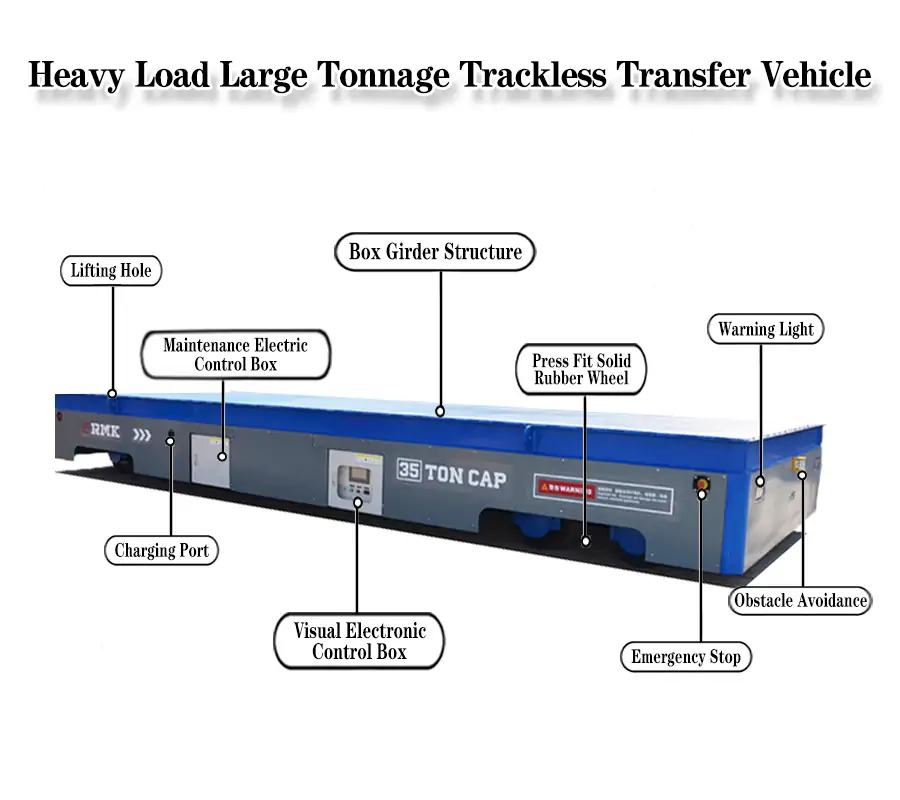

This Heavy Duty Material Transfer Carts are a kind of trackless handling equipment designed for industrial heavy-duty working conditions, mainly used for short-distance transportation of heavy materials in workshops, warehouses and other fixed places. It uses lead-acid batteries or lithium batteries as energy source and adopts DC motor speed drive technology, multi-wheel hydraulic steering technology and dual operation modes of wire control and remote control.

- Tragfähigkeit: 1~500 ton

- Größe des Tisches: customizable

- Operating speed: 0~25m/min

- Kontrollmodus: push button/remote control

Arbeitsprinzip

Heavy Duty Material Transfer Carts use an electric motor (usually an AC variable frequency or DC motor) to drive the gearbox and transmit power to the travel wheel set. The operator sends instructions through the control cabinet or wireless remote control, and the PLC control system adjusts the motor speed and direction to achieve forward/reverse, acceleration/deceleration, and other actions.

Heavy Duty Material Transfer Carts have the driving functions of starting, stopping, forward, backward, turning, etc. Without laying a predetermined track route, they can walk freely from indoor to outdoor, rotate and turn in 360 degrees, with a small turning radius, turn while walking, and travel to any area by wireless remote control. The load capacity is usually 10-200 tons, widely used in heavy manufacturing, steel, shipbuilding, and other industries.

40 Tons Heavy Duty Raw Material Transfer Carts

Omni-directional Material Handling Carts

Teile

Heavy-duty material transfer truck adopts a modular steel structure design, which is mainly composed of the following components:

- Main frame: welded from Q345B low alloy steel box beams, equipped with reinforcing plates, with sandblasted rust removal and double-layer anticorrosion treatment on the surface.

- Drive system: contains an IP55 protection frequency conversion motor, a hardened gear reducer, and a hardened alloy steel drive wheelset, supporting 50% short-time overload operation.

- Rail system: adopts high-hardness steel rail (QU80-120) with fishtail plate connection, and the precision of joints is controlled within 2mm.

- Electrical control system: the electrical control system is centered on a Siemens PLC and an ABB frequency converter, equipped with a 7-inch HMI interface and multiple safety protection functions, with emergency braking response time less than 0.5 seconds.

