The automatic trackless transfer cart, also known as an Carro de transferencia AGV, is an intelligent heavy-duty material handling device based on AGV technology. This 8-tonne lifting capacity AGV cart manufactured by REMARKABLE employs a laser navigation system, eliminating the need for track or magnetic strip installation to achieve autonomous navigation, path planning, and precise positioning. It supports multi-directional movement and high-precision docking, featuring a platform lifting function that enables flexible integration with production lines and workstations. Widely deployed in smart factories, heavy manufacturing, and automated production lines.

REMARCABLE offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- Load Capacity: 8 Tons

- Dimensiones: 3500 × 1700 × 400 mm

- Lifting Stroke: Hydraulic lifting, 100 mm

- Fuente de alimentación: Lithium iron phosphate battery

- Speed: 0–25 m/min (stepless speed regulation)

- A medida: Producción personalizada disponible, incluidos componentes adicionales, etc.

Working Principle of the Automatic Trackless Transfer Cart

This automatic trackless transfer cart employs a laser SLAM navigation system for operation. Through continuous scanning and mapping of the surrounding environment, it achieves real-time positioning and autonomous path planning. Furthermore, it automatically completes material handling tasks according to dispatch system instructions or manual commands, eliminating the need for human operation.

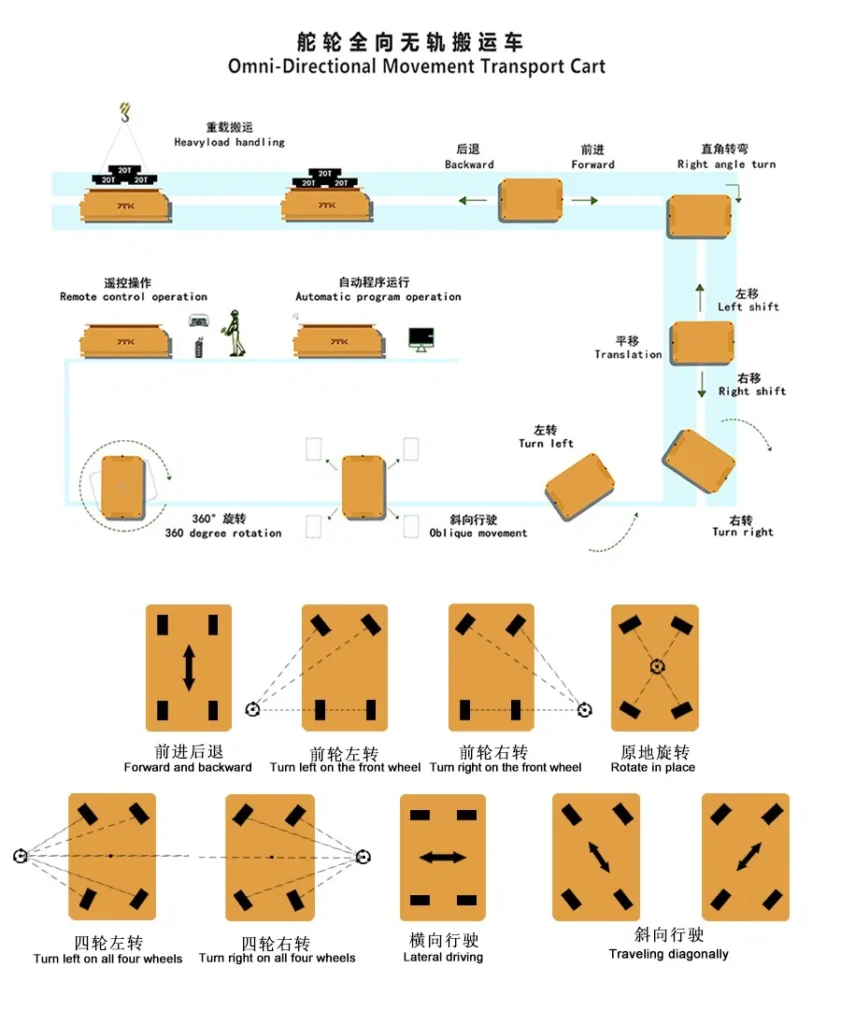

During operation, the transfer cart supports multiple movement modes, including forward, lateral, diagonal movement, and in-place rotation, flexibly adapting to complex factory layouts. When approaching target workstations, it achieves high-precision docking with ±20mm accuracy. Moreover, the full-surface hydraulic lifting mechanism permits fine height adjustment, ensuring smooth alignment between materials and production lines or equipment. Simultaneously, the laser obstacle avoidance system and multiple safety protection devices continuously monitor the operational environment, guaranteeing reliable and secure equipment operation.

