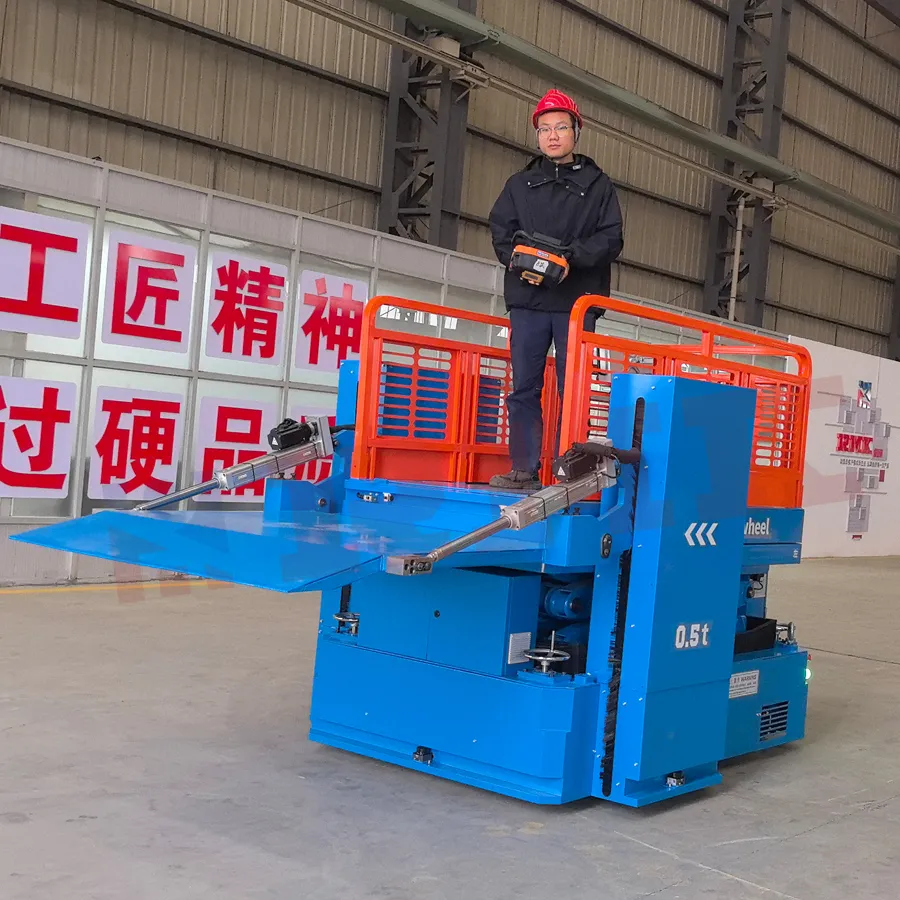

The Multifunctional Omnimove Transfer Cart is a 转运车 specifically designed and manufactured for aircraft maintenance operations.. Featuring 360° maneuverability, trackless operation, and multiple movement modes including longitudinal, lateral, diagonal, and rotational steering, it enables precise navigation within confined hangar spaces. This integrated system combines hydraulic lifting, platform sliding, and tilting functions to facilitate the handling of aircraft components and ensure personnel safety during operations. Equipped with an intelligent display, safety interlock devices, and protective systems, it ensures reliable handling of precision aerospace components.

了不起 offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- 型号 RWP

- 负载能力 0.5 Tons

- 尺寸 2100×1400 × 1200 mm

- Lifting Stroke: Hydraulic lifting, 1400 mm

- 电源: Maintenance-free battery (electric drive)

- 速度 0–20 m/min (stepless speed regulation)

- 自定义: 可定制生产,包括附加组件等。

Working Principle of the Multifunctional Omnimove Transfer Cart

The following explanation of the operating principles of the multifunctional omnimove transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

工作原理:

- Power-up

- Switch on the main power supply. The system draws power from the battery (48V/130Ah) to supply the vehicle controller, drive units, and hydraulic pump.

- Electronic control self-test: Display self-check, sensor and communication link verification, fault code clearance, and readiness confirmation.

