The Multifunctional Omnimove Transfer Cart is a transfer cart specifically designed and manufactured for aircraft maintenance operations.. Featuring 360° maneuverability, trackless operation, and multiple movement modes including longitudinal, lateral, diagonal, and rotational steering, it enables precise navigation within confined hangar spaces. This integrated system combines hydraulic lifting, platform sliding, and tilting functions to facilitate the handling of aircraft components and ensure personnel safety during operations. Equipped with an intelligent display, safety interlock devices, and protective systems, it ensures reliable handling of precision aerospace components.

REMARKABLE offers customization services covering load capacity, platform design, control modes, and functional modules to meet diverse operational requirements.

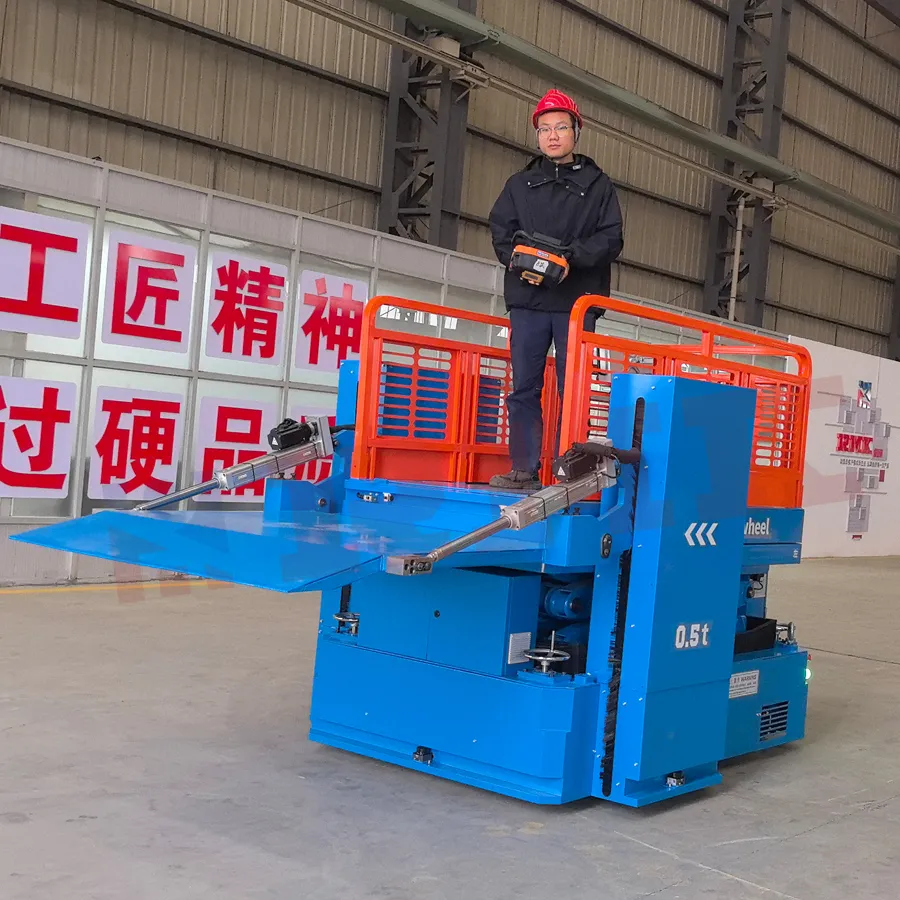

- Modell: RWP

- Tragfähigkeit: 0.5 Tons

- Abmessungen: 2100×1400 × 1200 mm

- Hebehub: Hydraulic lifting, 1400 mm

- Stromversorgung: Wartungsfreie Batterie (elektrischer Antrieb)

- Geschwindigkeit: 0-20 m/min (stufenlose Geschwindigkeitsregelung)

- Custom: Sonderanfertigung möglich, einschließlich zusätzlicher Komponenten usw.

