The Multifunctional Omnimove Transfer Cart is a carrinho de transferência specifically designed and manufactured for aircraft maintenance operations.. Featuring 360° maneuverability, trackless operation, and multiple movement modes including longitudinal, lateral, diagonal, and rotational steering, it enables precise navigation within confined hangar spaces. This integrated system combines hydraulic lifting, platform sliding, and tilting functions to facilitate the handling of aircraft components and ensure personnel safety during operations. Equipped with an intelligent display, safety interlock devices, and protective systems, it ensures reliable handling of precision aerospace components.

REMARKABLE oferece serviços de personalização que abrangem a capacidade de carga, a conceção da plataforma, os modos de controlo e os módulos funcionais para satisfazer diversos requisitos operacionais.

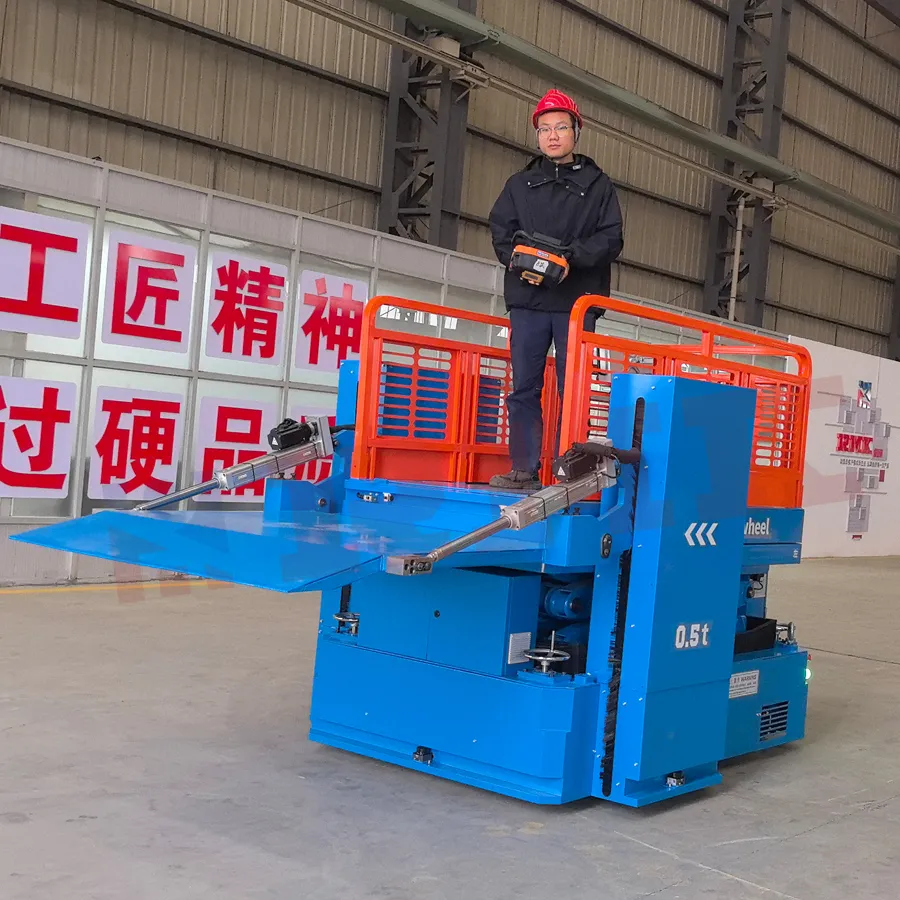

- Modelo: RWP

- Capacidade de carga: 0.5 Tons

- Dimensões: 2100×1400 × 1200 mm

- Curso de elevação: Hydraulic lifting, 1400 mm

- Fonte de alimentação: Maintenance-free battery (electric drive)

- Velocidade: 0–20 m/min (stepless speed regulation)

- Personalizado: Produção personalizada disponível, incluindo componentes adicionais, etc.

Working Principle of the Multifunctional Omnimove Transfer Cart

The following explanation of the operating principles of the multifunctional omnimove transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

Princípio de funcionamento:

- Power-up

- Switch on the main power supply. The system draws power from the battery (48V/130Ah) to supply the vehicle controller, drive units, and hydraulic pump.

- Electronic control self-test: Display self-check, sensor and communication link verification, fault code clearance, and readiness confirmation.

