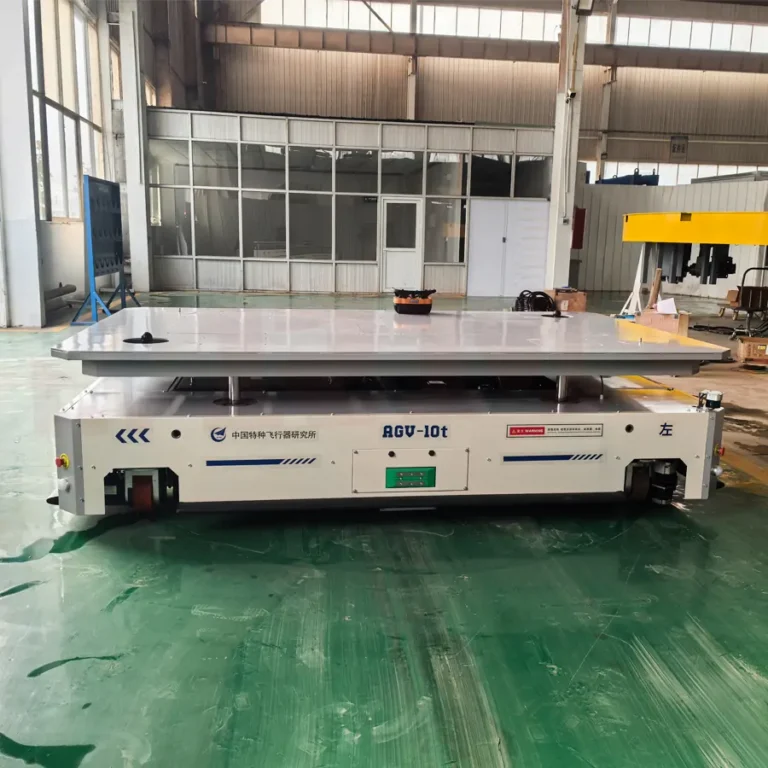

"(《世界人权宣言》) heavy load robot is an intelligent material handling device that combines material handling, customized requirements, precise positioning, and intelligent transportation. It transports goods in tons, typically using a high-quality chassis paired with an intelligent navigation system. It is designed to meet customized requirements such as lifting platforms, tooling fixtures, and robotic arms, and uses a central control system to achieve high-efficiency, high-precision, safe, and flexible material handling operations. Its core value lies in freeing workers from high-load, high-risk repetitive physical labor while significantly enhancing the precision, continuity, and overall efficiency of material handling processes.

Heavy-load robot working principle

Its operating principle can be divided into four parts: the basic configuration of the heavy load transfer cart, the intelligent navigation system, customization to meet specific requirements, and the overall central control system.

Basic Configuration of the 重物搬运车: The heavy load robot typically consists of a modular vehicle body made of a high-strength alloy steel frame combined with differential drive and Mecanum wheels, along with stable power motor equipment and safety systems. The modular design also facilitates maintenance and customization.

Intelligent Navigation System: Using sensors such as laser navigation (LIDAR), visual recognition cameras, inertial measurement units (IMU), and magnetic/QR code navigation, the heavy load robot can accurately perceive its real-time position and surrounding obstacles in the environment. It then uploads this real-time data to the central system.

Customization Options: Depending on specific operational requirements, the robot can be customized with forks, roller platforms, vacuum suction cups, mechanical clamping arms, and other components to perfectly accommodate various shapes and materials of cargo. Commonly used lifting equipment includes hydraulic cylinders, electric lead screws, and scissor lifts for pallet handling, cargo lifting, and lowering. We can customize solutions based on your specific needs.

Central Control System: This serves as the control center for the entire Heavy Load Robot. It issues commands based on pre-set work results, adjusts in real-time based on real-time data feedback from intelligent navigation, and achieves intelligent unmanned material handling by integrating pre-set processing for customized workpieces.

The working principle of the heavy-load robot is not a simple assembly of standard components but a comprehensive engineering design and integration tailored to your specific load, operating conditions, efficiency, and budget. Let’s take a look at the common customizable workpieces available.

Heavy load robot customization:

This is our biggest advantage over standard product suppliers. We don’t make you adapt to the machine; we tailor the heavy load robot to your needs.

Customization options include, but are not limited to:

| Customization Category | Sub-category | Specific Configurations & Description | Typical Application Scenarios |

| Load & Dimension Customization | 负载能力 | 1 to 100 tons and above, designed and reinforced precisely for your cargo’s weight. | Custom axle spacing, number, and layout of wheel assemblies (e.g., 3-point support, 4-point support). Constructed with high-strength steel/aluminum alloy and validated by FEA (Finite Element Analysis) for rigidity and stability. |

| Vehicle Dimensions | Customize the vehicle’s length, width, height, and turning radius based on cargo size and aisle restrictions. | Transport in narrow aisles, handling of long materials (e.g., pipes, beams). | |

| Structural Configuration | Fixed routes, budget-conscious projects, and traditional production lines with low flexibility needs. | Ensuring structural safety and operational smoothness under extreme loads. | |

| Navigation Customization | Laser Navigation (LIDAR) | Navigates by scanning natural features of the environment. No guidepaths required. Highly flexible for path changes. | Complex, dynamic environments with mixed traffic (human and vehicle); flexible manufacturing cells. |

| Magnetic Tape/QR Code Navigation | Follows pre-installed magnetic tape or scans floor-mounted QR codes. Fixed paths, cost-effective solution. | Coil clamps, sheet metal vacuum lifters, pipe V-cradles, glass suction cups, and container spreaders. | |

| Hybrid Navigation | Flexibly combines the above navigation methods (e.g., Laser + Inertial) to leverage the strengths of each for complex and varied operational environments. | Hybrid scenarios with multiple types of pathways and operational requirements within a single facility. | |

| End-of-Arm-Tooling (EOAT) Customization | Non-Standard Forks | Special spacing, length (for non-standard pallets), adjustable width (for multiple pallet types), rotational function (to reorient cargo during transport). | Non-standard pallets, soft packages, paper rolls. |

