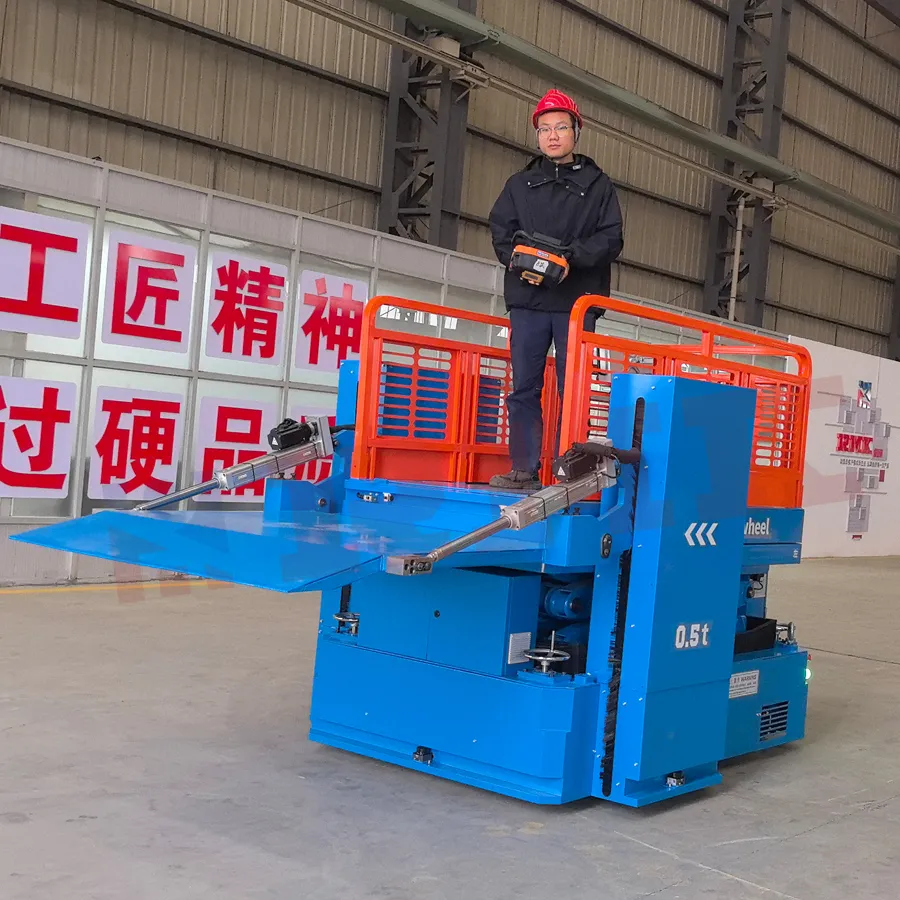

The Multifunctional Omnimove Transfer Cart is a transfer cart specifically designed and manufactured for aircraft maintenance operations.. Featuring 360° maneuverability, trackless operation, and multiple movement modes including longitudinal, lateral, diagonal, and rotational steering, it enables precise navigation within confined hangar spaces. This integrated system combines hydraulic lifting, platform sliding, and tilting functions to facilitate the handling of aircraft components and ensure personnel safety during operations. Equipped with an intelligent display, safety interlock devices, and protective systems, it ensures reliable handling of precision aerospace components.

リマーカブル 負荷容量、プラットフォーム設計、制御モード、機能モジュールなど、多様な運用要件を満たすカスタマイズサービスを提供している。

- モデル アールダブリューピー

- 耐荷重: 0.5 Tons

- 寸法: 2100×1400 × 1200 mm

- リフティング・ストローク Hydraulic lifting, 1400 mm

- 電源: Maintenance-free battery (electric drive)

- スピードだ: 0-20 m/min(無段階速度調節)

- カスタム: コンポーネントの追加など、カスタム生産も可能。

Working Principle of the Multifunctional Omnimove Transfer Cart

The following explanation of the operating principles of the multifunctional omnimove transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

動作原理:

- Power-up

- Switch on the main power supply. The system draws power from the battery (48V/130Ah) to supply the vehicle controller, drive units, and hydraulic pump.