- Inspection items: Battery charge display, braking system, laser obstacle avoidance/safety edge, outrigger sensors, and emergency stop button functionality check.

- Mode Selection

- The operator selects the operating mode (movement/lifting/translation/tilting/outrigger deployment) via wireless remote control or wired joystick.

- The controller issues commands to the functional modules based on the selected mode and activates the corresponding safety paths.

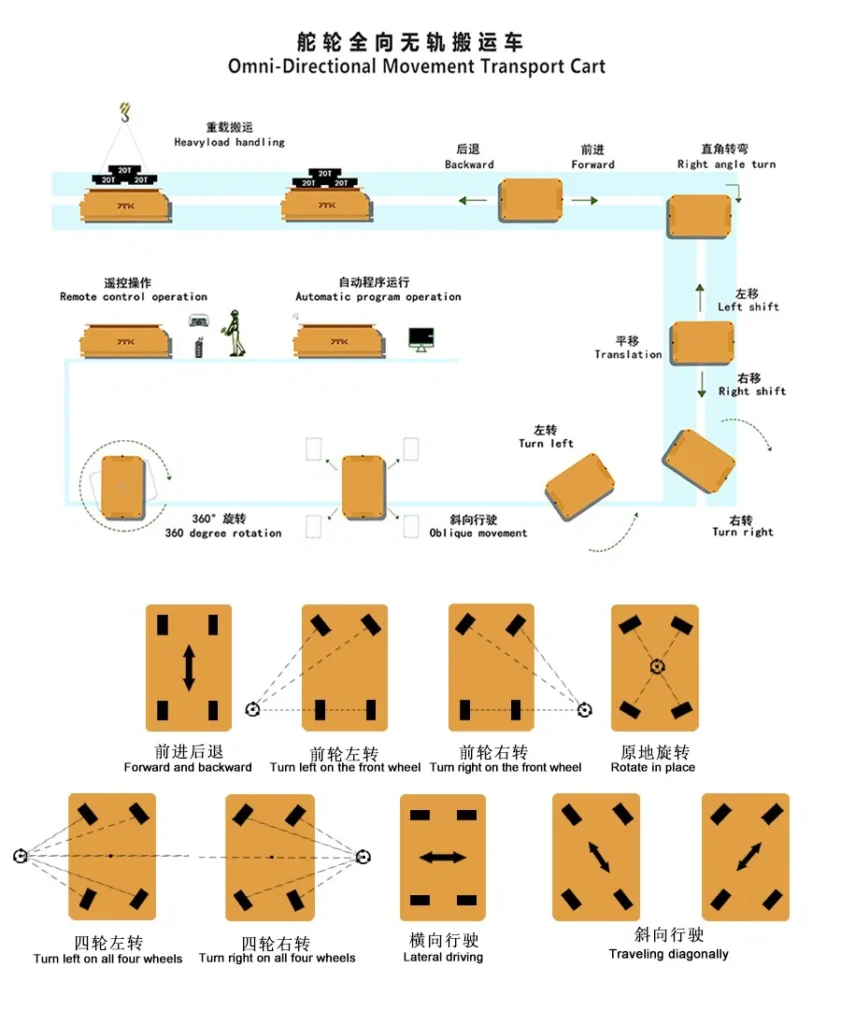

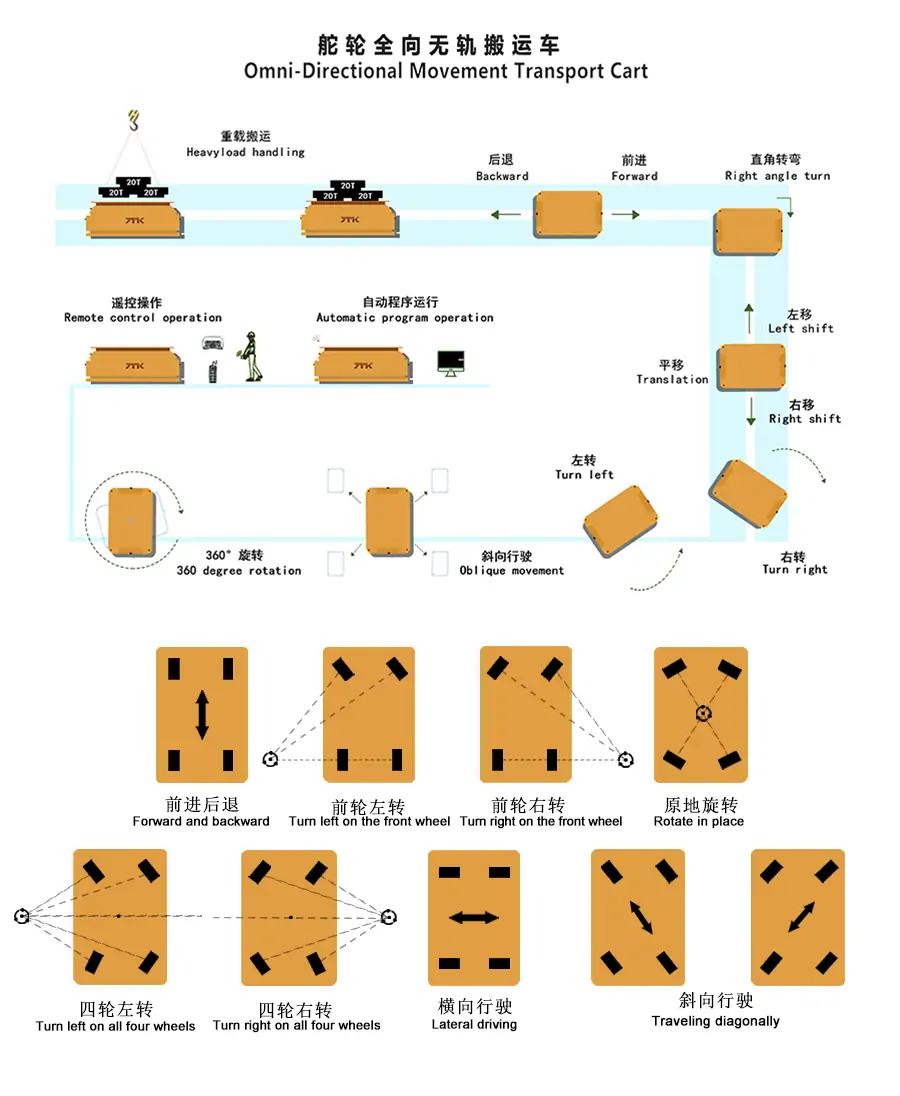

- Drive and Omnidirectional Mobility

- Dual drive motors (2 kW ×2) provide traction; four steering motors (0.75 kW ×4) independently control the steering angle of each of the four steering wheels.

- Control algorithms calculate each wheel’s speed and steering angle in real time, enabling: forward/reverse, lateral movement (sideways), diagonal movement, on-the-spot rotation, and diagonal traversing for omnidirectional motion.

- Encoders and speed sensors at the wheel ends feed back to the drives, forming a closed-loop speed/position control system that ensures positioning accuracy and motion smoothness.

- Positioning

- The operator or automated assistance system monitors position via on-board displays (platform surface and remote control).

- Laser obstacle avoidance and distance sensors operate during low-speed precision positioning, triggering deceleration and enabling precise approach to the docking point at a set step distance.

- Soft-cushion support and buffering mechanisms absorb micro-impacts upon contact, preventing damage to sensitive composite components.

