The main difference between an omnidirectional transfer cart and a 無軌道搬送台車 is mobility.

A trackless transfer cart moves forward and turns with a required turning radius, while an omnidirectional transfer cart can move in any direction, including sideways movement and in-place rotation without changing vehicle orientation.

Omnidirectional Transfer Cart vs Trackless Transfer Cart

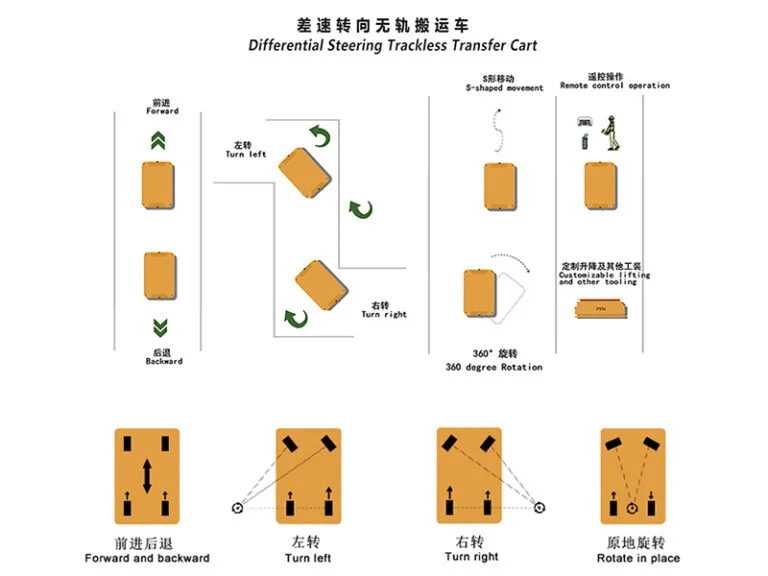

無軌道搬送台車

- Core Features: Operates without fixed rails and moves directly on the ground using wheels.

- Steering Method: Primarily relies on differential steering or front-wheel/rear-wheel steering. For example, similar to automobiles, it changes direction through front-wheel steering or by controlling speed differences between left and right drive wheels.

- Degrees of Freedom: Typically offers two degrees of freedom (forward/backward movement and steering). Turning requires a certain turning radius, and lateral movement or 360° in-place rotation is not possible.

- Technical Principle: Similar to traditional vehicles or forklifts, movement is achieved through wheel-ground friction to control direction and travel.

