The 3-tonne lifting AGV transfer cart manufactured by REMARKABLE is an intelligent transfer cart specifically developed for industrial automated logistics systems. It facilitates unmanned handling of medium-to-heavy loads between production workshops, warehouses, and workstations. This AGV integrates autonomous navigation, stable lifting, and multi-layered safety controls to achieve precise material handover with production lines and tooling equipment. It enhances internal logistics efficiency while reducing manual operation risks, serving as a vital component of modern smart manufacturing and flexible production lines.

REMARQUABLE offre des services de personnalisation couvrant la capacité de charge, la conception de la plate-forme, les modes de contrôle et les modules fonctionnels afin de répondre aux diverses exigences opérationnelles.

- Capacité de charge : 3 tonnes

- Dimensions : 1800 × 1500 × 500 mm

- Course de levage : Hydraulic lifting, 100 mm

- Alimentation électrique : Pile au lithium

- Vitesse : 0–25 m/min (stepless speed regulation)

- Sur mesure : Possibilité de production sur mesure, y compris des composants supplémentaires, etc.

Working Principle of the AGV Transfer Cart

The following explanation of the operating principles of the AGV transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

Principe de fonctionnement :

- Task Triggering and Dispatch Command Issuance

The AGV transfer cart receives transport task instructions from the dispatch system, PLC, or higher-level control system, specifying target workstations, operational routes, and working modes, and enters a standby state for execution. - Automatic Positioning and Path Recognition

Real-time positional data is acquired via magnetic strips, QR codes, laser, or inertial navigation systems. The onboard controller parses and corrects the path, enabling stable operation along the predefined route. - Autonomous Traverse and Speed Regulation

The AGV robot executes autonomous movement according to the planned route, automatically adjusting speed at turns, intersections, or critical junctions to achieve smooth acceleration, operation, and deceleration. - Precise Workstation Positioning

Upon reaching the designated workstation, the equipment achieves accurate positioning via navigation signals or sensors. The system confirms the arrival status, preparing for subsequent lifting and docking operations. - Lifting Execution and Workstation Docking

Under control system directives, the hydraulic lifting mechanism activates, driving the load platform to vertically adjust its height. This aligns the material level with the production line or fixture platform, enabling safe and stable docking. - Status Feedback and Task Completion

Upon completing lifting and docking, the AGV automated guide vehicle updates its operational and task status to the host system. It then awaits further instructions or proceeds to the next transport task. - Safety Monitoring and Anomaly Handling

Throughout the operation, the AGV continuously monitors forward obstacles, operational status, and safety signals. Upon detecting anomalies, the system automatically decelerates, halts, or triggers alarms to safeguard personnel and equipment.

This workflow applies to both single-vehicle operation and multi-vehicle coordination within AGV transfer cart systems. Clients may customise configurations based on process requirements, facility environments, and automation levels.