- Inspection items: Battery charge display, braking system, laser obstacle avoidance/safety edge, outrigger sensors, and emergency stop button functionality check.

- Mode Selection

- The operator selects the operating mode (movement/lifting/translation/tilting/outrigger deployment) via wireless remote control or wired joystick.

- The controller issues commands to the functional modules based on the selected mode and activates the corresponding safety paths.

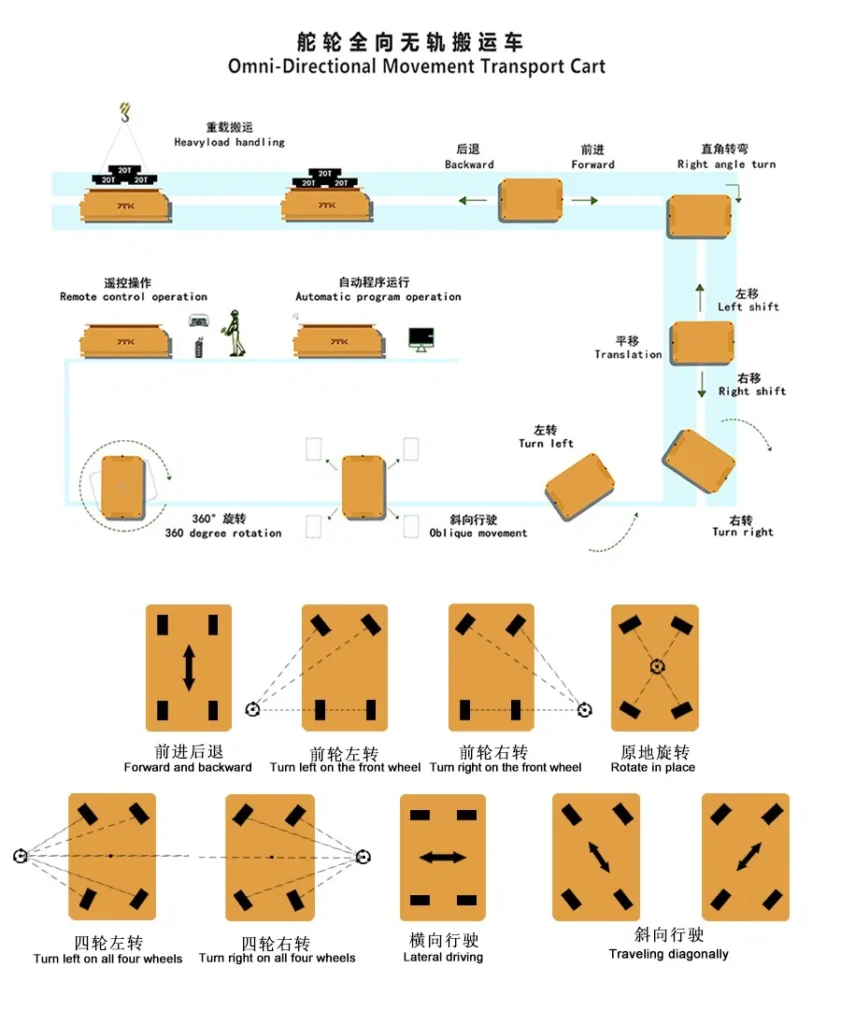

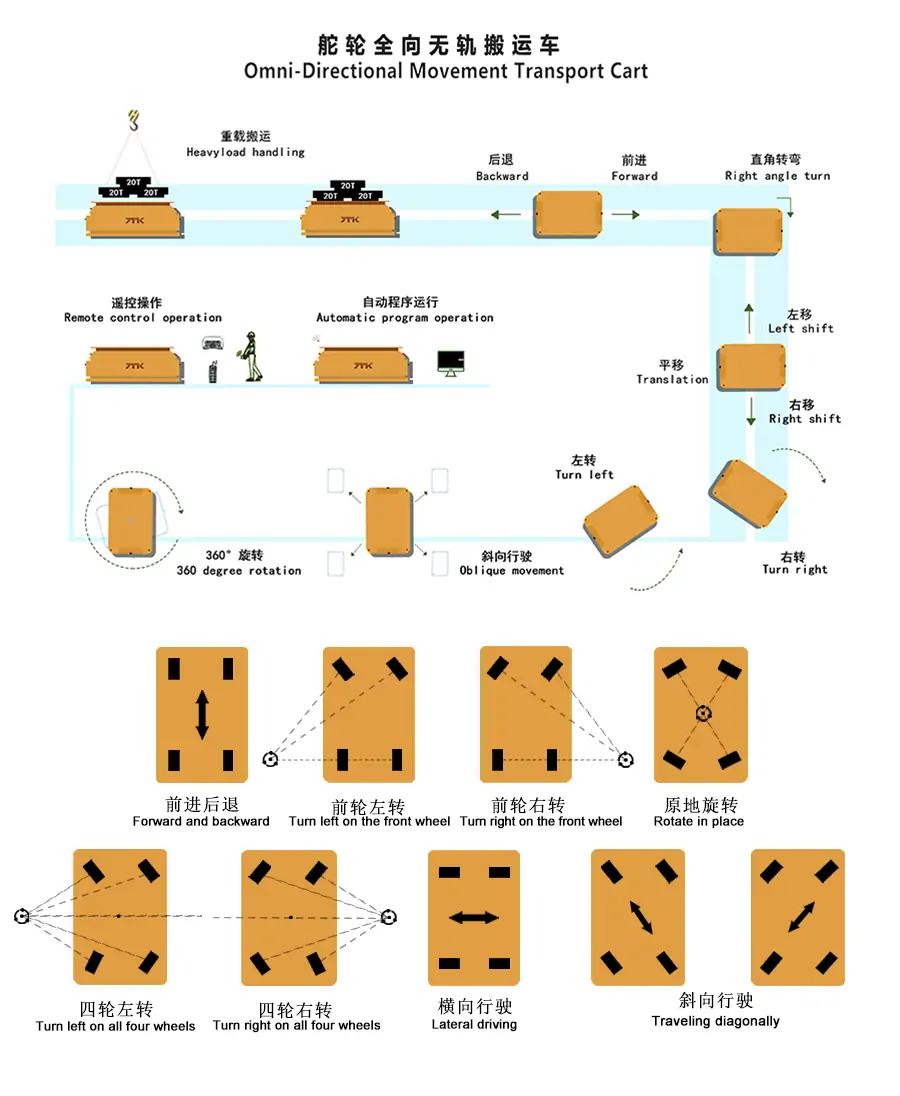

- Drive and Omnidirectional Mobility

- Dual drive motors (2 kW ×2) provide traction; four steering motors (0.75 kW ×4) independently control the steering angle of each of the four steering wheels.

- Control algorithms calculate each wheel’s speed and steering angle in real time, enabling: forward/reverse, lateral movement (sideways), diagonal movement, on-the-spot rotation, and diagonal traversing for omnidirectional motion.

- Encoders and speed sensors at the wheel ends feed back to the drives, forming a closed-loop speed/position control system that ensures positioning accuracy and motion smoothness.

- Positioning

- The operator or automated assistance system monitors position via on-board displays (platform surface and remote control).

- Laser obstacle avoidance and distance sensors operate during low-speed precision positioning, triggering deceleration and enabling precise approach to the docking point at a set step distance.

- Soft-cushion support and buffering mechanisms absorb micro-impacts upon contact, preventing damage to sensitive composite components.

- Hydraulic Platform Elevation and Translation (Upper Platform)

- Activate the hydraulic pump to drive cylinders or scissor mechanisms for platform elevation (upper platform translation stroke approx. 400 mm; elevation stroke ≥1400 mm, with customisable longer strokes available).

- Lifting employs flow/pressure closed-loop control, with the controller precisely limiting lifting speed via valves (e.g., 3–4 m/min) while continuously monitoring load and displacement sensors.

