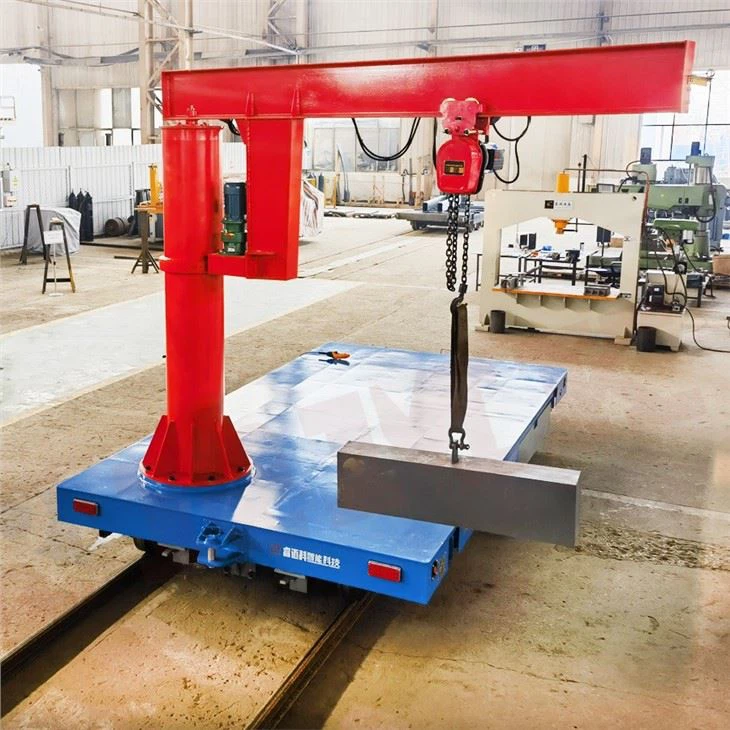

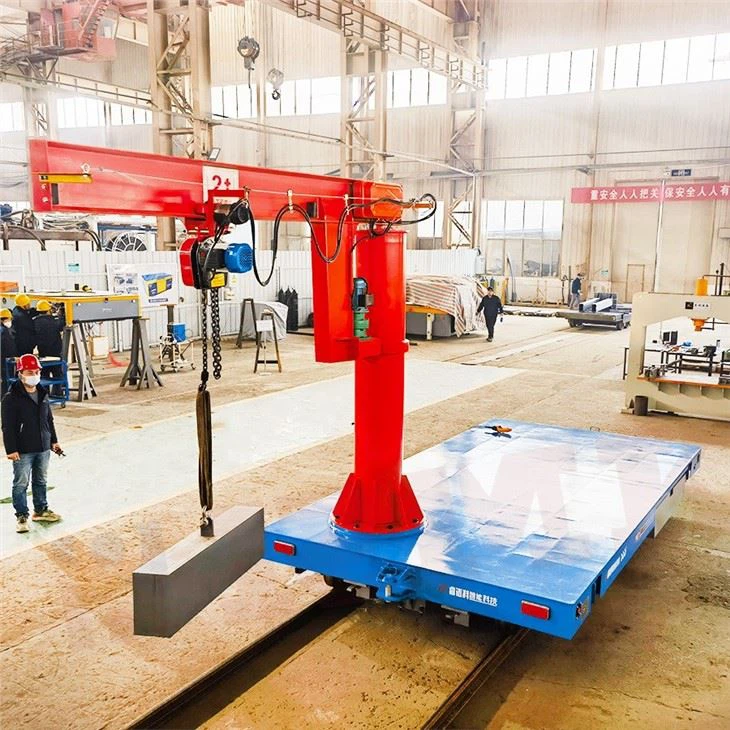

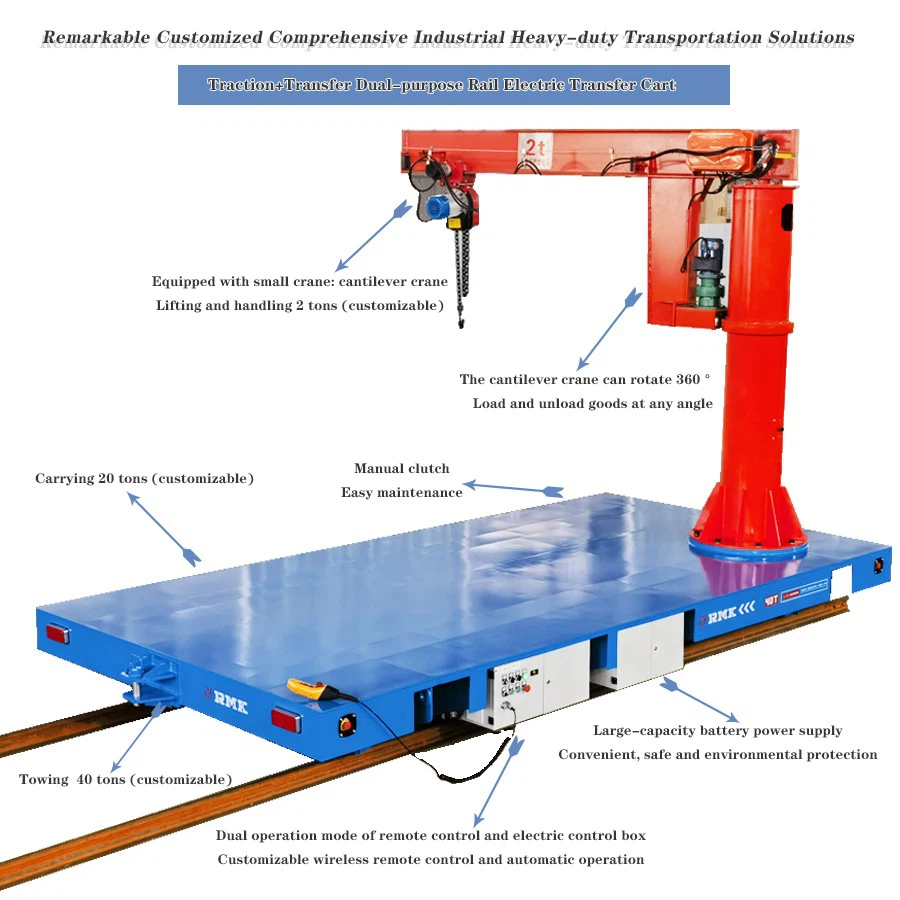

The 40 Tonne rail mounted transfer trolley with cantilever crane is a bespoke rail transfer cart manufactured by Remarkable. This rail mounted transfer trolley was designed as a comprehensive handling solution for an aerospace company. Customised from a rail transfer cart base, it incorporates a cantilever crane for workpiece handling, enabling three core functions: towing, transport, and lifting/loading/unloading. Below we outline the trolley’s key specifications.

