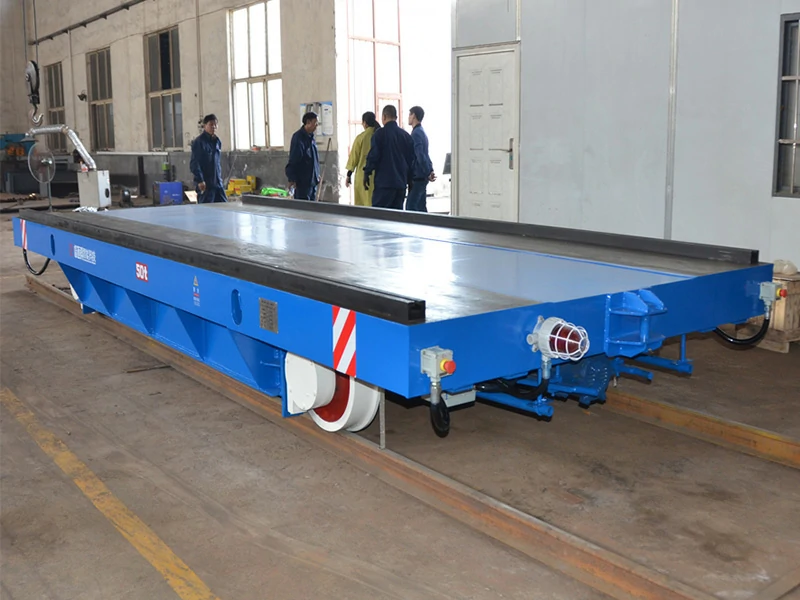

إن multidirectional transfer cart is trackless handling equipment powered by motors, batteries, and omnidirectional wheels as core drive units. They enable multi-directional movement, including forward, backward, lateral, diagonal travel, and on-the-spot rotation.

The omnidirectional transfer cart operates flexibly in confined workstations, complex routes, and multi-process environments, making it ideal for efficiently transporting heavy-duty components like large machinery, steel coils, molds, and battery packs. This article outlines the advantages of multidirectional transfer carts and guides selection and maintenance.

Advantages of Multidirectional Transfer Carts

Adaptability to confined spaces: Capable of lateral, diagonal, and in-place rotational movement, ideal for factory environments with narrow aisles and complex operational routes, significantly enhancing space utilization.

سعة تحميل عالية: Featuring high-strength steel frames and heavy-duty wheel assemblies, they handle loads ranging from 3 tons to approximately 300 tons or more, making them ideal for transporting heavy materials.

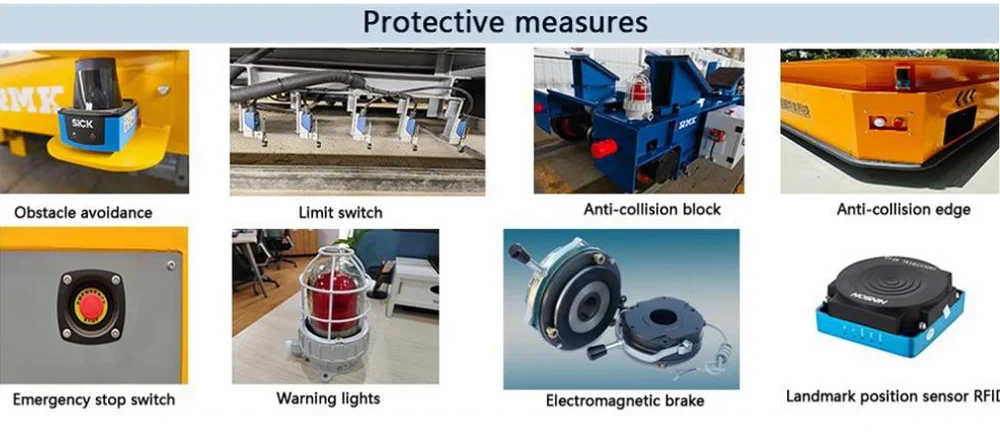

تشغيل مرن: Supports remote control, button operation, or driver cab modes. It can be equipped with laser obstacle avoidance, speed limit systems, and emergency stop devices to enhance operational safety.

High Cost-Effectiveness: Eliminates the need for track installation, allows flexible route changes, reduces facility modification costs, and offers low operational barriers, minimal maintenance expenses, and enhanced safety.