- Platform traversal and tilting are controlled by dedicated motors/actuators, achieving up to 70° tilt angles with position locking before and after operations.

- Small Platform Operation

- The small platform employs an independent hydraulic/electric drive, supporting ≥1100 mm vertical travel and 70° tilt for local assembly and workstation adjustments.

- During small platform operation, the system temporarily locks the vehicle’s movement and unrelated modules (interlock mechanism) to prevent concurrent actions from causing hazards.

- Outrigger/Stabiliser Deployment and Stability Control

- Before elevated or loaded operations, the control system deploys all four hydraulic outriggers to ground contact, with load feedback from outrigger sensors.

- Upon meeting load-bearing requirements, the vehicle disengages wheel-end drive (or switches to parking mode) to prevent overturning and enhance operational stability.

- Personnel and Cargo Safety

- Hardware and software interlocks operate between all modules: vehicle movement or platform tilting is prohibited if lifting is incomplete or outriggers are not deployed.

- Laser obstacle avoidance, edge contact protection, and audible/visual alarms immediately trigger emergency stop logic upon detecting imminent hazards.

- Operator displays and remote controllers simultaneously show status and warnings, facilitating coordinated decision-making between near and remote operators.

- Electromagnetic Braking

- During normal operation, the drive unit regulates braking force for smooth stopping. Upon power failure or emergency stop, electromagnetic brakes forcibly engage to ensure static safety.

- During lateral movement or under load, braking control integrates with torque monitoring algorithms to prevent slippage or positional drift.

- Charging

- A separate charger provides fully automated intelligent charging, with the system managing charging profiles and safeguarding against overvoltage, undervoltage, and overcurrent.

- The Battery Management System (BMS) monitors battery health and available capacity, issuing alerts or restricting non-essential functions during low charge states.

- Shutdown and Maintenance

- During shutdown, first retract the platform to transport position, retract outriggers, disconnect peripherals, then transition to standby/off mode.

- Regular maintenance points include: hydraulic oil replacement, tyre (polyurethane-coated) inspection, encoder/sensor calibration, battery health assessment, and brake system inspection.

全方位移动运输车

多功能 Omnimove 搬运车

Technical Specifications Overview

Discover the specifications of the multi-functional omnidirectional aircraft transfer trolley. Featuring 360° mobility, hydraulic lifting, platform sliding, and tilting capabilities, this transfer trolley enables safe and precise operations. Equipped with customisable features, it facilitates efficient aircraft inspection, maintenance, and MRO (Maintenance, Repair, and Overhaul) tasks.

| 参数 | Specification |

|---|---|

| 负载能力 | 0.5T |

| Dimensions (L × W, mm) | 2100 × 1400 |

| Table Height (mm) | 1200 |

| 离地间隙(毫米) | 60 |

| Floor Requirement | Concrete |

| 电源 | Maintenance-free Battery |

| 电池容量 | 48V 130Ah |

| Operation Mode | Wireless Remote + Wired Handle |

| Drive Motor Power | 2 kW × 2 |

| Steering Motor Power | 0.75 kW × 4 |

| 车轮直径(毫米) | 250 |

| 车轮数量 | 4 |

| 移动速度(米/分钟) | 0–25 |

| Braking Type | 电磁制动器 |

| 车轮材料 | Polyurethane Coated |

| Turning Mode | Steering Wheel |

| Movement Mode | Forward/Backward, Turn While Moving, Diagonal, Lateral |

| Charger Installation | Separate Type |

| Charger Function | Fully Automatic Intelligent Charging |

| Charging Time (h) | ≤8 |

| Upper Platform Lift Stroke (mm) | ≥1400 |

| Lift Speed (m/min) | 4 |

| Lift Power | 3 kW |

| Upper Platform Travel Stroke (mm) | 400 |

| Upper Platform Travel Power | 0.75 kW |

| Small Platform Lift Stroke (mm) | ≥1100 |

| Lift Speed (m/min) | 3 |

| Lift Power | 0.75 kW × 2 |

| Small Platform Tilt Angle | 70° |

| Small Platform Tilt Power | 0.75 kW × 2 |

| Safety Measures | Audible & Visual Alarm, Emergency Stop, Laser Obstacle Avoidance, Safety Edges |

| 其他职能 | Battery Level Display, Overvoltage, Undervoltage, Overcurrent, Outrigger Protection |