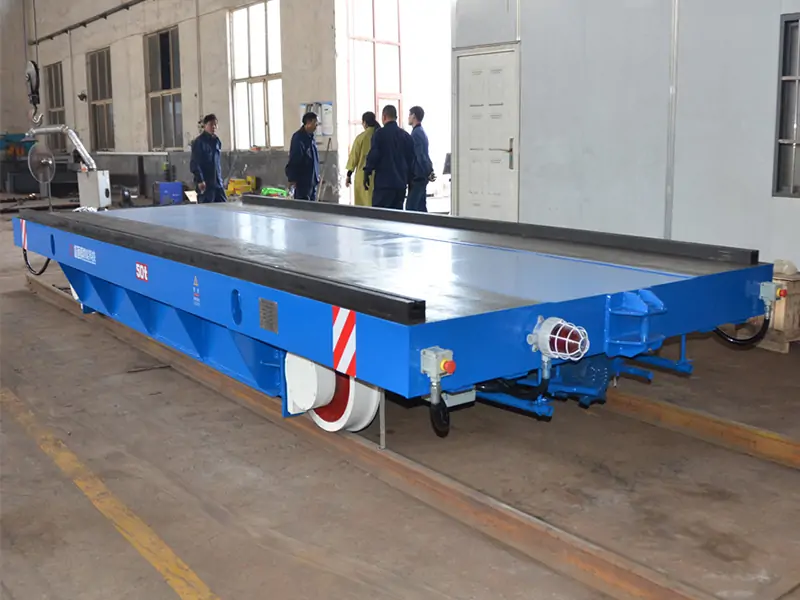

- Vehicle dimensions (mm): 5000 × 2600 × 500

- Load capacity (t): 20 t when loaded, 40 t when towing

- Vitesse de fonctionnement (m/min) : 0–20 m/min stepless speed adjustment

- Custom workpiece: Cantilever crane

- Cantilever crane load capacity (t): 2 T

- Braking method: Electromagnetic braking

- Personnalisation : Possibilité de production sur mesure, y compris des composants supplémentaires, etc.

Working Principle of Rail Mounted Transfer Trolley

40T rail-mounted transfer trolley with cantilever crane is a dual-purpose rail-mounted electric transfer cart.

Drive System: Powered by lead-acid batteries with high-capacity storage, offering greater convenience, safety, and environmental friendliness.

Charger Function: Fully automatic intelligent charging.

Operational Capabilities:

- Capable of direct goods transport with a 20-tonne capacity, or customisable load-bearing capacity to suit your operational requirements.

- Capable of towing rail-mounted trailers with a towing capacity of 40 tonnes, customisable to your operational requirements.

- The cantilever crane rotates 360 degrees and can hoist 2 tonnes of cargo, with its load capacity customisable to your specifications.

Control Methods: Customisable remote control with unlimited range and fully automatic operation, or wired control.

Sur mesure

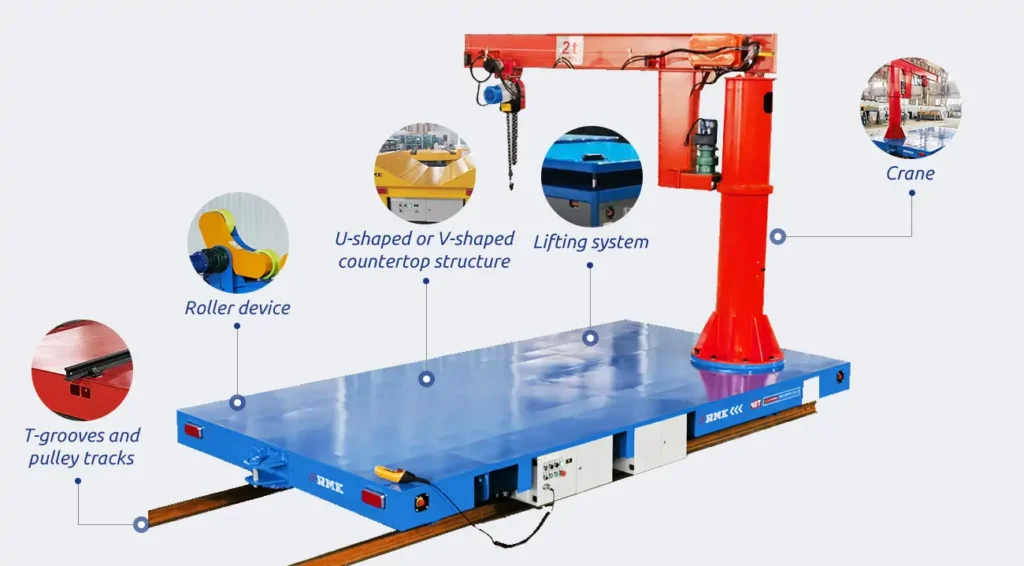

Remarkable is a professional Electric Transfer Carts manufacturer. Tools, components, and accessories for these carts can all be custom-produced, providing tailored solutions suited to your specific operational requirements:

Equipped with a compact crane: cantilever crane, lifting capacity 2 tonnes (customisable), with 360-degree rotation capability;

Lifting system: entire worktop elevation adjustable between 100-500mm;

U-shaped or V-shaped countertop structure: customisable U- or V-shaped workpiece platforms for stabilising steel coils and other mobile heavy loads;

Roller device: Protects transported items from surface damage.