AGV Transport Cart

The AGV Transfer Cart System

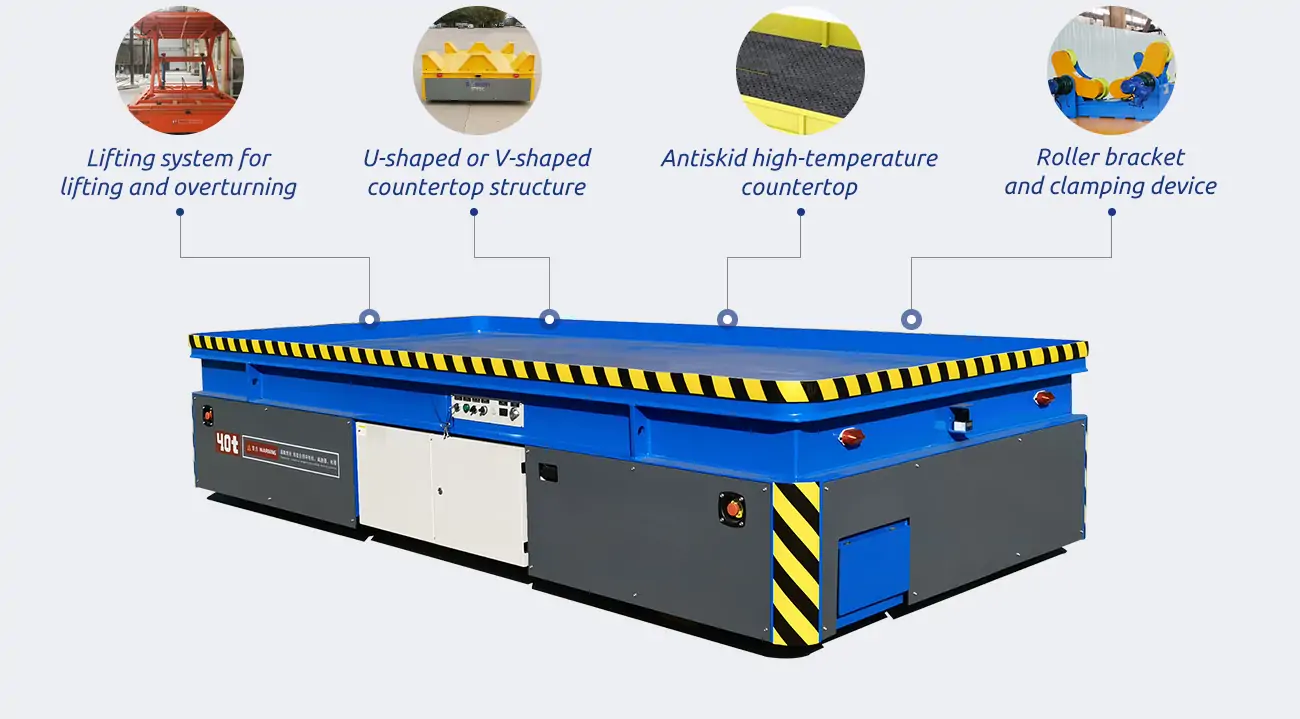

The 3-ton lifting capacity AGV transfer cart employs a modular design philosophy, featuring a stable overall structure and rational layout. It primarily comprises a load-bearing chassis, drive system, lifting system, control system, and safety protection system, enabling reliable operation under prolonged high-load working conditions.

Body Structure: Fabricated from high-strength steel welded components, the structure undergoes finite element analysis and optimised design to deliver exceptional load-bearing capacity and fatigue resistance, making it suitable for continuous heavy-duty operations.

Drive System: Equipped with industrial-grade drive motors and high-precision gearboxes, it operates smoothly with low noise levels. Supports precise start/stop control and speed regulation, enhancing AGV stability during cornering and docking manoeuvres.

Lifting System: The compact hydraulic lifting mechanism ensures excellent synchronisation, enabling smooth lifting and lowering under 3-tonne loads to accommodate varying workstation heights and process requirements.

Control System: Utilises PLC and AGV-specific controllers, supporting automatic, semi-automatic, and manual operation modes. Facilitates on-site commissioning, maintenance, and system upgrades.

Safety Protection System: Integrates laser obstacle avoidance, collision sensors, emergency stop buttons, audible/visual alarms, and overload protection devices, comprehensively enhancing operational safety standards.

Chariot de transfert AGV

Spécifications techniques Vue d'ensemble

Explore the technical specifications of this 3-tonne AGV transfer vehicle. Featuring 360-degree mobility and hydraulic lifting capabilities, it enables safe and precise operation.

| Paramètres | Spécifications | Remarks |

|---|---|---|

| Model Type | AGV Trackless Electric Transfer Cart | Véhicule à guidage automatique |

| Capacité de charge | 3 tonnes | Heavy-duty design |

| Overall Dimensions | 1800 × 1500 mm (L × W) | Personnalisable |

| Platform Height | 500 mm | Roller conveyor surface |

| Garde au sol | 50 mm | Suitable for indoor floors |

| Exigence de plancher | Cement / Concrete Floor | Smooth and flat |

| Alimentation électrique | Pile au lithium | Maintenance-free |

| Control Method | Laser Navigation + Wired Remote Control | High positioning accuracy |