视频展示

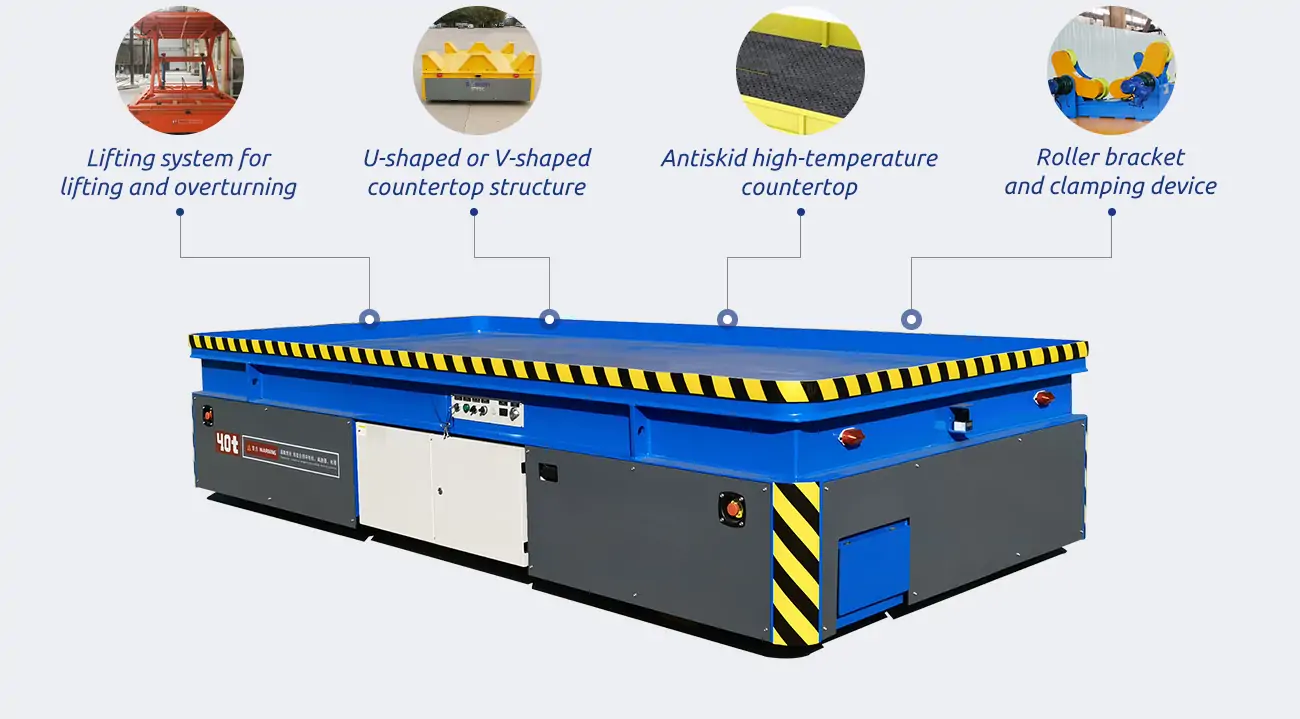

Custom Parts for Omnidirectional Transfer Cart

Custom Series Parameters for Omnidirectional Transfer Cart

| Technical Parameters Table Of RWP Trackless Electric Transfer Cart | |||||||||||

| 额定负载能力(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| 工作台尺寸(毫米) | 长度 | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| 宽度 | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| 高度 | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| 离地间隙(毫米) | ≥50 | ≥100 | |||||||||

| 转弯半径(毫米) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| 转向模式 | 差速转向 | 液压转向 | |||||||||