Working Principle of the Multifunctional Omnimove Transfer Cart

The following explanation of the operating principles of the multifunctional omnimove transfer cart facilitates rapid comprehension of the core motion sequences and control logic for engineering and maintenance personnel.

Arbeitsprinzip:

- Power-up

- Switch on the main power supply. The system draws power from the battery (48V/130Ah) to supply the vehicle controller, drive units, and hydraulic pump.

- Electronic control self-test: Display self-check, sensor and communication link verification, fault code clearance, and readiness confirmation.

- Inspection items: Battery charge display, braking system, laser obstacle avoidance/safety edge, outrigger sensors, and emergency stop button functionality check.

- Mode Selection

- The operator selects the operating mode (movement/lifting/translation/tilting/outrigger deployment) via wireless remote control or wired joystick.

- The controller issues commands to the functional modules based on the selected mode and activates the corresponding safety paths.

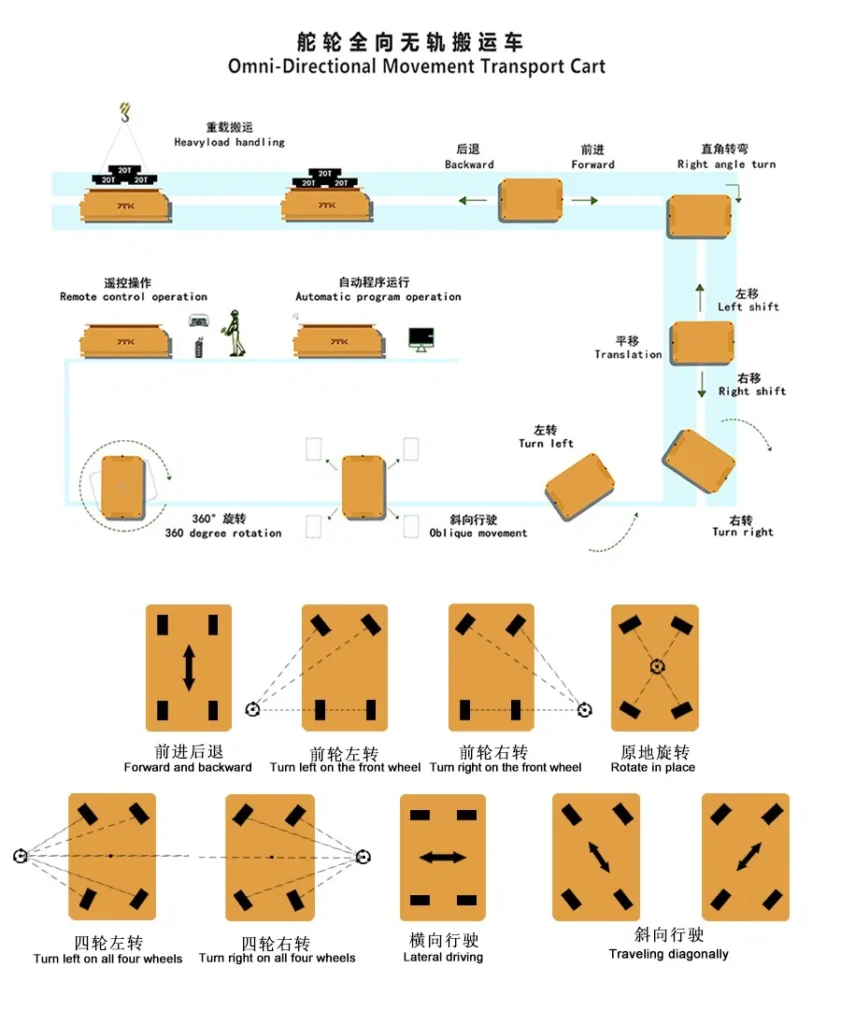