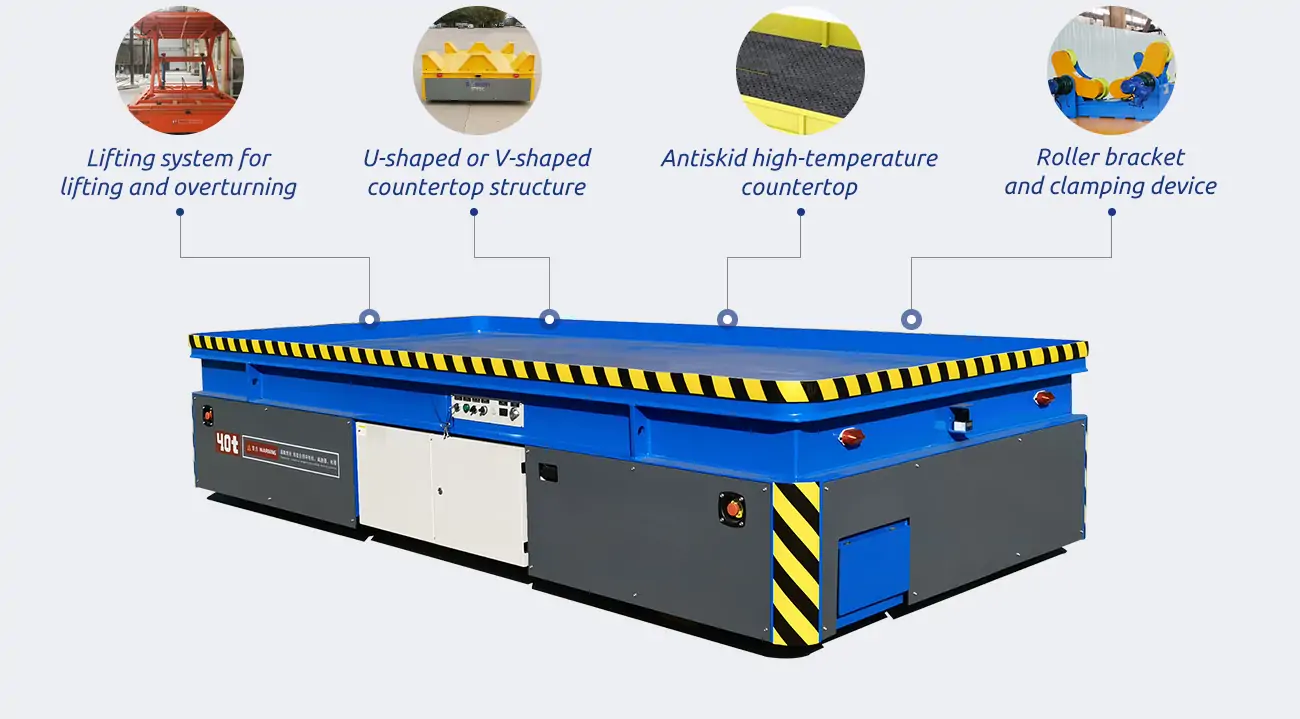

- Hydraulic Platform Elevation and Translation (Upper Platform)

- Activate the hydraulic pump to drive cylinders or scissor mechanisms for platform elevation (upper platform translation stroke approx. 400 mm; elevation stroke ≥1400 mm, with customisable longer strokes available).

- Lifting employs flow/pressure closed-loop control, with the controller precisely limiting lifting speed via valves (e.g., 3–4 m/min) while continuously monitoring load and displacement sensors.

- Platform traversal and tilting are controlled by dedicated motors/actuators, achieving up to 70° tilt angles with position locking before and after operations.

- Small Platform Operation

- The small platform employs an independent hydraulic/electric drive, supporting ≥1100 mm vertical travel and 70° tilt for local assembly and workstation adjustments.

- During small platform operation, the system temporarily locks the vehicle’s movement and unrelated modules (interlock mechanism) to prevent concurrent actions from causing hazards.

- Outrigger/Stabiliser Deployment and Stability Control

- Before elevated or loaded operations, the control system deploys all four hydraulic outriggers to ground contact, with load feedback from outrigger sensors.

- Upon meeting load-bearing requirements, the vehicle disengages wheel-end drive (or switches to parking mode) to prevent overturning and enhance operational stability.

- Personnel and Cargo Safety

- Hardware and software interlocks operate between all modules: vehicle movement or platform tilting is prohibited if lifting is incomplete or outriggers are not deployed.

- Laser obstacle avoidance, edge contact protection, and audible/visual alarms immediately trigger emergency stop logic upon detecting imminent hazards.

- Operator displays and remote controllers simultaneously show status and warnings, facilitating coordinated decision-making between near and remote operators.

- Electromagnetic Braking

- During normal operation, the drive unit regulates braking force for smooth stopping. Upon power failure or emergency stop, electromagnetic brakes forcibly engage to ensure static safety.

- During lateral movement or under load, braking control integrates with torque monitoring algorithms to prevent slippage or positional drift.

- Charging

- A separate charger provides fully automated intelligent charging, with the system managing charging profiles and safeguarding against overvoltage, undervoltage, and overcurrent.

- The Battery Management System (BMS) monitors battery health and available capacity, issuing alerts or restricting non-essential functions during low charge states.

