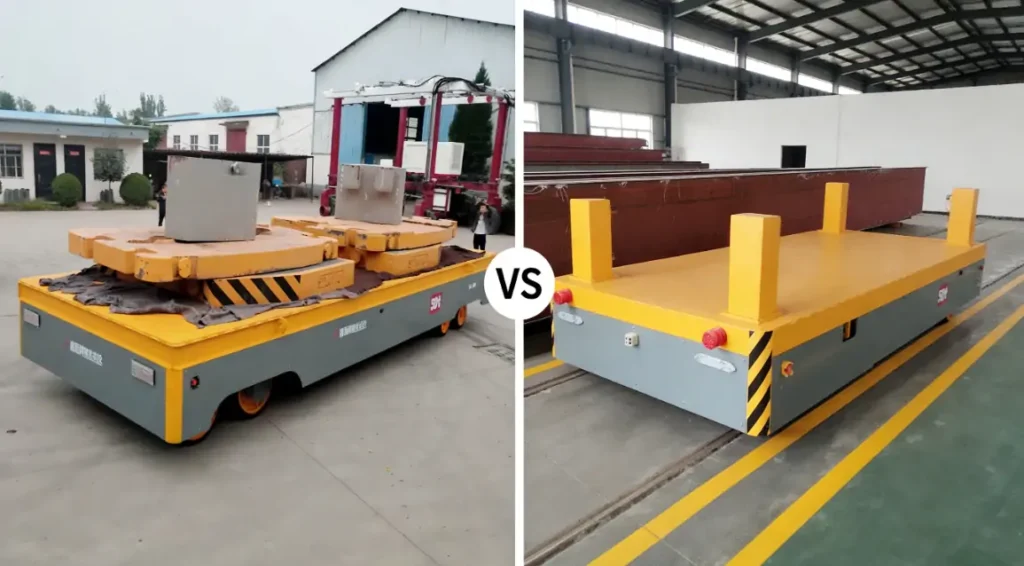

The Multi-Functional Integrated AGV builds upon traditional AGV technology by incorporating multiple actuators: a lifting platform, 360° rotating turntable, V-shaped lifting fixture, and intelligent alignment system. It navigates autonomously while achieving precise docking between workstations, lifting to designated heights, rotating to specific angles, and executing part handling operations. This AGV automated guided vehicle, offers the advantage of multi-purpose functionality, replacing multiple workstation devices to achieve seamless, continuous automated process integration. It is suitable for sectors including aerospace, water conservancy, and intelligent warehousing.

Having understood the multi-functional AGV automated guided cart, let’s look at its key advantages.

Advantages of the Multi-Functional AGV Guided Vehicle

Compared to traditional automated guided vehicles, the multi-functional AGV guided vehicle not only handles material transport but also delivers value-added benefits such as enhanced production efficiency, reduced space and equipment costs, and improved safety.

Multifunctional: Integrates handling, lifting, rotation, and workstation docking functions, eliminating the need for additional equipment such as lifting platforms, rotary tables, or manual alignment fixtures. Tasks previously requiring coordination between forklifts and manual labour are now performed autonomously by AGVs, reducing factory investment costs and enhancing automation rates.

Automatic Workstation Docking: Interconnects with production line PLCs and automated equipment via signal exchange to achieve automated docking, pick-and-place operations, and automatic reset functions. Combining lifting height with a 360° rotating platform enables precise positioning with millimetre-level accuracy, facilitating multi-angle, multi-directional automated assembly and process integration.

Synchronised Motion Execution: Supports concurrent execution logic for movement, lifting, and rotation, eliminating sequential action delays. For instance, lifting may commence during transit, with immediate rotational alignment upon reaching the workstation—eliminating waiting periods. This substantially reduces individual process durations, yielding a more compact overall cycle time.

Supports heavy-duty complex workpiece handling: Accommodates large-volume, heavy-load, or irregularly shaped components. The V-shaped platform securely supports tubular, cylindrical, or non-standard workpieces, effectively preventing rolling and displacement. The 360° rotation structure enables angle adjustments even in confined spaces, enhancing adaptability and safety.

Highly customisable: Load capacity, navigation methods (laser, SLAM, magnetic strip), lifting height, and table configurations can be tailored to requirements. This flexibility adapts to new processes and equipment, supporting flexible factory upgrades. Ideal for industries with diverse product ranges, small batches, or frequently changing demands.

Having explored the advantages of this versatile AGV, let us now examine its application domains.

Application Industries for Multi-Functional AGV Guided Vehicle

AGV transfer vehicles offer high flexibility, multi-functionality, and deep customisation capabilities, finding extensive application across multiple manufacturing sectors.

Aerospace Equipment: Suitable for handling large, high-precision, or specially structured components, enabling precise docking and rotational positioning to enhance assembly quality and safety.

New Energy Sector: Ideal for automated docking and transfer of modules, PACKs, and cell trays, supporting multi-directional assembly to improve production line cycle stability.

Water Engineering: Suited for transporting oversized components or lifting requirements, enabling automated interfaces between diverse equipment to minimise human error.

Automated Machinery Manufacturing: Ideal for handling complex components like steel structures, mechanical parts, and heavy assemblies. Combining V-shaped platforms and rotary tables enhances efficiency and safety.

High-End Equipment Handling: Employed for precise equipment placement, workstation docking, and orientation adjustments, delivering stable and reliable automated processes.

Equipamiento aeroespacial

Equipamiento aeroespacial Water Engineering

Water Engineering

Automated Machinery Manufacturing

Automated Machinery Manufacturing New Energy Sector

New Energy Sector Warehouse logistics

Warehouse logistics

Automated AGV guided vehicles find extensive application across industries requiring material transport. So how should one select a supplier? Let us explore.

Choosing the Right AGV Guided Vehicle Manufacturer

Multifunctional AGV robots are bespoke equipment requiring substantial capabilities from manufacturers. When selecting suppliers, focus on the following key aspects:

- In-house R&D Capabilities: Opt for manufacturers with proprietary development of core technologies such as navigation systems to ensure deep functional integration and sustainable system upgrades.

- Multi-functional integration capability: Possesses high customisation capacity to modularise complex structures like lifting, rotation, and work surfaces, meeting multi-process automation demands.

- Cross-industry project experience: Examine implementation cases in high-standard sectors such as power generation, water conservancy, aerospace, and new energy to verify technical maturity and engineering capability.

- Equipment reliability: Ensure devices undergo rigorous testing and industry safety certifications, delivering stable operation that meets safety and precision requirements.

- After-Sales Service System: A comprehensive support team and rapid response mechanism ensure prompt resolution of equipment faults, minimising downtime losses.

AGV guided vehicle manufacturers possessing these capabilities deliver genuinely reliable, efficient, and secure transport solutions, enabling production automation upgrades.

Conclusión:

This article has outlined the advantages of this multi-functional AGV guided vehicle, its application domains, and how to select an AGV transfer cart manufacturer. Should you be interested in our intelligent AGV automated transfer vehicles, please Contacto anytime. We are committed to providing customised solutions, offering you the most suitable products and premium service.