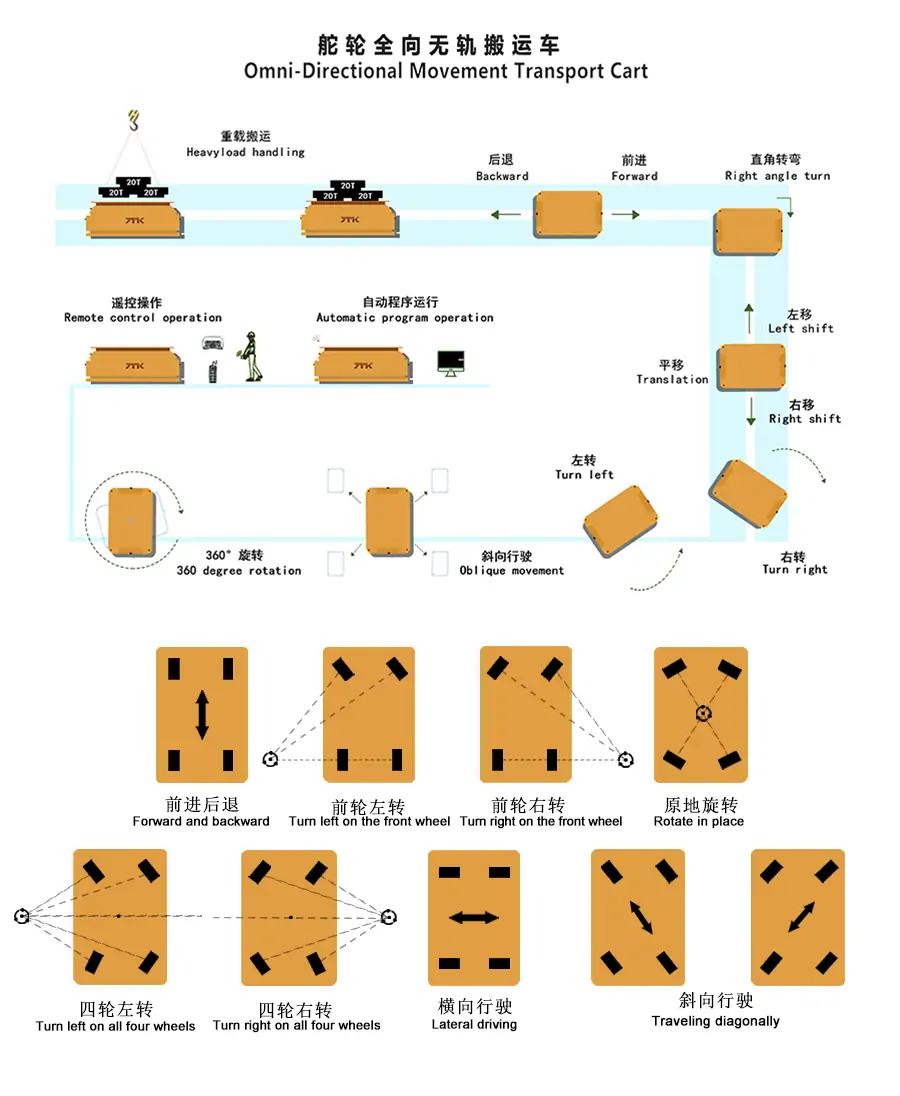

- Drive and Omnidirectional Mobility

- Dual drive motors (2 kW ×2) provide traction; four steering motors (0.75 kW ×4) independently control the steering angle of each of the four steering wheels.

- Control algorithms calculate each wheel’s speed and steering angle in real time, enabling: forward/reverse, lateral movement (sideways), diagonal movement, on-the-spot rotation, and diagonal traversing for omnidirectional motion.

- Encoders and speed sensors at the wheel ends feed back to the drives, forming a closed-loop speed/position control system that ensures positioning accuracy and motion smoothness.

- Positioning

- The operator or automated assistance system monitors position via on-board displays (platform surface and remote control).

- Laser obstacle avoidance and distance sensors operate during low-speed precision positioning, triggering deceleration and enabling precise approach to the docking point at a set step distance.

- Soft-cushion support and buffering mechanisms absorb micro-impacts upon contact, preventing damage to sensitive composite components.

