In large manufacturing workshops, transporting a precision mold weighing dozens or even hundreds of tons is never a trivial task. Traditional handling methods are inefficient and involve significant safety risks.

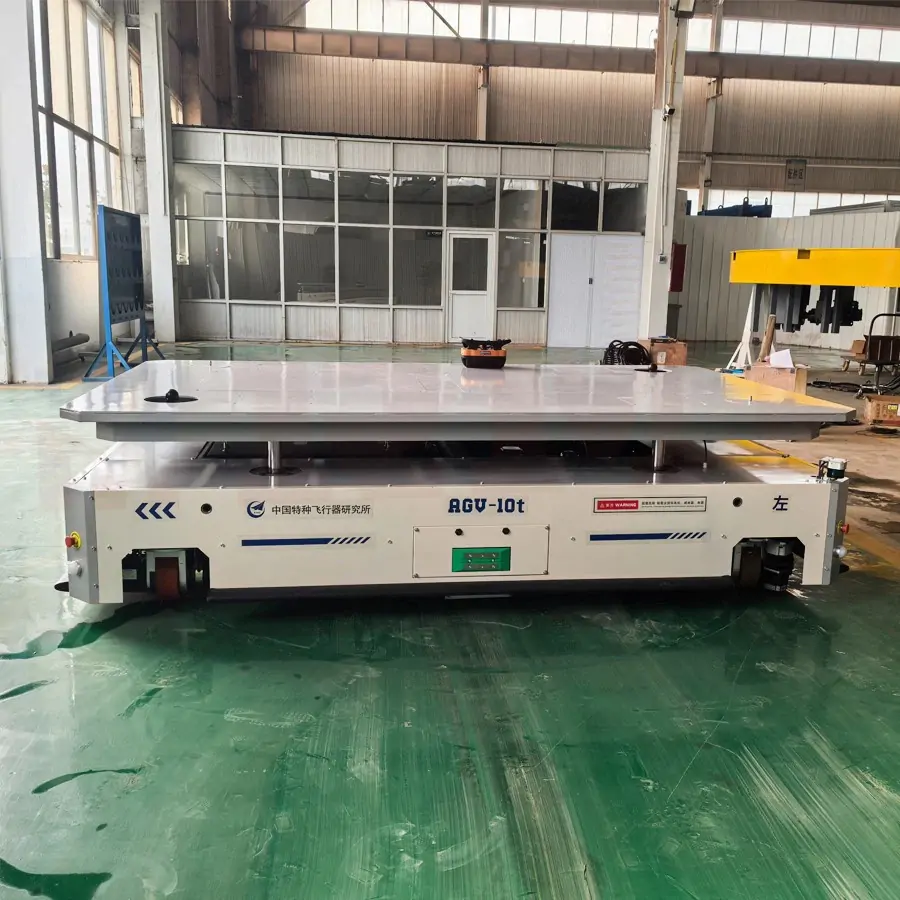

A heavy duty electric transfer cart is an industrial piece of equipment specifically designed for the safe and efficient transportation of large-tonnage molds within manufacturing workshops. By integrating electric drive systems, automated control, and multiple safety protection designs, this type of equipment systematically upgrades the mold transfer process from both efficiency and safety perspectives. It is widely used in automotive manufacturing, casting, aerospace, and heavy equipment manufacturing industries.

Electric transfer carts (also referred to as heavy-duty AGVs or industrial transfer carts) are gradually replacing traditional manual handling or forklift-based transportation by introducing automation and intelligent technologies, becoming key logistics equipment in modern intelligent manufacturing systems.

Main Types of Electric Transfer Carts

Heavy-Duty Transfer Cart / AGV

Core Points for Efficiency Improvement:

- Precise positioning and operation: Through wireless remote control or automatic control, millimeter-level precise positioning and operation can be achieved, reducing manual intervention.

- High maneuverability: Multi-wheel independent steering design allows flexible movement in narrow spaces, adapting to complex workshop layouts.

- High availability: Stable operation enables continuous alignment with production rhythms, reducing downtime risks.

Core Points for Safety Upgrades:

- Smooth lifting: Multiple synchronized hydraulic cylinders are used to ensure stable lifting and lowering of molds, preventing tipping or uneven stress.

- Strong environmental adaptability: Special wheel designs enable the transfer cart to traverse rails, floor height differences, and other common workshop obstacles.