| Motor Power | 2 × 2 kW | Drive system |

| Travel Speed | 0–25 m/min (Variable Speed) | Adjustable |

| Braking System | Frein électromagnétique | Safe and reliable |

| Matériau de la roue | Polyurethane-Coated Wheels | Wear-resistant & low noise |

| Steering Type | Steering Wheel Drive | Flexible maneuvering |

| Travel Modes | Forward / Reverse / Turning While Moving / Diagonal / Lateral Movement | Multi-directional |

| Lifting Stroke | 100 mm | Optional lifting function |

| Installation du chargeur | Separate Type Charger | Easy maintenance |

| Charging Function | Chargement intelligent entièrement automatique | AGV docking support |

| Protection de la sécurité | Audible & Visual Alarm + Emergency Stop + Laser Obstacle Avoidance | Multiple safety layers |

| Additional Functions | Battery Level Display, Over-voltage, Under-voltage & Over-current Protection | System protection |

These are some of the specifications for our AGV transfer cart. Should you be interested in our intelligent AGV cart, please contact us, and we shall provide customised services tailored to your requirements.

Vidéos Show

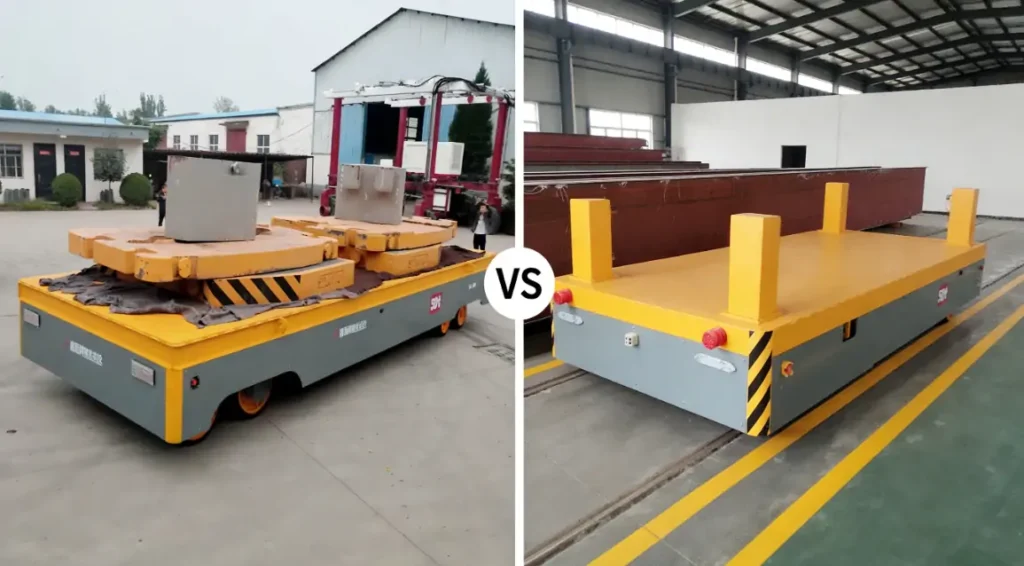

Custom Parts for AGV Transfer Cart

Custom Series Parameters for AGV Trackless Electric Transfer Cart

| Tableau des paramètres techniques du chariot de transfert électrique sans rail RWP | |||||||||||

| Capacité de charge nominale(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Taille du tableau (mm) | Longueur | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Largeur | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Hauteur | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Garde au sol(mm) | ≥50 | ≥100 | |||||||||

| Rayon de braquage(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Mode de pilotage | Direction différentielle | Direction hydraulique | |||||||||

| Méthode de fonctionnement | Télécommande et pendentif manuel | ||||||||||

| Bougez ! | Forward, backwards, turning while driving with no stop | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation (Customised for high-temperature and explosion-proof environments) | |||||||||

| Vitesse de course(m/min) | 25 | 20 | |||||||||

| Type de moteur | Moteur à courant alternatif (CA) à basse tension / moteur à courant continu sans balais (CC) | ||||||||||