Carro de transferencia automática sin orugas

The Automatic Trackless Transfer Cart Function

This heavy-duty 8-tonne automatic trackless transfer cart features highly integrated functional modules, designed for high-load, continuous operation scenarios to enhance long-term operational stability.

- Traverse and Steering System

Employing a composite traverse structure comprising four steering wheels and four swivel castors, it achieves omnidirectional movement, including forward, reverse, lateral, diagonal shifts, and on-the-spot rotation. This enables agile operation within narrow passages, intersections, and complex factory environments. - Drive and Power System

Features an independent multi-motor drive for stable, reliable power output, safely handling 8-tonne loads while maintaining smooth operation. Suited for high-frequency, prolonged continuous operation, effectively enhancing overall operational efficiency and service life. - Navigation and Control System

Equipped with a laser SLAM trackless navigation system, eliminating fixed routes by enabling autonomous mapping and path planning. Additionally, it supports multiple control methods, including autonomous operation, wireless remote control, and industrial tablet interfaces, facilitating seamless integration with automated systems. - Lifting System

Features a full-surface hydraulic lifting mechanism with smooth, synchronised movement. Enables precise height adjustment at workstations, ensuring safety and stability during material transfer and docking operations. Ideal for accurate height alignment with production lines, automated equipment, and workstations. - Safety Protection System

Integrated with laser obstacle avoidance, emergency stop buttons, safety edge sensors, and audible/visual alarms, it provides real-time monitoring of operational zones. Multi-layered safeguards prevent collision risks, ensuring personnel and equipment safety during operation.

Carro de transferencia automática sin orugas

Technical Specifications Overview

Explore the technical specifications of this 8-tonne automatic trackless transfer cart. Featuring 270-degree mobility and hydraulic lifting capabilities, it enables safe and precise operation.

| Tipo | Parameter | Remarks |

|---|---|---|

| Equipment Name | AGV-8t | 8-ton automatic trackless transfer cart |

| Carga nominal (t) | 8 | |

| Platform Size (mm) | 3500 × 1700 | |

| Platform Height (mm) | 400 | |

| Velocidad de desplazamiento (m/min) | 0–25 | Adjustable speed |

| Motor Power | 4 × 2 kW | |

| Power Supply | Lithium Iron Phosphate Battery | |

| Operating Time | Approx. 4 h | |

| Charging Time | ≤ 4 h | |

| Braking Mode | Electromagnetic Braking | Power-off brake |

| Wheel Configuration | 4 Steering Wheels + 4 Caster Wheels | |

| Material de la rueda | Polyurethane Coated Wheels | |

| Motion Modes | Forward, Backward, Lateral, Longitudinal, Diagonal, In-place Rotation | |

| Navigation Method | Laser SLAM Navigation | |

| Control Mode | Automatic Operation Wireless Remote / Wired Control Handle Industrial Tablet | |

| Platform Lifting | Full Platform Lifting | |

| Lifting Height (mm) | 100 | |

| Lifting Type | Hydraulic | |

| Protección de la seguridad | Laser Obstacle Avoidance | 270° front and rear |

| Protección de la seguridad | Audible & Visual Alarm Light | |

| Protección de la seguridad | Emergency Stop Button | |

| Protección de la seguridad | Safety Edge | |

| Body Color | Yellow | Personalizable |

| Positioning Accuracy | ±20 mm |

These are some of the specifications for our AGV transfer cart. If you are interested in our intelligent AGV cart, please contact us, and we will provide customised services tailored to your requirements.

Vídeos

Custom Series Parameters for Automatic Trackless Transfer Cart

| Technical Parameters Table Of RWP Trackless Electric Transfer Cart | |||||||||||

| Capacidad de carga nominal(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Tamaño de la mesa (mm) | Longitud | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Anchura | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Altura | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Altura libre al suelo(mm) | ≥50 | ≥100 | |||||||||

| Radio de giro(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Modo de dirección | Dirección diferencial | Dirección hidráulica | |||||||||

| Método de funcionamiento | Remote Control & Hand-Operated Pendant | ||||||||||

| Muévete | Forward, backwards, turning while driving with no stop | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customised for high-temperature and explosion-proof environments) | |||||||||

| Velocidad de carrera(m/min) | 25 | 20 | |||||||||

| Tipo de motor | Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| Modo Freno | Freno electromagnético | ||||||||||

| Medidas de protección | Luz de alarma acústica y visual+ Botón de parada de emergencia+Sensor láser de prevención de obstáculos(Opcional)+Borde de contacto anticolisión(Opcional) | ||||||||||

| Cantidad de ruedas | 4 | 6 | 8 | ||||||||

| Diámetro de la rueda motriz(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Material de la rueda | Steel Core + Polyurethane | ||||||||||

| Capacidad de la batería(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Tipo de batería | Batería de plomo-ácido | Batería de litio | |||||||||