- Shutdown and Maintenance

- During shutdown, first retract the platform to transport position, retract outriggers, disconnect peripherals, then transition to standby/off mode.

- Regular maintenance points include: hydraulic oil replacement, tyre (polyurethane-coated) inspection, encoder/sensor calibration, battery health assessment, and brake system inspection.

Carro de transporte de movimento omnidirecional

Carro de transferência multifuncional Omnimove

Especificações técnicas Visão geral

Discover the specifications of the multi-functional omnidirectional aircraft transfer trolley. Featuring 360° mobility, hydraulic lifting, platform sliding, and tilting capabilities, this transfer trolley enables safe and precise operations. Equipped with customisable features, it facilitates efficient aircraft inspection, maintenance, and MRO (Maintenance, Repair, and Overhaul) tasks.

| Parâmetro | Especificação |

|---|---|

| Capacidade de carga | 0.5T |

| Dimensões (C × L, mm) | 2100 × 1400 |

| Altura da mesa (mm) | 1200 |

| Distância ao solo (mm) | 60 |

| Requisito de piso | Betão |

| Fonte de alimentação | Maintenance-free Battery |

| Capacidade da bateria | 48V 130Ah |

| Modo de funcionamento | Wireless Remote + Wired Handle |

| Potência do motor de acionamento | 2 kW × 2 |

| Steering Motor Power | 0.75 kW × 4 |

| Diâmetro da roda (mm) | 250 |

| Number of Wheels | 4 |

| Velocidade de deslocação (m/min) | 0–25 |

| Tipo de travagem | Travão eletromagnético |

| Material da roda | Revestido a poliuretano |

| Modo de viragem | Steering Wheel |

| Modo de movimento | Forward/Backward, Turn While Moving, Diagonal, Lateral |

| Instalação do carregador | Separate Type |

| Função do carregador | Carregamento inteligente totalmente automático |

| Charging Time (h) | ≤8 |

| Upper Platform Lift Stroke (mm) | ≥1400 |

| Lift Speed (m/min) | 4 |

| Lift Power | 3 kW |

| Upper Platform Travel Stroke (mm) | 400 |

| Upper Platform Travel Power | 0.75 kW |

| Small Platform Lift Stroke (mm) | ≥1100 |

| Lift Speed (m/min) | 3 |

| Lift Power | 0.75 kW × 2 |

| Small Platform Tilt Angle | 70° |

| Small Platform Tilt Power | 0.75 kW × 2 |

| Medidas de segurança | Audible & Visual Alarm, Emergency Stop, Laser Obstacle Avoidance, Safety Edges |

| Outras funções | Battery Level Display, Overvoltage, Undervoltage, Overcurrent, Outrigger Protection |

Vídeos Show

Custom Parts for Omnidirectional Transfer Cart

Custom Series Parameters for Omnidirectional Transfer Cart

| Tabela de parâmetros técnicos do carrinho de transferência elétrico sem lagartas RWP | |||||||||||

| Capacidade de carga nominal(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Tamanho da mesa (mm) | Comprimento | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Largura | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Altura | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Distância ao solo(mm) | ≥50 | ≥100 | |||||||||

| Raio de viragem(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Modo de direção | Direção diferencial | Direção hidráulica | |||||||||

| Método de funcionamento | Controlo remoto e pendente de funcionamento manual | ||||||||||

| Mover Caminho | Avançar, recuar, rodar durante a condução sem paragem e uma rotação de 360 | Para a frente, para trás, virar durante a condução sem paragem | |||||||||

| Velocidade de funcionamento(m/min) | 25 | 20 | |||||||||

| Tipo de motor | Motor de corrente alternada (CA) de baixa tensão / motor de corrente contínua (CC) sem escovas | ||||||||||

| Modo de travagem | Travão eletromagnético | ||||||||||

| Medidas de proteção | Luz de alarme sonoro e visual+ Botão de paragem de emergência+ Sensor laser de desvio de obstáculos (opcional) + Borda de contacto anticolisão (opcional) | ||||||||||

| Quantidade de rodas | 4 | 6 | 8 | ||||||||

| Diâmetro da roda motriz(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Material da roda | Núcleo de aço + poliuretano | ||||||||||

| Capacidade da bateria(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Tipo de bateria | Bateria de chumbo-ácido | Bateria de lítio | |||||||||