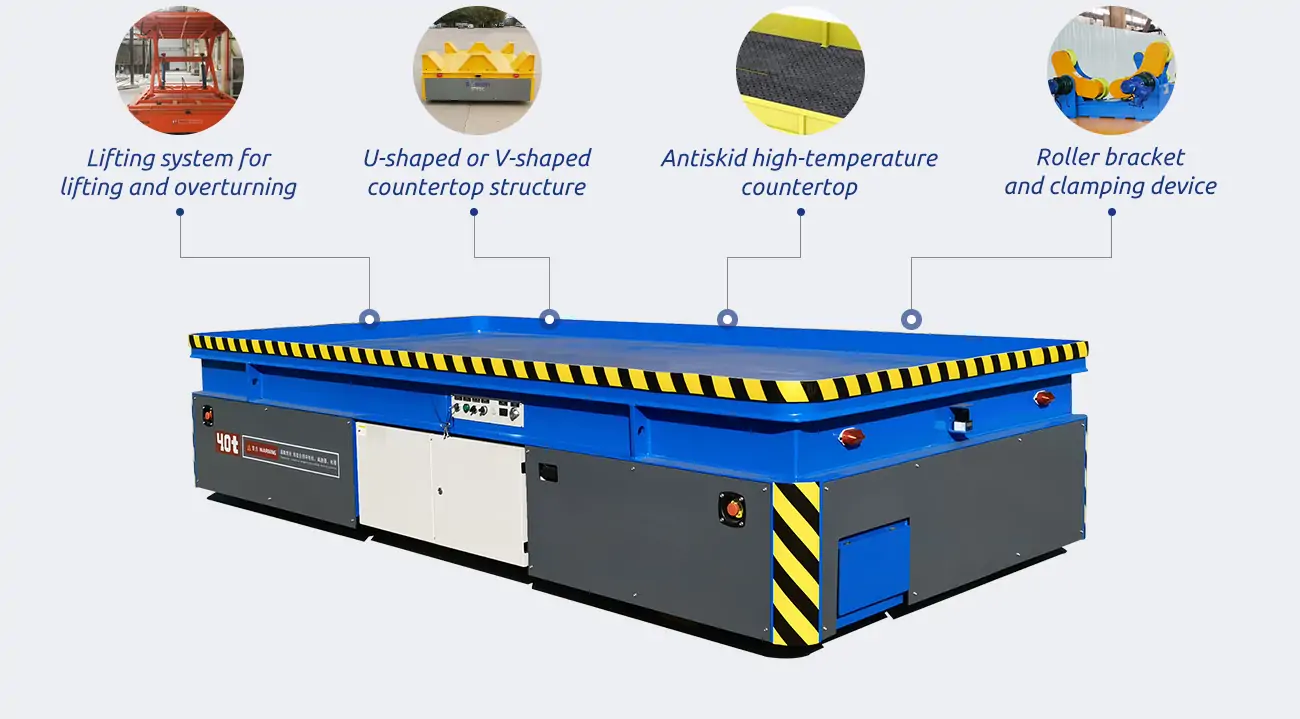

- Hydraulic Platform Elevation and Translation (Upper Platform)

- Activate the hydraulic pump to drive cylinders or scissor mechanisms for platform elevation (upper platform translation stroke approx. 400 mm; elevation stroke ≥1400 mm, with customisable longer strokes available).

- Lifting employs flow/pressure closed-loop control, with the controller precisely limiting lifting speed via valves (e.g., 3–4 m/min) while continuously monitoring load and displacement sensors.

- Platform traversal and tilting are controlled by dedicated motors/actuators, achieving up to 70° tilt angles with position locking before and after operations.

- Small Platform Operation

- The small platform employs an independent hydraulic/electric drive, supporting ≥1100 mm vertical travel and 70° tilt for local assembly and workstation adjustments.

- During small platform operation, the system temporarily locks the vehicle’s movement and unrelated modules (interlock mechanism) to prevent concurrent actions from causing hazards.

