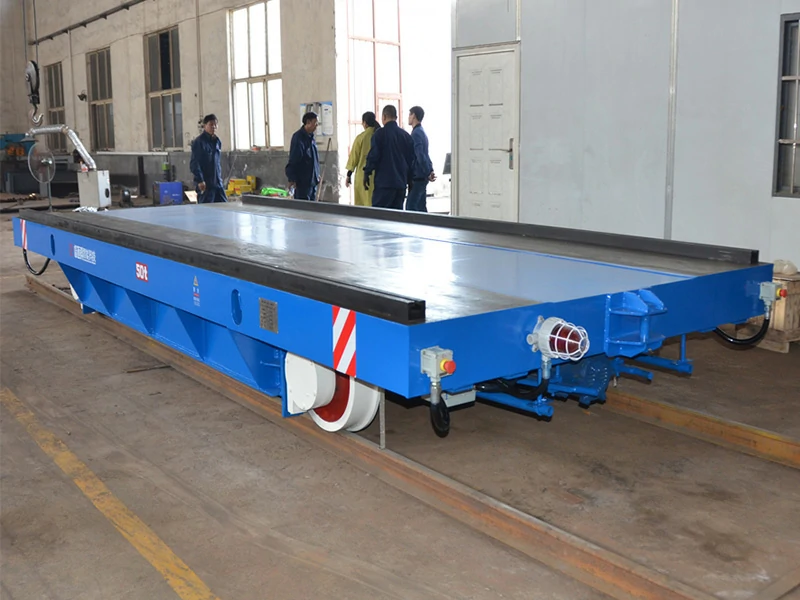

The RGV rail guided transfer cart is an automated heavy-duty material handling system operating along fixed rails, designed for internal factory logistics scenarios demanding high operational stability and positioning accuracy. The 10-tonne dual-lift RGV transfer cart introduced by REMARKABLE employs a PLC-programmed control system, integrating RFID and magnetic guidance for rail-guided travel and high-precision docking.

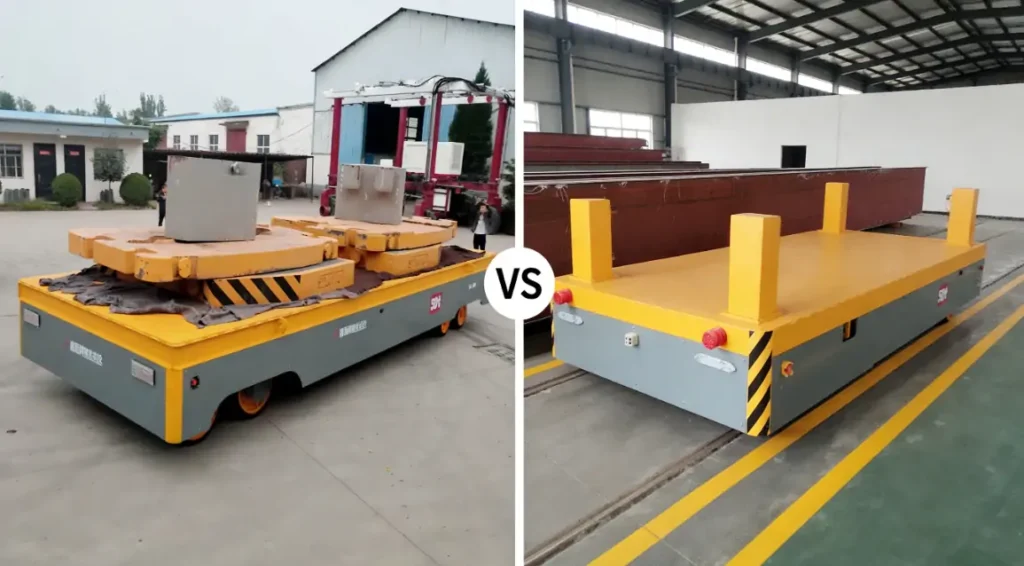

了不起 offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

- 负载能力 10 Tons

- 尺寸 6000 × 2500 × 500 mm

- Lifting Stroke: Hydraulic lifting, 250 mm

- 电源: Low-voltage wired power supply

- 速度 0–20 m/min (stepless speed regulation)

