A trackless transfer car is a kind of transportation equipment powered by batteries or cables, which can travel freely on flat ground without laying tracks. It has the characteristics of high safety, strong maneuverability, high flexibility, smooth operation, large load, and high efficiency. It is widely used in factories, workshops, warehouses, ports, and other places for short-distance transportation of heavy materials, molds, equipment, etc. We can provide customized solutions according to customers’ special working conditions. Please contact our professional team for details.

- Load capacity: 2 tons~500 tons

- Table size: customizable

- Operating speed: 0~25m/min

- Control mode: push button/remote control

Types of Trackless Transfer Carts

Electric trackless transfer cart

Chariot de transfert électrique sans rail is a kind of electric handling equipment that can run without fixed tracks, and is widely used in factories, warehouses, harbors and other scenarios for heavy material transportation. Different from traditional trackless transfer carts, it adopts rubber tires or polyurethane wheels, and its power supply may be driven by batteries, cables, or super capacitors, etc. It has the ability of autonomous navigation or manual control, and it can drive freely on flat ground, which is suitable for flexible and changeable logistics needs.

Battery trackless transfer cart

Chariot de transfert sans chenilles à batterie is a kind of rechargeable battery-powered industrial handling equipment, without relying on the fixed track or external cable power supply, and can be freely driven on flat ground, which is suitable for the efficient and flexible transfer of heavy materials.

Powered by lithium batteries or lead-acid batteries, it is free from the restrictions of tracks and cables, and can realize 360° steering and traveling in any path. Load range 1~500 tons+, customized hydraulic lifting, side shifting, or rotating platform, suitable for heavy materials such as steel coils, molds, and large equipment. Suitable for complex logistics environments, such as inter-regional transportation in workshops, warehouses, and loading/unloading, container transshipment in ports, etc.

Omni-directional transfer cart

Omni-directional Transfer Cart is a kind of intelligent handling equipment adopting multi-wheel synergistic driving technology, which is capable of realizing omni-directional movement, including straight line, lateral translation, oblique movement and in-situ rotation, and other steering modes. It can complete in-situ rotation with zero turning radius in a narrow space, providing flexibility and space utilization for industrial material handling. Optional laser/vision navigation system for automatic path planning and obstacle avoidance. Load range 5-100 tons, platform can be customized with a hydraulic lift (±200mm) and rotation (360°). Particularly suitable for advanced manufacturing fields that require high precision and high flexibility in material handling.

Self-propelled trackless transfer cart

Self-Propelled Trackless Transfer Cart is a kind of heavy-duty industrial transfer equipment with autonomous driving ability, which does not need to rely on the fixed track or external traction device, and can travel freely on flat ground, suitable for the flexible transfer of various types of large-tonnage materials. It adopts an independent electric drive system (AC/DC motor + reducer) and is equipped with a frequency conversion speed control function to realize smooth start/stop and precise speed control. A diesel or hybrid configuration is available to meet the needs of outdoor or no power supply scenarios. Load range covers 5-500 tons, and can be customized with modules such as a hydraulic lifting platform (stroke ±300mm) and a rotating table (360°continuous rotation). Particularly suitable for heavy industry that requires frequent adjustment of the transportation path.

Spécifications

| Capacité de charge nominale(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Taille du tableau (mm) | Longueur | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Largeur | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Hauteur | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Garde au sol(mm) | ≥50 | ≥100 | |||||||||

| Rayon de braquage(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Mode de pilotage | Direction différentielle | Direction hydraulique | |||||||||

| Méthode de fonctionnement | Remote Control & Hand Operated Pendant | ||||||||||

| Bougez ! | Avancer, reculer, tourner pendant la conduite sans arrêt, et une rotation de 360 | Avancer, reculer, tourner pendant la conduite sans arrêt | |||||||||

| Vitesse de course(m/min) | 25 | 20 | |||||||||

| Type de moteur | /Low-voltage alternating current (AC) motor / brushless direct current (DC) motor | ||||||||||