| 操作方法 | Remote Control & Hand-Operated Pendant | ||||||||||

| 移动方式 | 前进、后退、在不停车的情况下转弯以及 360° 旋转 | 不停车驾驶时向前、向后、转弯 | |||||||||

| 运行速度(米/分) | 25 | 20 | |||||||||

| 电机类型 | Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| 制动模式 | 电磁制动器 | ||||||||||

| 保护措施 | 声光报警灯+ 紧急停止按钮+ 激光避障传感器(选配)+ 防碰撞接触边缘(选配) | ||||||||||

| 车轮数量 | 4 | 6 | 8 | ||||||||

| 驱动轮直径(毫米) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| 车轮材料 | Steel Core + Polyurethane | ||||||||||

| 电池容量(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| 电池类型 | 铅酸电池 | 锂电池 | |||||||||

| 电池续航时间 | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| 电池充电时间 | ≤7h | ≤5h | |||||||||

| 电池充电器 | AC220V/AC380V | ||||||||||

| 地面类型 | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| 满负荷攀爬能力 | 5% | 3% | |||||||||

| 工作环境 | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customized for high-temperature and explosion-proof environments) | ||||||||||

| 车身颜色 | 定制 | ||||||||||

| 其他职能 | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection etc | ||||||||||

| 备注 1) 可根据用户要求定制其他台面尺寸和承载能力。 2) 在液压转向方面,可根据场地空间限制选择双液压转向系统,以减小转弯半径。 3) 电池类型和工作时间(电池续航时间)可根据客户需求定制。 4)产品会不断改进和升级,表中规格如有变更,恕不另行通知。 | |||||||||||

特点

Omnidirectional Mobility

Capable of 360° rotational movement for precise execution of aircraft maintenance tasks.

Multifunctional

Features hydraulic lifting, sliding and tilting capabilities.

Safe Operation

Emergency braking, laser obstacle avoidance and interlocking devices ensure operator safety.

Precision Handling

Flexible support pads safeguard delicate aircraft components during transfer and assembly.

智能控制系统

Real-time operational status display with fully interlocked functions for assured safety.

定制

Tailor-made transfer cart available to meet specific operational requirements.