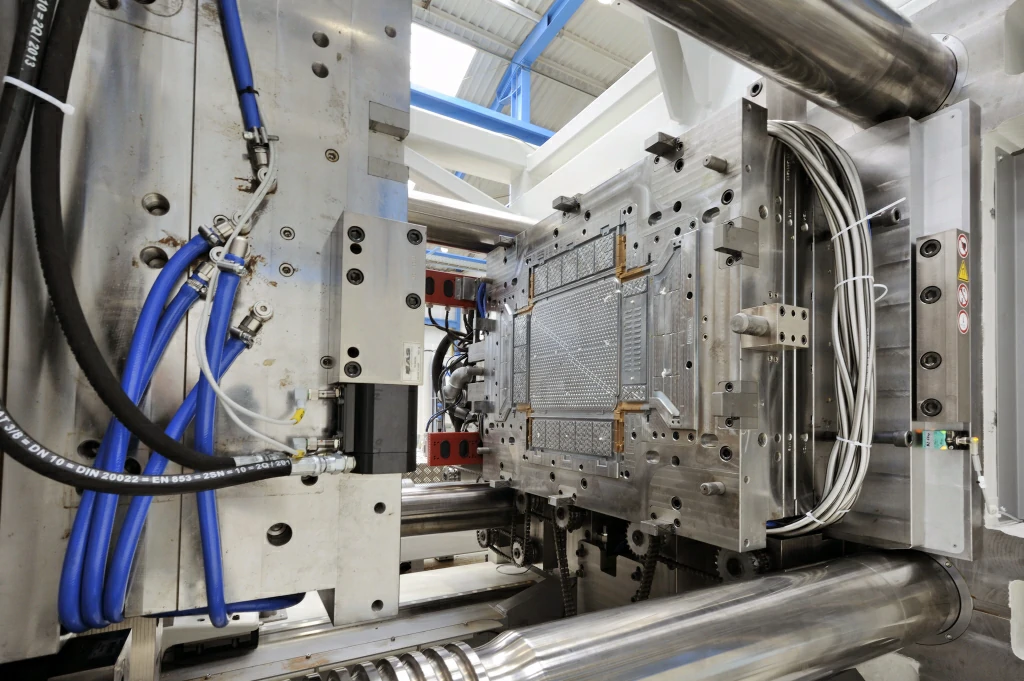

| Lifting Mechanisms | Very low entry height (under 50mm for slip-in racks), special lift heights, scissor lift/ drop-center lift mechanisms. | Machine tool loading/unloading, automated stamping press lines, assembly line对接 (docking). | |

| Specialized Tooling | Integration with plant door systems, elevators, and automatic doors; geofenced speed control (auto-slow in sensitive zones); comprehensive E-stop coverage; access permission management. | Specialized industries: steel, glass, construction, port logistics. | |

| Safety & Protection Customization | Active Safety | 360° laser obstacle avoidance (graded slowdown/stop zones), anti-collision tactile edges/bumpers (physical contact sensing), audible & visual alarm systems (warning signals). | Foundational safety configuration for all scenarios. |

| Environmental Protection Rating | Explosion-proof certification (Ex d/e, for flammable/combustible environments), IP Rating (e.g., IP54 dust/water resistance, for damp/dirty workshops). | Standard API interfaces for seamless integration with your MES, WMS, and ERP systems for task dispatch, status monitoring, and data upload (e.g., material ID, job status, location). | |

| System Safety Logic | Paint shops, petrochemical, food & pharmaceutical, and outdoor ports. | Achieving high coordination between people, machines, and the environment for a safe and reliable smart factory. | |

| Interface & Integration Customization | Software System Integration | Standard API interfaces for seamless integration with your MES, WMS, ERP systems for task dispatch, status monitoring, and data upload (e.g., material ID, job status, location). | Building a digital smart logistics system, unifying data flow with material flow. |

| Hardware Interface Integration | Custom automatic charging stations (wired/wireless, scheduled charging); automatic docking interfaces with machine tools, stamping presses, conveyor rollers, lifters (via PLC communication, mechanical alignment). | Enabling true “lights-out” manufacturing and fully unmanned automated production processes. |

结论

Through the above, we have gained an understanding of what a heavy-load robot is, its working principles, and its customization options. It will serve as a powerful industrial tool for material handling in enterprises. As a manufacturer deeply rooted in the industrial material handling sector and dedicated to providing customized material handling solutions for our clients, we fully understand the critical importance of safe, efficient, and flexible material handling in modern manufacturing, logistics, and warehousing, and heavy-duty assembly—especially when dealing with materials, components, or finished products weighing tons. So if you currently face such challenges, please 联系我们 immediately, and we will provide you with the latest material handling solutions.