| Resistencia de la batería | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| Tiempo de carga de la batería | ≤7h | ≤5h | |||||||||

| Cargador de batería | AC220V/AC380V | ||||||||||

| Tipo de suelo | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| Capacidad de ascenso a plena carga | 5% | 3% | |||||||||

| Entorno de trabajo | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection, etc | ||||||||||

| Color de la carrocería del vehículo | Personalizado | ||||||||||

| Otras funciones | Notas: 1) Other table sizes and load capacities can be customised according to user requirements. 2) For hydraulic steering, a dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints. 3) Battery type and operating time (battery endurance) can be customized to meet customer needs. 4)The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | ||||||||||

| Notas: 1) Other table sizes and load capacities can be customised according to user requirements. 2) For hydraulic steering, a dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints. 3) Battery type and operating time (battery endurance) can be customised to meet customer needs. 4)The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||||||

Features of Automatic Trackless Transfer Cart

Trackless Autonomous Operation

Utilises laser SLAM navigation, eliminating the need for track installation to enable flexible deployment and autonomous movement.

Gran capacidad de carga

Rated load capacity of 8 tonnes with robust construction, suitable for handling heavy components and equipment.

Omnidirectional Mobility

Supports forward, lateral, diagonal movement and in-place rotation, adapting to complex factory pathways.

High-Precision Docking

Utilises SLAM technology for positioning and docking accuracy of ±20mm, meeting production line interface requirements.

Full-Platform Hydraulic Lifting

Synchronised platform elevation facilitates precise integration with workstations and automated equipment.

Protección de la seguridad

Integrated laser obstacle avoidance, emergency stop, and audible/visual alarms provide comprehensive operational safeguards.

Application of Automatic Trackless Transfer Cart

The 8-tonne lift automatic trackless transfer cart finds extensive application across manufacturing, warehousing, and logistics sectors. This AGV enhances safety and efficiency, fulfilling diverse material handling requirements with flexibility and reliability.

Manufacturing production lines: Suitable for the automated transfer of raw materials, semi-finished products and tooling between different workstations, reducing manual handling and enhancing production efficiency.

Heavy industry and equipment manufacturing: Frequently employed for trackless handling of large structural components, heavy machinery and oversized workpieces, enabling safe and efficient transfer under complex operating conditions.

New Energy and Power Industry: Suitable for transporting high-value materials such as battery modules and electrical equipment, ensuring safety and stability throughout production and assembly processes.

Automotive and Component Manufacturing: Ideal for the automated transfer of engines, moulds, and body components, enhancing production line flexibility and overall automation levels.

Smart Warehousing and Logistics: Primarily employed for material transfer between storage and production zones, enabling automated scheduling and precise distribution to boost logistics operational efficiency.

Transfer Cart Case Showcase

Automatic Trackless Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and AGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised carros eléctricos de transferencia, rail-guided trolleys, omnidirectional mobile transfer carts, trackless transfer carts, AGV robotsy remolques industriales.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

¿Por qué elegirnos?

- Conocimientos específicos del sector - Servimos a los sectores de generación de energía, construcción naval, construcción y aeroespacial con soluciones a medida para transformadores, componentes de aerogeneradores, módulos prefabricados y mucho más.

- Fully Customised - Desde la capacidad de carga (1-500+ toneladas) hasta los sistemas de propulsión (eléctrico, híbrido o diésel), satisfaga sus requisitos exactos.

- Sistemas de control avanzados - Las opciones incluyen control remoto manual, planificación semiautomática de rutas o navegación totalmente automatizada (integración de AGV).

- Calidad y durabilidad - Robustos bastidores de acero, módulos de dirección de alto par y certificación CE, ISO.

- Apoyo total al proyecto - Desde la consulta inicial hasta el servicio posventa, nuestros ingenieros ofrecen asistencia técnica de por vida.

Artículos relacionados

Soluciones inteligentes de manipulación de materiales personalizadas

Para garantizar que un carro de traslado personalizado se adapte perfectamente a sus necesidades, facilítenos los siguientes datos:

- Capacidad de carga: _____ toneladas (1~500 toneladas)

- Tamaño de la mesa: _____ × _____ mm/m (por ejemplo, 1500×3000)

- Opciones de alimentación:

- ☐ Plomo-ácido ☐ Ión-litio ☐ Otros: _____

- ☐ Cable: _____V/_____A

- Estándar 380 V/50 Hz/3 fases

- Detalles de la carga:

- Tipo: _____ (por ejemplo, bobinas de acero, maquinaria)

- Necesidades especiales: _____ (por ejemplo, antideslizante, resistente a la corrosión)

- Características opcionales:

- ☐ Parada de emergencia ☐ Sensores anticolisión

- ☐ Guías de carril ☐ Mecanismo de elevación ☐ Mando a distancia