| Resistência da bateria | 5h (Personalizado conforme necessário) | 4h(Personalizado conforme necessário) | |||||||||

| Tempo de carregamento da bateria | ≤7h | ≤5h | |||||||||

| Carregador de bateria | AC220V/AC380V | ||||||||||

| Tipo de solo | Chão de cimento 、 Chão de chapa de aço 、 Chão de epóxi, chão de asfalto | ||||||||||

| Capacidade trepante de carga total | 5% | 3% | |||||||||

| Ambiente de trabalho | Temperatura: -10°c~40°c; Humidade: 20%~80%, Sem Condensação (Personalizado para ambientes de alta temperatura e à prova de explosão) | ||||||||||

| Cor da carroçaria do veículo | Personalizado | ||||||||||

| Outras funções | Indicação da energia da bateria, proteção contra sobretensão, subtensão, sobrecorrente, etc. | ||||||||||

| Notas: 1) Outros tamanhos de mesa e capacidades de carga podem ser personalizados de acordo com os requisitos do utilizador. 2) Para a direção hidráulica, pode ser selecionado um sistema de direção hidráulica duplo para reduzir o raio de viragem com base nas restrições de espaço do local. 3) O tipo de bateria e o tempo de funcionamento (duração da bateria) podem ser personalizados de acordo com as necessidades do cliente. 4)O produto está sujeito a melhorias e actualizações contínuas; as especificações na tabela podem ser alteradas sem aviso prévio. | |||||||||||

Caraterísticas

Omnidirectional Mobility

Capable of 360° rotational movement for precise execution of aircraft maintenance tasks.

Multifuncional

Features hydraulic lifting, sliding and tilting capabilities.

Safe Operation

Emergency braking, laser obstacle avoidance and interlocking devices ensure operator safety.

Manuseamento de precisão

Flexible support pads safeguard delicate aircraft components during transfer and assembly.

Intelligent Control System

Real-time operational status display with fully interlocked functions for assured safety.

Custom

Tailor-made transfer cart available to meet specific operational requirements.

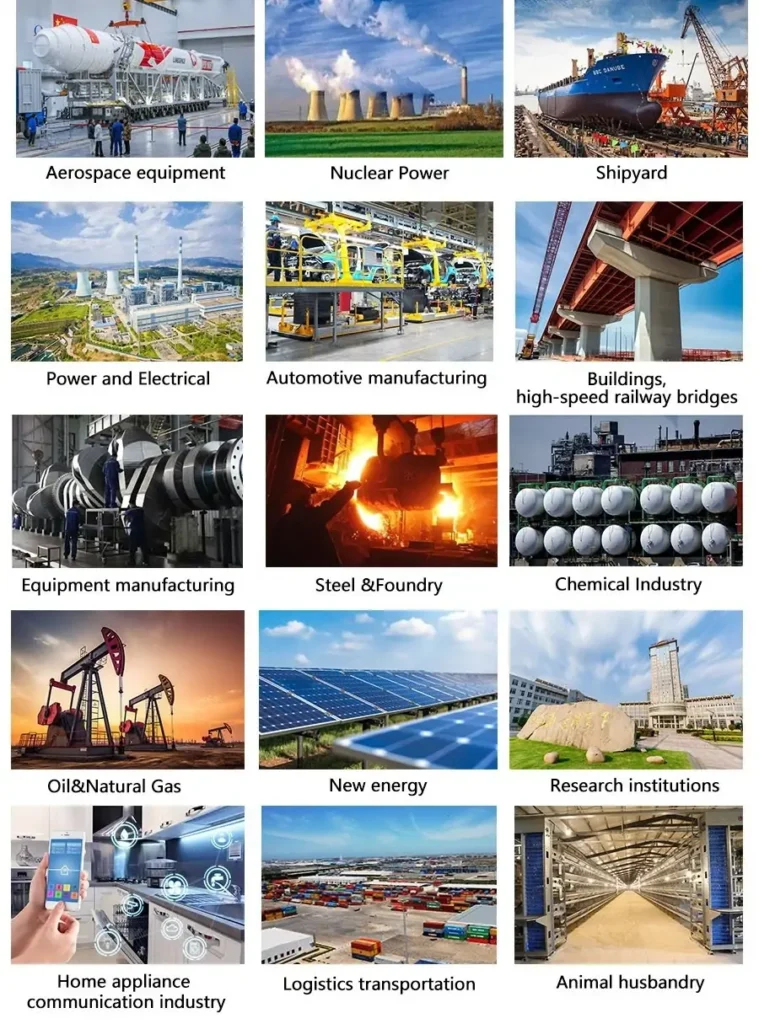

Aplicação

A Carro de transferência multifuncional Omnimove offers far more than aviation support. Its omnidirectional movement, precise positioning, and heavy-duty load capacity make it an ideal Transfer Cart solution for multiple industries. This all-direction transfer cart improves safety, efficiency, and workflow wherever flexible, reliable material handling is required.