| Mode de freinage | Frein électromagnétique | ||||||||||

| Mesures de protection | Voyant d'alarme sonore et visuel+ Bouton d'arrêt d'urgence+Capteur laser d'évitement d'obstacle (en option)+Bord de contact anticollision (en option) | ||||||||||

| Quantité de roues | 4 | 6 | 8 | ||||||||

| Diamètre de la roue motrice(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф550 | Ф600 | Ф550 | Ф550 | |

| Matériau de la roue | Steel Core + Polyurethane /Rubber Tire | ||||||||||

| Capacité de la batterie(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 22.5 | 30 | 37.8 | 45.3 | |

| Type de batterie | Batterie plomb-acide | Pile au lithium | |||||||||

| Autonomie de la batterie | 5h(Customized As Needed) | 4h(Customized As Needed) | |||||||||

| Temps de charge de la batterie | ≤7h | ≤5h | |||||||||

| Chargeur de batterie | AC220V/AC380V | ||||||||||

| Type de sol | Cement Floor、Steel Plate Ground 、Epoxy Floor, Asphalt Floor | ||||||||||

| Capacité d'escalade à pleine charge | 5% | 3% | |||||||||

| Environnement de travail | Temperature: -10°c~40°c; Humidity: 20%~80%, No Condensation(Customized for high-temperature and explosion-proof environments) | ||||||||||

| Couleur de la carrosserie du véhicule | Sur mesure | ||||||||||

| Autres fonctions | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection, etc | ||||||||||

1. Other table sizes and load capacities can be customized according to user requirements.

2. For hydraulic steering, dual hydraulic steering system can be selected to reduce the turning radius based on site space constraints.

3. Battery type and operating time (battery endurance) can be customized to meet customer needs.

4. The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice.

Principe de fonctionnement

Trackless transport carts are powered by batteries, cables or diesel engines, and the drive motor drives the wheels to move freely. The direction can be adjusted through the steering wheel, differential system or universal wheel, and flexible steering and precise positioning can be performed. It is controlled manually, remotely or automatically (such as AGV), and combined with sensors to achieve obstacle avoidance, path planning and load monitoring.