| Mode de freinage | Frein électromagnétique | ||||||||||

| Mesures de protection | Voyant d'alarme sonore et visuel+ Bouton d'arrêt d'urgence+Capteur laser d'évitement d'obstacle (en option)+Bord de contact anticollision (en option) | ||||||||||

| Quantité de roues | 4 | 6 | 8 | ||||||||

| Diamètre de la roue motrice(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Matériau de la roue | Noyau d'acier + polyuréthane | ||||||||||

| Capacité de la batterie(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Type de batterie | Batterie plomb-acide | Pile au lithium | |||||||||

| Autonomie de la batterie | 5h (sur mesure) | 4h (sur mesure) | |||||||||

| Temps de charge de la batterie | ≤7h | ≤5h | |||||||||

| Chargeur de batterie | AC220V/AC380V | ||||||||||

| Type de sol | Sol en ciment、Sol en tôle d'acier 、Sol en époxy, sol en asphalte | ||||||||||

| Capacité d'escalade à pleine charge | 5% | 3% | |||||||||

| Environnement de travail | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection, etc | ||||||||||

| Couleur de la carrosserie du véhicule | Sur mesure | ||||||||||

| Autres fonctions | Notes : 1) Other table sizes and load capacities can be customised according to user requirements. 2) Pour la direction hydraulique, un système de direction hydraulique double peut être sélectionné pour réduire le rayon de braquage en fonction des contraintes d'espace du site. 3) Le type de batterie et la durée de fonctionnement (endurance de la batterie) peuvent être personnalisés pour répondre aux besoins des clients. 4)Le produit fait l'objet d'améliorations et de mises à jour constantes ; les spécifications figurant dans le tableau peuvent être modifiées sans préavis. | ||||||||||

| Notes : 1) Other table sizes and load capacities can be customised according to user requirements. 2) Pour la direction hydraulique, un système de direction hydraulique double peut être sélectionné pour réduire le rayon de braquage en fonction des contraintes d'espace du site. 3) Battery type and operating time (battery endurance) can be customised to meet customer needs. 4)Le produit fait l'objet d'améliorations et de mises à jour constantes ; les spécifications figurant dans le tableau peuvent être modifiées sans préavis. | |||||||||||

Caractéristiques

Capacité de charge élevée

Rated load capacity of 3 tonnes, suitable for handling various heavy-duty materials.

Stable Lifting

Hydraulic platform ensures smooth and steady elevation for safe and reliable operation.

Protection de la sécurité

Laser obstacle avoidance, emergency stop and overload protection ensure operational safety.

Precise Positioning

Supports magnetic strip, laser and QR code navigation for accurate positioning.

Low-noise operation

Smooth and quiet drive system minimises operational noise and vibration.

Personnalisation flexible

Load capacity, dimensions, lifting height, and functional configurations can be tailored.