- Electronic control self-test: Display self-check, sensor and communication link verification, fault code clearance, and readiness confirmation.

- Inspection items: Battery charge display, braking system, laser obstacle avoidance/safety edge, outrigger sensors, and emergency stop button functionality check.

- Mode Selection

- The operator selects the operating mode (movement/lifting/translation/tilting/outrigger deployment) via wireless remote control or wired joystick.

- The controller issues commands to the functional modules based on the selected mode and activates the corresponding safety paths.

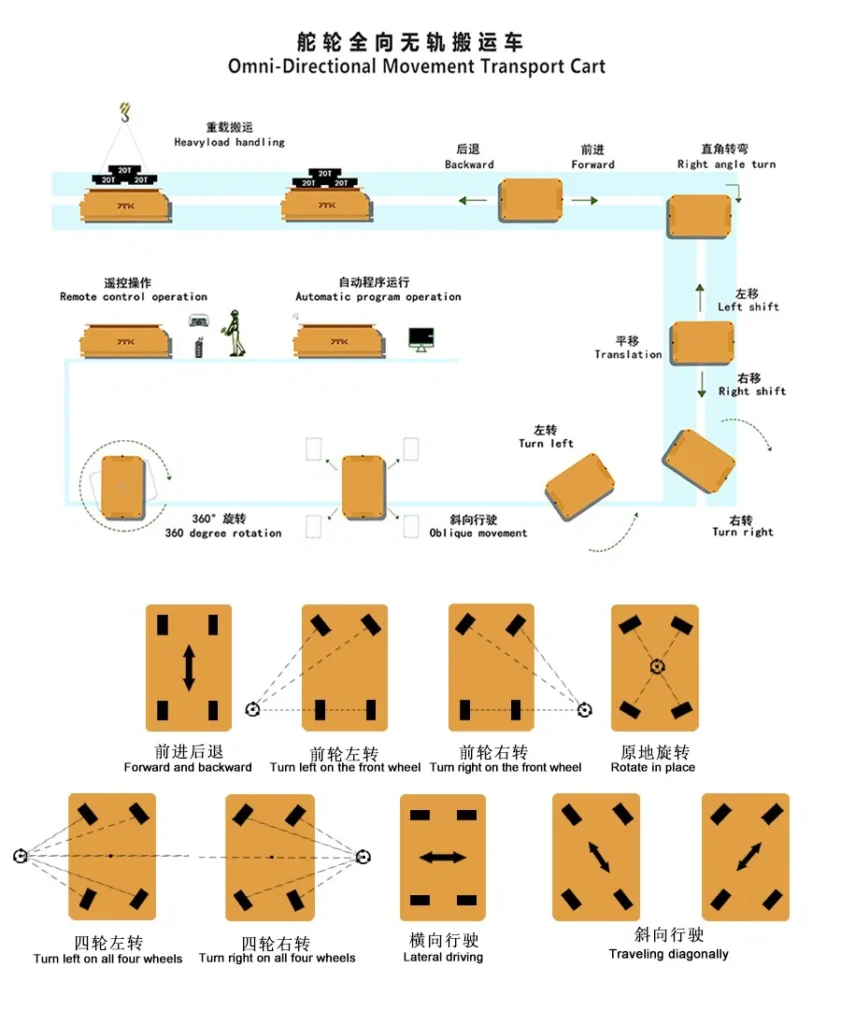

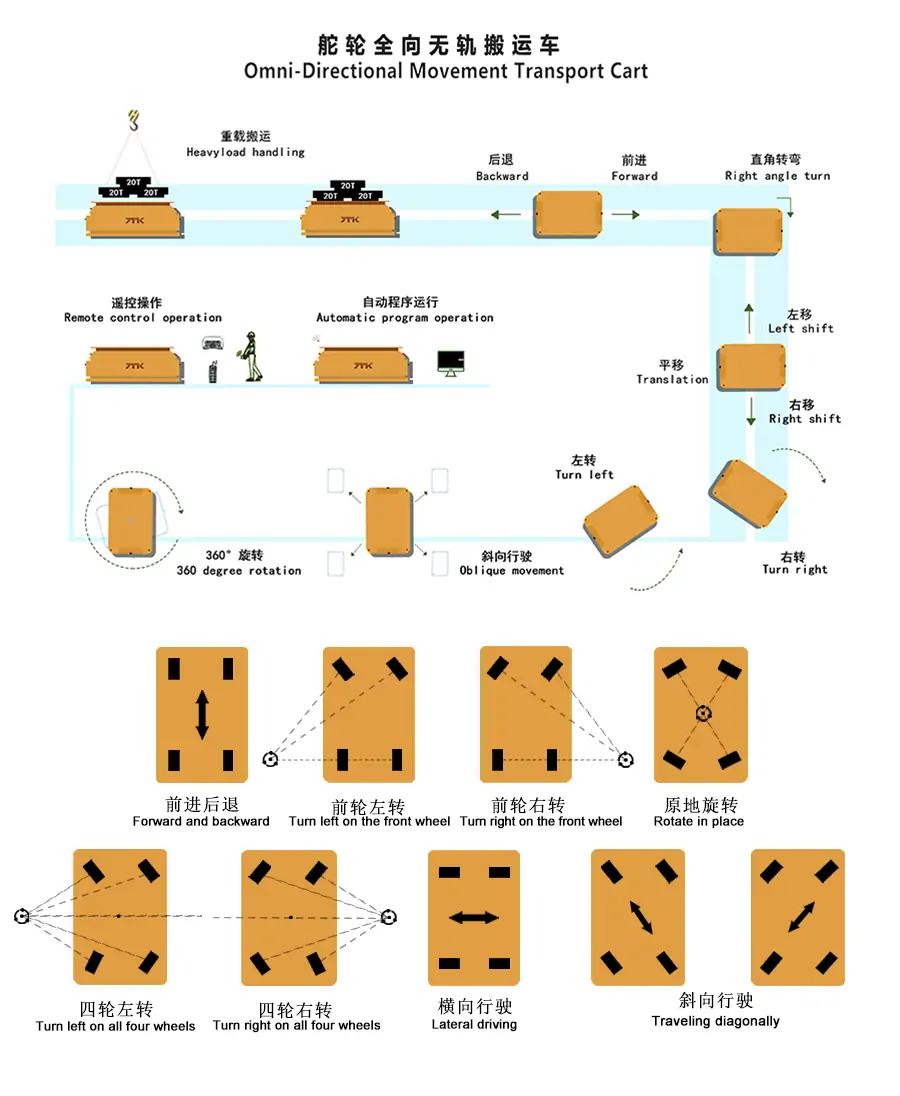

- Drive and Omnidirectional Mobility

- Dual drive motors (2 kW ×2) provide traction; four steering motors (0.75 kW ×4) independently control the steering angle of each of the four steering wheels.

- Control algorithms calculate each wheel’s speed and steering angle in real time, enabling: forward/reverse, lateral movement (sideways), diagonal movement, on-the-spot rotation, and diagonal traversing for omnidirectional motion.

- Encoders and speed sensors at the wheel ends feed back to the drives, forming a closed-loop speed/position control system that ensures positioning accuracy and motion smoothness.

- Positioning

- The operator or automated assistance system monitors position via on-board displays (platform surface and remote control).

- Laser obstacle avoidance and distance sensors operate during low-speed precision positioning, triggering deceleration and enabling precise approach to the docking point at a set step distance.

- Soft-cushion support and buffering mechanisms absorb micro-impacts upon contact, preventing damage to sensitive composite components.

- Hydraulic Platform Elevation and Translation (Upper Platform)

- Activate the hydraulic pump to drive cylinders or scissor mechanisms for platform elevation (upper platform translation stroke approx. 400 mm; elevation stroke ≥1400 mm, with customisable longer strokes available).

- Lifting employs flow/pressure closed-loop control, with the controller precisely limiting lifting speed via valves (e.g., 3–4 m/min) while continuously monitoring load and displacement sensors.

- Platform traversal and tilting are controlled by dedicated motors/actuators, achieving up to 70° tilt angles with position locking before and after operations.

- Small Platform Operation

- The small platform employs an independent hydraulic/electric drive, supporting ≥1100 mm vertical travel and 70° tilt for local assembly and workstation adjustments.