Manufacturing

Solução: This Omnimove Transfer Cart moves heavy components with precise control, solving space-limited handling issues on busy production floors.

Logistics

Solução: The all-direction transfer cart boosts warehouse efficiency by transferring pallets smoothly in narrow aisles and reducing forklift dependence.

Rail Maintenance

Solução: A multifunctional Transfer Cart positions tools and parts accurately, speeding inspection tasks and minimizing downtime around rail vehicles.

Energy Plants

Solução: This heavy-duty omnidirectional cart transports modules and inspection kits safely through complex power-plant layouts during critical maintenance.

Automóvel

Solução: The maintenance transfer cart moves engines and diagnostic tools between stations, improving workflow accuracy and repair efficiency.

Shipyards

Solução: This omnidirectional transport vehicle handles large components in tight dock areas, supporting inspection, refits, and safe heavy-load mobility.

Mostruário do carrinho de transferência

Multifunctional Omnimove Transfer Cart Manufacturer

Henan Remarkable Intelligent Technology Co., Ltd was founded in 2019 and is located at No. 22, Xinchang North Line, Xiaodian Town, Hongqi District, Xinxiang City, Henan Province. It is a professional handling equipment company integrating R&D, design, manufacturing, sales, and after-sales service. It specializes in the production of various types and tonnages of handling equipment and their accessories, and provides professional R&D, design, and manufacturing of various non-standard and Carros de transferência eléctricos, Carros de transferência de carris, Carros de transporte móveis omnidireccionais, Carrinhos de transferência de baterias, Carrinhos de transporte de cargas pesadas, Robôs de manuseamento AGVe reboques industriais.

The Remarkable’s products comply with the JB/T6127-2010 machinery industry standard, have passed the ISO three-system certification (quality, environment, and occupational health), and the CE certification. It has obtained 19 national product patents successively.

Porquê escolher-nos?

- Conhecimentos específicos do sector - Servimos os sectores da produção de energia, construção naval, construção e aeroespacial com soluções à medida para transformadores, componentes de turbinas eólicas, módulos pré-fabricados e muito mais.

- Totalmente personalizado - Desde a capacidade de carga (1-500+ toneladas) aos sistemas de acionamento (elétrico, híbrido ou diesel), satisfaça os seus requisitos exactos.

- Sistemas de controlo avançados - As opções incluem controlo remoto manual, planeamento semi-automático do percurso ou navegação totalmente automatizada (integração de AGV).

- Qualidade e durabilidade - Estruturas de aço robustas, módulos de direção de binário elevado e certificação CE e ISO.

- Apoio total ao projeto - Desde a consulta inicial até ao serviço pós-venda, os nossos engenheiros fornecem assistência técnica vitalícia.

Artigos relacionados

Soluções inteligentes e personalizadas de manuseamento de materiais

Para garantir que um carrinho de transferência personalizado se adapta perfeitamente às suas necessidades, forneça os seguintes dados:

- Capacidade de carga: _____ toneladas (1~500 toneladas)

- Tamanho da mesa: _____ × _____ mm/m (por exemplo, 1500×3000)

- Opções de alimentação:

- ☐ Chumbo-ácido ☐ Iões de lítio ☐ Outros: _____

- ☐ Cabo: _____V/_____A

- Padrão 380V/50Hz/3-fase

- Detalhes da carga:

- Tipo: _____ (por exemplo, bobinas de aço, maquinaria)

- Necessidades especiais: _____ (por exemplo, antiderrapante, à prova de corrosão)

- Caraterísticas opcionais:

- Paragem de emergência ☐ Sensores anti-colisão

- ☐ Guias de carris ☐ Mecanismo de elevação ☐ Controlo remoto