Grooves and pulley tracks: Custom-manufactured production tracks and pulleys tailored to the production environment;

Operating system: Customisable wireless remote control and fully automated operation, manual clutch, and convenient maintenance.

Safety system: Customisable auxiliary systems including safety alarms and safety pre-set functions.

Further customisation: Based on your operational conditions, our engineers will design and evaluate solutions to custom-manufacture products meeting your specific requirements.

For more information on the work of a rail-mounted transfer cart, please refer to the article: Comment fonctionnent les chariots de transfert sur rails ?

Vidéos Show

40 Tons Rail-Mounted Transfer Trolley

Spécifications

| Technical Parameters Table Of KPX Battery Transfer Cart | |||||||||||||

| Rated Load Capacity (t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 150 | 200 | |

| Taille du tableau (mm) | Longueur | 2000 | 2400 | 3000 | 3000 | 4000 | 4500 | 5000 | 5000 | 6000 | 6000 | 7000 | 8000 |

| Largeur | 1300 | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2500 | 2500 | 3000 | 3000 | |

| Hauteur | 450 | 500 | 550 | 550 | 600 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | |

| Garde au sol (mm) | ≥50 | ||||||||||||

| Empattement (mm) | 1300 | 1600 | 2000 | 2000 | 2700 | 3000 | 3300 | 3300 | 4000 | 4000 | 4800 | 5500 | |

| Rail Inner Distance (mm) | 900 | 1100 | 1435 | 1435 | 1435 | 1435 | 1650 | 1650 | 1650 | 1650 | 2000 | 2000 | |

| Méthode de fonctionnement | Remote Control & Hand Operated Pendant | ||||||||||||

| Bougez ! | Forward/backwards, Turning (Customized), Vertical-Horizontal Crisscross Movement (Customized) | ||||||||||||

| Running Speed (m/min) | 25 | 20 | |||||||||||

| Type de moteur | Moteur à courant alternatif (CA) à basse tension / moteur à courant continu sans balais (CC) | ||||||||||||

| Mode de freinage | Frein électromagnétique | ||||||||||||

| Mesures de protection | Audible and visual alarm lamp+ Emergency stop button+Limit switch+Laser obstacle avoidance sensor(Optional)+Anti-collision contact edge(Optional) | ||||||||||||

| Quantité de roues | 4 | 8 | |||||||||||

| Matériau de la roue | ZG55 | ||||||||||||

| Drive Wheel Diameter (mm) | Ф300 | Ф300 | Ф350 | Ф350 | Ф400 | Ф400 | Ф500 | Ф500 | Ф600 | Ф600 Heavy Duty Wheel | Ф700 Heavy Duty Wheel | Ф600 Heavy Duty Wheel | |

| Recommended Rail Type | P15 | P18 | P24 | P24 | P38 | P38 | P43 | P43 | QU70 | QU70 | QU100 | QU100 | |

| Battery Capacity (kW·h) | 4.8 | 7.2 | 8.6 | 8.6 | 10.5 | 14.4 | 15.8 | 18.7 | 21.6 | 28.8 | 36 | 57.6 | |

| Type de batterie | Batterie plomb-acide | ||||||||||||

| Autonomie de la batterie | 5h Customized As Needed | ||||||||||||

| Temps de charge de la batterie | ≤7h | ||||||||||||

| Chargeur de batterie | AC220V/AC380V | ||||||||||||

| Environnement de travail | Température : -10°c~40°c ; Humidité : 20%~80%, sans condensation (sur mesure pour les environnements à haute température et antidéflagrants). | ||||||||||||