- Outrigger/Stabiliser Deployment and Stability Control

- Before elevated or loaded operations, the control system deploys all four hydraulic outriggers to ground contact, with load feedback from outrigger sensors.

- Upon meeting load-bearing requirements, the vehicle disengages wheel-end drive (or switches to parking mode) to prevent overturning and enhance operational stability.

- Personnel and Cargo Safety

- Hardware and software interlocks operate between all modules: vehicle movement or platform tilting is prohibited if lifting is incomplete or outriggers are not deployed.

- Laser obstacle avoidance, edge contact protection, and audible/visual alarms immediately trigger emergency stop logic upon detecting imminent hazards.

- Operator displays and remote controllers simultaneously show status and warnings, facilitating coordinated decision-making between near and remote operators.

- Electromagnetic Braking

- During normal operation, the drive unit regulates braking force for smooth stopping. Upon power failure or emergency stop, electromagnetic brakes forcibly engage to ensure static safety.

- During lateral movement or under load, braking control integrates with torque monitoring algorithms to prevent slippage or positional drift.

- Charging

- A separate charger provides fully automated intelligent charging, with the system managing charging profiles and safeguarding against overvoltage, undervoltage, and overcurrent.

- The Battery Management System (BMS) monitors battery health and available capacity, issuing alerts or restricting non-essential functions during low charge states.

- Shutdown and Maintenance

- During shutdown, first retract the platform to transport position, retract outriggers, disconnect peripherals, then transition to standby/off mode.

- Regular maintenance points include: hydraulic oil replacement, tyre (polyurethane-coated) inspection, encoder/sensor calibration, battery health assessment, and brake system inspection.

Omni-Directional Movement Transport Cart

Multifunktionaler Omnimove-Transferwagen

Technical Specifications Overview

Discover the specifications of the multi-functional omnidirectional aircraft transfer trolley. Featuring 360° mobility, hydraulic lifting, platform sliding, and tilting capabilities, this transfer trolley enables safe and precise operations. Equipped with customisable features, it facilitates efficient aircraft inspection, maintenance, and MRO (Maintenance, Repair, and Overhaul) tasks.

| Parameter | Specification |

|---|---|

| Tragfähigkeit | 0.5T |

| Dimensions (L × W, mm) | 2100 × 1400 |

| Table Height (mm) | 1200 |

| Bodenfreiheit (mm) | 60 |

| Floor Requirement | Concrete |

| Power Supply | Maintenance-free Battery |

| Batteriekapazität | 48V 130Ah |

| Operation Mode | Wireless Remote + Wired Handle |

| Drive Motor Power | 2 kW × 2 |

| Steering Motor Power | 0.75 kW × 4 |

| Raddurchmesser (mm) | 250 |

| Number of Wheels | 4 |

| Travel Speed (m/min) | 0–25 |

| Braking Type | Elektromagnetische Bremse |

| Material der Räder | Polyurethane Coated |

| Turning Mode | Steering Wheel |

| Movement Mode | Forward/Backward, Turn While Moving, Diagonal, Lateral |

| Charger Installation | Separate Type |

| Charger Function | Fully Automatic Intelligent Charging |

| Charging Time (h) | ≤8 |

| Upper Platform Lift Stroke (mm) | ≥1400 |

| Lift Speed (m/min) | 4 |

| Lift Power | 3 kW |

| Upper Platform Travel Stroke (mm) | 400 |

| Upper Platform Travel Power | 0.75 kW |

| Small Platform Lift Stroke (mm) | ≥1100 |

| Lift Speed (m/min) | 3 |

| Lift Power | 0.75 kW × 2 |

| Small Platform Tilt Angle | 70° |

| Small Platform Tilt Power | 0.75 kW × 2 |

| Safety Measures | Audible & Visual Alarm, Emergency Stop, Laser Obstacle Avoidance, Safety Edges |

| Andere Funktionen | Battery Level Display, Overvoltage, Undervoltage, Overcurrent, Outrigger Protection |