- 自定义: 可定制生产,包括附加组件等。

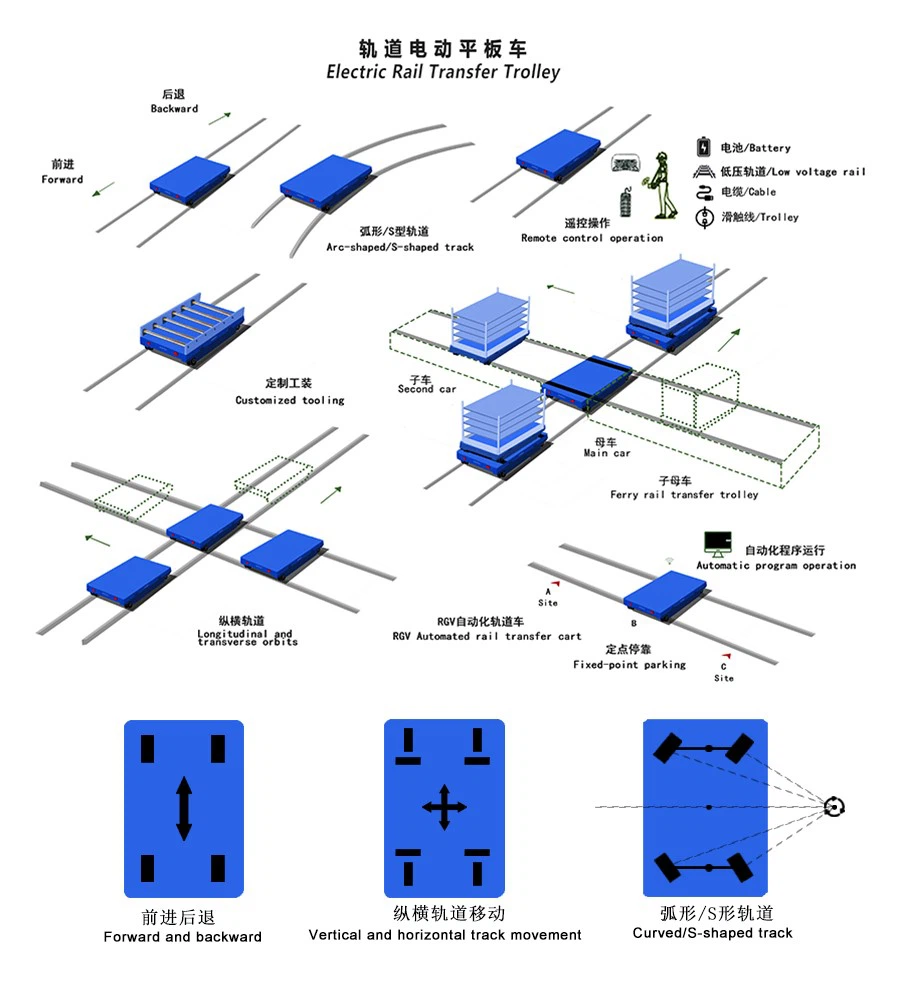

Working Principle of the RGV 轨道引导式转运车

The RGV rail guided transfer cart achieves stable transfer of heavy-duty materials through the coordinated operation of rail guidance, automated control, and a hydraulic lifting system. The specific process is as follows:

- System Task Triggering

The RGV receives operational commands from the automation control system, PLC master station, or LAN dispatch system. - Rail-Guided Travel

The rail-guided vehicle operates along pre-installed P18 steel rails at adjustable speeds of 0–20 m/min, ensuring stable direction and path adherence. - Real-Time Communication and Status Feedback

Via wireless communication modules, the RGV maintains data exchange with the control system, providing real-time feedback on operational status and positional information. - Precision Positioning Control

RFID tags integrated with magnetic positioning devices enable workstation-level precise docking, achieving positioning accuracy of ±3mm. - Hydraulic Lifting and End-to-End Docking

Hydraulic direct-lift mechanisms facilitate 250mm localised elevation, enabling height-matched docking with workstations, platforms, or equipment. - Stable Heavy-Load Material Handling

The lifting platform incorporates locating pins to prevent workpiece displacement during lifting and transport. - Safety Monitoring and Protection

Laser obstacle avoidance, edge contact switches, and emergency stop buttons continuously monitor operations to safeguard personnel and equipment. - Task Completion and Cycle Operation

Upon task completion, the RGV transfer vehicle may return to a standby position or automatically execute the next transfer assignment.