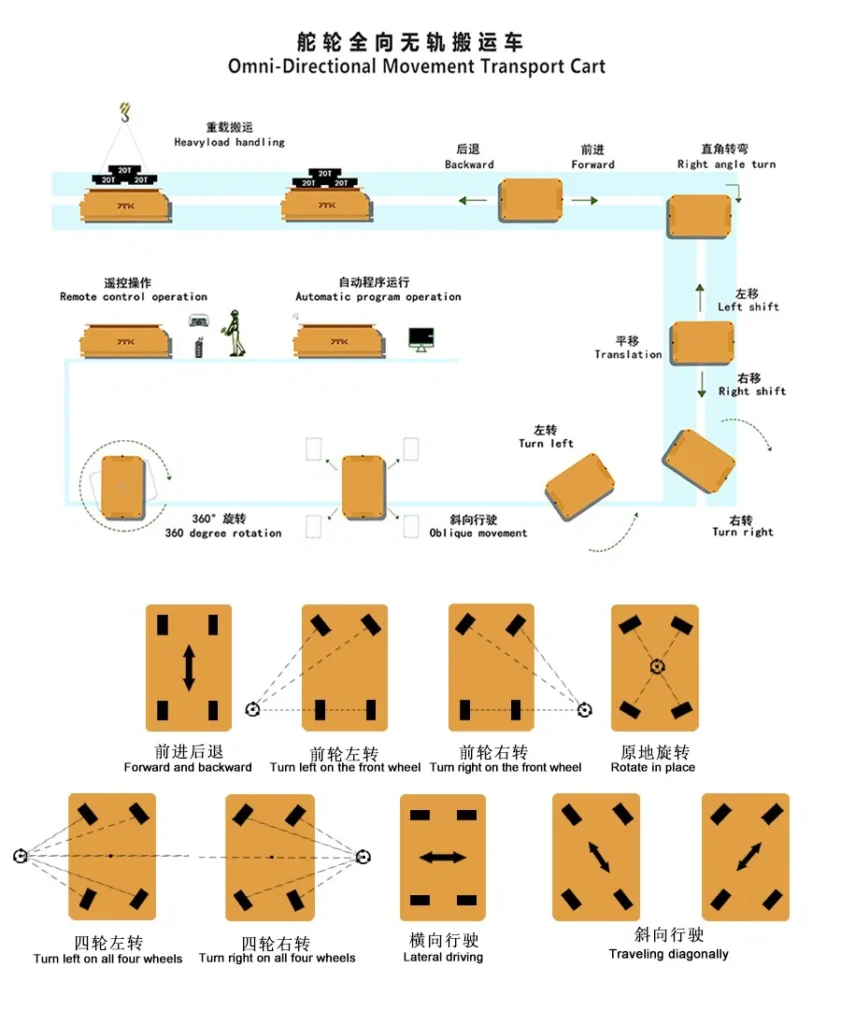

Omnidirectional Transfer Cart

- Core Features: Provides 360° omnidirectional movement, including forward, backward, lateral, diagonal movement, and in-place rotation.

- Steering Method: Relies on specialized wheel assemblies, most commonly Mecanum wheels or omni wheels.

- Degrees of Freedom: Theoretically offers three degrees of freedom (X-axis translation, Y-axis translation, and rotation around the Z-axis). The cart can move in any direction without changing its orientation, with a minimum turning radius of zero.

- Technical Principle: Through independently driven specialized wheels, power is decomposed into multiple directional forces. By precisely controlling wheel speed and direction, these forces are combined to achieve movement in any desired direction.

Performance Comparison

The table below compares omnidirectional transfer carts and trackless transfer carts across key performance parameters.

| Comparison Aspect | 無軌道搬送台車 | Omnidirectional Transfer Cart |

| Mobility Flexibility | Moderate, dependent on turning radius | Extremely high, supports movement in any direction |

| Minimum Turning Radius | Relatively large (usually greater than vehicle length) | 0 (in-place rotation) |

| Lateral Movement | Not supported | Supported |

| Technical Complexity | Lower, simpler mechanical structure | Higher, requires complex wheel systems and motion control algorithms |

| コスト | Relatively lower | Relatively higher |

| Floor Requirements | General hardened and flat floors | Higher requirements for flatness and cleanliness |

| 負荷容量 | Can be designed for heavy-duty loads | Heavy-load design is more challenging due to wheel structure |

アプリケーション・シナリオ

Applications for Trackless Transfer Carts

- Wide Aisles: Large warehouses and main factory workshop pathways

- Fixed or Simple Routes: Point-to-point transportation between production lines

- Heavy-Duty Loads: Transporting heavy molds, steel components, and large equipment

- Cost-Sensitive Projects: Emphasis on cost-effectiveness and proven reliability

Applications for Omnidirectional Transfer Carts

- Confined Spaces: Dense storage areas, compact workshops, laboratories, and clean rooms

- Complex Routes and Frequent Direction Changes: Flexible movement between multiple workstations and obstacle-rich environments

- High-Precision Docking: Automated production lines and precise material loading/unloading

- Special Maneuvering Requirements: Situations requiring lateral parking or in-place orientation adjustment

結論

If you need to eliminate rail installation and operate freely in open spaces, a trackless transfer cart is the practical choice. It is economical, mature in design, and suitable for most conventional material handling applications.

If you require navigating confined spaces with maximum flexibility, moving sideways like a crab or rotating in place like a spinning top, then an omnidirectional transfer cart is the ideal solution. It represents a key enabling technology for advanced automation and intelligent material handling systems.

In simple terms, a trackless transfer cart solves the problem of “no rails needed,” while an omnidirectional transfer cart solves the problem of “moving freely in any direction.”

Custom Transfer Cart Solutions

If you are unsure whether an omnidirectional transfer cart or a trackless transfer cart is more suitable for your application,

our engineering team can design a custom transfer cart solution based on your load capacity, workspace layout, and operating conditions, delivering a safer and more efficient material handling system.

Phone: +86-18637369355