Pièces détachées

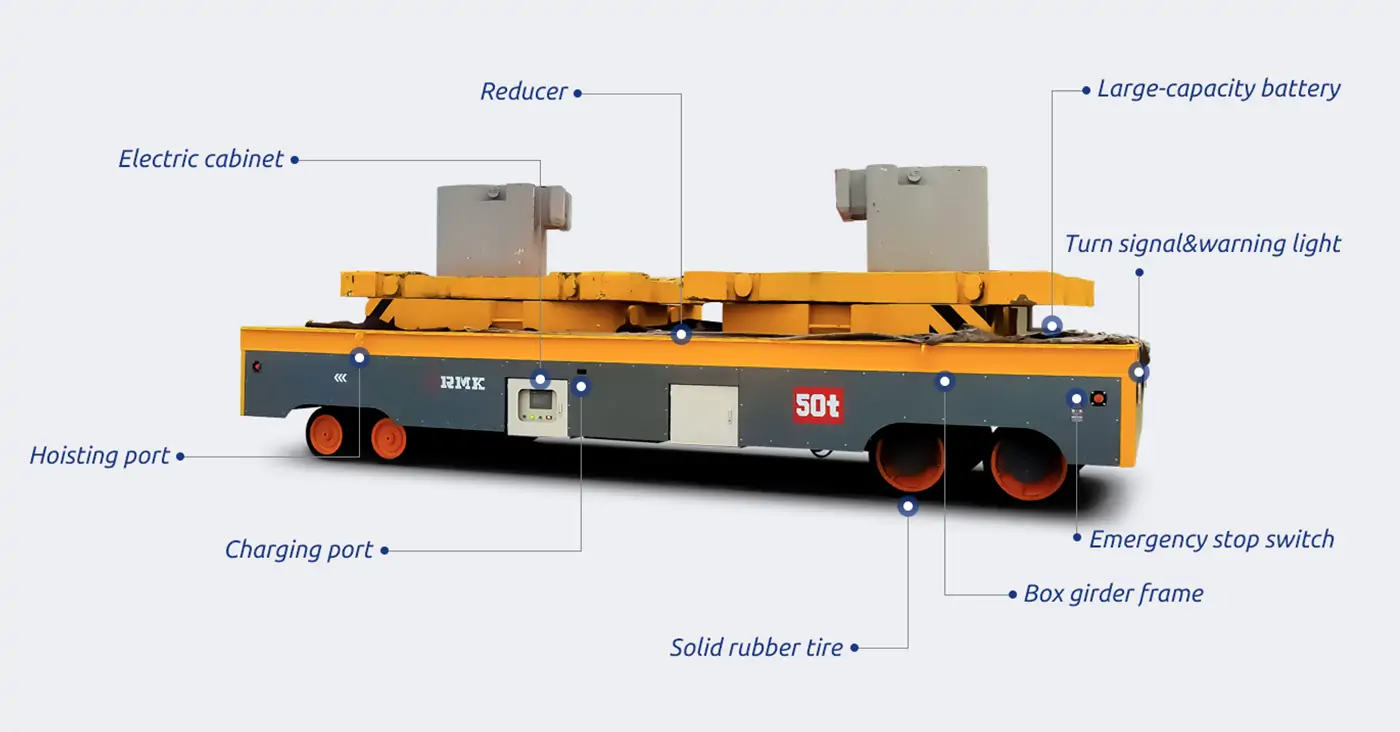

Trackless Transfer Cart is mainly composed of body frame, drive system, control system, steering system, power supply system, safety device and other parts. The following are the detailed structural features:

Body Frame: Adopting box beam/I-beam frame, with load range of 5~100+ tons, equipped with vibration damping device, it can transport heavy materials stably.

Flexible drive and steering: electric (battery/cable) or diesel drive, supporting single/four-wheel drive modes; with multiple steering modes (including front-wheel steering, differential steering, and universal wheel), it can be adapted to narrow space or long-distance transportation.

Intelligent control system: manual driving, wireless remote control or AGV automatic navigation (laser/magnetic stripe), integrated PLC, sensors (obstacle avoidance/weighing) to realize precise operation.

Multi-functional working platform: standard with flat loading table, optional hydraulic lifting (mold handling), rotary table (angle adjustment) or explosion-proof design (chemical/oil depot).

Safety and extended configuration: standard with emergency stop button, anti-collision alarm, optional weighing system, LED lighting, automatic charging, etc., to meet the needs of different scenarios (clean workshop, outdoor, intelligent factory).

Caractéristiques

Trackless design

No need to lay tracks, relying on tires to move freely, adapting to a variety of ground and complex paths.

Flexible driving mode

Optional battery (lithium/lead-acid), cable power supply or diesel drive to meet the range and power requirements of different scenarios.

Intelligent control system

Support manual driving, wireless remote control or AGV automatic navigation (laser/magnetic stripe), precise control of driving and positioning.

Multi-functional loading platform

Standard flat structure, optional hydraulic lifting, rotary table or explosion-proof configuration, suitable for mold, heavy equipment handling.

High load bearing and stability

The frame is made of high strength steel, with a load range of 5~100 tons, equipped with shock absorbing device to ensure smooth transportation.

Multiple safety protection devices

Integrated emergency stop button, anti-collision sensors, sound and light alarms, etc., to ensure the safety of human and machine operation.

Application

- Mould transportation: pour le transfert en atelier des moules d'injection et des moules d'emboutissage.

- Transport de matériel lourd : utilisé pour le transfert de pièces dans la fabrication de machines et l'industrie métallurgique.