| Couleur de la carrosserie du véhicule | Sur mesure | ||||||||||||

| Autres fonctions | Battery Power Display, Over Voltage, Under Voltage, Over Current Protection, etc | ||||||||||||

| Versione Automatica – RGV | Combined With An Automatic Positioning System, Signal Reception System, And Programmable System, the RGV realizes Automated Handling Functions. Customizable Rgv Carts, Such As Mother-Child Carts (Ferry Carts), Vertical-Horizontal Moving Carts, And Curved Track Carts, Can Be Provided. | ||||||||||||

| Notes : 1) Other gauges, table sizes, and load tonnages can be customized according to user requirements. 2) This model of rail trolleys can be customized with special vehicles such as mother-child cars, curved track carts, vertical-horizontal moving carts, etc., to meet specific usage needs. 3) This model of rail trolleys can receive instructions from call boxes and host computers to achieve automated handling. 4) Battery type and operating time (battery endurance) can be customized to meet customer needs. 5) The product is subject to continuous improvement and upgrades; specifications in the table may change without prior notice. | |||||||||||||

Caractéristiques

Safety and Flexibility

Multiple safety systems with flexible customization for complex environments.

Easy Maintenance

Modular components allow quick inspection, repair, and reduced downtime.

Long Service Life

Durable materials and advanced technology ensure reliable long-term use.

Anti-high Temperature

Resistant to heat, suitable for harsh working conditions.

Explosion-proof

Enhanced protection for hazardous or flammable environments.

Intelligent & Robotization

Supports automation, wireless remote control, and intelligent upgrades.

Application

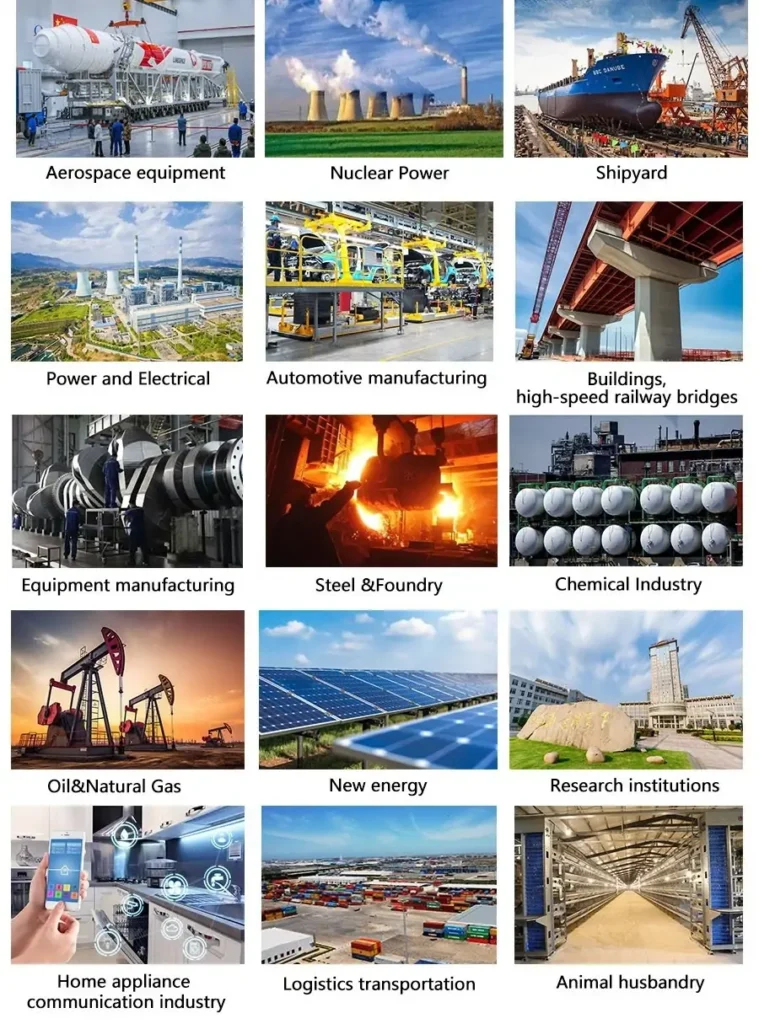

Le 40 Tons Rail rail-mounted transfer Trolley with Cantilever Crane is widely used in industries that require safe, efficient, and multifunctional material handling.