- During small platform operation, the system temporarily locks the vehicle’s movement and unrelated modules (interlock mechanism) to prevent concurrent actions from causing hazards.

- Outrigger/Stabiliser Deployment and Stability Control

- Before elevated or loaded operations, the control system deploys all four hydraulic outriggers to ground contact, with load feedback from outrigger sensors.

- Upon meeting load-bearing requirements, the vehicle disengages wheel-end drive (or switches to parking mode) to prevent overturning and enhance operational stability.

- Personnel and Cargo Safety

- Hardware and software interlocks operate between all modules: vehicle movement or platform tilting is prohibited if lifting is incomplete or outriggers are not deployed.

- Laser obstacle avoidance, edge contact protection, and audible/visual alarms immediately trigger emergency stop logic upon detecting imminent hazards.

- Operator displays and remote controllers simultaneously show status and warnings, facilitating coordinated decision-making between near and remote operators.

- 電磁ブレーキ

- During normal operation, the drive unit regulates braking force for smooth stopping. Upon power failure or emergency stop, electromagnetic brakes forcibly engage to ensure static safety.

- During lateral movement or under load, braking control integrates with torque monitoring algorithms to prevent slippage or positional drift.

- Charging

- A separate charger provides fully automated intelligent charging, with the system managing charging profiles and safeguarding against overvoltage, undervoltage, and overcurrent.

- The Battery Management System (BMS) monitors battery health and available capacity, issuing alerts or restricting non-essential functions during low charge states.

- Shutdown and Maintenance

- During shutdown, first retract the platform to transport position, retract outriggers, disconnect peripherals, then transition to standby/off mode.

- Regular maintenance points include: hydraulic oil replacement, tyre (polyurethane-coated) inspection, encoder/sensor calibration, battery health assessment, and brake system inspection.

全方向移動搬送台車

多機能オムニムーブ搬送台車

技術仕様の概要

Discover the specifications of the multi-functional omnidirectional aircraft transfer trolley. Featuring 360° mobility, hydraulic lifting, platform sliding, and tilting capabilities, this transfer trolley enables safe and precise operations. Equipped with customisable features, it facilitates efficient aircraft inspection, maintenance, and MRO (Maintenance, Repair, and Overhaul) tasks.

| パラメータ | 仕様 |

|---|---|

| 負荷容量 | 0.5T |

| 寸法(長さ×幅、mm) | 2100 × 1400 |

| テーブル高さ (mm) | 1200 |

| 地上高 (mm) | 60 |

| フロア要件 | コンクリート |

| 電源 | Maintenance-free Battery |

| Battery Capacity | 48V 130Ah |

| 動作モード | Wireless Remote + Wired Handle |

| 駆動モーター出力 | 2 kW × 2 |

| Steering Motor Power | 0.75 kW × 4 |

| ホイール径(mm) | 250 |

| Number of Wheels | 4 |

| 移動速度 (m/min) | 0-25 |

| ブレーキタイプ | 電磁ブレーキ |

| ホイール材質 | ポリウレタン・コーティング |

| ターニング・モード | Steering Wheel |

| ムーブメント・モード | Forward/Backward, Turn While Moving, Diagonal, Lateral |

| 充電器の取り付け | Separate Type |

| チャージャー機能 | 完全自動インテリジェント充電 |

| Charging Time (h) | ≤8 |

| Upper Platform Lift Stroke (mm) | ≥1400 |

| Lift Speed (m/min) | 4 |

| Lift Power | 3 kW |

| Upper Platform Travel Stroke (mm) | 400 |

| Upper Platform Travel Power | 0.75 kW |

| Small Platform Lift Stroke (mm) | ≥1100 |

| Lift Speed (m/min) | 3 |

| Lift Power | 0.75 kW × 2 |

| Small Platform Tilt Angle | 70° |

| Small Platform Tilt Power | 0.75 kW × 2 |

| 安全対策 | Audible & Visual Alarm, Emergency Stop, Laser Obstacle Avoidance, Safety Edges |

| その他の機能 | Battery Level Display, Overvoltage, Undervoltage, Overcurrent, Outrigger Protection |