Highly Customizable: Platform structure (flatbed, V-groove, support clamps), battery capacity, and control systems can be tailored to specific work conditions, reducing manual handling and improving transport efficiency.

Having learned about the advantages of multidirectional transfer vehicles, how should buyers select the right model for their specific operations?

How to choose a multidirectional transfer cart?

When selecting a multidirectional transfer car, key factors such as load capacity and site conditions must be prioritized to ensure efficient, flexible, and long-term stable operation under complex working conditions. Below are critical considerations for buyers during selection:

Consider load capacity:

- Calculate based on maximum transport weight, allowing a 20%-30% safety margin to prevent overloading during long-term use.

- For high-frequency or continuous handling scenarios, opt for high-strength steel structures and heavy-duty wheel assemblies to enhance durability.

Proper load matching reduces failure rates and improves overall transport stability.

Selecting the Appropriate Platform Structure:

- Flat Platform: Suitable for general materials like frames, panels, and boxes. Simple and durable structure.

- V-Groove Platform: Designed for steel coils, aluminum coils, and cylindrical workpieces to prevent rolling and shifting.

- Adjustable Support Platform: Ideal for complex-shaped items like molds and equipment components, improving securing effectiveness.

- Anti-Slip Platform: Primarily used in environments with ground vibrations or slippery materials to enhance safety.

Customize platforms based on workpiece dimensions and shapes to enhance transport safety.

Consider Facility Environment:

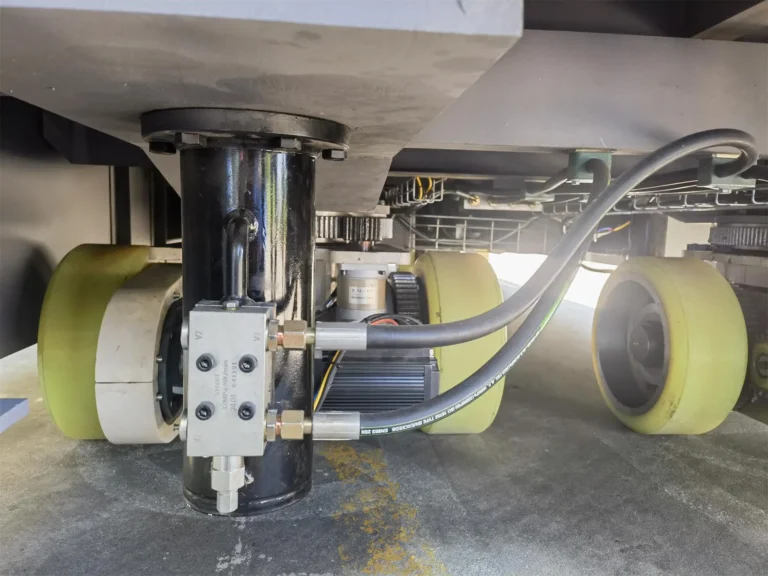

- Mecanum Wheels: Ideal for narrow spaces requiring lateral, diagonal movement, or in-place rotation, such as battery workshops or assembly lines.

- Four-Wheel Independent Drive Steering: Offers high stability for complex routes with slightly wider passages.

- Dual-wheel differential drive structure: Cost-effective for larger spaces with simpler routes.

Select appropriate wheel types based on workshop aisle width and equipment density to optimize operational efficiency.

Consider Operating Distance and Duration:

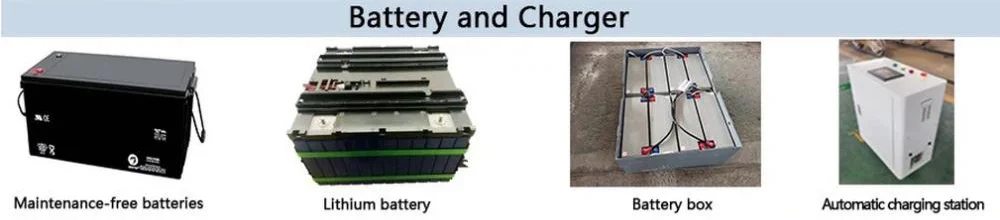

- Long-distance, multi-shift, high-frequency transport: Opt for high-capacity lithium batteries, high-power motors, and fast-charging configurations.