Videos anzeigen

Custom Parts for Omnidirectional Transfer Cart

Custom Series Parameters for Omnidirectional Transfer Cart

| Tabelle der technischen Parameter des spurlosen Elektro-Transferwagens RWP | |||||||||||

| Nennbelastbarkeit(t) | 5 | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | |

| Tischgröße (mm) | Länge | 2400 | 2700 | 2700 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 6000 |

| Breite | 1500 | 1800 | 1800 | 2000 | 2200 | 2000 | 2200 | 2500 | 3000 | 3000 | |

| Höhe | 470 | 550 | 600 | 700 | 700 | 800 | 900 | 1000 | 1000 | 1000 | |

| Bodenfreiheit(mm) | ≥50 | ≥100 | |||||||||

| Wenderadius(mm) | 2200 | 2500 | 2500 | 2800 | 3300 | 6000 | 6800 | 7500 | 9000 | 9000 | |

| Modus Lenkung | Differentiallenkung | Hydraulische Lenkung | |||||||||

| Operation Methode | Fernbedienung & Handbedientes Pendel | ||||||||||

| Weg bewegen | Vorwärts, rückwärts, Drehen während der Fahrt ohne Stopp und eine 360°-Drehung | Vorwärts, rückwärts, Wenden während der Fahrt ohne Halt | |||||||||

| Laufgeschwindigkeit(m/min) | 25 | 20 | |||||||||

| Motor Typ | Niedervolt-Wechselstrommotor (AC) / bürstenloser Gleichstrommotor (DC) | ||||||||||

| Bremsen-Modus | Elektromagnetische Bremse | ||||||||||

| Schützende Maßnahmen | Akustische und optische Alarmlampe+ Not-Aus-Taste+Laser-Hindernisvermeidungssensor (optional)+Kontaktleiste zur Kollisionsvermeidung (optional) | ||||||||||

| Rad Anzahl | 4 | 6 | 8 | ||||||||

| Durchmesser der Antriebsräder(mm) | Ф360 | Ф400 | Ф400 | Ф450 | Ф500 | Ф500 | Ф600 | Ф550 | Ф550 | ||

| Material der Räder | Stahlkern + Polyurethan | ||||||||||

| Batteriekapazität(kW-h) | 5.5 | 8.5 | 10.5 | 14 | 18.5 | 18.5 | 30 | 37.8 | 45.3 | ||

| Akku-Typ | Blei-Säure-Batterie | Lithium-Batterie | |||||||||

| Ausdauer der Batterie | 5h (je nach Bedarf) | 4h (je nach Bedarf) | |||||||||

| Akku-Ladezeit | ≤7h | ≤5h | |||||||||

| Batterieladegerät | AC220V/AC380V | ||||||||||

| Bodenart | Zementboden、Stahlplattenboden 、Epoxidboden, Asphaltboden | ||||||||||

| Steigfähigkeit bei voller Beladung | 5% | 3% | |||||||||

| Arbeitsumfeld | Temperatur: -10°c~40°c; Luftfeuchtigkeit: 20%~80%, keine Kondensation (kundenspezifisch für Hochtemperatur- und explosionsgeschützte Umgebungen) | ||||||||||

| Farbe der Karosserie | Kundenspezifisch | ||||||||||

| Andere Funktionen | Batteriestromanzeige, Überspannungs-, Unterspannungs- und Überstromschutz usw. | ||||||||||

| Anmerkungen: 1) Andere Tischgrößen und Tragfähigkeiten können je nach Benutzeranforderungen angepasst werden. 2) Für die hydraulische Lenkung kann ein duales hydraulisches Lenksystem gewählt werden, um den Wenderadius je nach den Platzverhältnissen vor Ort zu verringern. 3) Der Batterietyp und die Betriebszeit (Batterielebensdauer) können an die Bedürfnisse des Kunden angepasst werden. 4) Das Produkt unterliegt ständigen Verbesserungen und Upgrades; die Spezifikationen in der Tabelle können sich ohne vorherige Ankündigung ändern. | |||||||||||

Eigenschaften

Omnidirectional Mobility

Capable of 360° rotational movement for precise execution of aircraft maintenance tasks.