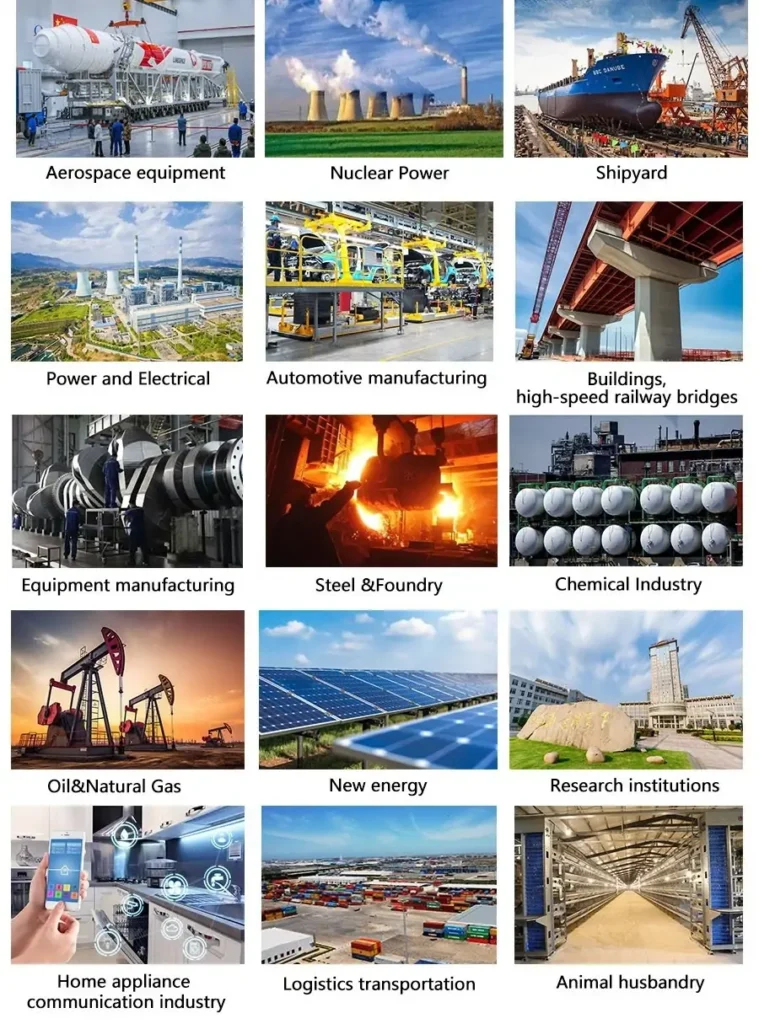

应用

A 多功能 Omnimove 搬运车 offers far more than aviation support. Its omnidirectional movement, precise positioning, and heavy-duty load capacity make it an ideal Transfer Cart solution for multiple industries. This all-direction transfer cart improves safety, efficiency, and workflow wherever flexible, reliable material handling is required.

Manufacturing

解决方案 This Omnimove Transfer Cart moves heavy components with precise control, solving space-limited handling issues on busy production floors.

Logistics

解决方案 The all-direction transfer cart boosts warehouse efficiency by transferring pallets smoothly in narrow aisles and reducing forklift dependence.

Rail Maintenance

解决方案 A multifunctional Transfer Cart positions tools and parts accurately, speeding inspection tasks and minimizing downtime around rail vehicles.

Energy Plants

解决方案 This heavy-duty omnidirectional cart transports modules and inspection kits safely through complex power-plant layouts during critical maintenance.

汽车

解决方案 The maintenance transfer cart moves engines and diagnostic tools between stations, improving workflow accuracy and repair efficiency.

Shipyards

解决方案 This omnidirectional transport vehicle handles large components in tight dock areas, supporting inspection, refits, and safe heavy-load mobility.

Transfer Cart Case Showcase

Multifunctional Omnimove Transfer Cart Manufacturer

河南卓越智能科技有限公司成立于2019年,位于河南省新乡市红旗区小店镇新昌北线22号。是一家集研发、设计、制造、销售、售后服务为一体的专业搬运设备公司。公司专业生产各种类型和吨位的搬运设备及其配件,并提供各种非标和特种搬运设备的专业研发、设计和制造。 电动搬运车, 轨道转运车, 全方位移动运输车, Battery transfer carts, 重型运输车, AGV 搬运机器人和 工业拖车.

公司产品符合 JB/T6127-2010 机械行业标准,通过了 ISO 三体系认证(质量、环境、职业健康)和 CE 认证。先后获得 19 项国家产品专利。

为什么选择我们?

- 特定行业的专业知识 - 我们为发电、造船、建筑和航空航天领域提供变压器、风力涡轮机组件、预制模块等定制解决方案。

- Fully Customized - 从负载能力(1-500 多吨)到驱动系统(电动、混合动力或柴油),都能满足您的确切要求。

- 先进控制系统 - 选项包括手动遥控、半自动路径规划或全自动导航(AGV 集成)。

- 质量与耐用性 - 坚固的钢架、大扭矩转向模块,并通过了 CE 和 ISO 认证。

- 全面项目支持 - 从初步咨询到售后服务,我们的工程师将提供终身技术援助。

相关文章

定制的智能物料装卸解决方案

为确保定制的转运车完全满足您的需求,请提供以下详细信息:

- 负载能力:_____ 吨(1~500 吨)

- 工作台尺寸:_____ × _____ mm/m(如 1500×3000)

- 电源选项:

- 铅酸电池 ☐ 锂离子电池 ☐ 其他:_____

- ☐ 电缆:_____V/_____A

- ☐ 标准 380 伏/50 赫兹/3 相

- 货物详情:

- 类型:_____ (如钢卷、机械)

- 特殊需求:_____ (例如防滑、防腐蚀)

- 可选功能

- ☐ 紧急制动 ☐ 防碰撞传感器

- ☐ 导轨 ☐ 提升装置 ☐ 遥控装置