- Logistique d'entrepôt : remplace le chariot élévateur traditionnel pour le transport de matériaux ou de conteneurs de grande taille.

- Environnement particulier : Le type antidéflagrant est adapté aux endroits dangereux, le type intelligent est utilisé dans les lignes de production automatiques.

Chariot de transfert sans chenilles à vendre

Chariot de transport de moules de 25 tonnes

Chariot de transport de moules de 25 tonnes Chariot de transfert sans chenilles de 30 tonnes à levage hydraulique

Chariot de transfert sans chenilles de 30 tonnes à levage hydraulique Chariot de transfert sans rail 40 tonnes à batterie

Chariot de transfert sans rail 40 tonnes à batterie Chariot de transport électrique antidéflagrant

Chariot de transport électrique antidéflagrant Chariot de transfert sans rail pour matériaux lourds de 5 tonnes

Chariot de transfert sans rail pour matériaux lourds de 5 tonnes Chariot de transfert sans rail intelligent

Chariot de transfert sans rail intelligent

Chariot de transport de moules de 25 tonnes : Conçu pour le transport de moules lourds, le chariot de transport sans chenilles a une capacité de charge allant jusqu'à 25 tonnes et peut être utilisé dans les usines, les ateliers et d'autres environnements, ce qui le rend flexible et efficace.

Chariot de transfert sans rail de 30 tonnes à levage hydraulique : Doté de fonctions de chargement et de levage robustes, il convient à la manipulation et au positionnement de pièces ou d'équipements de grande taille.

Chariot de transfert sans rail 40 tonnes à batterie : Chariot de transfert sans chenilles de 40 tonnes alimenté par des batteries de grande capacité, respectueuses de l'environnement et économes en énergie, adaptées à une utilisation intensive et de longue durée.

Chariot de transfert électrique antidéflagrant : Chariot de transport électrique antidéflagrant, adapté au pétrole, aux produits chimiques et à d'autres produits inflammables et explosifs, sûr et fiable, facile à utiliser.

Chariot de transfert sans rail pour matériaux lourds de 5 tonnes : Convient pour le transport à courte et moyenne distance de toutes sortes de matériaux, structure robuste, économique et pratique.

Chariot de transfert intelligent sans rail : Le chariot de transfert sans rail intelligent, équipé d'un système de navigation ou de contrôle automatisé, peut réaliser un positionnement précis, une planification de trajectoire et d'autres fonctions avancées afin d'améliorer l'efficacité de la logistique.

Cas Montrer

Fabricant de chariots de transfert sans rail

En tant que fabricant leader de chariots de transfert sans rail, Remarkable est spécialisé dans la conception et la production de solutions de transfert personnalisées et de haute performance pour les applications industrielles. Nos chariots sont dotés d'une flexibilité sans piste, de systèmes de contrôle intelligents et de capacités de charge élevées (de 5 à plus de 100 tonnes) pour répondre aux divers besoins de manutention. Contactez-nous pour des solutions de transport de haute qualité !

Articles connexes

Produits apparentés

Solutions personnalisées de manutention intelligente

Pour qu'un chariot de transfert personnalisé corresponde parfaitement à vos besoins, veuillez fournir les informations suivantes :

- Capacité de charge : _____ tonnes (1~500 tonnes)

- Taille du tableau : _____ × _____ mm/m (par exemple, 1500×3000)

- Options d'alimentation :

- ☐ Plomb-acide ☐ Lithium-ion ☐ Autre : _____

- ☐ Câble : _____V/_____A

- ☐ Standard 380V/50Hz/3-phases

- Détails de la cargaison :

- Type : _____ (par exemple, bobines d'acier, machines)

- Besoins particuliers : _____ (par exemple, antidérapant, résistant à la corrosion)

- Caractéristiques optionnelles :

- ☐ Arrêt d'urgence ☐ Capteurs anti-collision

- ☐ Guides de rail ☐ Mécanisme de levage ☐ Télécommande