Multifunctional

Features hydraulic lifting, sliding and tilting capabilities.

Safe Operation

Emergency braking, laser obstacle avoidance and interlocking devices ensure operator safety.

Precision Handling

Flexible support pads safeguard delicate aircraft components during transfer and assembly.

Intelligentes Kontrollsystem

Real-time operational status display with fully interlocked functions for assured safety.

Custom

Tailor-made transfer cart available to meet specific operational requirements.

Anmeldung

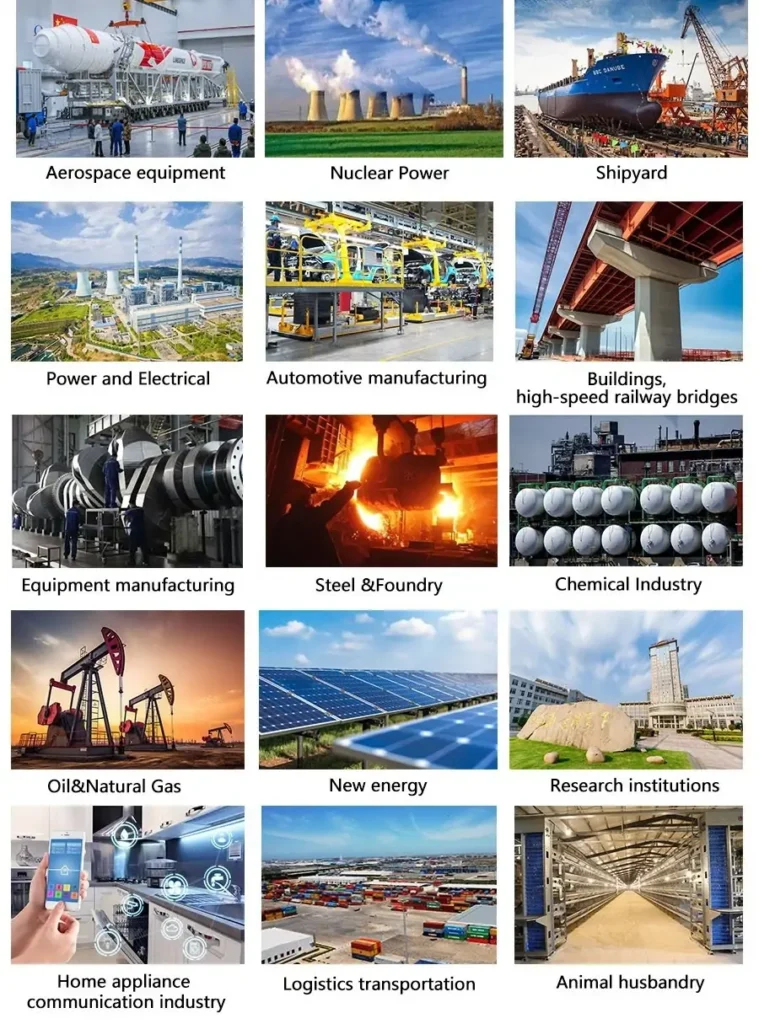

A Multifunktionaler Omnimove-Transferwagen offers far more than aviation support. Its omnidirectional movement, precise positioning, and heavy-duty load capacity make it an ideal Transfer Cart solution for multiple industries. This all-direction transfer cart improves safety, efficiency, and workflow wherever flexible, reliable material handling is required.

Manufacturing

Lösung: This Omnimove Transfer Cart moves heavy components with precise control, solving space-limited handling issues on busy production floors.

Logistics

Lösung: The all-direction transfer cart boosts warehouse efficiency by transferring pallets smoothly in narrow aisles and reducing forklift dependence.

