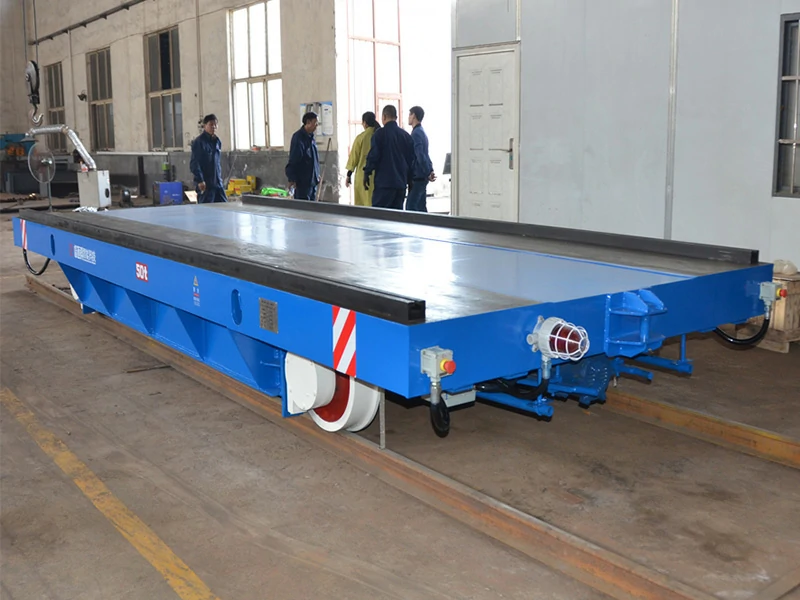

Steerable transfer carts are industrial handling equipment featuring manual or mechanical steering systems. Through four-wheel linkage, hydraulic steering, or mechanical steering mechanisms, they achieve multi-directional movement. With agile steering, high load capacity, no track installation required, and adaptability to complex terrain, they are commonly used for transporting heavy items like molds, steel coils, and equipment components within factory premises. This article provides an in-depth look at the structure and working principles of a steerable transfer cart.

Structure of the Steerable Transfer Cart

The heavy-duty steerable transfer cart structure is simple, primarily comprising the following elements:

Frame Body

The frame serves as the vehicle’s foundational structure, typically fabricated from high-strength carbon steel welded into a box-beam configuration using channel steel or rectangular tubing. Reinforcing gusset plates at the base prevents deformation from concentrated loads, while a corrosion-resistant coating extends service life.

The frame bears the material weight while providing a fixed mounting structure for wheels, steering components, and the platform. Its high rigidity and overall stability enhance the transfer cart’s load capacity and safety performance.

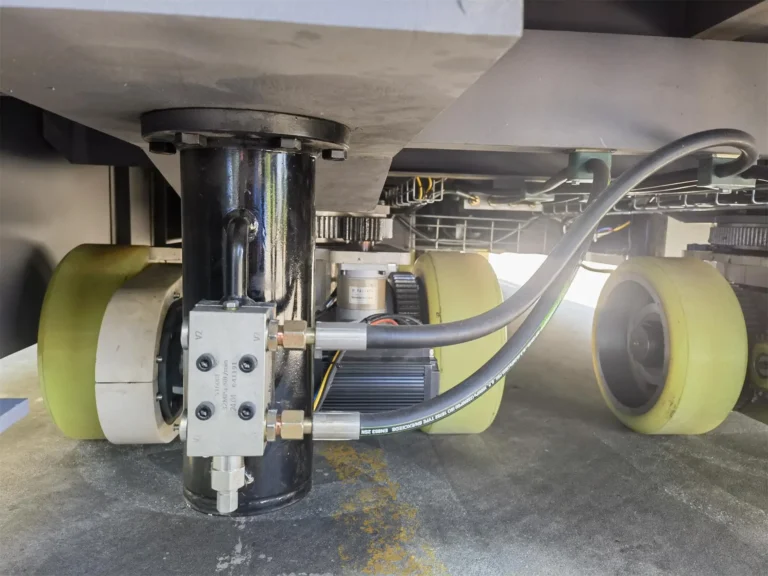

Wheel and Axle System

Wheels are available in various materials, including PU wheels, rubber wheels, and cast steel wheels. Different shapes and materials suit diverse factory floor conditions.

Axles employ either solid or split-type structures, with precision bearings ensuring stable rolling and low resistance.

The wheel system is a critical component supporting the vehicle and its movement. It ensures smooth operation under heavy loads during transport while enhancing durability.

If you are interested in learning about the types of wheels on transfer carts, please refer to the article: أنواع عجلات عربات النقل

Steering System

The steering system is the key structural feature distinguishing this equipment from standard flatbed carts. Common configurations include:

- Mechanical Linkage Steering: Structure path: drawbar → steering linkage → steering shaft → wheels. Simple and reliable, commonly used for medium to light-duty transport.

- Hydraulic steering: Hydraulic cylinders actuate wheel deflection, enabling low-speed fine adjustments and precise positioning during heavy-load handling. Primarily used for high-tonnage transport.

- Four-wheel synchronized steering: Enables tight-radius turns with high maneuverability. Front and rear wheels share load distribution, enhancing vehicle balance and stability. Ideal for factories with narrow passages and frequent turns.

The steering mechanism controls turning angle and precision, enabling agile operation in confined factory spaces, aisles, or workstations. It constitutes a critical functional component of the vehicle.

Towing System

The towing system facilitates manual pulling or integration with tow tractors. The tow bar connects to the steering assembly, while tow eyes or trailer hitches enable external vehicle towing. Its foldable design simplifies parking.