- Medium-to-short distance, intermittent operation: Standard battery solutions reduce procurement costs.

Select battery and drive systems based on distance and duration to avoid frequent charging disruptions and extend battery lifespan.

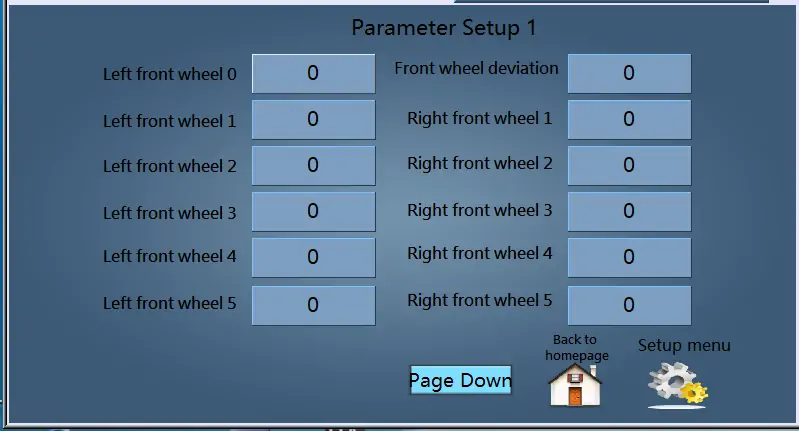

Be careful with operation methods and management modes:

- Remote control: Suitable for workshops with manual supervision and high maneuverability.

- Button station control: Ideal for fixed routes or repetitive cycles.

- الملاحة بالليزر: Optimized for smart factories to elevate logistics automation.

Enterprises should select control systems based on current and future development plans to avoid retrofitting costs.

Supplier Capabilities:

- Proven experience in designing and manufacturing heavy-duty multidirectional transfer carts

- Capability to customize non-standard platforms and intelligent control systems

- Comprehensive after-sales support, including spare parts supply and on-site engineer assistance

- Extensive successful case studies, such as cold rolling mills and mold factories

Multi-directional transfer vehicles are heavy-duty, customized equipment. Selecting an experienced manufacturer is essential for establishing long-term, mutually beneficial partnerships. Now that we understand how to select a multidirectional transfer cart, how should we maintain it?

If you wish to learn about the structure of multidirectional transfer carts, you may refer to the article: الهيكل التفصيلي لعربة النقل القابلة للتوجيه

How to Maintain a Multidirectional Transfer Cart

To ensure long-term stable operation and reduce failure rates, daily maintenance is crucial. Below are key maintenance points enterprises should focus on.

Regularly inspect wheel assemblies, drive wheels, and steering mechanisms:

Multi-directional wheels and drive wheels endure repeated impacts during transport, making them high-wear components. To maintain optimal mechanical condition and effectively prevent issues like drifting or vibration, focus on inspecting:

- Tire wear, cracks, or looseness

- Drive wheel eccentricity, noise, or vibration

- Lubrication status of steering joints

Battery System Maintenance and Charging Management:

Battery issues are common failure points in trackless equipment. Proper battery maintenance extends lifespan by:

- Avoid deep discharges; charge according to specified intervals

- Regularly inspect battery terminals and cables for oxidation or loose connections

- Clean dust from battery surfaces and ensure adequate ventilation for heat dissipation

Electrical Control System and Safety Device Inspection:

The electrical control system is the core of multidirectional transfer carts. Proper maintenance prevents unexpected shutdowns and safety hazards. Key tasks include:

- Regular inspection of controllers, sensors, and wiring harnesses

- Testing of safety devices such as emergency stops, warning lights, and buzzers

- Keep the electrical control box dry to prevent moisture-induced short circuits

Frame, Platform, and Fastener Inspections:

The frame bears heavy loads continuously. To ensure structural integrity and enhance transport safety, regularly inspect:

- Cracks, deformation, or corrosion

- Looseness in the platform’s anti-slip layer and support structures

- Tightness of all vehicle bolts

الخلاصة:

Through this article, we have gained insights into the characteristics of multidirectional transfer carts and how to select and maintain them. These carts are essential material handling equipment in modern factories.

As a professional Chinese manufacturer of transfer carts, we are committed to providing customized, reliable, and efficient material handling solutions. If your business requires transfer equipment, please feel free to اتصل بنا anytime. We will offer you the most suitable products and premium service.