RGV 轨道引导式转运车

RGV 轨道引导式转运车

Technical Specifications Overview

The 10t RGV rail guided transfer cart is a heavy-duty material handling solution designed for fixed-route transportation in industrial environments. The following specifications detail its load capacity, structure, control systems and safety features.

| 项目 | Specification | Remarks |

|---|---|---|

| 模型 | RGV-10t | RGV transfer cart |

| 额定负载 | 10 t | Safety factor 1.25 |

| Platform Size | 6000 × 2500 × 500 mm | Overall maximum dimensions |

| Lifting Stroke | 250 mm | |

| Lifting Type | Hydraulic direct lifting | Partial lifting |

| Operation Mode | Automatic control + Remote control | |

| 控制系统 | PLC program control | |

| Communication Method | Wireless communication | On-board module transmission |

| Control Function | Receives automation control and LAN wireless dispatch signals | |

| Positioning Method | RFID + Magnetic positioning | |

| Positioning Accuracy | ±3 mm | |

| Wheel Diameter | Φ350 mm | 4 wheels |

| 车轮材料 | ZG55 | |

| 电机功率 | 2.2 kW | |

| Travel Speed | 0–20 m/min | |

| Frame Structure | I-beam, channel steel, steel plate welding | Standard Q235B |

| 供电模式 | Low-voltage cable power supply | |

| Power Input | 380 VAC – 36 V – 380 V | |

| Warning Device | Audible and visual alarm | |

| Protection Devices | Overload, overcurrent, undervoltage, short-circuit protection | |

| Anti-collision Safety | Laser obstacle avoidance + safety edge + emergency stop | |

| Color | Yellow | 可定制 |

| 推荐轨道型号 | P18 | |

| Platform Positioning | 4 positioning pins installed on lifting platform | 4 positioning pins installed on the lifting platform |

The above details the specifications for our RGV rail guided cart. If you are interested in our rail transfer trolley, please do not hesitate to contact us. We shall provide customised solutions tailored to your requirements.

视频展示

Custom Parts for RGV 轨道引导式转运车

Custom Series Parameters for RGV Rail Guided Transfer Cart

| 参数名称 | 规格 |

|---|---|

| Rated Load Capacity (Ton) | 2.8, 5.9, 8, 14.6, 26.8, etc., are related to the load capacity and structural design. |

| Tabletop Size (mm) | 长度可以是 2000、4000、5500、6500、10000 等,宽度可以是 1500、2200、2500、2800、3000 等,均可根据需要定制。 |

| Tabletop Height (mm) | 一般为 450、550、650、900、1200 等,可定制。 |

| Wheel Track (mm) | 如 1200、2800、4200、4900、7000 等。不同的承载能力对应不同的轮轨。 |

| Inner Distance between Rails (mm) | 一般为 1200、1435、2000 等,取决于导轨的类型和设计。 |

| Number of Wheels(Piece) | Generally is 4, and it may be 8 when the load capacity is large. |

| 离地间隙(毫米) | 50、75 等,影响传球能力。 |

| Running Speed (M/min) | The speed range is generally between 0 – 18 and 0 – 25, and the speed is adjustable. |

| 电机功率(千瓦) | 1、2.2、5、10、15 等,根据负载能力和运行速度确定。 |

| Battery Capacity (Ah) | 180、330、440、600 等,从而影响耐久性 |

| Battery Voltage (V) | 24、48、72 等,与电池组配置有关。 |

| Full-load Running Time (Hour) | 如 4.32、4、3.3、3.2、2.9 等,具体取决于电池容量和运行条件。 |

| Running Distance per Charge (Km) | 2.8, 5.9, 8, 14.6, 26.8, etc., are related to the load capacity and structural design. |

