Esta carretilla de transferencia de materiales pesados es un tipo de equipo de manipulación sin rieles diseñado para condiciones de trabajo industriales pesadas, utilizado principalmente para el transporte de corta distancia de materiales pesados en talleres, almacenes y otros lugares fijos. Utiliza baterías de plomo-ácido o baterías de litio como fuente de energía y adopta tecnología de accionamiento de velocidad de motor DC, tecnología de dirección hidráulica de múltiples ruedas y modos de operación dual de control por cable y control remoto.

- Capacidad de carga: 1~500 toneladas

- Tamaño de la mesa: personalizable

- Velocidad de funcionamiento: 0~25m/min

- Modo de control: pulsador/mando a distancia

Principio de funcionamiento

Las carretillas de transferencia de materiales para cargas pesadas utilizan un motor eléctrico (normalmente un motor de frecuencia variable CA o CC) para accionar la caja de engranajes y transmitir potencia al juego de ruedas de desplazamiento. El operador envía instrucciones a través del armario de control o del mando a distancia inalámbrico, y el sistema de control PLC ajusta la velocidad y la dirección del motor para lograr el avance/retroceso, la aceleración/desaceleración y otras acciones.

Los carros de transferencia de materiales de alta resistencia tienen las funciones de conducción de arranque, parada, avance, retroceso, giro, etc. Sin necesidad de trazar una ruta predeterminada, pueden caminar libremente de interior a exterior, rotar y girar en 360 grados, con un radio de giro pequeño, girar mientras caminan y desplazarse a cualquier zona mediante control remoto inalámbrico. La capacidad de carga suele ser de 10-200 toneladas, y se utilizan ampliamente en la fabricación pesada, el acero, la construcción naval y otras industrias.

Carros de transferencia de materias primas de alta resistencia de 40 toneladas

Carros de manipulación de materiales omnidireccionales

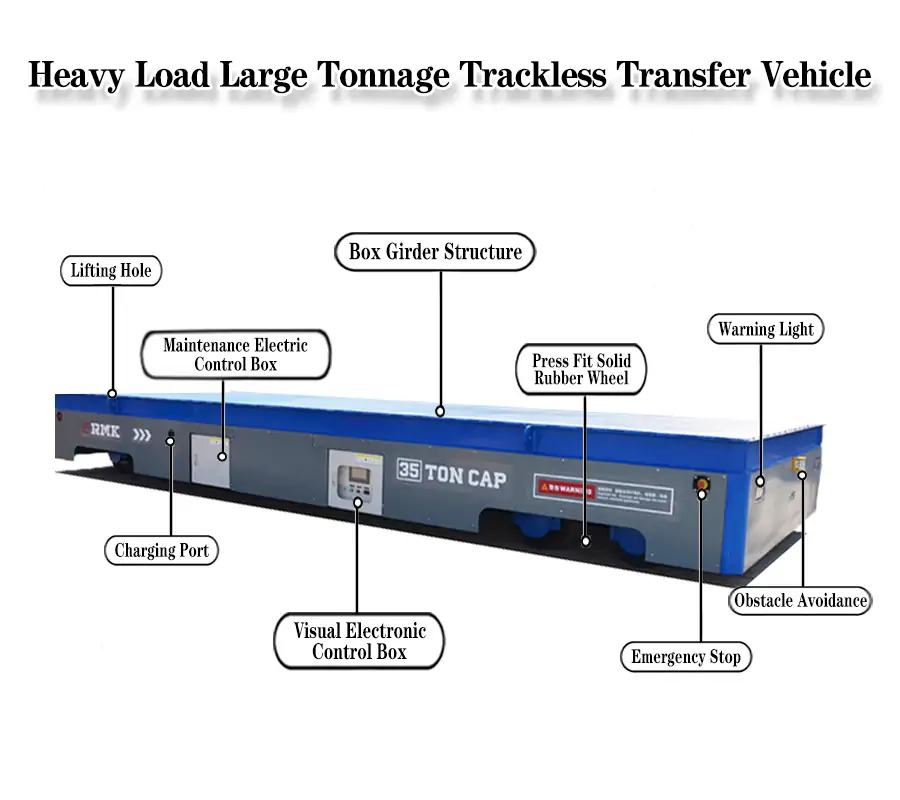

Piezas

El camión de transferencia de material de alta resistencia adopta un diseño de estructura de acero modular, que se compone principalmente de los siguientes componentes:

- Marco principal: Soldadas a partir de vigas cajón de acero de baja aleación Q345B, equipadas con placas de refuerzo, con eliminación de óxido mediante chorro de arena y tratamiento anticorrosión de doble capa en la superficie.

- Sistema de tracción: contiene un motor de conversión de frecuencia con protección IP55, un reductor de engranajes endurecido y un juego de ruedas motrices de aleación de acero endurecido, que soportan el funcionamiento con sobrecarga de corta duración 50%.

- Sistema ferroviario: adopta carril de acero de alta dureza (QU80-120) con conexión de placa de cola de pez, y la precisión de las juntas se controla dentro de 2 mm.

- Sistema de control eléctrico: el sistema de control eléctrico se centra en un PLC Siemens y un convertidor de frecuencia ABB, equipado con una interfaz HMI de 7 pulgadas y múltiples funciones de protección de seguridad, con un tiempo de respuesta de frenado de emergencia inferior a 0,5 segundos.