- Power supply system: it provides three power supply solutions: low-voltage rail, cable reel, and lithium battery pack, and can be equipped with a hydraulic lifting platform (accuracy ±1mm), automatic centering mechanism, and anti-collision radar and other intelligent auxiliary devices.

Special working conditions can be customized for high-temperature insulation type, Ex d Ⅱ BT4 explosion-proof, or 304 stainless steel corrosion-resistant variant products.

If you would like to learn about the common components of a material transfer cart, please refer to the following article: Was sind die gängigen Teile für Materialtransportwagen?

Spezifikationen

| Kapazität | 2 Ton | 5 Ton | 10 Ton | 16 Ton | 20 Ton | 30 Ton | 40 Ton | 50 Ton | |

| Tischgröße (mm) | Länge | 2000 | 3500 | 3600 | 4000 | 4000 | 4500 | 5000 | 5500 |

| Breite | 1500 | 2000 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | |

| Höhe | 450 | 450 | 500 | 500 | 550 | 600 | 650 | 650 | |

| Radstand(mm) | 1200 | 2500 | 2600 | 2800 | 2800 | 3200 | 3800 | 4200 | |

| Schiene Innenspur(mm) | 1200 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | |

| Raddurchmesser(mm) | Φ270 | Φ300 | Φ300 | Φ350 | Φ350 | Φ400 | Φ500 | Φ500 | |

| Rad Anzahl | 4 | ||||||||

| Bodenfreiheit(mm) | 50 | ||||||||

| Laufgeschwindigkeit (m/min) | 0-25 | ||||||||

| Motorleistung (kw) | 1 | 1.2 | 1.6 | 2 | 2.2 | 3.5 | 4 | 5 | |

| Transformatorleistung (KVA) | 3 | 5 | 5 | 6.8 | 6.8 | 10 | 10 | 10 | |

| Maximale Radlast (KN) | 14.4 | 25.8 | 42.6 | 64.5 | 77.7 | 110.4 | 142.8 | 174 | |

| Referenzgewicht(t) | 2.8 | 3.6 | 4.2 | 5.5 | 5.9 | 6.8 | 7.6 | 8 | |

| Empfohlenes Schienenmodell | P15 | P18 | P18 | P24 | P24 | P38 | P43 | P43 | |

Eigenschaften

High-carrying design

Adopting box-beam frame and alloy steel axle, the single-unit carrying capacity is up to 500 tons.

Multi-drive configuration

Single-drive, double-drive or all-wheel-drive modes can be selected according to the load demand.

Präzise Positionierung

Optional encoder or laser positioning system, stopping accuracy ±5mm.

Safety protection

Standard mechanical brake + electrical brake double insurance, overload automatic power cut off.

Multi-mode power supply program

Optional low-voltage rail (36V/48V), cable reel (100m) or lithium battery pack (48V/200Ah), to adapt to different working conditions.

Special environment adaptation

Provide high temperature insulation type, insulation, explosion-proof type (Ex dⅡBT4 certification) and 304 stainless steel corrosion-resistant type and other customized solutions.

Anwendungen

Heavy-duty material transfer trucks are mainly used in the following material handling solutions:

- Iron and steel industry: Used in foundries for hot state transfer of continuous casting billets and steel coils.

- Heavy machinery: for assembly transfer of press beams, wind turbine blades.

- Shipbuilding: for assembly and transportation of segmented hulls.

- Power equipment: for in-plant transportation of transformers and generator stators.

- Special working conditions: for explosion-proof design can be used in petrochemical, military, and other hazardous areas.

Verwandte Artikel

Verwandte Produkte

Maßgeschneiderte intelligente Materialtransportlösungen

Um sicherzustellen, dass ein maßgeschneiderter Transferwagen perfekt auf Ihre Bedürfnisse zugeschnitten ist, geben Sie bitte die folgenden Details an:

- Tragfähigkeit: _____ t (1~500 t)

- Tischgröße: _____ × _____ mm/m (z. B. 1500×3000)

- Strom-Optionen:

- ☐ Blei-Säure ☐ Lithium-Ionen ☐ Andere: _____

- ☐ Kabel: _____V/_____A

- ☐ Standard 380V/50Hz/3-Phasen

- Angaben zur Ladung:

- Art: _____ (z. B. Stahlspulen, Maschinen)

- Besondere Anforderungen: _____ (z. B. rutschfest, korrosionsbeständig)

- Optionale Merkmale:

- ☐ Not-Aus ☐ Antikollisionssensoren

- ☐ Schienenführungen ☐ Hebemechanismus ☐ Fernsteuerung