ビデオショー

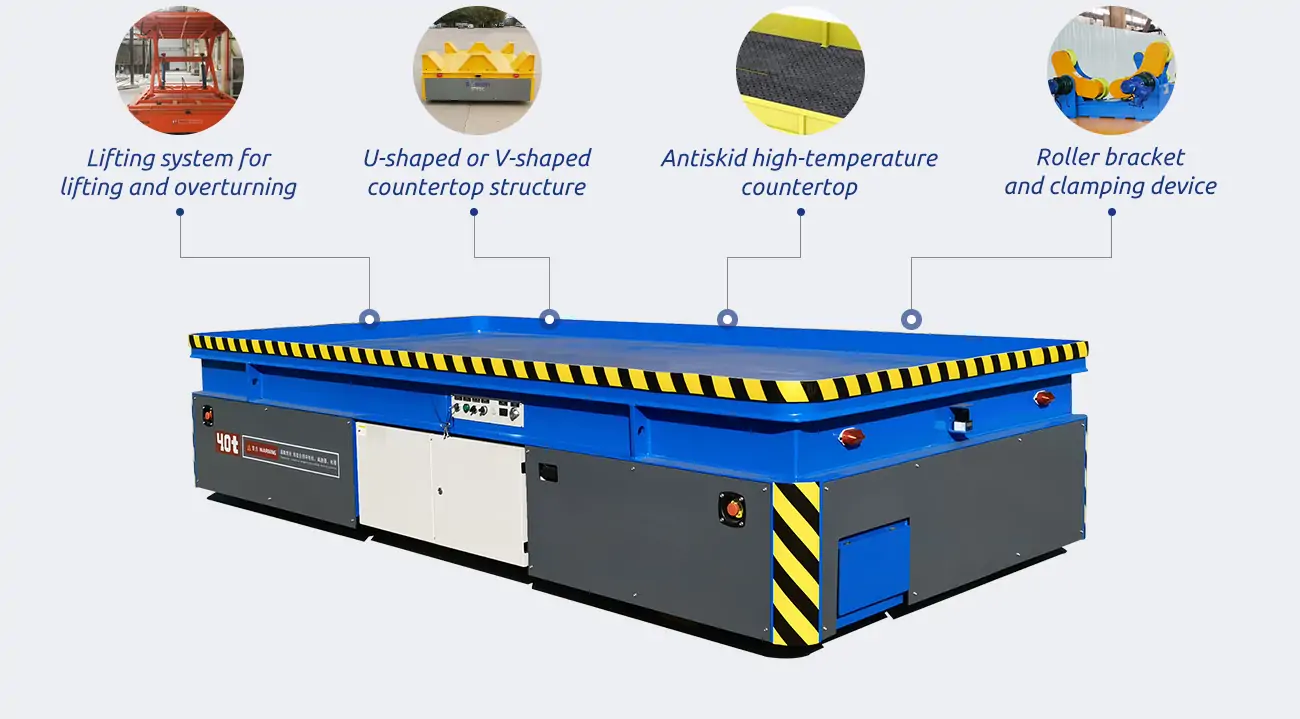

Custom Parts for Omnidirectional Transfer Cart

Custom Series Parameters for Omnidirectional Transfer Cart

| RWPトラックレス電動カート技術パラメーター表 | |||||||||||

| 定格荷重(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| テーブルサイズ(mm) | 長さ | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| 幅 | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| 高さ | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| 地上高(mm) | ≥50 | ≥100 | |||||||||

| 回転半径(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| ステアリングモード | ディファレンシャル・ステアリング | 油圧ステアリング | |||||||||

| 操作方法 | リモコン&手元ペンダント | ||||||||||

| ムーブ・ウェイ | 前進、後進、停止なしの走行中の旋回、360°回転 | 前進、後進、停止なしの走行中の旋回 | |||||||||

| 走行速度(m/min) | 25 | 20 | |||||||||

| モータータイプ | 低電圧交流(AC)モーター / ブラシレス直流(DC)モーター | ||||||||||

| ブレーキモード | 電磁ブレーキ | ||||||||||

| 保護措置 | 可聴および視覚警報ランプ+緊急停止ボタン+レーザー障害物回避センサー(オプション)+衝突防止コンタクトエッジ(オプション) | ||||||||||