The towing system transmits force from manual operators or tow trucks to the steering system, enabling both movement and directional control. It serves as the power and directional end for vehicle mobility.

Towing System

Towing System

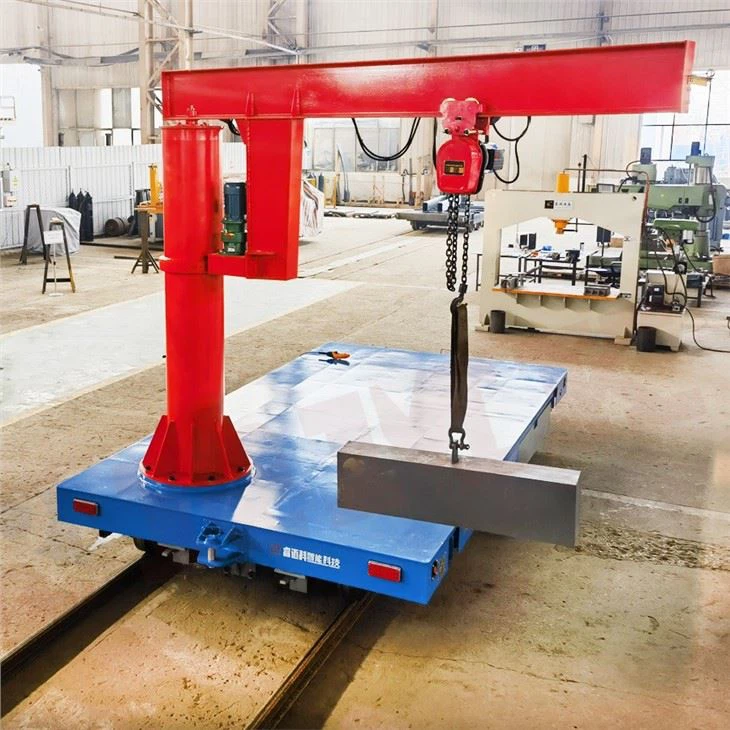

Load Platform

The load platform provides the working surface for supporting cargo. Different structures can be customized based on the transported materials:

- Flatbed Platform: A common platform structure featuring a flat steel plate working surface. The surface can be treated with anti-slip patterns. It offers a simple structure and easy maintenance.

- V-Groove Platform: Features a central “V” groove designed with adjustable angles for specific materials, commonly used for transporting steel coils and cylindrical goods.

- Supporting Devices: Secure cargo using support frames, positioning blocks, or interlocking bases. Customized for material mounting holes, ideal for complex-shaped items, large equipment, or molds.

- Anti-Slip Platform: Features patterned steel plates or rubber anti-slip mats on the surface to increase friction and prevent cargo slippage. Commonly used for barrel-packed, box-packed, or slippery materials.

Steerable Transfer Cart

Steerable Transfer Cart V Steerable Transfer Cart

V Steerable Transfer Cart

The load-bearing platform supports transported materials, with structural strength and stability directly impacting cargo safety. Different industries achieve higher efficiency and better protection through customized platform solutions.

The steerable transfer cart has a simple structure, but how does it work? Let’s take a brief look.

How Does a Steerable Transfer Cart Work

The traction force of a steerable transfer cart is provided by manual labor, a tow vehicle, or an electric system, with the wheels working in coordination with the steering system. By altering the wheel deflection angle through the steering mechanism, the steering wheels and load platform achieve synchronized movement. This enables the vehicle to perform agile reversing and turning maneuvers within confined factory areas, ensuring stable operation.

Steering Mechanism Principle: The operator pushes or pulls the steering handle, which drives the front wheels or all four wheels to turn synchronously. The change in wheel deflection angle alters the vehicle’s direction. This design offers a small turning radius, precise directional control, and suitability for confined factory spaces.

Load-bearing and force transmission principle: The chassis bears concentrated loads from materials and distributes them evenly to the wheels. Tire materials must match ground suitability and load capacity. Its high-strength steel structure ensures safe transport of heavy loads.

Travel process principle: Manual/electric traction provides forward momentum. Wheels generate rolling friction with the ground, while the braking system controls stopping and parking. It features low failure rates and easy maintenance.

Having understood the structure and working principles of steerable transfer carts, are we clear on their application domains? Let’s explore below.

What Are the Application Fields of Steerable Transfer Carts

Steerable transfer carts are suitable for industrial scenarios requiring flexible steering, short-distance transport, and confined spaces. They are commonly used in mold processing, metal manufacturing, and equipment assembly industries.

| Industry Typical | Transported Materials |

|---|---|

| Mold Manufacturing | Molds, stamping dies, and injection molds |

| Steel and Metal Industry | Coiled steel, aluminum coils, castings, forgings |

| Machinery Equipment | Manufacturing Frames, welded structural components, and large equipment parts |

| صناعة الطاقة الجديدة | Battery packs, structural components, energy storage equipment parts |

| Warehousing & Logistics | Pallets, totes, finished goods |

| Chemical Industries | Material drums, chemical containers, packaging materials |

If you’re interested in steerable transfer carts and want to choose a suitable multidirectional transfer cart, you can contact us or refer to this article: كيفية اختيار عربة نقل متعددة الاتجاهات

الخاتمة

Through the above article, we understand that steerable transfer carts are simple in structure and agile in maneuverability, serving as efficient and safe material handling tools. As a professional Chinese manufacturer of transfer carts, we are committed to providing customized, reliable, and efficient material handling solutions. If your business requires transfer equipment, please feel free to اتصل بنا anytime. We will offer you the most suitable products and premium service.