| Maximum Wheel Pressure (kN) | 14.4、77.7、174、343.8、265.2 等,反映了车轮的承载能力。 |

| Reference Dead Weight (Ton) | 2.8、5.9、8、14.6、26.8 等,与承载能力和结构设计有关。 |

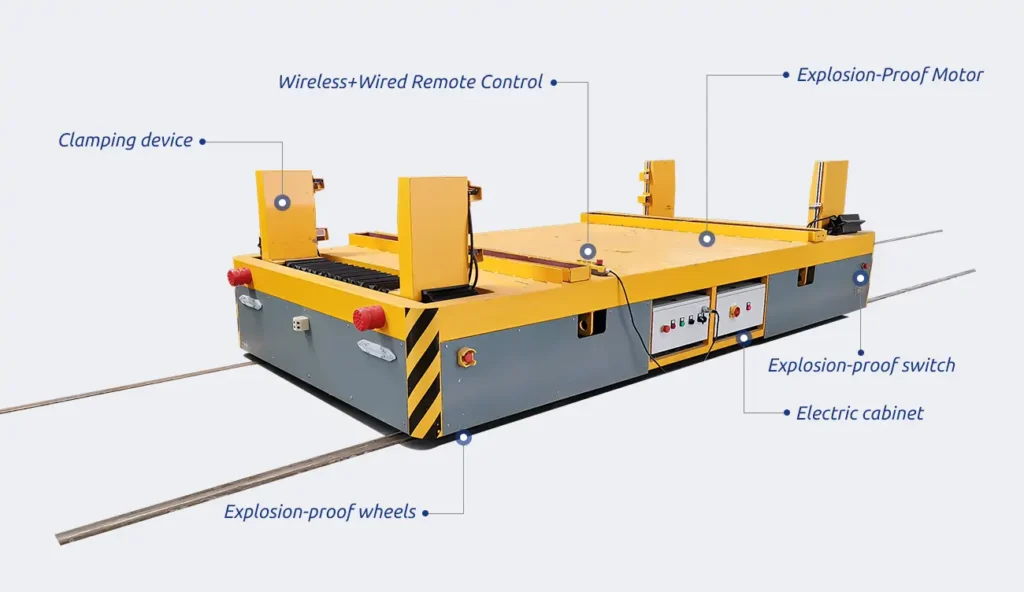

Features of RGV Rail Guided Transfer Cart

Heavy-duty Construction

High-strength steel frame capable of bearing 10 tonnes, suitable for prolonged heavy-load operation.

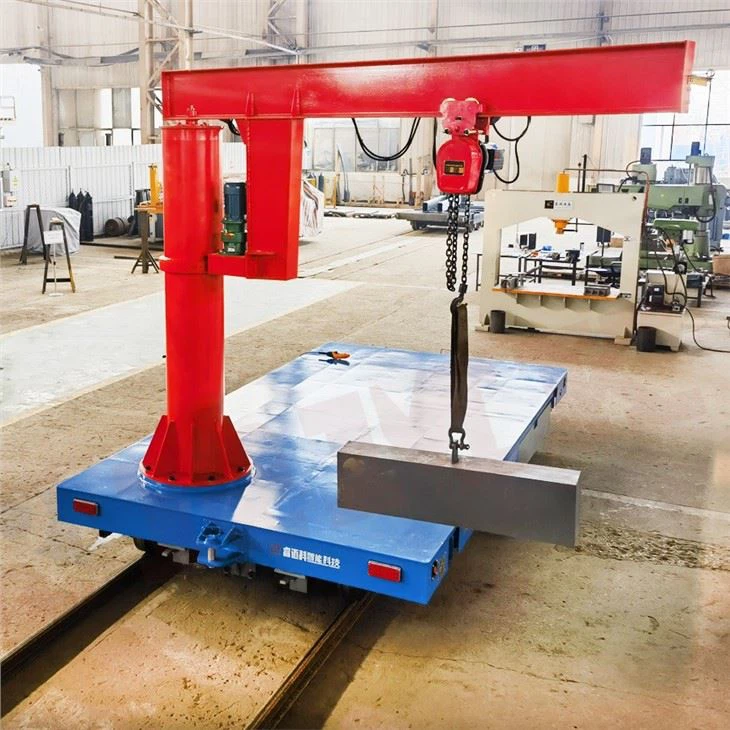

Hydraulic Lifting at Both Ends

Equipped with hydraulic direct-lift mechanisms enabling synchronised lifting at both ends for precise height alignment.

Rail-guided Operation

Operates along fixed steel rails for controlled, stable movement, ideal for high-frequency, repetitive routes.

High-Precision Positioning

RFID and magnetic positioning systems enable workstation-level accurate docking, meeting automated production line requirements.

Automated Control Architecture

PLC-programmed control supports multiple operating modes, facilitating flexible integration with automated systems.

安全保护

Equipped with laser obstacle avoidance, edge collision prevention, emergency stop buttons, and multiple electrical safety devices.

Application of RGV Rail Guided Transfer Cart

The 10-tonne RGV rail guided transfer cart is primarily deployed in automated material handling scenarios involving heavy loads and fixed routes, serving extensively across heavy industry manufacturing, automated production lines, and equipment manufacturing sectors. Its stable operation and precise positioning fulfil the demands for high-frequency, heavy-load, safe, and reliable transfer operations.