| ホイール数量 | 4 | 6 | 8 | ||||||||

| 駆動輪径(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| ホイール材質 | スチールコア+ポリウレタン | ||||||||||

| バッテリー容量(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| バッテリータイプ | 鉛蓄電池 | リチウム電池 | |||||||||

| バッテリーの耐久性 | 5h(必要に応じてカスタマイズ) | 4h(必要に応じてカスタマイズ) | |||||||||

| バッテリー充電時間 | ≤7h | ≤5h | |||||||||

| バッテリーチャージャー | AC220V/AC380V | ||||||||||

| グラウンドタイプ | セメント床、鉄板地面、エポキシ床、アスファルト床 | ||||||||||

| フルロード登坂能力 | 5% | 3% | |||||||||

| 労働環境 | 温度:-10℃~40℃、湿度:20%~80%、結露無きこと(高温・防爆環境用にカスタマイズ可) | ||||||||||

| 車体色 | カスタマイズ | ||||||||||

| その他の機能 | バッテリー電力表示、過電圧、低電圧、過電流保護など | ||||||||||

| 注釈 1) 他のテーブルサイズと負荷容量は、ユーザーの要求に応じてカスタマイズすることができます。 2) 油圧ステアリングの場合、敷地スペースの制約に基づき、旋回半径を小さくするためにデュアル油圧ステアリングシステムを選択することができる。 3)バッテリーの種類と動作時間(バッテリーの耐久性)は、顧客のニーズに合わせてカスタマイズすることができます。 4)本製品は継続的な改良とアップグレードを行うため、表の仕様は予告なく変更されることがあります。 | |||||||||||

特徴

全方位モビリティ

Capable of 360° rotational movement for precise execution of aircraft maintenance tasks.

多機能

Features hydraulic lifting, sliding and tilting capabilities.

Safe Operation

Emergency braking, laser obstacle avoidance and interlocking devices ensure operator safety.

精密ハンドリング

Flexible support pads safeguard delicate aircraft components during transfer and assembly.

Intelligent Control System

Real-time operational status display with fully interlocked functions for assured safety.

Custom

Tailor-made transfer cart available to meet specific operational requirements.