Rail Maintenance

Lösung: A multifunctional Transfer Cart positions tools and parts accurately, speeding inspection tasks and minimizing downtime around rail vehicles.

Energy Plants

Lösung: This heavy-duty omnidirectional cart transports modules and inspection kits safely through complex power-plant layouts during critical maintenance.

Automotive

Lösung: The maintenance transfer cart moves engines and diagnostic tools between stations, improving workflow accuracy and repair efficiency.

Shipyards

Lösung: This omnidirectional transport vehicle handles large components in tight dock areas, supporting inspection, refits, and safe heavy-load mobility.

Transfer Cart Case Showcase

Multifunctional Omnimove Transfer Cart Manufacturer

Henan Remarkable Intelligent Technology Co., Ltd wurde 2019 gegründet und befindet sich in Nr. 22, Xinchang North Line, Xiaodian Town, Hongqi District, Xinxiang City, Henan Province. Es ist ein professionelles Unternehmen für Fördertechnik, das Forschung und Entwicklung, Design, Herstellung, Vertrieb und Kundendienst integriert. Das Unternehmen ist auf die Herstellung verschiedener Arten und Mengen von Fördergeräten und deren Zubehör spezialisiert und bietet professionelle Forschung und Entwicklung, Design und Herstellung verschiedener nicht standardisierter und nicht standardisierter Produkte an. Elektrische Verschiebewagen, Schienentransferwagen, Omnidirektionale mobile Transportwagen, Battery transfer carts, Schwerlasttransportwagen, AGV-Handhabungsroboterund Industrie-Anhänger.

Die Produkte von Remarkable entsprechen der Maschinenbaunorm JB/T6127-2010, haben die ISO-Dreisystemzertifizierung (Qualität, Umwelt und Arbeitsschutz) und die CE-Zertifizierung erhalten. Das Unternehmen hat nacheinander 19 nationale Produktpatente erhalten.

Warum uns wählen?

- Branchenspezifisches Fachwissen - Wir beliefern die Bereiche Energieerzeugung, Schiffbau, Bauwesen und Luft- und Raumfahrt mit maßgeschneiderten Lösungen für Transformatoren, Windturbinenkomponenten, vorgefertigte Module und vieles mehr.

- Vollständig kundenspezifisch - Von der Tragfähigkeit (1-500+ Tonnen) bis hin zu den Antriebssystemen (Elektro-, Hybrid- oder Dieselantrieb) können wir Ihre Anforderungen genau erfüllen.

- Fortgeschrittene Kontrollsysteme - Zu den Optionen gehören die manuelle Fernsteuerung, die halbautomatische Bahnplanung oder die vollautomatische Navigation (FTS-Integration).

- Qualität und Langlebigkeit - Robuste Stahlrahmen, drehmomentstarke Lenkmodule, CE- und ISO-zertifiziert.

- Vollständige Projektunterstützung - Von der ersten Beratung bis zum Kundendienst bieten unsere Ingenieure lebenslange technische Unterstützung.

Verwandte Artikel

Maßgeschneiderte intelligente Materialtransportlösungen

Um sicherzustellen, dass ein maßgeschneiderter Transferwagen perfekt auf Ihre Bedürfnisse zugeschnitten ist, geben Sie bitte die folgenden Details an:

- Tragfähigkeit: _____ t (1~500 t)

- Tischgröße: _____ × _____ mm/m (z. B. 1500×3000)

- Strom-Optionen:

- ☐ Blei-Säure ☐ Lithium-Ionen ☐ Andere: _____

- ☐ Kabel: _____V/_____A

- ☐ Standard 380V/50Hz/3-Phasen

- Angaben zur Ladung:

- Art: _____ (z. B. Stahlspulen, Maschinen)

- Besondere Anforderungen: _____ (z. B. rutschfest, korrosionsbeständig)

- Optionale Merkmale:

- ☐ Not-Aus ☐ Antikollisionssensoren

- ☐ Schienenführungen ☐ Hebemechanismus ☐ Fernsteuerung