- Sistema de alimentación: Ofrece tres soluciones de alimentación eléctrica: carril de baja tensión, enrollador de cable y paquete de baterías de litio, y puede equiparse con una plataforma de elevación hidráulica (precisión de ±1 mm), un mecanismo de centrado automático y un radar anticolisión y otros dispositivos auxiliares inteligentes.

Las condiciones especiales de trabajo se pueden personalizar para el tipo de aislamiento de alta temperatura, Ex d Ⅱ BT4 a prueba de explosiones, o productos de acero inoxidable 304 variante resistente a la corrosión.

Si desea conocer los componentes comunes de un carro de transferencia de materiales, consulte el siguiente artículo: ¿Cuáles son las piezas comunes de las vagonetas de transferencia de materiales?

Especificaciones

| Capacidad | 2 Toneladas | 5 toneladas | 10 toneladas | 16 toneladas | 20 toneladas | 30 toneladas | 40 toneladas | 50 toneladas | |

| Tamaño de la mesa (mm) | Longitud | 2000 | 3500 | 3600 | 4000 | 4000 | 4500 | 5000 | 5500 |

| Anchura | 1500 | 2000 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | |

| Altura | 450 | 450 | 500 | 500 | 550 | 600 | 650 | 650 | |

| Distancia entre ejes (mm) | 1200 | 2500 | 2600 | 2800 | 2800 | 3200 | 3800 | 4200 | |

| Calibre interior del raíl (mm) | 1200 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | |

| Diámetro de la rueda (mm) | Φ270 | Φ300 | Φ300 | Φ350 | Φ350 | Φ400 | Φ500 | Φ500 | |

| Cantidad de ruedas | 4 | ||||||||

| Distancia al suelo (mm) | 50 | ||||||||

| Velocidad de marcha (m/min) | 0-25 | ||||||||

| Potencia del motor (kw) | 1 | 1.2 | 1.6 | 2 | 2.2 | 3.5 | 4 | 5 | |

| Potencia del transformador (KVA) | 3 | 5 | 5 | 6.8 | 6.8 | 10 | 10 | 10 | |

| Carga máxima por rueda (KN) | 14.4 | 25.8 | 42.6 | 64.5 | 77.7 | 110.4 | 142.8 | 174 | |

| Peso de referencia(t) | 2.8 | 3.6 | 4.2 | 5.5 | 5.9 | 6.8 | 7.6 | 8 | |

| Modelo de raíl recomendado | P15 | P18 | P18 | P24 | P24 | P38 | P43 | P43 | |

Características

Diseño de gran capacidad de carga

Con un bastidor de viga cajón y un eje de aleación de acero, la capacidad de carga de una sola unidad es de hasta 500 toneladas.

Configuración multidrive

Los modos de tracción simple, doble o total pueden seleccionarse en función de la demanda de carga.

Posicionamiento preciso

Codificador opcional o sistema de posicionamiento láser, precisión de parada ±5 mm.

Protección de seguridad

Freno mecánico de serie + freno eléctrico de doble seguro, corte automático por sobrecarga.

Programa de alimentación multimodo

Carril de baja tensión opcional (36V/48V), carrete de cable (100m) o paquete de baterías de litio (48V/200Ah), para adaptarse a diferentes condiciones de trabajo.

Adaptación a entornos especiales

Proporcionar el tipo de aislamiento de alta temperatura, el aislamiento, el tipo a prueba de explosiones (certificación Ex dⅡBT4) y el tipo resistente a la corrosión de acero inoxidable 304 y otras soluciones personalizadas.

Aplicaciones

Las carretillas de transferencia de materiales de gran tonelaje se utilizan principalmente en las siguientes soluciones de manipulación de materiales:

- Industria siderúrgica: Se utiliza en fundiciones para la transferencia en caliente de palanquillas de colada continua y bobinas de acero.

- Maquinaria pesada: para la transferencia de montaje de vigas de prensa, palas de aerogeneradores.

- Construcción naval: para el montaje y transporte de cascos segmentados.

- Equipo eléctrico: para el transporte en planta de transformadores y estatores de generadores.

- Condiciones especiales de trabajo: para un diseño a prueba de explosiones puede utilizarse en zonas petroquímicas, militares y otras zonas peligrosas.

Artículos relacionados

Productos relacionados

Soluciones inteligentes de manipulación de materiales personalizadas

Para garantizar que un carro de traslado personalizado se adapte perfectamente a sus necesidades, facilítenos los siguientes datos:

- Capacidad de carga: _____ toneladas (1~500 toneladas)

- Tamaño de la mesa: _____ × _____ mm/m (por ejemplo, 1500×3000)

- Opciones de alimentación:

- ☐ Plomo-ácido ☐ Ión-litio ☐ Otros: _____

- ☐ Cable: _____V/_____A

- Estándar 380 V/50 Hz/3 fases

- Detalles de la carga:

- Tipo: _____ (por ejemplo, bobinas de acero, maquinaria)

- Necesidades especiales: _____ (por ejemplo, antideslizante, resistente a la corrosión)

- Características opcionales:

- ☐ Parada de emergencia ☐ Sensores anticolisión

- ☐ Guías de carril ☐ Mecanismo de elevación ☐ Mando a distancia