Application

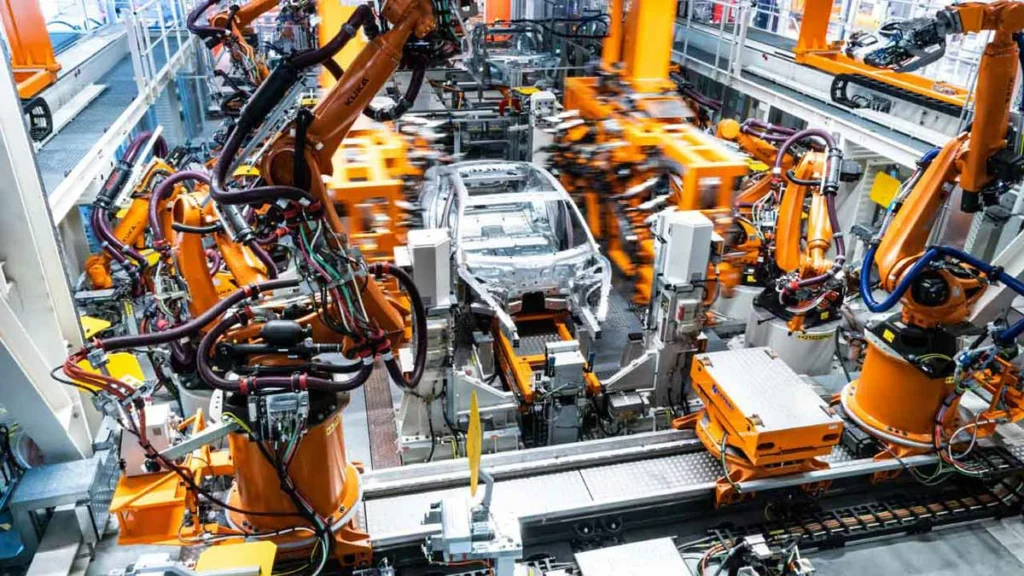

This 3-tonne lifting AGV transfer cart finds application not only in automated logistics warehousing but also across automotive manufacturing, aerospace, and other sectors. It significantly enhances safety and efficiency, meeting diverse requirements for flexible and reliable material handling.

Automotive Manufacturing: Used for the automated transfer of engines, moulds, and body components between workstations, achieving precise integration with production lines to boost assembly efficiency.

Metallurgy and Steel: Designed for high-load and high-dust environments, the AGV transfer cart safely handles steel structures, tooling, and heavy components, ensuring stable transportation.

Equipment Manufacturing: Enables continuous transfer of heavy components between welding, assembly, and inspection processes, optimising production cadence and enhancing overall workshop logistics efficiency.

Energy and Power: Suitable for internal workshop transport of heavy materials such as power generation equipment and electrical components. Ensures safe transportation of high-value equipment through stable lifting and precise navigation.

Aérospatiale: The 3-tonne lifting capacity AGV transfer cart enables smooth and precise handling of critical components, meeting intelligent logistics demands in high-standard production environments

Chariot de transfert Vitrine

AGV Transfer Cart Manufacturer

Henan REMARKABLE Intelligent Technology Co., Ltd. is a specialist manufacturer dedicated to the research, development, design, production, sales, and after-sales service of industrial transfer carts and AGV transfer carts. The company manufactures handling equipment and accessories across various tonnage capacities, while also providing professional R&D, design, and manufacturing services for customised electric transfer carts, rail-guided trolleys, omnidirectional mobile transfer carts, trackless transfer carts, AGV robotset remorques industrielles.

The REMARKABLE possesses a comprehensive production system, stringent quality management, and extensive industry experience. Its products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

Pourquoi nous choisir ?

- Expertise sectorielle - Nous proposons aux secteurs de la production d'énergie, de la construction navale, de la construction et de l'aérospatiale des solutions sur mesure pour les transformateurs, les composants d'éoliennes, les modules préfabriqués, etc.

- Fully Customised - De la capacité de charge (1-500+ tonnes) aux systèmes d'entraînement (électrique, hybride ou diesel), nous répondons à vos besoins exacts.

- Systèmes de contrôle avancés - Les options comprennent la commande manuelle à distance, la planification semi-automatique du trajet ou la navigation entièrement automatisée (intégration d'un AGV).

- Qualité et durabilité - Cadres en acier robustes, modules de direction à couple élevé, certifiés CE et ISO.

- Soutien complet au projet - De la consultation initiale au service après-vente, nos ingénieurs fournissent une assistance technique à vie.

Articles connexes

Solutions personnalisées de manutention intelligente

Pour qu'un chariot de transfert personnalisé corresponde parfaitement à vos besoins, veuillez fournir les informations suivantes :

- Capacité de charge : _____ tonnes (1~500 tonnes)

- Taille du tableau : _____ × _____ mm/m (par exemple, 1500×3000)

- Options d'alimentation :

- ☐ Plomb-acide ☐ Lithium-ion ☐ Autre : _____

- ☐ Câble : _____V/_____A

- ☐ Standard 380V/50Hz/3-phases

- Détails de la cargaison :

- Type : _____ (par exemple, bobines d'acier, machines)

- Besoins particuliers : _____ (par exemple, antidérapant, résistant à la corrosion)

- Caractéristiques optionnelles :

- ☐ Arrêt d'urgence ☐ Capteurs anti-collision

- ☐ Guides de rail ☐ Mécanisme de levage ☐ Télécommande