Industrie aérospatiale: Ideal for transporting, lifting, and positioning large aerospace components, providing an integrated heavy load handling solution.

Métallurgie et sidérurgie: The U-shaped or V-shaped platform and roller device ensures safe transfer of steel coils, heavy rolls, and raw materials.

Manufacturing Plants: Works as a dual-purpose rail transfer cart for direct transportation and trailer towing up to 40 tons, with a cantilever crane for efficient loading and unloading.

Secteur de l'électricité et de l'énergie: With anti-high-temperature and explosion-proof design, this electric transfer trolley is suitable for handling transformers, turbines, and large machinery.

Automated Workshops: Supports wireless remote control and intelligent automation, improving logistics efficiency and reducing manual labor.

Industrie des nouvelles énergies: Used for safe handling of battery modules, wind turbine blades, and photovoltaic components with stable heavy load performance.

Industrie de la construction navale: Efficient for moving ship sections, steel plates, and large marine equipment, enhancing shipyard assembly productivity.

Petroleum and Chemical Industry: Explosion-proof design ensures safety during the transfer and lifting of heavy equipment in oil fields and chemical plants.

Logistics and Warehousing: Applied in warehouses, ports, and large logistics parks for bulk cargo rail transfer, sorting, and automated distribution.

Cas Montrer

Rail-Mounted Transfer Trolley Manufacturer

As a leading manufacturer of rail-mounted transfer trolleys, we specialize in designing and building custom-engineered transfer solutions for handling heavy oil and gas tanks, as well as other oversized equipment. With over 10 years of expertise in omnidirectional steering technology, we provide reliable and precision-driven transfer trolleys that ensure safe, efficient, and flexible movement in workshops with limited space and complex layouts.

Pourquoi nous choisir ?

- Expertise sectorielle - Nous proposons aux secteurs de la production d'énergie, de la construction navale, de la construction et de l'aérospatiale des solutions sur mesure pour les transformateurs, les composants d'éoliennes, les modules préfabriqués, etc.

- Fully Customization - De la capacité de charge (1-500+ tonnes) aux systèmes d'entraînement (électrique, hybride ou diesel), nous répondons à vos besoins exacts.

- Systèmes de contrôle avancés - Les options comprennent la commande manuelle à distance, la planification semi-automatique du trajet ou la navigation entièrement automatisée (intégration d'un AGV).

- Qualité et durabilité - Cadres en acier robustes, modules de direction à couple élevé, certifiés CE et ISO.

- Soutien complet au projet - De la consultation initiale au service après-vente, nos ingénieurs fournissent une assistance technique à vie.

Articles connexes

Produits apparentés

Solutions personnalisées de manutention intelligente

Pour qu'un chariot de transfert personnalisé corresponde parfaitement à vos besoins, veuillez fournir les informations suivantes :

- Capacité de charge : _____ tonnes (1~500 tonnes)

- Taille du tableau : _____ × _____ mm/m (par exemple, 1500×3000)

- Options d'alimentation :

- ☐ Plomb-acide ☐ Lithium-ion ☐ Autre : _____

- ☐ Câble : _____V/_____A

- ☐ Standard 380V/50Hz/3-phases

- Détails de la cargaison :

- Type : _____ (par exemple, bobines d'acier, machines)

- Besoins particuliers : _____ (par exemple, antidérapant, résistant à la corrosion)

- Caractéristiques optionnelles :

- ☐ Arrêt d'urgence ☐ Capteurs anti-collision

- ☐ Guides de rail ☐ Mécanisme de levage ☐ Télécommande