Typical Application Scenarios / Case:

Suitable for point-to-point automated transfer within workshops, especially for direct docking with high-temperature equipment such as ovens and die-casting machines.

Example: The German Aerospace Center uses a 20-ton AGV transfer cart / industrial transfer cart to safely deliver molds into a 400°C high-temperature oven.

Overall Evaluation:

This type of equipment significantly improves transfer efficiency through automated control while reducing safety risks during heavy-load handling through stable structures and synchronized lifting systems.

Large-Tonnage Electric Lifting Transfer Cart

Core Points for Efficiency Improvement:

- High load capacity and lifting capability: Load capacity can exceed 12 tons, with lifting heights of several meters, enabling direct access to high-position mold storage.

- Intelligent operation: Equipped with wireless remote control, height preset functions, and one-button hooking, reducing manual operation steps.

Core Points for Safety Upgrades:

- Omnidirectional movement and obstacle avoidance: Supports 360° omnidirectional movement and is equipped with safety edge protection systems that respond immediately to potential collision risks.

- Stable load bearing: Dual hydraulic motor drive structures ensure stability during heavy-load lifting and travel.

Typical Application Scenarios / Case:

Mainly used for mold circulation between warehouses and workshops, especially suitable for environments requiring frequent vertical lifting and stacking.

Overall Evaluation:

While meeting large-tonnage load requirements, this type of transfer cart integrates lifting and movement functions, effectively improving efficiency between warehousing and production and enhancing operational safety.

Low-Voltage Rail-Guided Transfer Cart

Core Points for Efficiency Improvement:

- Long-distance continuous transportation: Rail power supply allows theoretically unlimited travel distance, making it suitable for fixed-route transportation across workshops or plants.

- Stepless speed control: Adjustable running speed (e.g., 0–25 m/min) enables easy matching with different production rhythms.

Core Points for Safety Upgrades:

- Automatic power-off protection: Power is automatically cut off in the event of a short circuit on the rail, ensuring electrical system safety.

- Robust structure: Specially designed for ultra-heavy loads of over 100 tons, ensuring stable and reliable operation.

Typical Application Scenarios / Case:

Suitable for fixed routes, long-distance, and large-tonnage mold transportation, commonly found in large foundries and heavy equipment manufacturing workshops.

Overall Evaluation:

Low-voltage rail guided transfer carts are known for their stability and continuous operation capability, making them a highly reliable solution for large-tonnage, fixed-path transfer scenarios.

Specialized Auxiliary Transfer Carts

Core Points for Efficiency Improvement:

Convenient loading design: Equipped with liftable or tiltable roller tables and adjustable platforms, significantly reducing manual loading difficulty and labor intensity.

Core Points for Safety Upgrades:

- Anti-tilt and shock-absorption measures: Guard plates, pneumatic buffer cylinders, and other devices prevent mold displacement, falling, or vibration damage during transportation.

- Anti-collision and anti-rollover structures: Some patented designs introduce side collision protection or automatic anti-rollover support legs to improve operational safety.

Typical Application Scenarios / Case:

Suitable for high-frequency manual transfer of small and medium-sized molds within workshops, mainly addressing “last-meter” loading and short-distance movement issues.

Overall Evaluation:

Without significantly increasing automation costs, this type of auxiliary transfer cart effectively improves manual transfer efficiency and reduces operational risks.

Summary of Selection Logic for Different Electric Transfer Carts

In practical applications, electric transfer cart types should be selected based on mold weight, transfer distance, lifting requirements, and workshop space conditions.

- Heavy-duty transfer carts / AGV transfer carts are more suitable for flexible point-to-point transfer scenarios.

- Large-tonnage electric lifting transfer carts are suitable for warehousing and high-position stacking requirements.

- Rail-guided transfer carts are ideal for large-tonnage, long-distance transportation on fixed routes.

- Specialized auxiliary transfer carts are better suited for manual loading/unloading and short-distance movement tasks.

Through reasonable selection, heavy-duty electric transfer carts not only improve mold transfer efficiency but also significantly enhance overall safety levels in terms of structural stability and active protection.

Through the above content, we gain an understanding of the performance characteristics and application scenarios of different types of transfer carts.

了不起 specializes in the customized manufacturing of various electric transfer carts. If you have further questions, please contact our professional team to help solve your material handling challenges.

电子邮件: transfercart@rmkzn.com

Phone: +86-18637369355