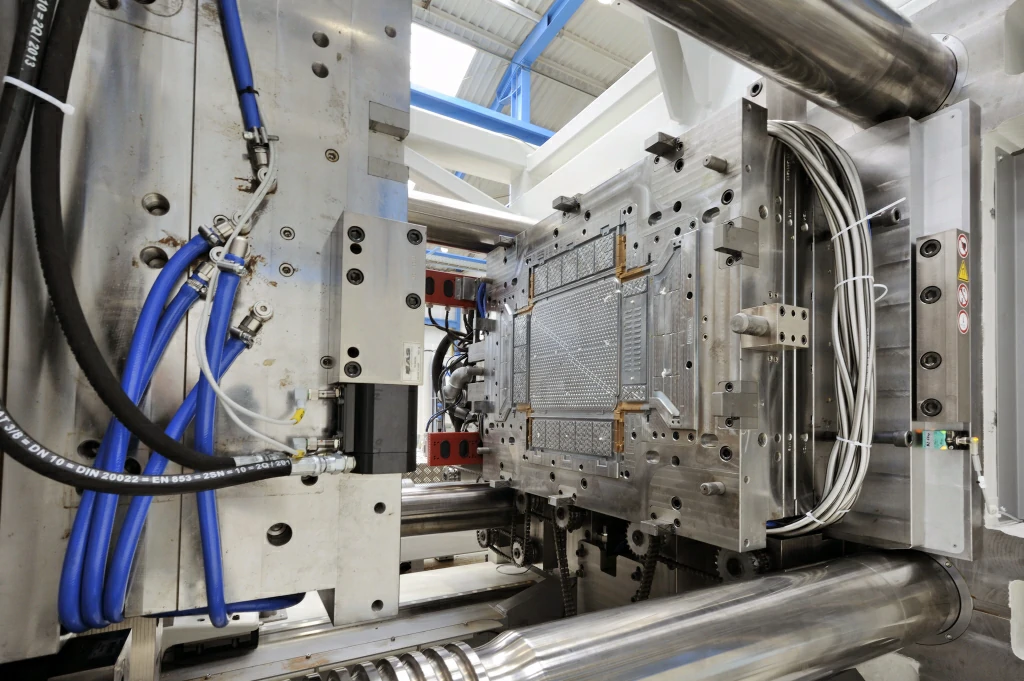

汽车制造: Facilitates rail-based transfer of engines, moulds, and body components between workstations, enabling precise integration with assembly lines to enhance production cadence and automation levels.

Heavy Industry & Equipment Manufacturing: Suited for workshop transfer of large structural components, heavy machinery, and steel framework parts, enabling secure and efficient heavy-load handling along fixed routes.

New Energy & Power Equipment: Employed for production and assembly transfer of battery modules, transformers, and complete power equipment sets, ensuring stable and reliable heavy-load material transport.

Automated Production Line Integration: Serves as the logistical interface between production lines, enabling continuous material flow between processes and boosting overall production efficiency.

Machining and Tooling Workshops: Meets the directional transfer requirements for large workpieces and moulds between machining and assembly zones, reducing manual handling intensity and safety risks.

RGV Transfer Cart Videos Showcase

RGV Rail Guided Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and RGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised electric transfer carts, rail-guided trolleys, omnidirectional mobile transfer carts, 无轨运输车, AGV robots和 工业拖车.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

为什么选择我们?

- 特定行业的专业知识 - 我们为发电、造船、建筑和航空航天领域提供变压器、风力涡轮机组件、预制模块等定制解决方案。

- Fully Customised - 从负载能力(1-500 多吨)到驱动系统(电动、混合动力或柴油),都能满足您的确切要求。

- 先进控制系统 - 选项包括手动遥控、半自动路径规划或全自动导航(AGV 集成)。

- 质量与耐用性 - 坚固的钢架、大扭矩转向模块,并通过了 CE 和 ISO 认证。

- 全面项目支持 - 从初步咨询到售后服务,我们的工程师将提供终身技术援助。

相关文章

定制的智能物料装卸解决方案

为确保定制的转运车完全满足您的需求,请提供以下详细信息:

- 负载能力:_____ 吨(1~500 吨)

- 工作台尺寸:_____ × _____ mm/m(如 1500×3000)

- 电源选项:

- 铅酸电池 ☐ 锂离子电池 ☐ 其他:_____

- ☐ 电缆:_____V/_____A

- ☐ 标准 380 伏/50 赫兹/3 相

- 货物详情:

- 类型:_____ (如钢卷、机械)

- 特殊需求:_____ (例如防滑、防腐蚀)

- 可选功能

- ☐ 紧急制动 ☐ 防碰撞传感器

- ☐ 导轨 ☐ 提升装置 ☐ 遥控装置