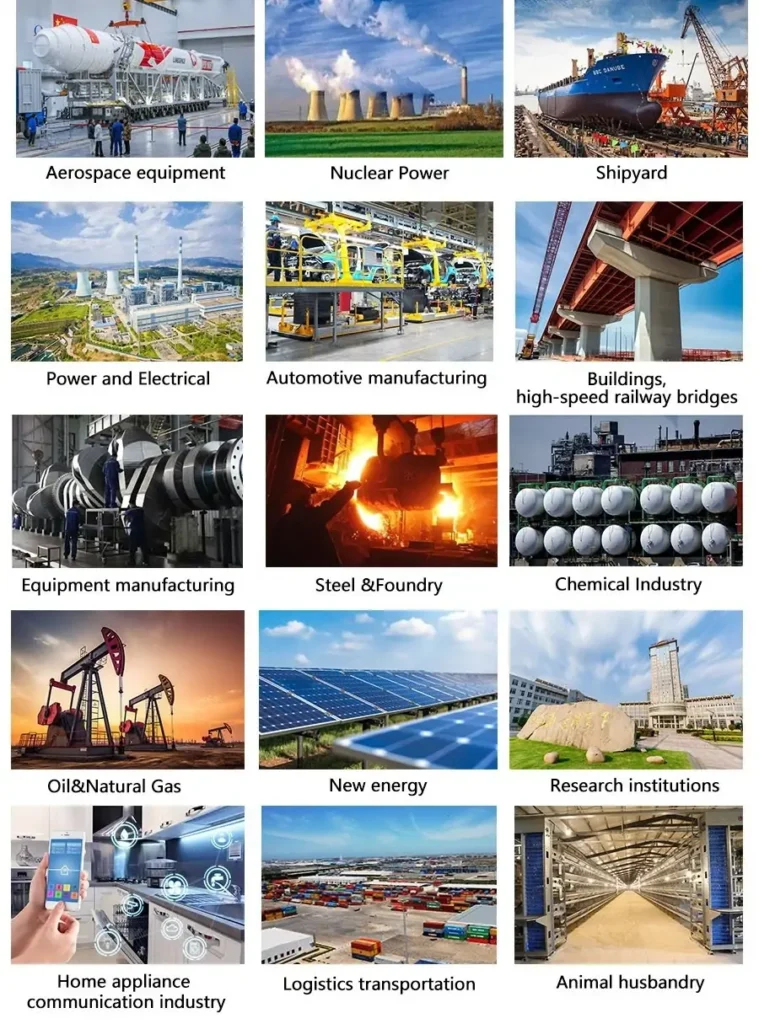

申し込み

A 多機能オムニムーブ搬送台車 offers far more than aviation support. Its omnidirectional movement, precise positioning, and heavy-duty load capacity make it an ideal Transfer Cart solution for multiple industries. This all-direction transfer cart improves safety, efficiency, and workflow wherever flexible, reliable material handling is required.

Manufacturing

解決策 This Omnimove Transfer Cart moves heavy components with precise control, solving space-limited handling issues on busy production floors.

Logistics

解決策 The all-direction transfer cart boosts warehouse efficiency by transferring pallets smoothly in narrow aisles and reducing forklift dependence.

Rail Maintenance

解決策 A multifunctional Transfer Cart positions tools and parts accurately, speeding inspection tasks and minimizing downtime around rail vehicles.

Energy Plants

解決策 This heavy-duty omnidirectional cart transports modules and inspection kits safely through complex power-plant layouts during critical maintenance.

Automotive

解決策 The maintenance transfer cart moves engines and diagnostic tools between stations, improving workflow accuracy and repair efficiency.

Shipyards

解決策 This omnidirectional transport vehicle handles large components in tight dock areas, supporting inspection, refits, and safe heavy-load mobility.

トランスファー・カート・ケース・ショーケース

Multifunctional Omnimove Transfer Cart Manufacturer

Henan Remarkable Intelligent Technology Co., Ltd was founded in 2019 and is located at No. 22, Xinchang North Line, Xiaodian Town, Hongqi District, Xinxiang City, Henan Province. It is a professional handling equipment company integrating R&D, design, manufacturing, sales, and after-sales service. It specializes in the production of various types and tonnages of handling equipment and their accessories, and provides professional R&D, design, and manufacturing of various non-standard and 電動トランスファーカート, レール搬送台車, 全方向移動式搬送台車, バッテリー搬送カート, 重量物運搬台車, AGVハンドリングロボットそして 産業用トレーラー.

The Remarkable’s products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

当社を選ぶ理由

- 業界固有の専門知識 - 変圧器、風力タービン部品、プレハブ・モジュールなどのオーダーメード・ソリューションで、発電、造船、建設、航空宇宙分野に貢献しています。

- フルカスタマイズ - 積載量(1~500トン以上)から駆動システム(電気、ハイブリッド、ディーゼル)まで、お客様のご要望に的確にお応えします。

- 高度制御システム - オプションには、手動遠隔操作、半自動経路計画、または完全自動化ナビゲーション(AGV統合)が含まれます。

- 品質と耐久性 - 頑丈なスチールフレーム、高トルクのステアリングモジュール、CE、ISO認証。

- フル・プロジェクト・サポート - 最初のご相談からアフターサービスまで、当社のエンジニアが生涯にわたって技術支援を行います。

関連記事

カスタマイズされたインテリジェントなマテリアルハンドリングソリューション

カスタマイズされたトランスファーカートがお客様のニーズにぴったり合うように、以下の詳細をお知らせください:

- 積載量トン(1~500トン)

- テーブルサイズmm/m (例:1500×3000)

- 電源オプション:

- 鉛蓄電池 ☐ リチウムイオン ☐ その他_____

- ケーブルV/_____A

- 標準 380V/50Hz/3 相

- 荷物の詳細

- 種類鋼鉄コイル、機械など

- 特別なニーズ_____ (例:滑り止め、耐腐食性)

- オプション機能:

- エマージェンシーストップ ☐ アンチコリジョンセンサー

- レールガイド ☐ リフト機構 ☐ リモコン